WARRIORTECHUserManual

Information manual for the WARRIOR TECH welder protective helmets complying with Par. 1.4 of Appendix ll of the EC regulations.The WARRIOR TECH welding helmets are high quality products that contribute

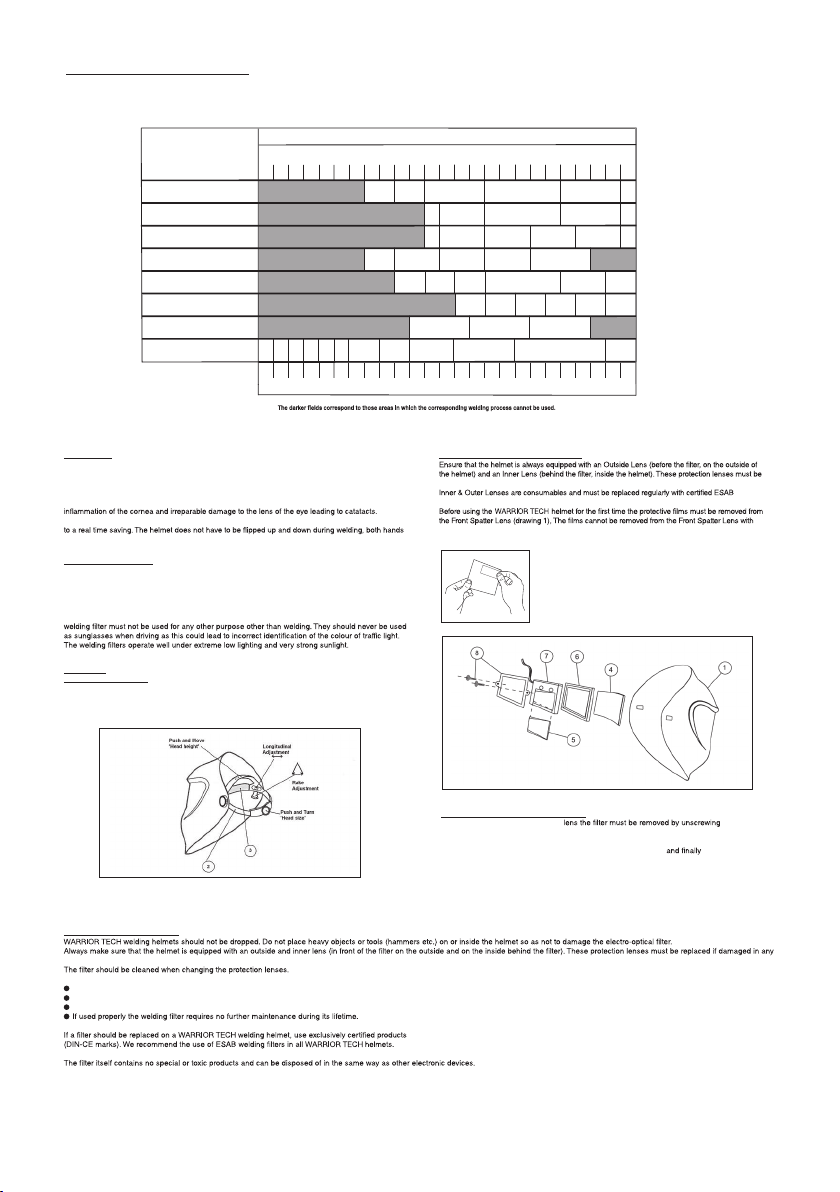

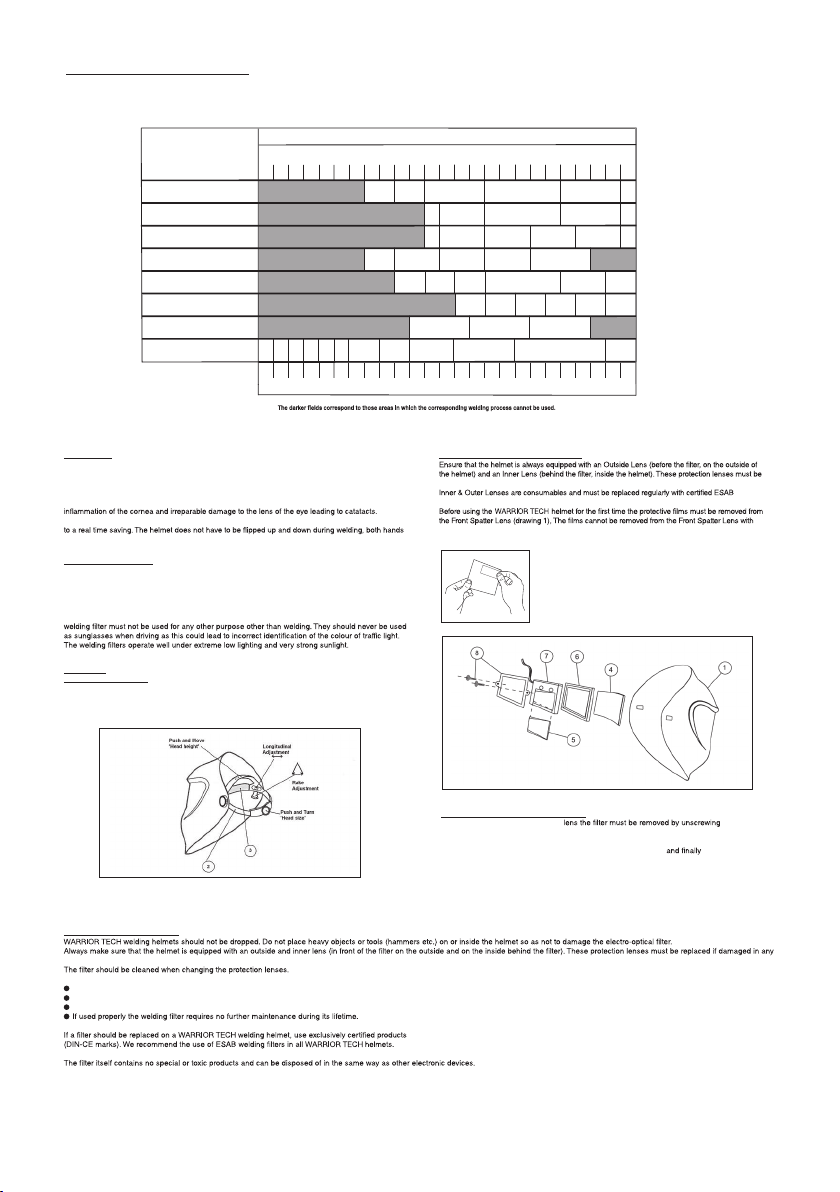

to the comfort and safety of the welder. WARRIOR TECH welding helmets may be used only in connection with arc welding. The chart below shows how to choose the most suitable shade level:

Information

WARRIOR TECH welding helmets afford reliable protection for the eyes whilst electric arc welding.They offer

permanent protection against UV/IR rays, heat & sparks in any state from the clear to dark.The

protection shades of the WARRIOR TECH welding helmets have been chosen to avoid eye damage

caused by the welding arc.

Do not look directly at welding rays with unprotected eyes when the arc strikes. This can cause a painful

WARRIOR TECH welding helmets allow the welder to see the point of arc strike more precisely. This leads

are kept free and because of the helmets light weight fatigue is reduced.

Rangeofapplication:

The WARRIOR TECH welding helmets can be used for the following applications:

Electrode

MIG

Mag

Tig (>=5A)

They are not suitable for use with laser systems and oxy-acetylene (gas welding) applications.The

