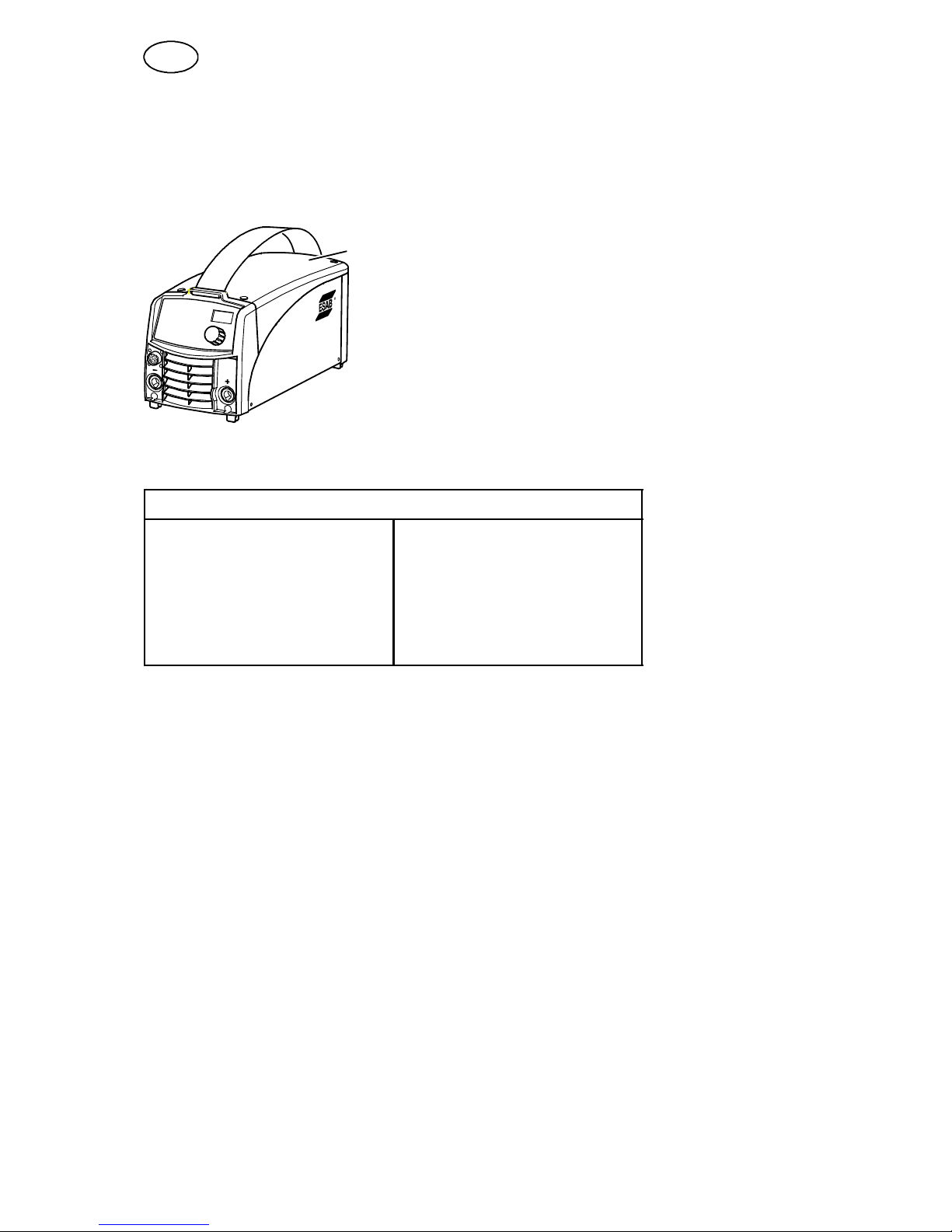

ESAB Caddy Arc 251i User manual

Other ESAB Welding System manuals

ESAB

ESAB MIG 301i User manual

ESAB

ESAB Warrior 500i CC/CV User manual

ESAB

ESAB LHJ 750 Guide

ESAB

ESAB CIGWELD WeldSkill MicroArc 140 User manual

ESAB

ESAB LKA 180 User manual

ESAB

ESAB EASY-WELD SSR 400 Owner's manual

ESAB

ESAB Warrior Feed 304 User manual

ESAB

ESAB Aristo 300 User manual

ESAB

ESAB Origo M13 Feed 304 User manual

ESAB

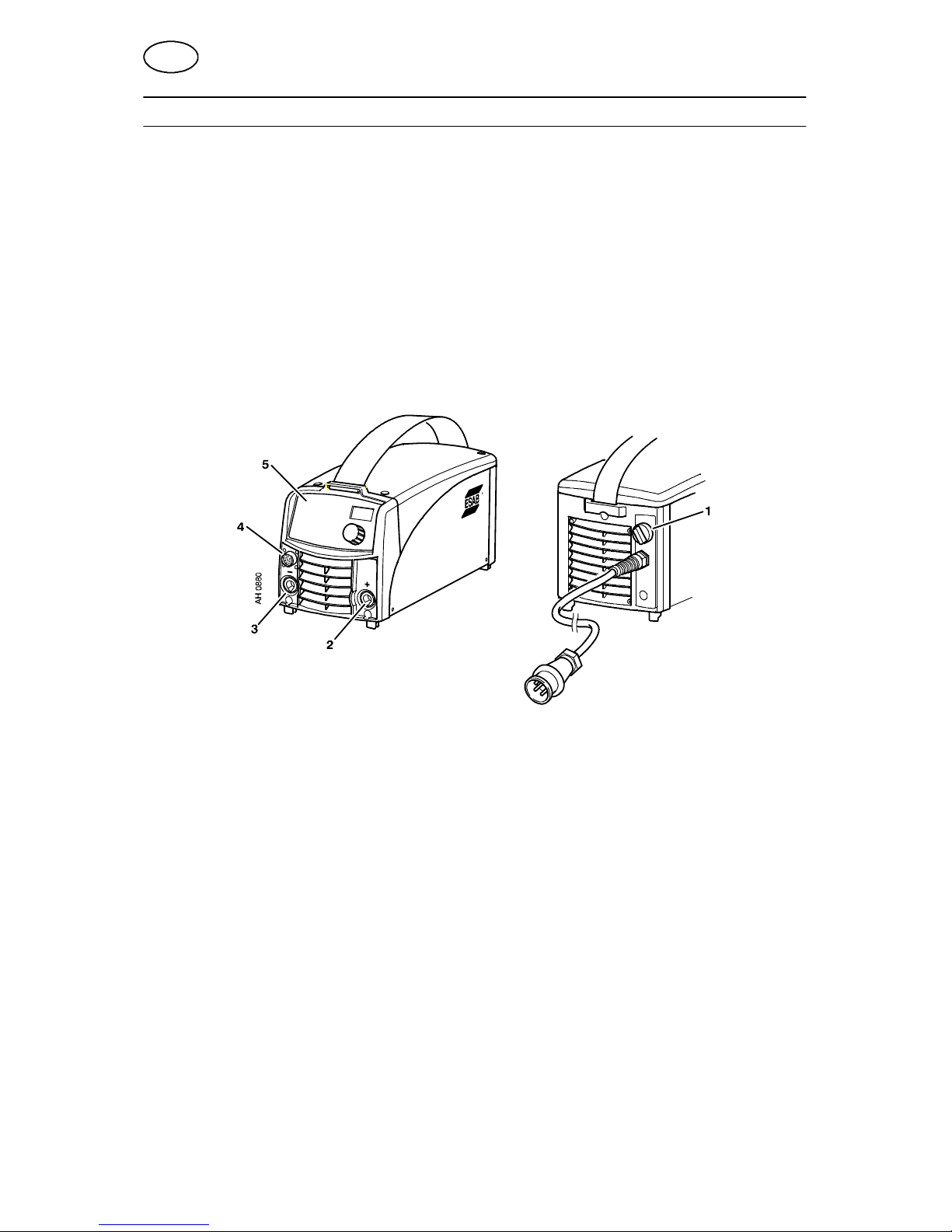

ESAB ES 150i User manual

ESAB

ESAB Aristotig 255 LTN 255 User manual

ESAB

ESAB Precision Plasmarc IEFC-S PT-24 General instructions

ESAB

ESAB LKB 265 User manual

ESAB

ESAB Renegade ET 300i User manual

ESAB

ESAB LTG 410 User manual

ESAB

ESAB EMP 215ic User manual

ESAB

ESAB Precision Plasmarc EPP-600 User manual

ESAB

ESAB LHF 400 User manual

ESAB

ESAB OrigoArc 150 User manual

ESAB

ESAB Origo Mig C170 3ph User manual

Popular Welding System manuals by other brands

TAFA

TAFA 30*8B35 owner's manual

Lincoln Electric

Lincoln Electric INVERTEC V350-PRO CE Technical specifications

CIGWELD

CIGWELD 636804 use instructions

Red-D-Arc

Red-D-Arc DC-400 Operator's manual

Hobart Welding Products

Hobart Welding Products Spool Gun DP 3035-10 owner's manual

Elettro

Elettro HI-MIG 3000 SYNERGIC instruction manual