Esta MOBEX P-24 User manual

OPERATING INSTRUCTIONS

The World of Extraction

MOBEX

Compact dust extractor

Your purchase of an ESTA machine has

been a good decision. The design of

our quality products complies with the

latest state of the art. ESTA products

have been devised to provide for clean

air at the workplaces at which they are

applied. This results in an even more

enhanced level of quality and longer

machine times and, particularly, healthier

working conditions. Should you have

any questions pertaining to suction tech-

nology issues, please feel free to contact

us at any time. Our experts will be gladly

at your disposal.

Your ESTA Absaugtechnik Team

The World of Extraction

www.esta.com

Welcome to the sphere of suction

technology

Operating manual

MOBEX P

MOBEX P-24 (Item-No. 09.831)

MOBEX P-36 (Item-No. 09.832)

and variations

Do not use this device unless you have

read the user manual and understand it.

Translation of the original operating manual

09831-08-02

2 MOBEX P 09831-52-02

Edition notice

Original operating manual

Document No.: 09831-08-02

Publishing date: 17.10.2013

Type of device: MOBEX P stationary extractor

Item No.: 09.831 // 09.832 and variations

Publisher

ESTA Apparatebau GmbH & Co. KG Tel.: +49 (0) 73 07 80 4 -0

Gotenstraße 2-6 Fax: +49 (0) 73 07 80 4 -500

Germany www.esta.com

Copyright notice (per DIN ISO 16016:2007-12)

Transfer or reproduction of this document, or the use or communication of its content, is

forbidden without explicit consent. Violators will be liable for damages. All rights to patent, utility

or design registration are reserved.

09831-52-02 MOBEX P 3

Contents

Contents.................................................................................................................................3

1.General information ........................................................................................................5

2.Product identification......................................................................................................6

2.1Technical Data .........................................................................................................6

2.2Intended use............................................................................................................. 6

2.2.1Environmental conditions .........................................................................................6

2.2.2Intended use............................................................................................................. 7

2.2.3Unintended use ........................................................................................................7

2.2.4Reasonably foreseeable misuse ..............................................................................8

3.Product description.........................................................................................................8

3.1Product representation .............................................................................................8

3.1.1MOBEX P-24............................................................................................................8

3.1.2MOBEX P-36............................................................................................................8

3.2Functional description ..............................................................................................9

3.3Monitoring the minimum airflow volume ...................................................................9

4.Safety instructions........................................................................................................10

4.1Hazard classes.......................................................................................................10

4.2Explanation of symbols ..........................................................................................10

4.2.1Symbols on the device ...........................................................................................11

4.3General safety notes ..............................................................................................12

4.4Preventing mechanical hazards .............................................................................12

4.5Preventing electrical hazards .................................................................................13

4.6Preventing dust hazards.........................................................................................14

4.7Preventing hazards - Noise ....................................................................................15

5.Delivery and start-up.....................................................................................................16

5.1Delivery and transport ............................................................................................16

5.2Connection .............................................................................................................16

5.2.1Description switch box............................................................................................17

5.2.2Compressed air connection....................................................................................18

5.2.3Electrical connection ..............................................................................................18

5.2.4Switch-on operations for motors:............................................................................19

5.3Functional inspection.............................................................................................. 20

5.3.1Checking the direction of rotation ...........................................................................20

5.4Preparing the dust collection container ..................................................................21

5.4.1Base body ..............................................................................................................21

5.4.2Lid for dust collection container .............................................................................. 22

5.5Start up...................................................................................................................23

5.6Connecting the suction line ....................................................................................24

5.7Troubleshooting at start-up.....................................................................................25

6.Operating instructions..................................................................................................26

6.1Operating the device ..............................................................................................26

6.2Jet pulse cleaning................................................................................................... 26

6.2.1Automatic cleaning during suction operation..........................................................27

6.2.2Automatic post-cleaning .........................................................................................27

6.2.3Manual cleaning .....................................................................................................27

4 MOBEX P 09831-52-02

7.Maintenance and troubleshooting...............................................................................28

7.1Maintenance instructions........................................................................................28

7.2Inspection and servicing intervals........................................................................... 29

7.2.1Replacement and wear parts..................................................................................31

