RBLO Series

12

GENERAL ADVICE

1_ If not foreseen in the electronic control unit instructions, check

that a suitable differential switch and an overcurrent protection

are present at the source of the electrical system (C6 single-

pole circuit breaker with a minimum contact opening of 3 mm)

that have the international standards conformity mark. The said

device must be safeguarded against involuntary closure (e.g.

installing a locked panel inside).

2_ Positioning of a pair of photocells: the range of the photocells

must be at a height of 50 ÷ 60 cm from ground level and at a

distance of no more than 15 cm from the movement level of the

bar. Their correct functioning must be veried at the end of the

installation in accordance with the EN 12445 standard.

N.B. Grounding of the system is compulsory!

The data indicated in the present instructions is purely indicative;

TAU Srl reserve the right to modify them at any time.

The system must be produced in compliance with local laws

and regulations.

INSTALLATION WARNINGS

• This instructions booklet is aimed at qualied personnel only

that are aware of the constructional methods and the accident

prevention protection devices for motorised gates, doors and

main doors (abide by the present standards and laws).

• The end user must be issued with an instructions booklet by

the installer in accordance with the EN12635 standard.

• Before commencing with installation, the installer must deter-

mine the risk analysis of the nal automation system and the

placing in safety of the identied hazardous points (in accord-

ance with the EN 12453 and EN 12445 standards).

• The wiring of the various electrical accessories (e.g. photocells,

ashing lights, etc.) must be performed in accordance with the

EN 60204-1 standard and their modication in accordance with

the EN 12453 standard.

• Eventual tting of a manual manoeuvre control button, must be

performed by positioning the button in an area that is not at risk

when operated; furthermore, it must be performed in such a

manner that the risk of involuntary use of the button is reduced

to a minimum.

• Keep the automation controls (buttons, remote controls, etc.)

out of reach of children. The controls must be positioned at

a height no less than 1.5 m from the ground and outside the

operating range of the moving parts.

• Before performing any type of installation, adjustment, main-

tenance operation on the system, turn off the power supply by

means of the thermal-magnetic circuit breaker positioned be-

fore the system.

THE COMPANY TAU HOLD NO RESPONSIBILITY WHAT SO

EVER for possible damages caused by the non-compliance of the

present safety standards and laws during installation.

OVERALL DIMENSIONS

The main dimensions of the barrier are indicated in Fig. 1; Fig. 2

illustrates the dimensions of the foundation base plate.

POSITIONING OF THE BARRIER

The following principles must be followed in addition to the func-

tionality:

1_ before installing the bar, make sure that the area above the bar

is free of all obstacles (balconies, cables, trees, etc.)

2_ a good visibility at a sufcient distance to avoid collision (pay

attention to bushes, etc.)

3_ suitable base to guarantee the secure positioning of the barrier

4_ absence of pipes and/or electrical cables that could be dam-

aged when preparing the site

5_ minimization of the length of the electrical cables that are nec-

essary to operates the barrier

6_ positioning in accordance with the present national standards.

