Esco 10316 User manual

REV. 7.20

COPYRIGHT © 2020 EQUIPMENT SUPPLY CO., ALL RIGHTS RESERVED

Thank you for choosing ESCO tire service tools and equipment. We suggest you read this instruction manual

thoroughly before using the product. Save this instruction manual for future use.

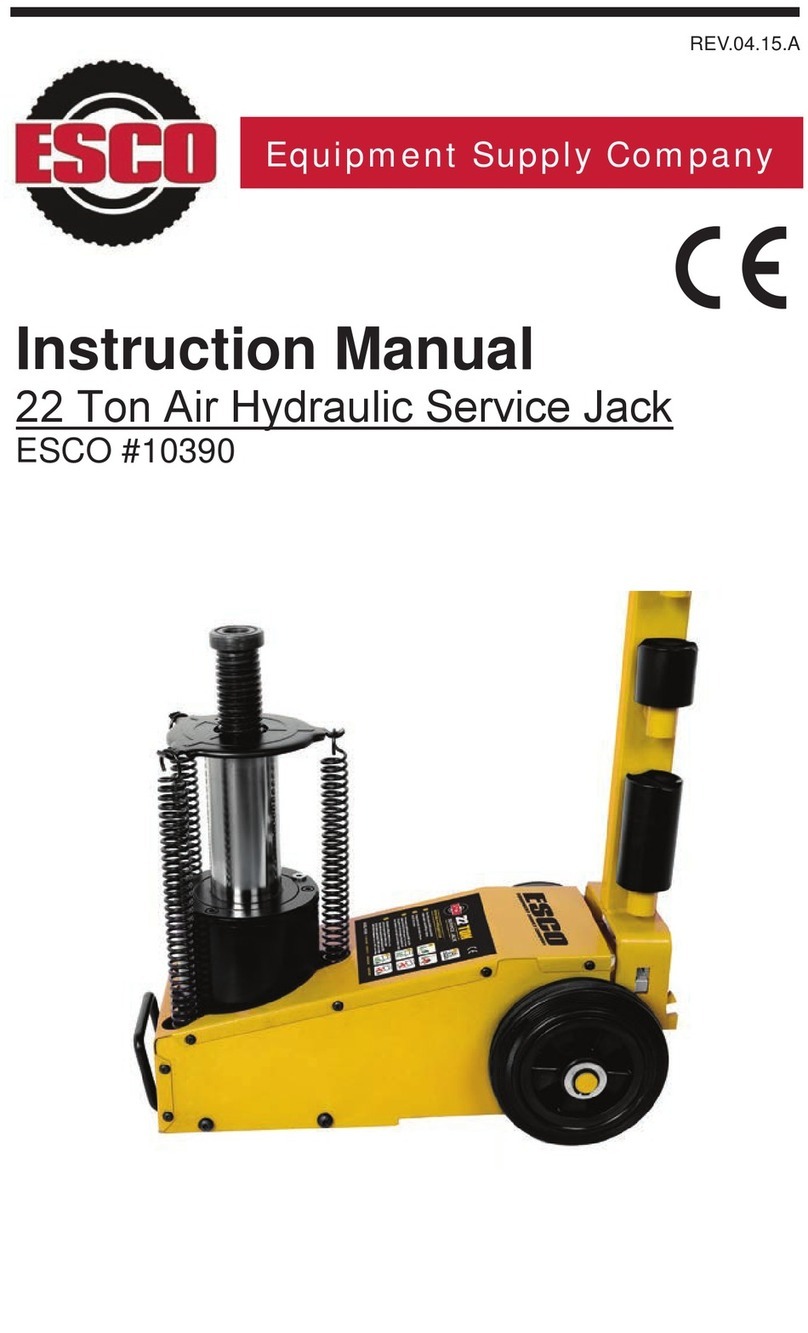

INSTRUCTION MANUAL

Stak-Able Hydraulic Ram Kit

(10 Ton Ram w/ Saddle, 1 in.; 2 in.; & 3 in. Exts.)