7.3Cleaning the air baffle ............................................................................................ 32

7.3.1At MOBEX P-24 .....................................................................................................33

7.3.2At MOBEX P-36 .....................................................................................................34

7.4Replacing the dust collection container .................................................................. 35

7.5Replacing the filter cartridge...................................................................................37

7.5.1Pre-coating during commissioning or when installing new filter cartridges.............39

7.6Adjust the monitoring the minimum airflow volume ................................................40

7.6.1MOBEX P-24..........................................................................................................41

7.6.2MOBEX P-36..........................................................................................................41

7.7Removing the fan filter pad.....................................................................................42

7.8Removing the exhaust filter pad .............................................................................43

7.9Cleaning the device................................................................................................ 44

7.10Storing the device................................................................................................... 44

7.11Troubleshooting......................................................................................................45

8.Disposal .........................................................................................................................47

8.1Disposing of collected dust materials .....................................................................47

8.2Disposing of the dust extractor ...............................................................................47

9.Optional equipment.......................................................................................................48

9.1Start-up with potential-free contact.........................................................................48

9.1.1Installation at the potential-free contact..................................................................48

9.2Mobile version ........................................................................................................49

9.3Integrated spark pre-separator (FVA)..................................................................... 51

9.3.1Cleaning the spark pre-separator ...........................................................................52

9.3.2Inspecting and cleaning the material pre-separator................................................ 53

9.3.3Inspecting and cleaning the coarse dust collection drawer ....................................54

9.4Spark detection ......................................................................................................55

9.4.1Extinguishing equipment ........................................................................................55

9.5Exhaust port ...........................................................................................................56

9.6Control filter ............................................................................................................56

9.6.1Replacing the filter cassette (control filter) .............................................................57

9.7Forklift tilting mechanism for dust collection drawer ...............................................59

10.EC declaration of conformity .......................................................................................60

Notes.....................................................................................................................................61

Notes.....................................................................................................................................62

Notes.....................................................................................................................................63

Notes.....................................................................................................................................64

09831-52-02 MOBEX P 5

1. General information

Before operation, all persons who are to use the dust extractor or perform

maintenance on it must be provided with information, instructions and training in

using the device and on the substances for which it is to be used, including the

procedure for safe disposal of the collected material. Responsibilities must be

clearly established for the following:

Installation

Start-up

Operation

Maintenance and repair

Read the operating manual carefully before working with the device.

The device must be used only by persons who have been instructed in its

handling and are explicitly authorized to use it.

Always keep the operating manual at the place where the dust extractor is being

used, so that it can be seen by personnel at all times.