Operation

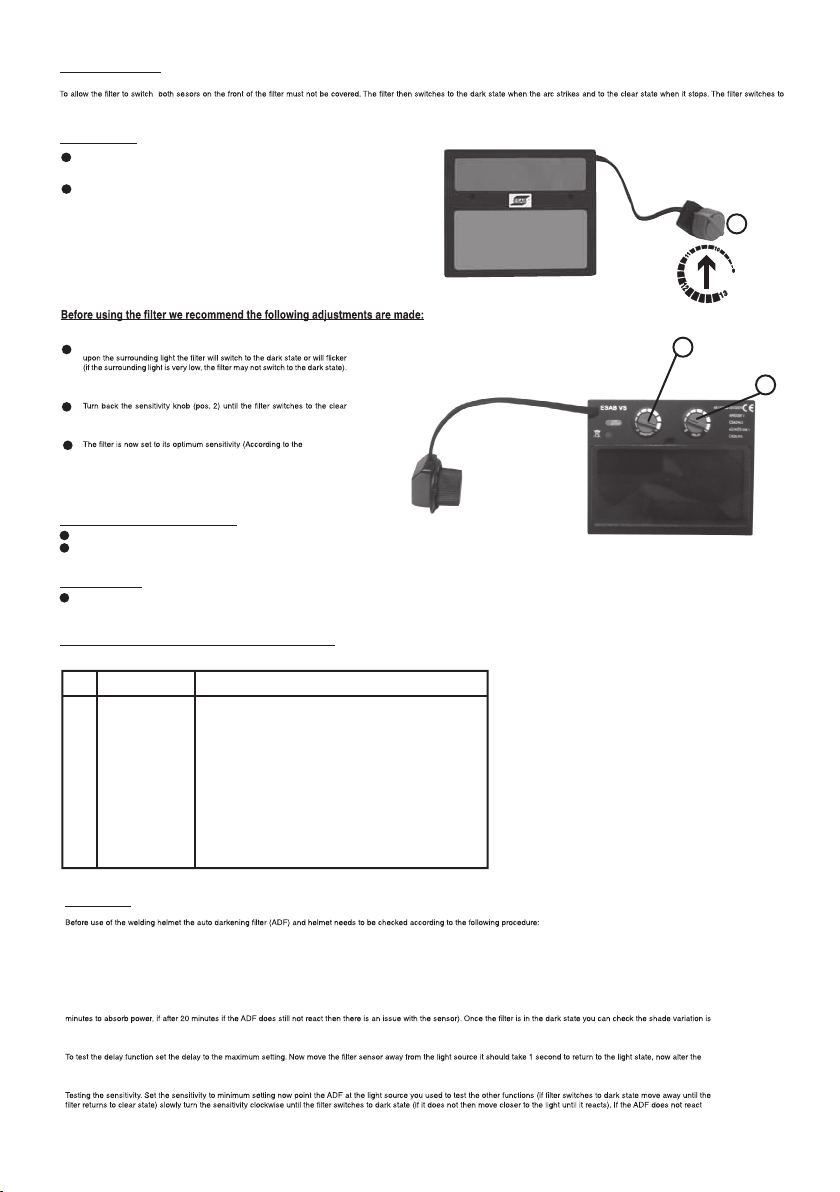

Adjustment of headgear:

WARRIOR TECH welding helmets are equipped with a comfortable headgear that can be adjusted in

three different ways

Weldingprocess

Orrelatedtechniques

Currentinternallyinamperes

0.52.510204080125175225275350450

15153060100150200250300400500

Emanual

Fluxcoreelectrodes

Fluxedstickelectrodes

MIG/Metal-Inert-GasArgon(Ar/He)

Steels,alloyedsteels,

Copper&itsalloysetc.

MIG/Metal-Inert-GasArgon(Ar/He)

Aluminium,copper,nickel

Andotheralloys.

TIG/Tungsten-InertGasArgon(Ar/H2)(Ar/He)

Allweldablemetalssuchas:steels,aluminium,

Copper,nickelandtheiralloys.

MAG/Metal-activeGas(Ar/Co2O2)(Ar/Co2/He/H2)

ConstructionSteel,hardened&temperedsteels

Cr-Ni-steel,Cr-steel&otheralloyedsteels.

Electricarccompressedairjoining

(Meltjoining)carbonelectrodes(O2)

Flamegroovingcompressedair(O2)

Plasmacutting(fusioncutting)

AllweldablemetalsseeWIG

Centreandoutergas:Argon(Ar/H2)(Ar/He)

Plasmacutting(Fusioncutting)

Micro-plasmawelding

Centreandoutergas:Argon(Ar/H2)(Ar/He)

0.52.510204080125175225275350450

15153060100150200250300400500

910 11 12 13 14

10 11 12 13 14

10

10

10

10

10

11

11

11

11

11

11

12

12

12

12

12

12

13

13

13 14

13

13

13

14

15

14 15

14

15

15

9

8765

2.5

4

9

Dependingupontheapplicationconditions,thenexthighestornextlowestprotectionlevelcanbeused.