MODEL #10316

EQUIPMENT SUPPLY COMPANY

TABLE OF CONTENTS

• Introduction……………………………………………………………………………………………….2

• Specifications…………………………………………………………………………………………….2

• General Safety Rules…………………………………………………………………………………....3

• Operating Instructions………………………………………………………………………………….4

• Parts Breakdown …………………………………………………………………………….………… 5

• Warranty………………………………………………………………………………………………….. 6

• Parts and Repair Service……………………………………………………………………………… 7

INTRODUCTION

The high quality ESCO Stak-able 10 Ton Hydraulic Ram Kit is specifically designed for a wide range of

heavy duty applications. The Stak-able Ram Kit eliminates the tedious effort required to push rusted, corrod-

ed wheels off of hubs. Ideal for stubborn 22.5 and 24. wheels, the Stak-able Ram Kit is far more resilient and

robust than any other equipment alike on the market. Designed for applications in heavy-duty commercial

and OTR industry use. Use extensions within the kit separately or as a single long extension.

SPECIFICATIONS

STAK-ABLE HYDRAULIC RAM KIT #10316

MODEL NO. CAPACITY OPERATING

PRESSURE WEIGHT DIMENSIONS

10316 10 TONS

20,000 LBS

10,000 PSI

700 BAR

10 LBS

4.5 KG

12” (304.8 MM) X 5” (127 MM) X 5” (127) MM

WARNING

• To avoid personal injury or property damage, please follow all safety precautions. ESCO cannot be responsible for injury or damage resulting

from unsafe and incorrect products use or system operation, or lack of maintenance.

• Do not allow children or untrained individuals to use this product. Operator of this product must be trained and familiar with the correct use of

hydraulic equipment.

• Always wear ANSI and OSHA standard Personal Protective Equipment when using this product. Not wearing eye wear, non-slip shoes or hearing

protection may result in injury.

• Do not modify or use non-factory authorized parts on this product.

• Do not use hoses in system exceeding 10,000 PSI (700 BAR)

• Never use hydraulic hose to move or carry hydraulic components.

• Keep hydraulic equipment away from flames and heat

• Only use compatible high quality hydraulic fluids

• Only connect coupler fittings with quick disconnects. Never use tools to tighten coupler.

• Never lift a load more than the capacity of the cylinders, overloading causes equipment failure and possible personal injury.

• The operating pressure of cylinders are designed for a max pressure of 10,000 psi (700 bar), please do not use a pump or relief valve with a

higher pressure rating to connect the cylinder. Higher pump or relief valve may cause equipment failure and possible personal injury.

• Please install pressure gauges in the system to watch the operating pressure. The gauge must have the same pressure rating as the pump and

cylinder(s). The wrong gauges may result in personal injury. Always use an air pressure reducer or regulator with filter in hydraulic system.

• Please keep the cylinder clean all the time.

• Do not attempt to disconnect coupler while system is under pressure.

• Do not put poor-balanced or off-center loads on cylinders. The incorrect load or side loading can result in equipment failure and possible personal

injury.

• When the cylinder is not in use, please keep the piston rod fully return, remove hose and use rubber cap to recover the coupler(s). If you use

collar threads, please use the thread protector to recover the collar threads.

• Please use hydraulic equipment in normal temperature, do not use equipment in temperatures of 65 ℃ (150℃) or higher. Overheating will soften

seals and weakens hose materials, resulting in oil leaking or other equipment failure.

• Always follow OSHA 1910.77 standard* while using this product.

• Please carefully inspect cylinders, couplers and hose before use hydraulic equipment, if you find any damage on the couplers, hose, port threads

and cylinders, please contact our technical service department with any questions or issues by calling 800-352-9852.

EYE PROTECTION

MUST BE WORN

HEARING PROTECTION

MUST BE WORN

GENERAL SAFETY RULES

Warning: PLEASE READ AND FOLLOW THIS INSTRUCTION BEFORE YOU USE ESCO CYLINDERS.