6 MOBEX P 09831-52-02

2. Product identification

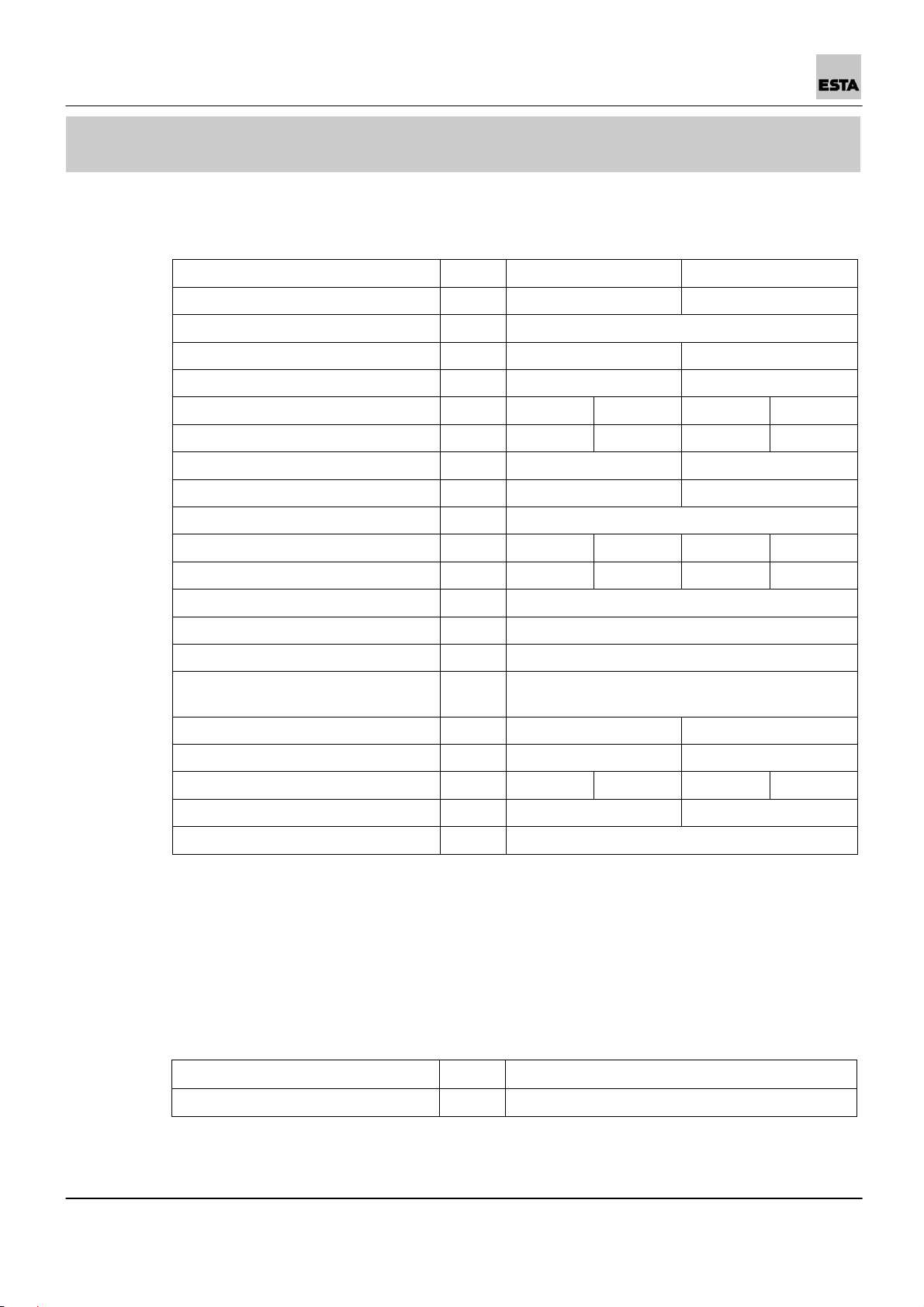

2.1 Technical Data

Subject to change without notice

Item.-No. 09831 09832

Type MOBEX P-24 P-36

Filter type Cartridge filter

Number of filter elements [Pc.] 2 3

Filter surface [m²] 24 36

max. negative pressure [Pa] 3.400 3.640 3.400 ___**

max. air flow [m³/h] 2.800 2.635 4.500 ___**

min. air flow [m³/h] 2.400 3.200

Drive [kW] 3,0 4,0

Voltage [V] 400

Nominal frequency [Hz] 50 60 50 60

Rated current [A] 7 5,7 9 ___**

Fuse [A] 16

Type of protection IP 54

Dust collection drawer [l] 100 - 150

Dust collection container

(each ~38 litre) [pc.] 2

Intake port diameter ø [mm] 200 250

Dimensions (L x W x H) [mm] 1.910 x 1.040 x 2.030 2.030 x 1.040 x 2.030

Sound pressure level LpA * [dBA] 71 69 74 ___**

Weight [kg] ca. 310 ca. 350

Production year see label

*measured at minimum airflow volume, noise measurement margin of error approx. 4 dBA

** Custom voltage on request

2.2 Intended use

2.2.1 Environmental conditions

Ambient temperature [°C] 540

Relative humidity [%] 30 - 70

09831-52-02 MOBEX P 7

2.2.2 Intended use

The device has been manufactured according to recognized safety regulations

and must be used as intended:

for commercial use, such as in industrial enterprises and workshops.

for separation of dry, free-flowing, non-flammable dusts of dust class M.

for suction at individual workstations.

as a central exhaust system at machines that produce dust.

only for dry cleaning.

as a central exhaust system at machines that produce shavings.

For suction processes that produce shavings or for very fine dusts (grain size

≤10μm), a pre-separator may be required.

