FLUE DRAUGHT READING

Two flue draught readings should be taken, one with the cooking stove at minimum firing rate and one

at maximum firing rate. The flue draught test hole must be drilled in the flue pipe as close to the

cooking stove as possible and before any flue draught stabiliser.

MINIMUM

The cooking stove should be lit and allowed to warm the flue thoroughly. The air controls can then be

set so that the cooking stove burns on a low setting. Allow the burning rate to become steady. The flue

draught reading should now be taken with the primary air intake closed and the secondary air control

fully open. The minimum flue draught required is 12 pascals (0.05” w.g.).

MAXIMUM

The primary air intake can now be opened to allow the cooking stove to burn at maximum rate. Give

the cooking stove some time for the burning rate to become steady and then close the primary air

intake. ake sure the secondary air control is fully open and take a flue draught reading immediately.

The minimum flue draught required is 12 pascals (0.05” w.g.).

The maximum is 24 pascals (0.1” w.g.).

FLUE DRAUGHT

The chimney can be checked, before the cooking stove is installed, with a smoke match. If the

chimney doesn’t pull the smoke it may suggest the chimney needs attention (see the Flue Diagnosis

Table below and the flue performance diagrams on page 6).

4 5

Note: This test is only a guide as an apparently poor flue may improve once the cooking stove is

installed, lit and the flue is warmed. Once the cooking stove is installed, a flue draught reading

should be taken.

High flue draught symptoms: fire difficult to control, fuel will not last, cooking stove too hot, cooking stove damage, chimney fire

Cause

External wind conditions combined with chimney terminal

Remedy

Fit stabilizer cowl. Fit flue draught stabilizer.

Low flue draught symptoms: difficult to light and smoke coming into the room.

Cause

Cold chimney

Chimney too short

Down draught

Chimney diameter too large

Chimney obstruction

Restricted air supply

Remedy

Line the chimney

Extend the chimney

Relocate/extend chimney terminal. Fit an anti down

draught cowl

Line the chimney

Clear/sweep the chimney

Check for competing draughts (other chimneys,

extractor hoods/fans). Fit an air vent if the room is

sealed.

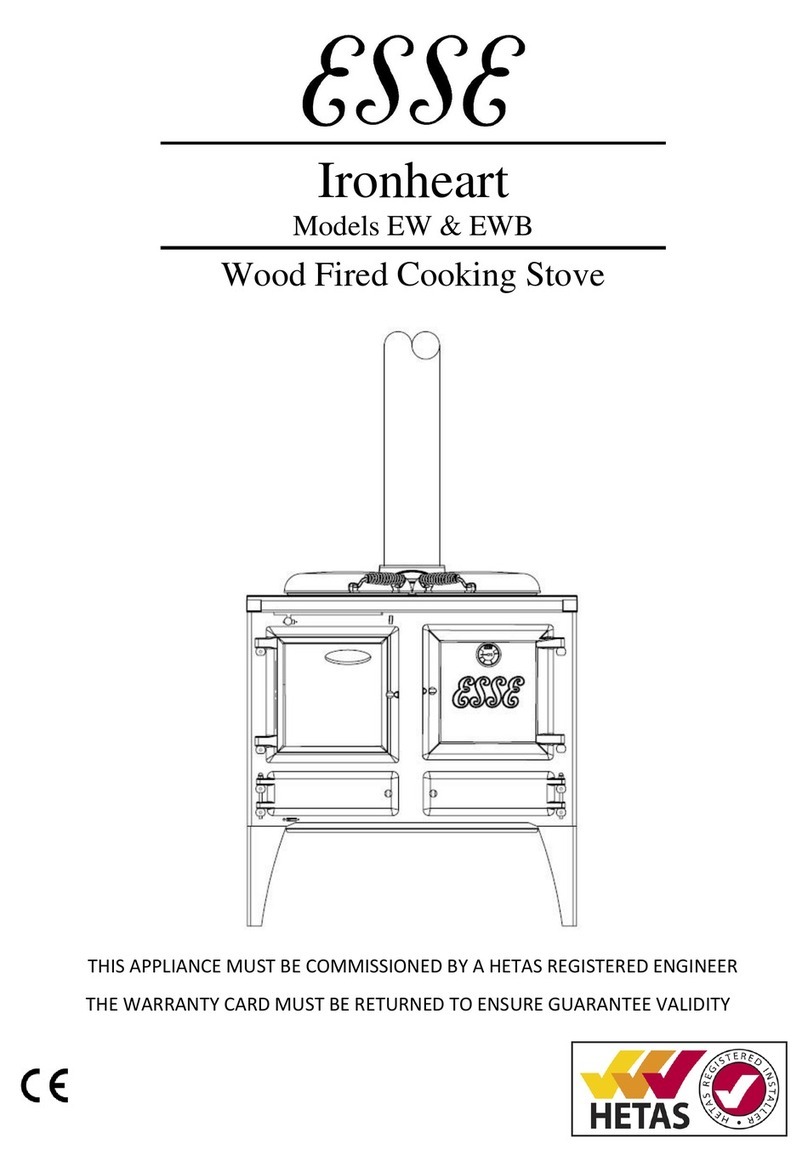

The successful operation of this appliance is entirely

dependent on the adequate performance (pull) of

the chimney or flue to which it is connected. A

partially blocked or dirty flue can have disastrous

implications for an otherwise perfectly installed

ESSE as can be seen here looking at the underside

of the hotplate from 2 identical ESSEs.

A) Has been used regularly for over a year

following simple ESSE maintenance guidelines

(supplied with this appliance) and with a clean flue

drawing correctly.

B) Was just 6 weeks old when the picture was

taken and shows how quickly tar deposits will build

up if the flue performance is poor and clogged with

old soot as it was in this case.

THE I PORTANCE OF A HEALTHY FLUE

Good draft & clean flue

Efficient wood burning, clear

flue ways, minimal soot and

no tar deposits.

Poor draft & dirty flue

Inefficient wood burning,

blocked flue ways, lots of

soot and tar deposits.

A

B

lIt should have an internal cross section of no

less than 320 cm.sq (200mm dia.) If a flueliner

is used, it should be 6” diameter and be

made of suitable material for burning wood).

The flue diameter is 6”.

lVoids in the chimney should be avoided, as

these will prevent a steady flue draught. The

appliance flue pipe should pass beyond the

narrowing of the chimney.

lBe terminated at least 1m above roof level

so that the chimney does not terminate in a

pressure zone.

lIf the appliance is installed as a freestanding

appliance, it should not support any part of the

chimney.

lBe connected to this one appliance only.

lBe free from cracks, severe bends, voids

and obstructions.

lNew chimneys must be in accordance with

local regulations.

lThe chimney must be capped to prevent

ingress of rain.

lA flue/chimney access point may also be

required so that the state of the chimney can

be checked and any fallen soot removed.

lExternal flues must be insulated to prevent

heat loss.

lDo not fit an extractor fan in the same room

as the appliance.

lBe a minimum 4.6m high from hob chimney level

to pot.

Note: The chimney / flue to which this appliance is being connected must be swept and examined

for soundness prior to installation. Remedial action should be taken if required, seeking expert

advice if necessary. Where the chimney is believed to have served an open fire installation it is

possible that a higher flue gas temperature from a closed appliance may loosen deposits that

were firmly adhered, with the consequent risk of flue blockage. It is therefore recommended that

the chimney be swept a second time within a month of regular use after installation.

The successful operation of the cooking appliance relies on the adequate performance of the chimney

to which it is connected. The following chimney guidelines must be followed:

CHI NEY AND FLUE INFOR ATION