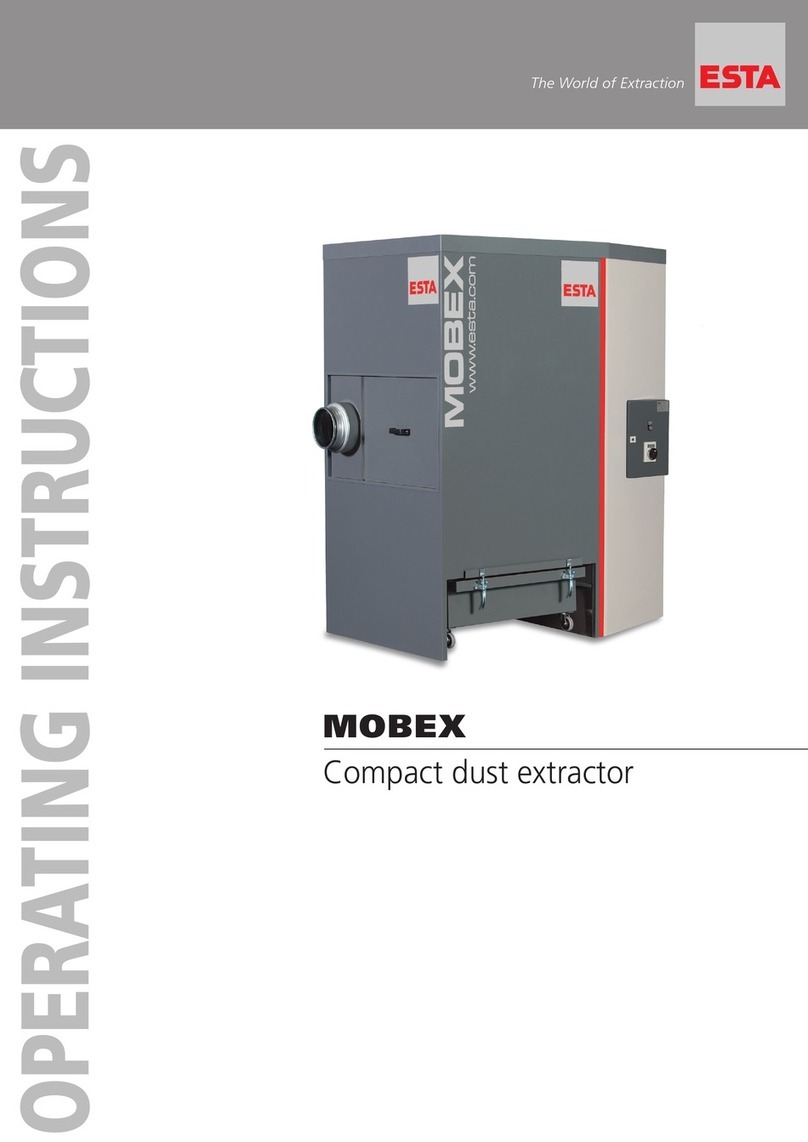

09201-52-01 DUSTOMAT-10 3

Contents

Contents .....................................................................................................................................3

1.General safety notes ...........................................................................................................4

2.Preventing mechanical hazards.........................................................................................6

3.Preventing electrical hazards.............................................................................................6

4.Preventing dust hazards.....................................................................................................6

5.Intended use ........................................................................................................................7

6.Technical data and description..........................................................................................8

6.1 DUSTOMAT-10 ..................................................................................................................8

6.2 Functional description.........................................................................................................9

7.Delivery and commissioning ............................................................................................ 10

7.1 Delivery and transport ......................................................................................................10

7.2 Commissioning................................................................................................................. 10

8.Maintenance and troubleshooting ................................................................................... 12

8.1 Maintenance instructions..................................................................................................1 2

8.2 Inspection and maintenance intervals ..............................................................................13

8.3 Troubleshooting................................................................................................................ 15

9.Monitoring the minimum volume flow .............................................................................16

9.1 Dust extractor - operation .................................................................................................16

9.2 Industrial dust extractor - operation ..................................................................................17

10.Cleaning .............................................................................................................................17

10.1 Cleaning the filter............................................................................................................ 17

10.2 Filter replacement...........................................................................................................18

11.Disposal ............................................................................................................................. 19

11.1 Disposing of collected dust materials .............................................................................19

11.2 Disposing of the dust extractor .......................................................................................20

12.Optional equipment...........................................................................................................21

12.1 Pre-separator ................................................................................................................. 21

13.Device diagram..................................................................................................................22

14.Declaration of conformity .................................................................................................23

Notes.........................................................................................................................................24