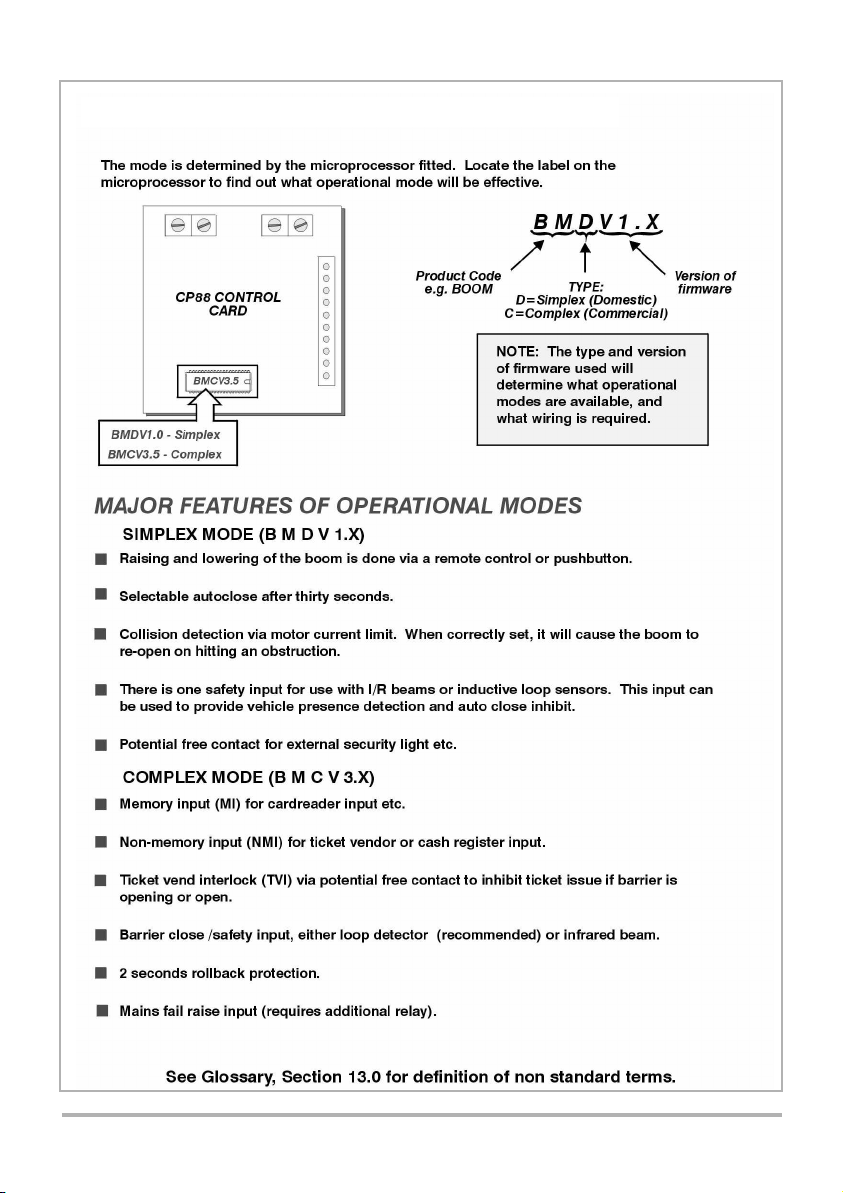

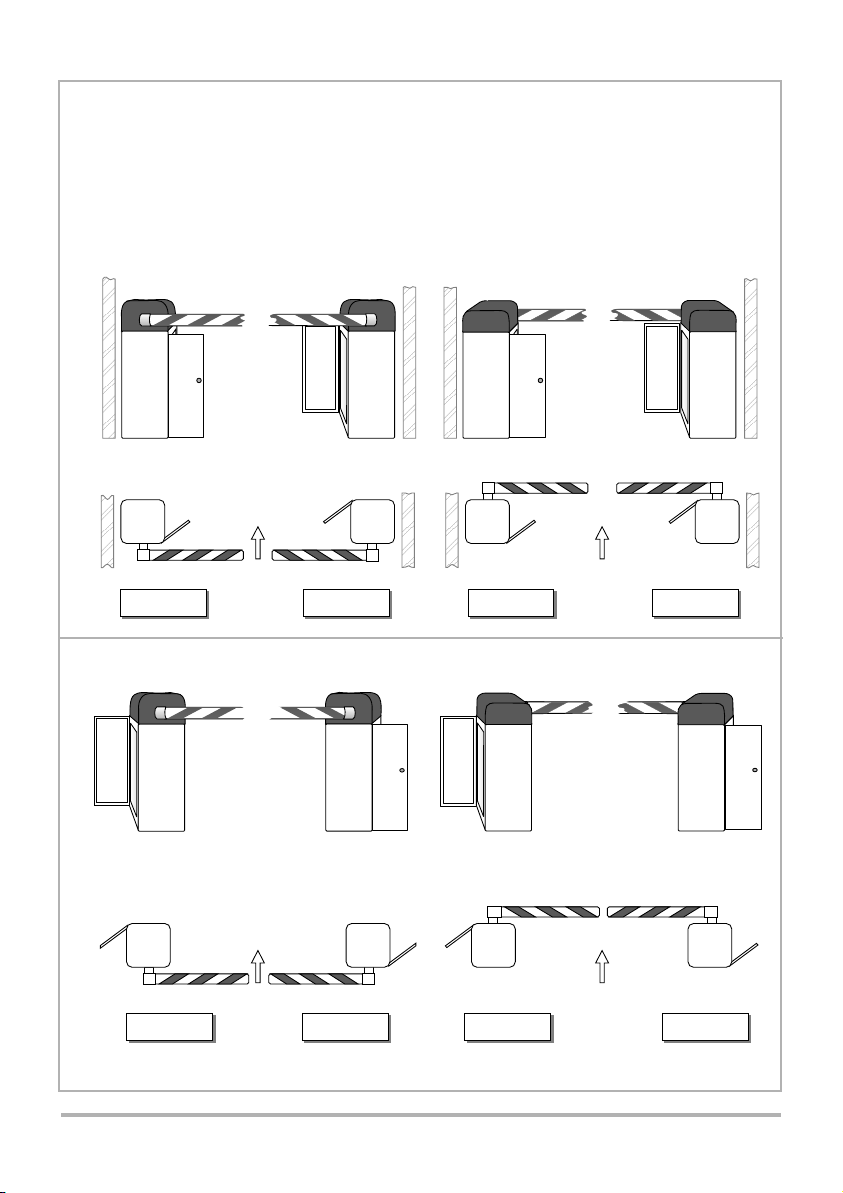

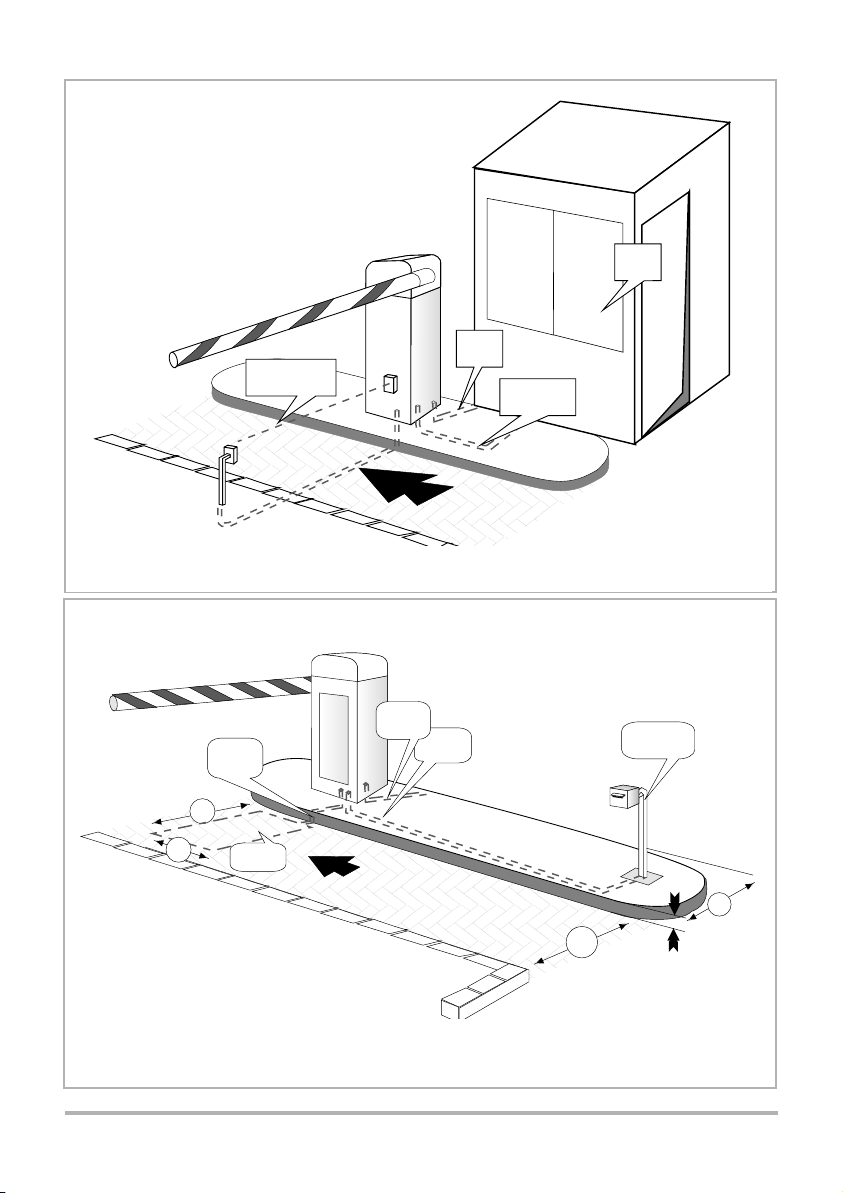

6.2 COMPLEX (Commercial) (Basic Application)

No Ticket Spitter

6.0 CABLING REQUIREMENTS

EI

D RC TOFI ON

ER A V L

T

EI

D RC TOFI ON

ER A V L

T

INFRARED BEAM

(OR LOOP)

Before doing any cabling, check which operational

mode is required for the barrier. (See Section 4.1)

NOTE: 1. Guard controls operation of barrier using

pushbutton inside guardhut.

99

RESTRICTING KERB

3,5M

1M1M

100100

LOOP

WIRE

FEED

2M2M

CLOSING

LOOP

1M1M

POWER

220V

20mm

CONDUIT

CARD READER

/ KEYPAD

CABLING TO

PUSHBUTTON

GUARD

HUT

220V AC

INPUT

6.1 SIMPLEX (Domestic) (Typical Application)

IMPORTANT :

2. Infra red safety beam can be replaced with inductive loop detector, fitted to the "safety loop" relay base

3. Fit BMDV1.X microprocessor to CP88 control card.

NOTE - 1. Loop detector is fitted to "safety loop" relay base.

- 2. Card reader is connected to MI input.

- 3. Fit BMCV3.X microprocessor to CP88 control card.