For more information, please contact

ESTA Customer service: +49 (0) 7307 804 - 0

Other applications are considered unintended use. ESTA is not liable for damages

due to unintended use!

ESTA sets up the dust extractor according to the operator’s information.

2.2.3 Unintended use

The device has been manufactured according to the state of the art and

recognized safety regulations. Unintended use may cause hazards.

Therefore,

do not use or store the device outdoors or under wet conditions.

do not change the location of the device during suction operation.

do not set up or operate in gas-explosive areas.

do not use in painting operations.

do not connect to processing machines that may produce active ignition

sparks or hot embers.

do not suck up liquids.

do not exhaust aggressive gases.

do not exhaust mildly combustible or glowing particles.

8 MOBEX P 09831-52-02

2.2.4 Reasonably foreseeable misuse

do not suck up hot embers, such as cigarette butts.

do not cause complete closure of the suction ports.

3. Product description

3.1 Product representation

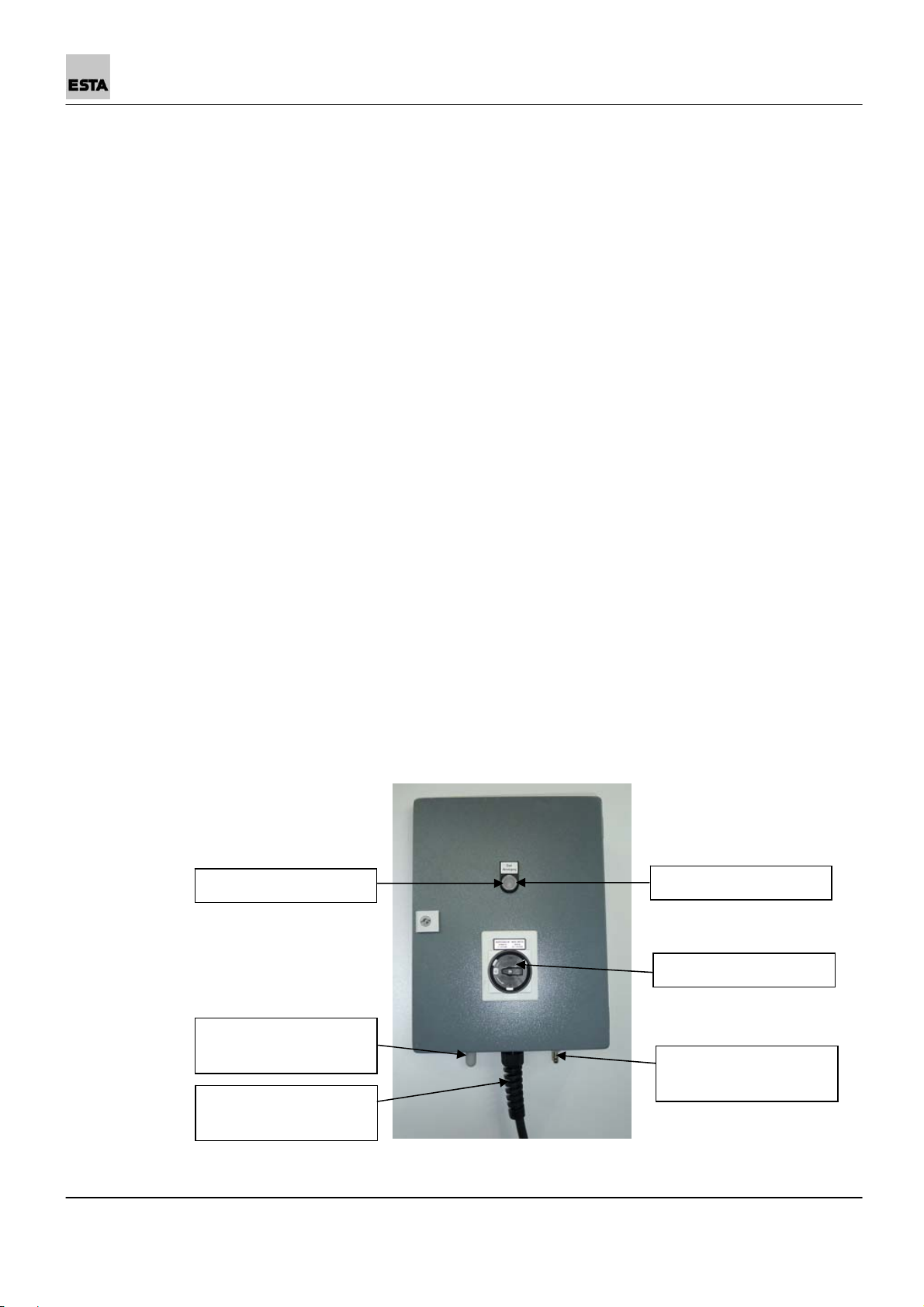

3.1.1 MOBEX P-24

3.1.2 MOBEX P-36

Intake port

Dust collection

drawer

Switch box

Lid

Fan unit

Filter unit

Dust collection

drawer

Switch box

Filter unit

Intake port

Lid

Fan unit

Inlet

Inlet

Maintenance lid

09831-52-02 MOBEX P 9

3.2 Functional description

The DUSTOMAT is equipped with a three-phase motor that drives a radial fan.

The main switch supplies or cuts off the necessary power to the device, and the

fan is turned on and off from the control unit. The device starts running as soon as

the main switch is turned on.

The vacuum created by the fan draws air through the suction pipe or hose

connected to the intake port. A permanent filter set up within the filter housing

separates the dust that is in the exhausted air. The purified air is guided draft-free

back into the room through the exhaust openings on the top of the device.

With the filter cartridges used, the device is equipped with a vacuum monitor as a

control device for overseeing minimum airflow volume. This monitoring device

measures the vacuum in the filter. With increased dust soiling of the filter, the flow

resistance increases along with the vacuum behind the filter.

If the value set on the vacuum monitor is reached, the filter cartridges are

automatically cleaned with compressed air. A pneumatic jet pulse cleaning device

is integrated for this purpose. Intense pulses of compressed air are successively

introduced into the filter cartridges. The cleaning frees the filters of dust and

