ESAB Aristo 500ix User manual

Other ESAB Welding System manuals

ESAB

ESAB ESABMig 405 User manual

ESAB

ESAB A6 Mastertrac User manual

ESAB

ESAB MT-450W User manual

ESAB

ESAB Aristo Mig 5000i User manual

ESAB

ESAB LPH 120 User manual

ESAB

ESAB HandyPlasma 250 User manual

ESAB

ESAB Caddyt Tig 150i User manual

ESAB

ESAB Origo Mig 4002cw User manual

ESAB

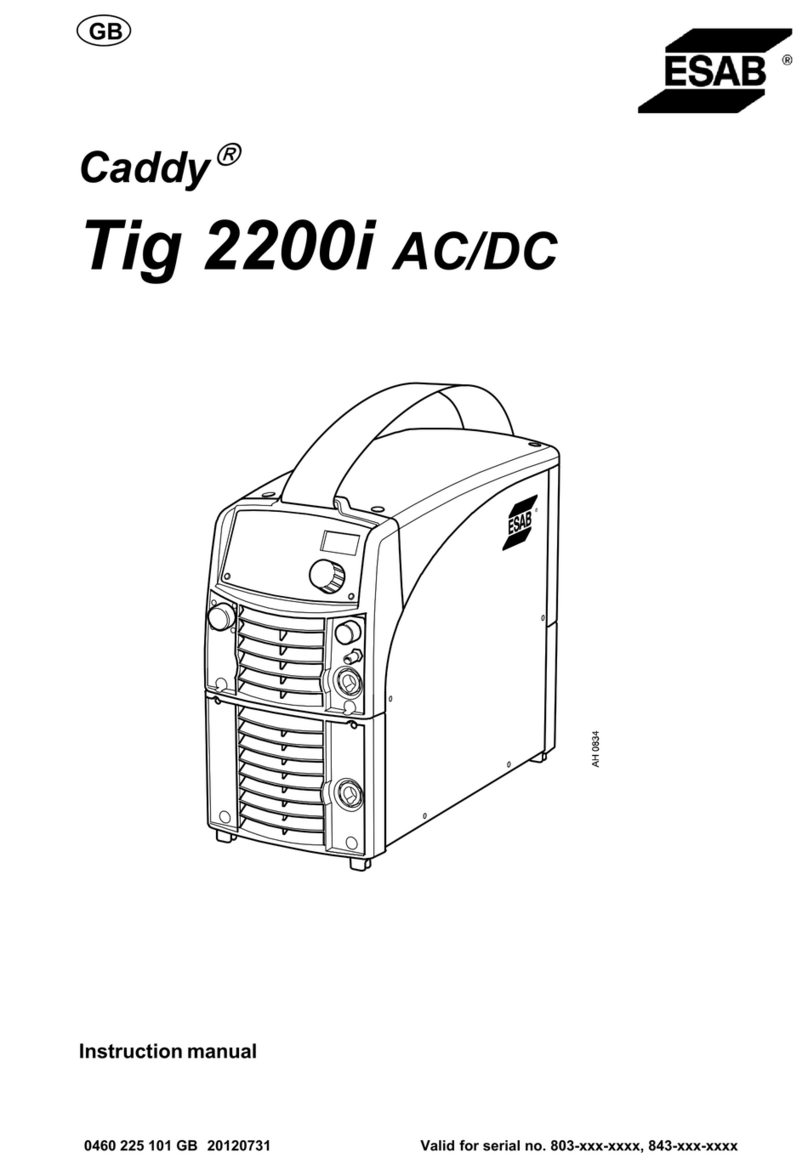

ESAB Caddy Tig 2200i AC/DC User manual

ESAB

ESAB Aristo Robust Feed U6 User manual

ESAB

ESAB MultiMaster 160 User manual

ESAB

ESAB EASY-WELD SSR 400 Owner's manual

ESAB

ESAB TIG 401iW User manual

ESAB

ESAB PLASMAWELD 202 User manual

ESAB

ESAB Renegade ET 300i User manual

ESAB

ESAB CaddyArc 150 User manual

ESAB

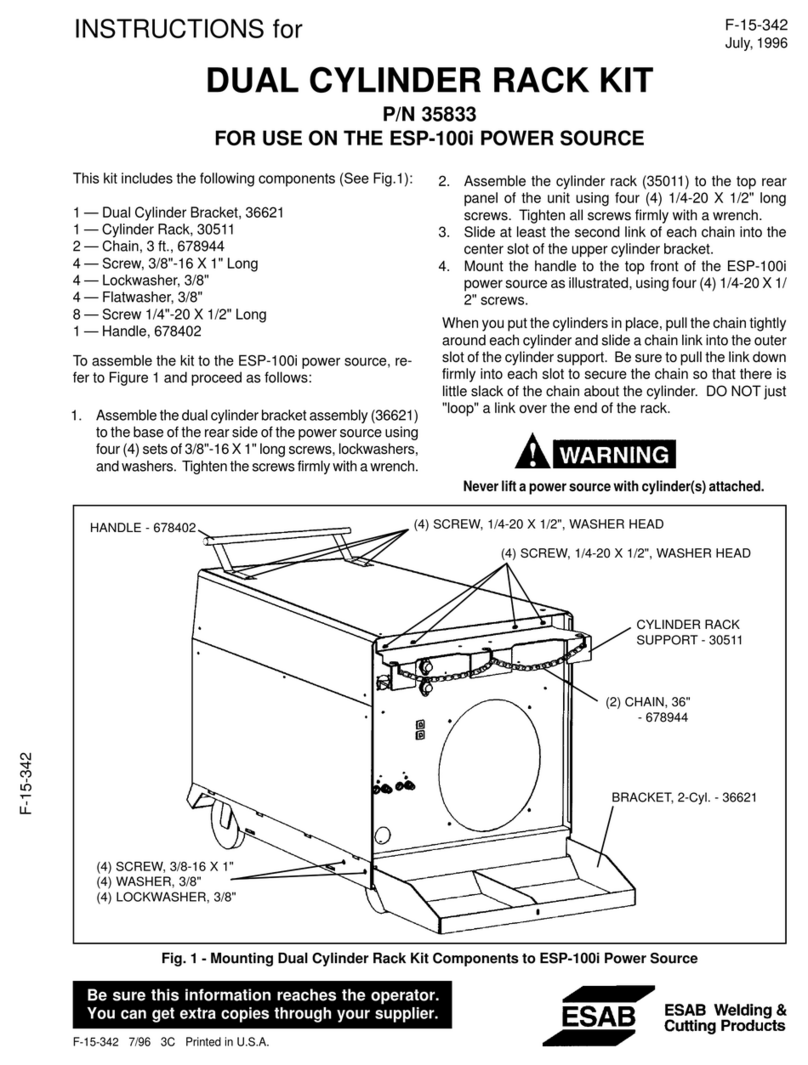

ESAB 35833 User manual

ESAB

ESAB Origo Mig 4002c User manual

ESAB

ESAB Aristo YardFeed 2000 User manual

ESAB

ESAB Caddy Arc 152i User manual

Popular Welding System manuals by other brands

TAFA

TAFA 30*8B35 owner's manual

Lincoln Electric

Lincoln Electric INVERTEC V350-PRO CE Technical specifications

CIGWELD

CIGWELD 636804 use instructions

Red-D-Arc

Red-D-Arc DC-400 Operator's manual

Hobart Welding Products

Hobart Welding Products Spool Gun DP 3035-10 owner's manual

Elettro

Elettro HI-MIG 3000 SYNERGIC instruction manual