Table of content

1. INTRODUCTION .....................................................................................................................................................5

2. WHAT IS I-XL COMPARED TO XL?...............................................................................................................6

2.1 I-CUT USER INTERFACE.........................................................................................................................................6

2.2 THE I-CUT COMPUTER STAND...............................................................................................................................6

2.3 THE I-CUT CAMERA ...............................................................................................................................................6

2.4 MORE VACUUM SECTIONS .....................................................................................................................................7

2.5 PRESSURIZED AIR SUPERVISION ..........................................................................................................................7

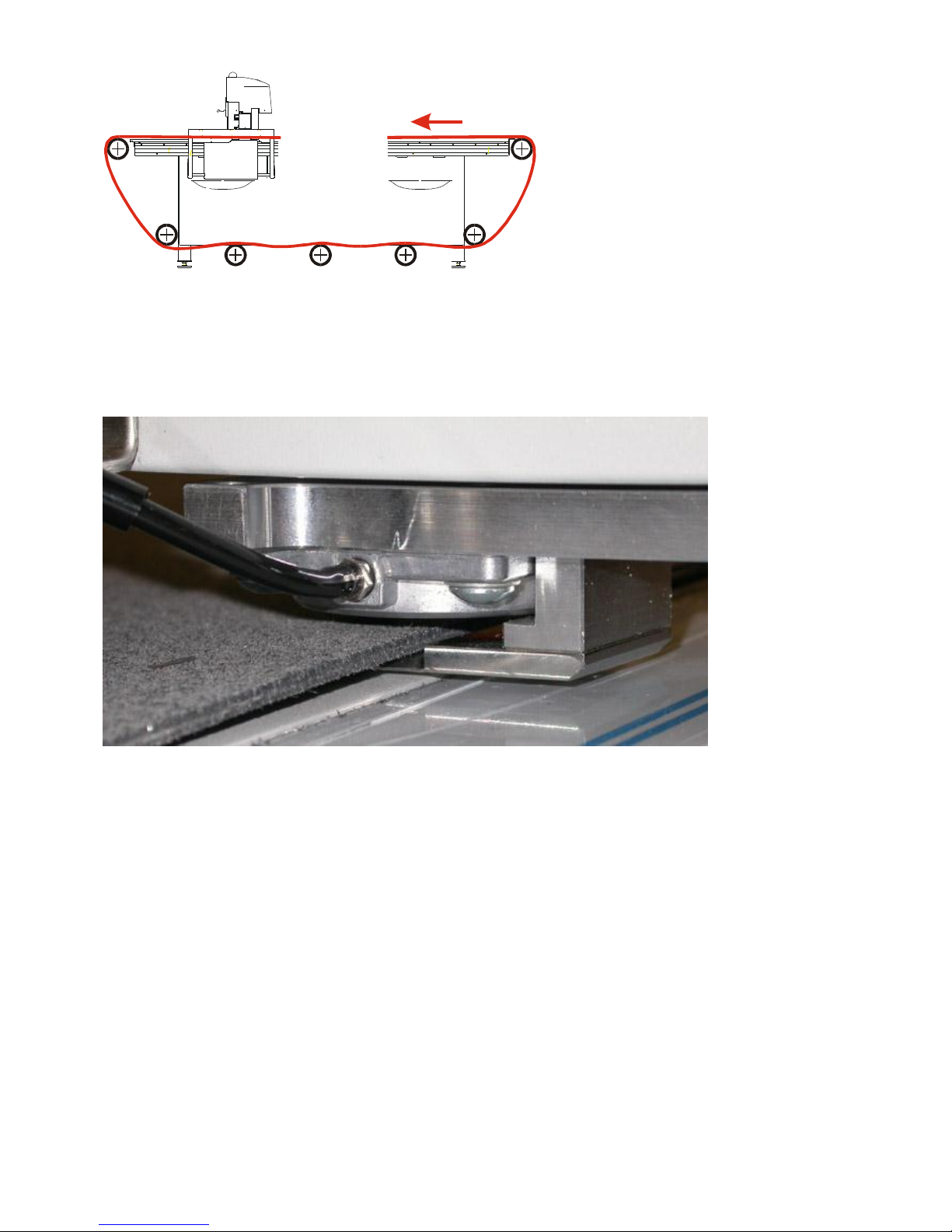

2.6 THE CONVEYOR BELT (OPTIONAL)........................................................................................................................7

2.6.1 The belt clamps ............................................................................................................................................8

2.6.2 The feeder paws...........................................................................................................................................9

2.6.3 Vacuum reverse ...........................................................................................................................................9

2.7 THE VINYL ROLL HOLDER (OPTIONAL)................................................................................................................10

2.8 THE SHEET FEEDER (OPTIONAL).........................................................................................................................10

2.9 THE KISS-CUT TOOL (OPTIONAL).......................................................................................................................10

3. THE MAIN REFERENCE POINT POSITION .............................................................................................11

3.1 GENERAL INFORMATION ABOUT REFERENCE POINTS.........................................................................................11

3.2 SET THE MAIN REFERENCE POINT FOR I-CUT....................................................................................................11

3.3 SET THE MAIN REFERENCE POINT ON A TABLE WITH RULERS ..........................................................................12

3.3.1 If your table is running XL-Guide ........................................................................................................12

3.3.2 If your table is running i-Cut.................................................................................................................12

3.3.3 Execution ......................................................................................................................................................12

4. FLEXIHEAD WITH I-CUT .................................................................................................................................13

5. MULTICUT WITH I-CUT ...................................................................................................................................13

6. I-CUT CAMERA CONNECTION TO PC ........................................................................................................14

7. I-CUT CAMERA ADJUSTMENT.......................................................................................................................14

8. SOFTWARE INSTALLATION...........................................................................................................................15

8.1 INSTALL XL-GUIDE .............................................................................................................................................15

8.2 INSTALL I-CUT HARDWARE AND SOFTWARE......................................................................................................15

8.3 HOW TO UPDATE THE I-CUT LICENSE CODES....................................................................................................15

8.4 CONFIGURE XL-GUIDE FOR I-CUT CONTROL....................................................................................................16

8.5 CONFIGURE I-CUT FOR THE KONGSBERG I-XL.................................................................................................16

9. HOW TO CHECK CAMERA OPERATION ....................................................................................................17

10. THE KISS-CUT KNIFE TOOL ......................................................................................................................18

11. BELT TENSION..................................................................................................................................................21

12. HOW TO GLUE THE BELT ............................................................................................................................22

12.1 INTRODUCTION ....................................................................................................................................................22

12.2 BELT GLUE PROCEDURE,NOVEMBER 05, 2007...............................................................................................22

12.3 OLD BELT GLUE PROCEDURE ...............................................................................................................................28

12.3.1 Tools you need .......................................................................................................................................28

12.3.2 Procedure .................................................................................................................................................29

13. SHEET FEEDER..................................................................................................................................................35

13.1 SHEET FEEDER POSITION ....................................................................................................................................35

13.2 SHEET FEEDER USB TO SERIAL LINE SETUP......................................................................................................35

13.3 SHEET FEEDER SETUP ..........................................................................................................................................35

13.4 SHEET FEEDER LOAD TABLE BRACKETS..............................................................................................................36

14. AIR AND VACUUM, BLOCKED SCHEMATIC .......................................................................................38

14.1 PRESSURIZED AIR LAYOUT WHEN SHEET FEEDER IS INSTALLED ......................................................................38