reconditions them. The dust collection container underneath the filter catches the

dust that is cleared.

For easy disposal of the collected dust material, the dust collection drawer is

released, pulled out and removed from the dust collection container complete with

contents.

The device is equipped with a pre-separator / baffle. This pre-separator / baffle is

built in behind the intake port, before the actual pre-filters. It pre-separates the

coarse particles and thus prevents them from being sucked against the filters. The

pre-separator / baffle must be checked regularly for contamination. For this, follow

the safety instructions for cleaning.

3.3 Monitoring the minimum airflow volume

The minimum airflow volume is monitored though a differential pressure

measurement. Capture elements with various exhaust port diameters can be used

with the device. Here it should be ensured

that suction does not go below the minimum airflow volume

- This minimum airflow volume depends on the capture element’s port

diameter and the required flow velocity.

10 MOBEX P 09831-52-02

4. Safety instructions

4.1 Hazard classes

Safety instructions and cross-topic information are indicated in this manual by

symbols.

Based on the severity of the hazard, the hazard warnings are categorized as

follows:

DANGER

Hazard warning about an immediate danger to people.

Failure to comply can lead to severe injury or death.

WARNING

Warning about a recognizable hazard.

Failure to comply can lead to severe injury or death, and can destroy the device or

parts thereof.

CAUTION

Instruction about a hazard.

Failure to comply can lead to mild injury and to damage to the device.

4.2 Explanation of symbols

Further information

Reference to ESTA customer service

Reference to legal regulations

09831-52-02 MOBEX P 11

4.2.1 Symbols on the device

Turn the device off.

Wait 5 minutes.

Then pull out the dust collection drawer or open the device.

Before commissioning, read and observe the operating manual and safety

instructions (per ISO 11684)

Hand injury warning (per BGV A8 W27)

Short-term loads on the surface must not exceed 175 kg!

Do not take in glowing dust or other sources of ignition. Do not use with

machines that produce sparks!

12 MOBEX P 09831-52-02

4.3 General safety notes

During exhaust, the volume flow returned from the dust extractor into the room

must be no more than 50% of incoming air. With free room ventilation, the

incoming airflow must equal the room volume every hour. This means that the rate

of air replacement must be once per hour.