STAK-ABLE HYDRAULIC RAM KIT #10316

OPERATING & MAINTENANCE INSTRUCTIONS

Connection a Single Acting Cylinder

1. Connect the hydraulic hose to the air/hydraulic pump to the hydraulic coupling on the

air-hydraulic powered cylinder.

2. Please use a pump with a release valve or a 3-way valve and one hose to connect with

Single Acting Cylinder (Figure 1). After connected all parts, please fully hand-tighten all

couplers. If not, oil will be leaked between the pump and cylinder.

Bleeding Air from the Cylinder

Air may accumulate within a cylinder during shipment or after prolonged use; this air can cause the piston rod

to respond “dithering.” Please follow the steps below to bleed the air from cylinder.

Single-Acting Cylinders:

Position the cylinder as figure 3 shows, so that the piston rod is extended down and the cylinder lower than

the pump. Fully extend and retract the cylinder 1 or 2 times. It may be necessary to repeat the above steps

several times.

For single acting cylinders, please do not allow piston rod to rotate when installing adaptors or during the

work. Rotating piston rod may damage the return spring.

Maintenance

1. Please always use clean oil or other approved hydraulic oil with these cylinders. Use other unapproved oil

or dirty oil will damage the cylinders.

2. Always keep cylinder clean, use thread protector and dust cap to protect collar thread and couplers.

3. After finish work, Cylinder must be fully retracted, cleaned and stored in ventilation, moist-proof, corrosion

-proof place.

STAK-ABLE HYDRAULIC RAM KIT #10316

Figure 2.

Figure 1.

Warning: PLEASE READ AND FOLLOW THIS INSTRUCTION BEFORE YOU USE ESCO CYLINDERS.

WARNING: Before use cylinder read and understand general safety rules and warnings. Always

visually check all units, to make sure there are no damage on cylinder, port threads, couplers and hose. Be

mindful of oil leaking and shortage of parts, if missing or leaking, do not use equipment and contact ESCO

repair technician.