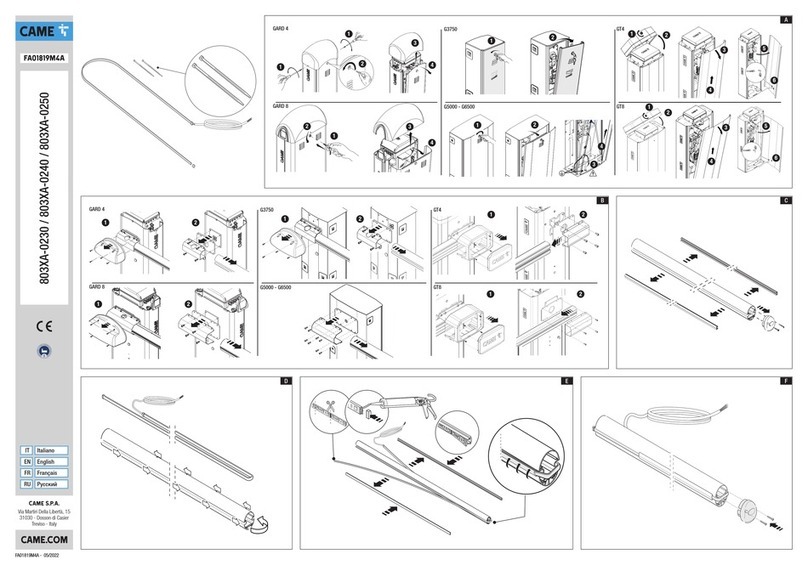

SITE PREPARATION

Construct a rectangular concrete slab (A g. 3) of suitable size

which includes cable outlet holes. If possible use the foundation

base plate (B g. 3), with the 4 supplied tie bars to submerge into

the slab; or secure the barrier cabinet directly to the nished slab

with 4 anchor bolts M10x120 (C g. 3). The thickness of the slab

must be at least 10 cm, remembering that it can be deeper if the

ground conditions require it.

ANCHORING OF THE BARRIER

The barrier is now placed in position, without the bar, and xed to

the base by securely tightening the nuts to the tie bars (or anchor

bolts). The perfect stability of the anchorage is controlled and if

necessary, the nuts are tightened further.

BARRIER DIRECTION ADJUSTMENT

Right-hand barriers (RH) are barriers that have the cabinet on the

right-hand side viewed from the inside of the passageway (the

door is normally on the inside).

1_ The barrier can be right-hand operating (RH) by tting the

plates as shown in A Fig. 4.

Left-hand barriers (LH) are barriers that have the cabinet on the

left-hand side viewed from the inside of the passageway (the door

is normally on the inside).

2_ The barrier can be left-hand operating (LH) by tting the plates

as shown in D Fig. 4.

“RBLO” is normally delivered in the RIGHT-HAND (RH) version.

If it needs to be transformed to LEFT-HAND (LH), proceed as fol-

lows:

1_ after having removed the nuts and washers, remove the upper

support (B g. 4), rotate it through 180° and secure it again;

RBLO-E: remove the limit switches and install them on the op-

posite side of the support (1B, g. 4);

2_ Remove the mechanical stopper (1C, g. 4) and install it on the

opposite side oh the cabinet (2C, g. 4);

3_ Once the barrier direction has been changed the motor con-

nections must be inverted (see K205M instructions for RBLO,

K101M instructions for RBLO-E).

Note: once the direction of the barrier has been changed, the

position of the devices are inverted.

SECURING OF BAR AND BALANCING

Balancing is fundamental for the correct function of the barrier.

This operation is only performed after the bar has been tted

in its nal position with all possible accessories.

All operations are performed with the power supply switched off

and the barrier released (see chapter “manual release”):

g. 5: close the end with the supplied cap (E); insert the bar (A)

into the bar holder (B) and secure it with the 2/4 bolts (C)

and nuts (D);

Important: the boom must be completely inserted into the

boom holder.

g. 6: keeping at a safe distance, operate the manual release (A).

The bar must lift to 45° on its own, otherwise turn the spring

preloading nut (B) (19 Allen wrench). Lower the bar, release

it and check that it has reached 45°.

Note: if a load is needed that is greater/lower than that permit-

ted when balancing, move the eyelet (1 D g. 4) into the hole

on the right or left to increase/decrease the load capacity.

MANUAL RELEASE

1_ Introduce the supplied release key (1 g. 7);

2_ turn the key through approx. 330° in a clockwise direction (if

it is a bit tight at the beginning, apply more force, there is no

danger of causing damage).

Turn the key as far as it will go before manually operating the

bar.

Once the bar has been released it should automatically posi-

tion itself in the balanced position (approx. 45°)

POWER SUPPLY CONNECTION AND EXTERNAL CON-

TROL AND SAFETY SYSTEMS

Each device, including the power supply, must be correctly in-

stalled in accordance with the present standards. Separate the

power cables from the control cables, especially if the distances

are long (over 50 m). TAU advise that the cable sections (exclud-

ing the aerial) should be: power supply 1.5 mm², other cables 0,5

mm² and in any case should abide by the IEC 364 standard and

the local installation standards. After having removed the locking

nut (2 g. 8), remove the cabinet cover (1 g. 8) to access the

control unit.

N.B.: The internal wiring has already been made and tested.

The power supply, external photocell, and possible remote

control must be connected and the control unit programmed.

ENGLISH