Incoming airflow [m³/h] = room volume [m³] air replacement rate [1/h]

Example:

When the dust extractor is operating at the nominal airflow volume of 1060 m³/h

the same volume of fresh air must therefore be fed in. This occurs with natural

ventilation if the volume of the work room is 1060 m³ (e.g. 353 m² surface with a

3m ceiling height).

According to work equipment user directives 2009/104/EG and TRGS 560, safety

devices for prevention or removal of hazards must be regularly maintained and

regularly inspected by an expert for safe, flawless operation.

In all emergencies, the device must be disconnected from the power supply

immediately. Turn the device off with the main switch and pull the plug.

If there is a fire, alert the fire department immediately, and contain the fire by

appropriate means! Therefore keep a suitable extinguishing agent near the device

before start-up and during operation.

4.4 Preventing mechanical hazards

WARNING

Crushing hazard due to loose or open covers

Keep covers closed during operation!

All movable machine parts driven by electric motors must be covered by fixed,

securely fastened protective covers that can be removed only with tools.

09831-52-02 MOBEX P 13

4.5 Preventing electrical hazards

DANGER

High-voltage electric shock

Follow the safety rules for working with electrical devices!

Secure the device with a padlock against reactivation!

Cut off the device's power supply by pulling the electrical plug!

Work on the electrical grid and on voltage conducting parts must be done

only by an electrical specialist.

DANGER

High-voltage electric shock due to damaged power cable

Do not damage by running over, crushing, straining, etc.

Regularly check the power cable for damage and ageing.

Do not use if damage has been found on the power cable!

Work on the electrical grid and on voltage conducting parts must be done

only by an electrical specialist.

Use only original ESTA replacement parts.

DANGER

High-voltage electric shock due to working at the running device

Turn off at the main switch and secure with a padlock against reactivation!

Cut off the device's power supply by pulling the electrical plug!

Work on the electrical grid and on voltage conducting parts must be done

only by an electrical specialist.

DANGER

Residual hazard from loose or open covers

Keep covers closed during operation!

Work on the electrical grid and on voltage conducting parts must be done

only by an electrical specialist.

All electrical parts must be covered by fixed, securely fastened protective covers

that can be removed only with tools. The device complies with Protection Class I

according to EN 60 335.

After use, before moving the device to another site and before cleaning,

maintenance, or replacement or removal of movable parts, the device must be

turned off at the main switch and the electrical plug must be pulled.

14 MOBEX P 09831-52-02

4.6 Preventing dust hazards

CAUTION

Damage due to dust release

Maintenance, cleaning, repair and emptying must be done only by expert

personnel.

Wear personal protective gear.

- Respirator mask (particle filter class P3)

- Protective clothing

- Safety gloves

Set up locally filtered forced-air ventilation when the device is being

maintained, inspected or cleaned.

Operate the device only with the complete filtration system.

During transport, close the intake port dust-free with sealing plugs.

CAUTION

Damage due to dust build-up in the pipe system

Regularly check the connected pipe system for dust build-up.

Observe the minimum air speed for your application and the resulting

minimum airflow volume.

When emptying the dust collection bag, it is possible to inhale

dust. Therefore all repair, cleaning and maintenance procedures,

including removing and emptying the dust collection container,

must be performed by expert personnel using personal protective

gear.

The people assigned to cleaning work must be instructed on the

aspirated toxic materials. Negative impacts on uninvolved persons

and the environment must be prevented. Clean the maintenance

area thoroughly after maintenance is finished.

09831-52-02 MOBEX P 15

4.7 Preventing hazards - Noise

CAUTION

Danger of hearing damage from release of compressed air impulses when filter

elements are being cleaned

Keep the device's covers closed.

Wear ear protection.

Open the device only when the compressed air tank has been relieved.

To do this:

- Turn the device off at the main switch.

- Wait for automatic post-cleaning to end,

- Cut the compressed air supply directly at the control cabinet

- If necessary, empty the compressed air tank through "Start Cleaning".

Open the device only when it has stopped.

To do this

- Cut off the power supply by pulling the electrical plug

If the device — especially the cleaning module — must be opened during

operation, during normal operation automatic cleaning can be triggered through

the controls. The cleaning impulse can damage human hearing. The manometer

attached to the compressed air tank is for checking the tank’s pressure.