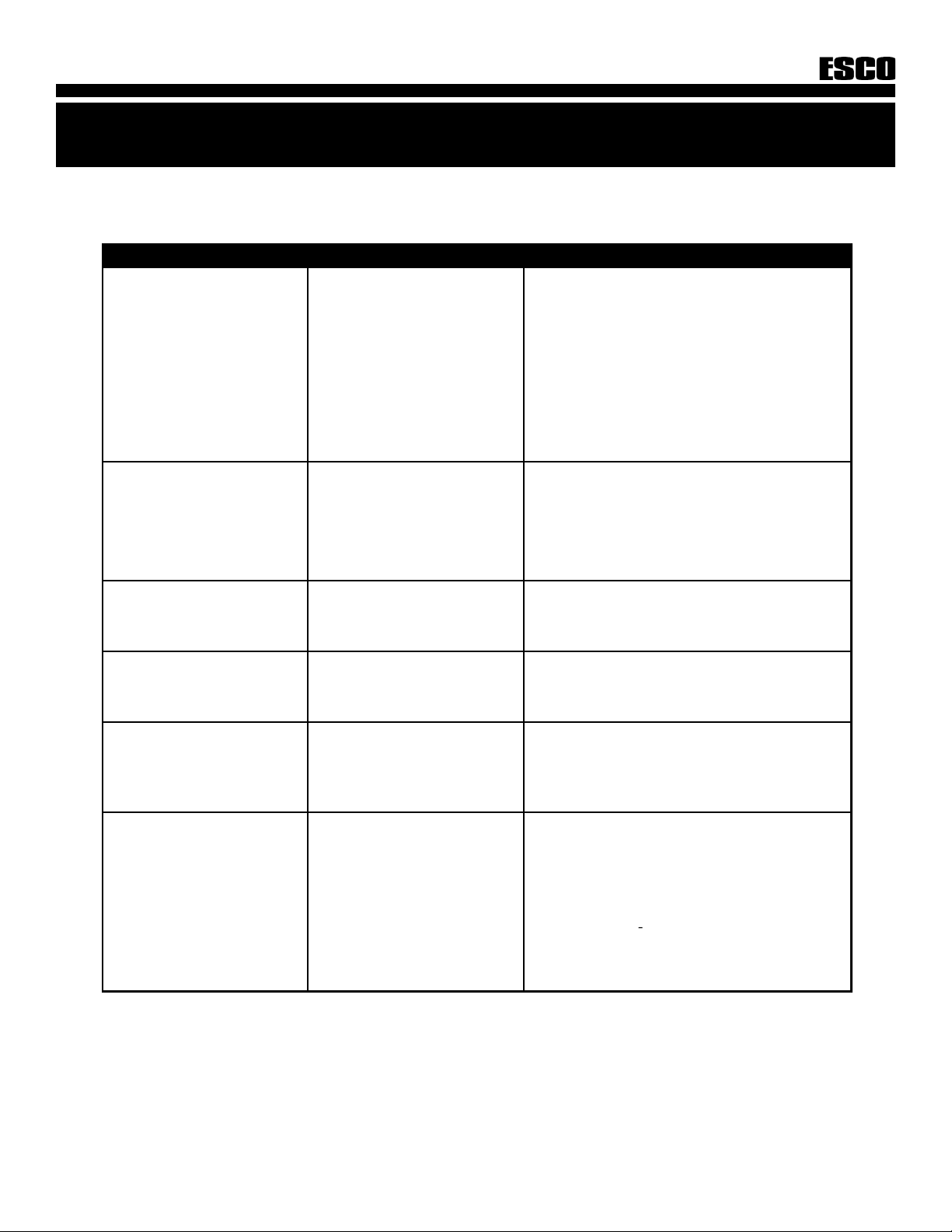

TROUBLESHOOTING

STAK-ABLE HYDRAULIC RAM KIT #10316

Problem Cause Solution

Cylinder will not extend or

extend completely 1. Pump release valve open

2. Couplers not fully tightened

3. Oil level in pump reservoir is

low

4. Pump or valve malfunction-

ing

5. Overload for cylinder

6. Cylinder piston rod binding

1. Fully tighten pump release valve

2. Fully tighten couplers

3. Fill oil in pump

4. Repair, or use another pump and valve

5. Change another cylinder with appropriate ca-

pacity

6. Check for dirt or leaks, change the damage

parts

Cylinder can not

maintain pressure

1. Leaky connection

2. Cylinder seals leaking

3. release valve not fully closed

4. Pump or valve malfunction-

ing

1. clean and reseal thread, tighten connection

2. Replace worn seals. Clean inside cylinder and

use clean hydraulic oil

3. Fully tightening the release valve

3. Repair, or use another pump and valve

Cylinder extends slower than

normal 1. Leaky connection.

2. Coupler not fully tightened.

3. Pump malfunctioning.

1. clean and reseal thread, tighten connection

2. Fully tighten couplers

3. Repair, or use another pump and valve

Cylinder extend in dithering 1. Air in cylinder

2. Cylinder piston rod binding.

1. bleed air

2. Check for dirt or leaks. Check for bent, misa-

ligned and worn parts

Cylinder leaks hydraulic oil

1. Leaky connection.

2. Worn or damaged seals

3. Cylinder damage.

1. clean and reseal thread, tighten connection

2. Replace worn seals, clean inside cylinder and

use clean hydraulic oil

3. Use new cylinder of contact with your nearest

Authorized ESCO Hydraulic Service Center.

Cylinder will not retract or

Retracts slower than normal

1. Pump release valve closed.

2. Couplers are not fully tight-

ened.

3. Pump reservoir is full

4. hose is blocked

5. Return spring is damaged

6. Cylinder damaged.

1. open release valve

2.Tightening the couplers

3. Drain hydraulic oil to correct level

4. clean or change hose

5. change return spring

6. Use new cylinder or contact your nearest Au-

thorized ESCO Hydraulic Service Center.

Please release pressure and disconnect hose(s) before making repair. Carefully inspect cylinders, couplers and hose

before use hydraulic equipment, if you find any damage on the couplers, hose, port threads and cylinders, please con-

tact our technical service department with any questions or issues by calling 800-352-9852.

