8

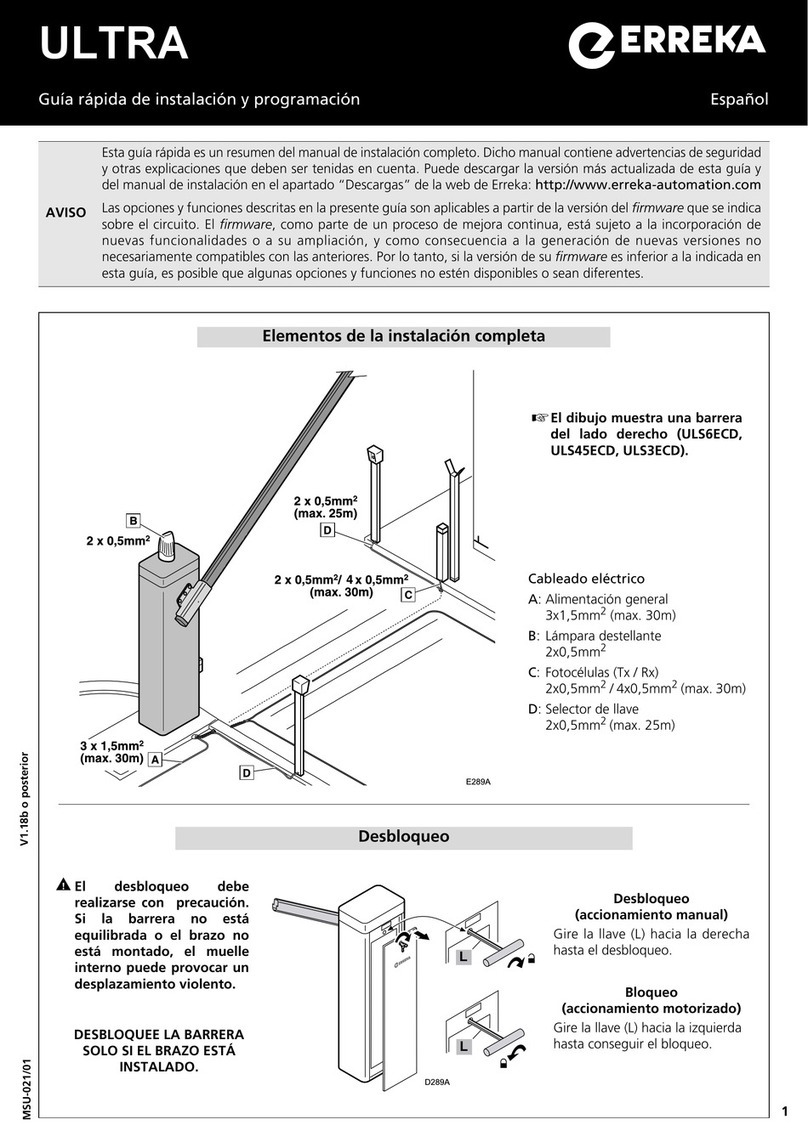

Choosing the spring and

anchoring hole

The balancing

spring and the hole

it is anchored in

depend on the

length of the barrier

arm, the type of

arm and the

accessories placed

on the arm (in short,

the weight of the

arm).

The barriers are supplied with one spring

mounted in the box (S) and one spring

removed:

•Spring removed: Ø5.5mm, blue

•Spring mounted:

ULS45EC: Ø6.5mm (yellow), mounted

in hole 2

ULS6EC: Ø6.5mm (yellow) x2,

mounted in hole 2

The table below shows the spring to be

used and the anchoring hole, as

appropriate. Using other accessories may

influence the choice of spring and orifice.

If the spring or anchoring hole must

be changed, do this before

installing the barrier and arm.

P289L

21

S

ULS45EC barrier with AUL13 arm (3m, 100x45mm), 10A001 flange

Springs / Hole bar only bar + LED bar + leg

bar + LED + leg

1x Ø6.5 / 1 x x x x

1x Ø6.5 / 2 x x 3 m 2.8 - 3 m

1x Ø5.5 / 2 3 m 2.6 - 3 m 2.5 - 3 m 2.5 - 2.8 m

ULS45EC barrier with AUL02 arm (4.5m, 100x45mm), 10A001 flange

Springs / Hole bar only bar + LED bar + leg

bar + LED + leg

1x Ø6.5 / 1 x 4.1 - 4.5 m 4 - 4.5 m 3.5 - 4.5 m

1x Ø6.5 / 2 3.8 - 4.5 m 3.4 - 4.1 m 3 - 4 m 2.8 - 3.5 m

1x Ø5.5 / 2 3 - 3.8 m 2.6 - 3.4 m 2.5 - 3 m 2.5 - 2.8 m

ULS45EC barrier with ANT09 arm (4.3m, Ø70), 10A072 flange

Springs / Hole bar only bar + LED bar + leg

bar + LED + leg

1x Ø6.5 / 1 3.9 - 4.3 m 3.7 - 4.3 m 3.3 - 4.3 m 3.2 - 4.3 m

1x Ø6.5 / 2 3.2 - 3.9 m 3 - 3.7 m 2.6 - 3.3 m 2.5 - 3.2 m

ULS6EC barrier with AUL01 arm (6m, 100x45mm), 10A001 flange

Springs / Hole bar only bar + LED bar + leg

bar + LED + leg

2x Ø6.5 / 1 x x x 5.3 - 6 m

2x Ø6.5 / 2 5 - 6 m 4.7 - 6 m 4.5 - 6 m 4.2 - 5.3 m

1x Ø6.5 / 1 4.5 - 5 m 4 - 4.7 m 4 - 4.5 m 4 - 4.2 m

1x Ø6.5 / 2 4 - 4.5 m x x x

ULS6EC barrier with ANT10 arm (3.5+2.8m + Ø70 joint), 10A072 flange

Springs / Hole bar only bar + LED bar + leg

bar + LED + leg

2x Ø6.5 / 1 5.6 - 6.3 m 5.2 - 6.3 m 5 - 6.3 m 4.8 - 6.3 m

2x Ø6.5 / 2 4.5 - 5.6 m 4.2 - 5.2m 4 - 5 m 4 - 4.8 m

More arms than those shown in this table can be mounted; see the complete manual for more information.

Changing the anchoring hole

+

–

P289J

M

1

2

S

V

1Put the barrier arm in

upright position.

2Turn the tensioning

handle (M) anti-

clockwise until the

spring is tensionless.

3Release the anchoring

bolt (1) and mount it in

the other hole.

4Balance the barrier as

described below.

Changing the spring

1Place the arm in upright position.

2Turn the tensioning handle (M) anti-clockwise until

the spring is tensionless.

3Release the anchoring bolt (1).

4Take down the spring box (S), releasing the pivot (V).

5Completely unscrew the tensioning handle, remove

the spring and put the new spring in place. Finally,

screw in the tensioning handle.

6Mount the spring box (S), inserting the pivot (V).

7Screw the anchoring bolt in the appropriate hole (1)

or (2).

8Balance the barrier as described below.

If the spring or anchoring hole must be changed, do this before installing the barrier and arm.

The illustrations and explanations refer to ULS45EC barriers, which have a single balancing spring.

The procedure for ULS6EC barriers is similar, bearing in mind that the spring and its adjacent

elements are duplicated.