After use, before moving the device to another site and before cleaning,

maintenance, or replacement or removal of movable parts, disconnect the device

at the control cabinet.

16 MOBEX P 09831-52-02

5. Delivery and start-up

5.1 Delivery and transport

DANGER

Danger from falling device

Do not walk under heavy loads.

The lifting equipment must be designed for the weight of the device.

WARNING

Crushing hazard if the device settles during transport

Secure the device during transport.

Wear safety shoes.

VORSICHT

The device may be damaged if transported wrong.

Do not slide the device across the floor if it has no casters.

Use only suitable lifting equipment (such as a crane) and transport

equipment (such as a forklift or lift truck) when transporting the device to its

set-up location.

When setting down, beware of the off-centre centre of gravity.

Make sure the floor has adequate weight capacity and can be properly driven on

when transporting the device.

At delivery, the device is fastened to a pallet. Remove the protective cover and

floor securing devices. Inspect the delivery for completeness. Lift the device with a

crane, using the eye hooks on the top of the device, or with a forklift. Pay attention

to the weight of the device and its high centre of gravity during all transport

operations.

Upon delivery, please inspect the device for transportation damage. Damage

determined must be reported and documented immediately.

ESTA customer service: +49 (0) 7307 804 - 0

5.2 Connection

Before setting up the cable connection between the device and the power grid,

check to make sure the operating voltage shown on the model plate is the same

as that of the grid.

The device must be placed on a level surface as near as possible to the dust

source. During set-up, make sure that the device is level. For this, use the shims

included in delivery as installation material.