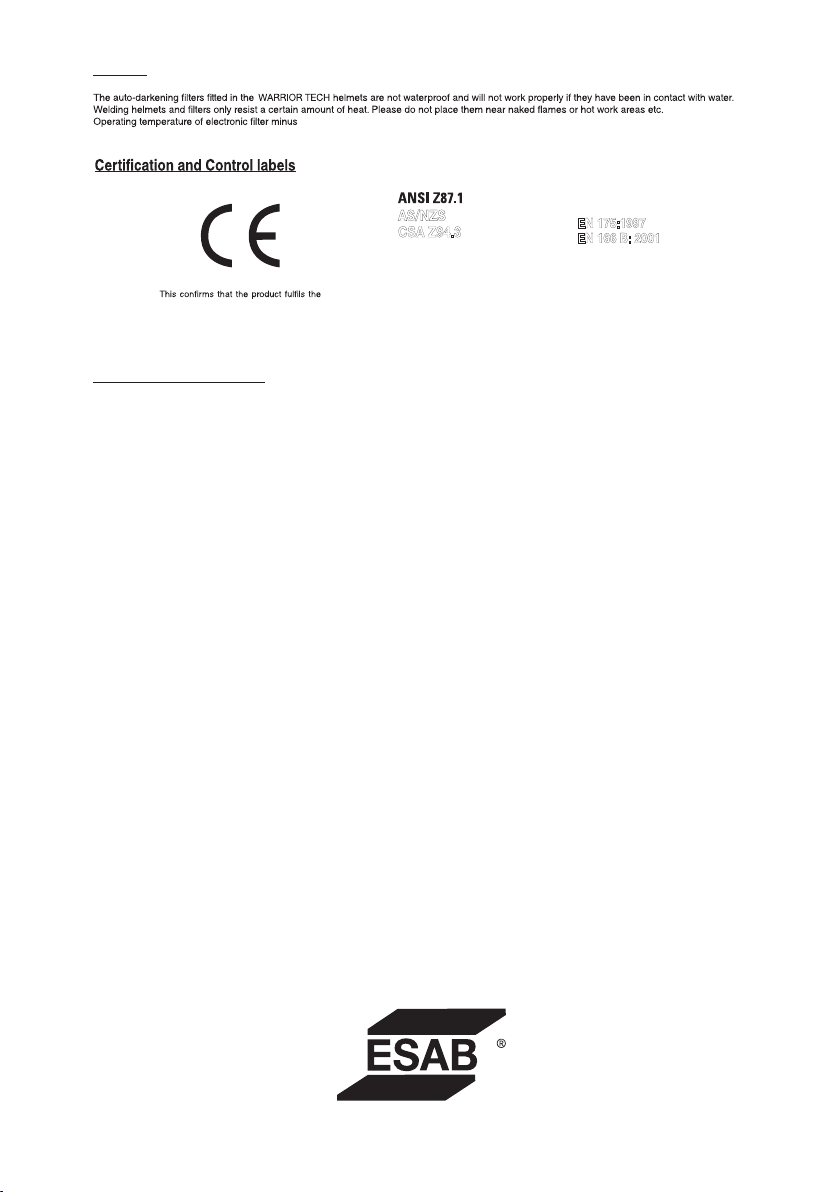

Servicingandmaintenance

way (see overleaf). They are consumables and should checked and replaced regularly.

This can be done by any of the following ways:

Wipe with a clean, dry piece of cloth.

Clean with a piece of smooth cloth moistened with pure alcohol.

Clean with a commercial disinfectant

ReplacingtheOuterSpatterLens:

replaced if broken, damaged or covered with welding spatter to such an extent that vision is impaired.

spare parts (CE marked).

the Lens in place, Please follow the instructions below to remove the Spatter Lens.

Drawing1

Drawing2

Insertingandremovinganewprotectionlens:

To insert the new outer protection

➃

the two retaining screws

➇

from the inside of the helmet

➀.The old protection lens

can then be removed and the new lens inserted followed by the light seal cradle

➅,

ADF➆,

inner protection lens

➄

and then the ADF retaining frame

➇

replace the two retaining screws (see drawing 2).

HL:Voor gebruik folie verwijderen!!

D: VorGebrauchSchutzfolie entfernen!!

F: Enleverlefilm protecteur avant utilisatio

UK:Beforeuse remove protective coating!!

I: Primade’lluso togliere la protezione in p

LAN1F DINplus GS 0196 CE