Esta NA-K User manual

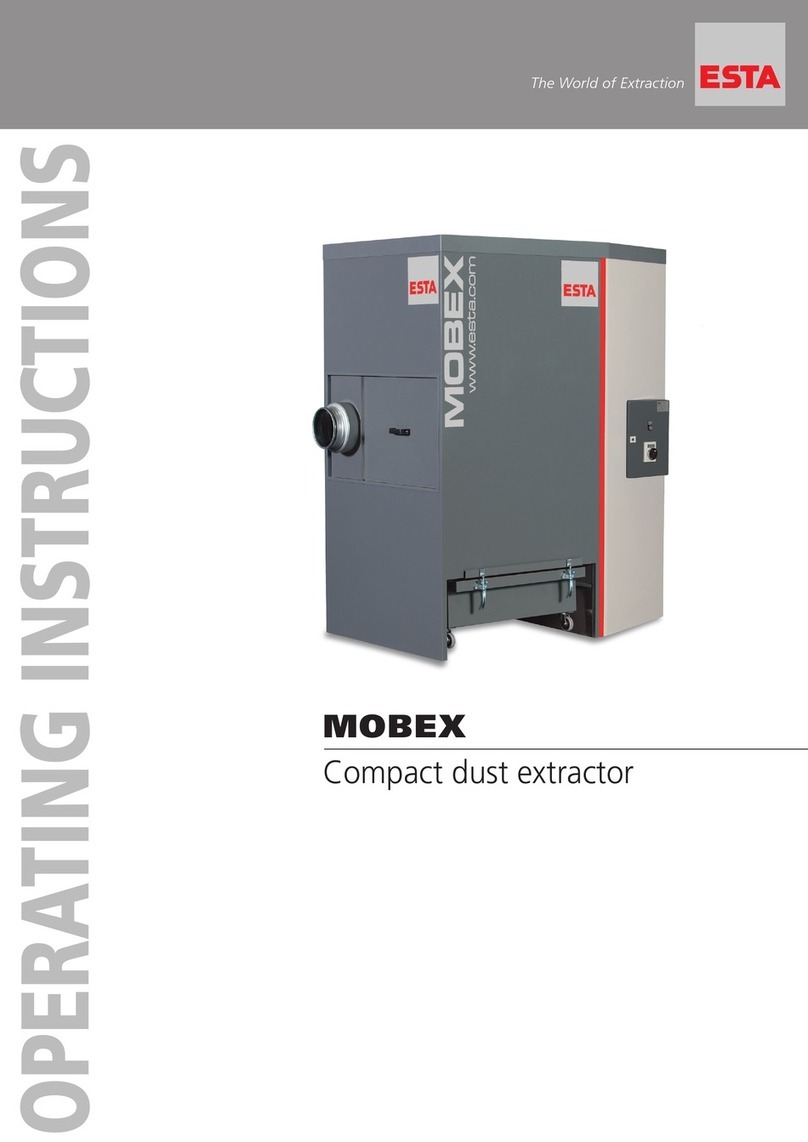

OPERATING INSTRUCTIONS

The World of Extraction

NA-K

Stationary Dust Extractors

Your purchase of an ESTA machine has

been a good decision. The design of

our quality products complies with the

latest state of the art. ESTA products

have been devised to provide for clean

air at the workplaces at which they are

applied. This results in an even more

enhanced level of quality and longer

machine times and, particularly, healthier

working conditions. Should you have

any questions pertaining to suction tech-

nology issues, please feel free to contact

us at any time. Our experts will be gladly

at your disposal.

Your ESTA Absaugtechnik Team

The World of Extraction

www.esta.com

Welcome to the sphere of suction

technology

Operating manual

Wet separator

NA-K

Item No. 45.183 (NA-K 1800)

Item No. 45.363 (NA-K 3600)

Item No. 45.603 (NA-K 6000)

Do not use this device unless you have

read the user manual and understand it.

Translation of the original instructions

45603-08-01

2 NA-K 45603-52-01

Edition notice

Original operating manual

Document No.: 45603-08-01

Publishing date: 12.03.2013

Type of device: Wet separator NA-K

Article-No.: 45.183 // 45.363 // 45.603

Publisher

ESTA Apparatebau GmbH & Co. KG Tel.: +49 (0) 73 07 80 4 -0

Gotenstraße 2-6 Fax: +49 (0) 73 07 80 4 -500

Germany Web: www.esta.com

Copyright notice (per DIN ISO 16016:2007-12)

Transfer or reproduction of this document, or the use or communication of its content, is

forbidden without explicit consent. Violators will be liable for damages. All rights to patent, utility

or design registration are reserved.