Register your ESCO tool for warranty repairs at www.esco.net/warranty

STAK-ABLE HYDRAULIC RAM KIT #10316

• ESCO will pick up product for repair/warranty at your location.

• ESCO will guarantee Repair/Service for 30 days.

• ESCO has rental tools available

• ESCO repairs IMT, FEC, Stellar, Blackhawk, OTC, Power Team,

Ame Int., & Enerpac hydraulic pumps, bead breaker, and cylin-

ders.

• Authorized ESCO Repair & Warranty Centers Located through

the US & Canada. For more information contact your ESCO

sales representative.

• Technical Support Over the Phone Available by Calling 1-800-352-9852

GUARANTEED 1-Day Turnaround Service.

Received by ESCO - Repaired in 24 Hours - Returned to you!

Prompt, reliable service after the sale is very important to ESCO. ESCO maintains an in-house repair facility

in Brooksville, Florida. To insure that our customers have as little down-time as possible, we offer a 1 day

turnaround service. Our factory repair service is equipped with all the tools and machinery needed to repair

your equipment quickly and affordably. Our trained technicians are the best in the industry. Not only do we

service our own products, but we also service our competitors’ products.

In addition to ESCO’s 30 years of providing quality repair service, ESCO has reached out and partnered with

more than 50+ hydraulic repair facilities across the US & Canada, to deliver quality repair and timely return of

products. Visit www.esco.net or call 1.800.352.9852 to hear more about the newly added “Authorized ESCO

Warranty & Repair Facilities” across the US.

If you have a bead breaker, ram, or hydraulic pump that needs repair, ESCO fixes your product with factory

parts and guarantees the repair. In addition to servicing ESCO brand products, we also re-pair CP, IMT,

Elrick, Branick, Goodyear, FEC, AME Int., and Haltec lines of hydraulic bead breakers, rams, pumps, jacks,

and many other hydraulic tire service equipment.

PARTS AND REPAIR SERVICE

WARRANTY

Products sold by Equipment Supply Company (ESCO) are warranted to be free from defects

in material and workmanship under proper use, application, and maintenance in accordance

with ESCO's written recommendations, instructions, and specifications for a period of 1

year (365 days) from the date of shipment to the end user, unless otherwise noted. ESCO's

obligation under this warranty is limited to, and the sole remedy for any such defect shall be

the repair or replacement (at ESCO's discretion) of unaltered parts returned to ESCO, freight

prepaid, and proven to have such defect, provided such defect occurs within the 90-day

warranty period (or otherwise noted) and is reported within 14 days of occurrence.

This is the only authorized ESCO warranty and is in lieu of all other express or implied war-

ranties or representations, including any implied warranties of merchantability or fitness.

Warranty claims must be submitted and be processed in accordance with ESCO's estab-

lished warranty claim procedure. In no event will ESCO be liable for business interruptions,

loss of sales and/or profits, personal injury, costs of delay, or for any other special, indirect,

incidental or consequential losses, costs, or damages.

PURCHASE DATE:___________________________________________

MODEL NO.:________________________________________________

SERIAL NO. (If Applicable):____________________________________

NOTES:

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

Return to ESCO, 15270 Flight Plath Blvd. Brooksville, FL 34604

Or Visit www.esco.net/warranty

STAK-ABLE HYDRAULIC RAM KIT #10316

REV. 7.20

COPYRIGHT © 2020 EQUIPMENT SUPPLY CO., ALL RIGHTS RESERVED

Thank you for choosing ESCO tire service tools and equipment. We suggest you read this instruction manual

thoroughly before using the product. Save this instruction manual for future use.

CONTACT INFO:

15270 Flight Path Drive

Brooksville, FL 34604

PH. 352.754.1117

Toll Free. 1.800.352.9852 (US, Canada Only) Fax: 352.754.4508

Stay Connected with ESCO….

WARNING: Cancer and Reproductive Harm- www.P65Warnings.ca.gov

EQUIPMENT SUPPLY COMPANY

Other Esco Tools manuals