09831-52-02 MOBEX P 17

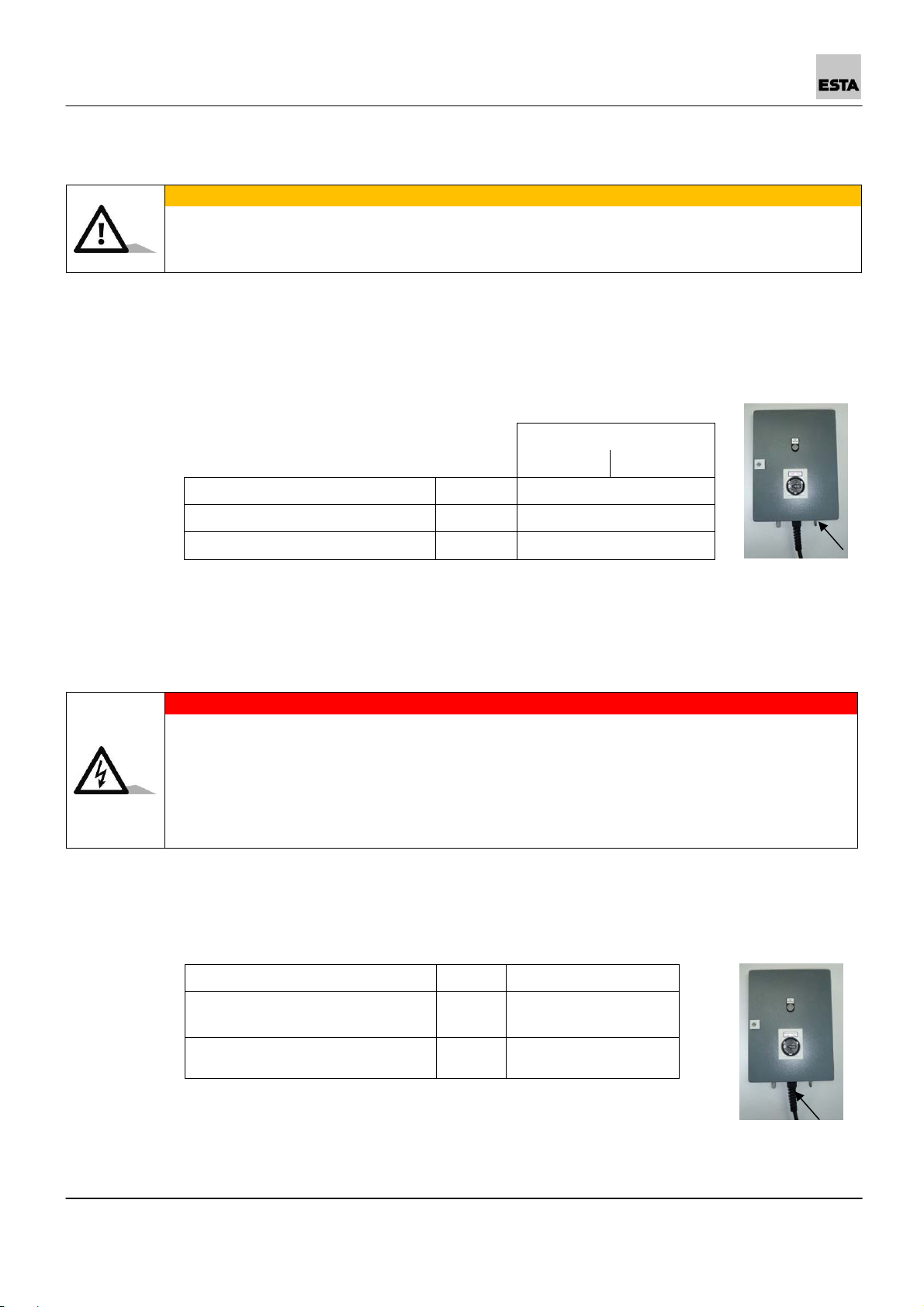

5.2.1 Description switch box

The control cabinet is equipped with the following elements.

MAIN SWITCH

A main switch for turning the device on and off. The device starts running

immediately after the switch is activated.

The switch can be secured with a padlock against unintentional activation.

START CLEANING (Push-button)

For starting the cleaning equipment manually.

ROTARY FIELD CONTROL (light in push-button)

Lights if the rotating electrical field is wrong during commissioning.

ELECTRICAL CONNECTION

To be connected to the required power supply. The electrical plug is also used to

cut power to the device. In an emergency, pull this immediately as an emergency

shut-off.

COMPRESSED AIR CONNECTION

To be connected to the required compressed air supply.

CONNECTION ATMOSPHERE

For measuring the pressure against the atmosphere. Combined with the vacuum

measured in the device, this gives the differential pressure.

Main switch

Start cleaning

Rotary field control

Compressed air

connection

Electrical

connection

Connection

atmosphere

18 MOBEX P 09831-52-02

5.2.2 Compressed air connection

WARNING

Danger of corrosion when using unfiltered compressed air

Use a compressed air maintenance unit (not included in delivery) to make

sure that only oil- and water-free compressed air is fed to the device.

Compressed air is needed for pneumatic jet pulse cleaning of the filter

elements. Connect oil- and water-free compressed air to ensure operating

safety and machine availability.

Connection to the compressed air network is made at the set-up site.

MOBEX

P-24 P-36

Pressure [bar] 4 - 6

Connection-ø [''] 1/4 (ø9mm)

Requirement of compressed air* [l/impulse] 19

* at 4 bar with a valve opening time of 0.12 sec.

5.2.3 Electrical connection

DANGER

High-voltage electric shock

Follow the safety rules for working with electrical devices!

Secure the device with a padlock against reactivation!

Cut off the device's power supply by pulling the electrical plug!

Work on the electrical grid and on voltage conducting parts must be done

only by an electrical specialist.

To supply the device with power, a CEE wall socket with a slow-blow fuse must

be available.

Connection to the on-site power grid is made at the set-up location.

* Custom voltage on request; observe the data on the model plate.

Connection plug [Amp.] CEE 16 Amp.

Electrical network (standard)* Three-phase current

400V; 50 Hz; 3N~

Fuse [Amp.] 16 (slow blow)

This manual suits for next models

3

Table of contents

Other Esta Vacuum Cleaner manuals

Esta

Esta EUROSOG-W/N User manual

Esta

Esta DUSTOMAT-160 S User manual

Esta

Esta DUSTOVAC 5.5 FM User manual

Esta

Esta EUROSOG - ATEX User manual

Esta

Esta DUSTOMAT-10 User manual

Esta

Esta NA-K B/VA User manual

Esta

Esta NA-K User manual

Esta

Esta DDE 1500 User manual

Esta

Esta DUSTOMAT 4 ATEX User manual

Esta

Esta WHISPERSOG User manual