Warnings and safety instructions

Reference to legal regulations

Note

45603-52-01 NA-K 3

Table of contents

Table of contents 3

1. General safety notes 4

2. Preventing mechanical hazards 4

3. Preventing electrical hazards 4

4. Intended use 5

5. Technical data and description 6

5.1 Technical data (all models) 6

5.2 Functional description 7

6. Delivery and assembly 8

6.1 Connecting processing machines 9

7. Start-up 10

8. Repair and maintenance 12

8.1 Routine tasks 12

8.2 Environmental conditions 13

8.3 Troubleshooting 13

9. Cleaning 14

9.1 Cleaning the wet separator 14

9.2 Cleaning the droplet separator 14

10. Disposal 15

10.1 Disposing of and replacing the contaminated water 15

10.2 Dismantling or disposing of the device 15

11. Device diagram from declaration of conformity 16

12. Declaration of conformity 17

Notes 18

Notes 19

Notes 20

4 NA-K 45603-52-01

1. General safety notes

The device must be used only by persons who have been instructed in its

handling and are explicitly authorized to use it. No aggressive gases may be

exhausted. Make sure that the power cable does not become damaged by being

run over, compressed, pulled, etc. The power cable must be examined regularly

for signs of damage or ageing. When replacing electrical parts and cables, only

original ESTA replacement parts must be used. Work on electrical parts,

including replacement of electrical cables, must be performed only by electrical

experts or people trained for the purpose. When operating a device, use only

original ESTA accessories. Connecting extension cords, coupling devices, etc.,

is not permitted.

Exhausting or dust removal from machines and/or workplaces that

produce aluminium or magnesium dust is not permitted.

According to work equipment user directive 2009/104/EEC, safety devices

for prevention or removal of hazards must be regularly maintained and

inspected by an expert for safe, flawless operation.

2. Preventing mechanical hazards

All movable machine parts driven by electric motors must be covered by securely

fastened protective covers that can be removed only with tools.

If a covering that can only be unfastened with tools is removed, there is risk

of injury if the machine is running.

3. Preventing electrical hazards

All electrical parts must be covered by fixed, securely fastened protective covers

that can be removed only with tools. The device complies with Protection Class I

according to EN 60 204.

Residual risk:

If a covering that can only be unfastened with a tool is removed, a hazard is

posed by electric current.

The power cable (H07RN – F5G2.5... metres long with CEE 32 A plug) must be

replaced only by an authorized electrical specialist.

The power separator (plug) must be activated only when it is shut off.

45603-52-01 NA-K 5

4. Intended use

NA-K series devices are suitable for exhausting dust-producing machines that

give off moist dust or flying sparks. Avoid vacuuming up ignition sources.

In this regard, follow the general safety notes in point 1.

Exhausting or dust removal from machines and/or workplaces that produce

aluminium or magnesium dust and/or combustible or explosive dusts or

combustible gases is not permitted.

Connecting extension cords, coupling devices, etc., is not permitted.

6 NA-K 45603-52-01

5. Technical data and description

5.1 Technical data (all models)

NA-K 1800 NA-K 3600 NA-K 6000

Mode of operation:S1 (continuous

operation)

S1 (continuous

operation)

S1 (continuous

operation)

Type of current: 3N ~ 3N ~ 3N ~

Drive power: kW 3.0 5.5 7.5

Supply voltage: V 400 400 400

Power frequency: Hz 50 50 50

Current consumption: A 6.3 11 14.7

Dimensions: mm

800 x

800 x

2.94

950 x

950 x

3.460

950 x

950 x

3.460

Empty weight approx.: kg 420 500 500

Water capacity approx.: l 290 390 390

Max. volume flow: m³/h 2,100 3,200 5,150

Max. vacuum: Pa 4,200 3,500 3,500

Environmental conditions: °C 5 ≤≤45 °C

Measuring surfaces - sound

pressure level: db (A) 75 79 81

Production year: See model plate

45603-52-01 NA-K 7

5.2 Functional description

This device produces the volume flow and vacuum necessary for suction using a

radial fan that is on top of the housing or next to it.

The dusty air exhausted from the processing machine is guided through a pipeline

or a suitable hose connection to the device’s intake port. The wet separator’s

intake port goes directly into a specially shaped swirl chamber.

The lower portion of the swirl chamber is in water. The exhausted air flows at a

high speed through this chamber and swirls intensely with the water. In this way,

the dust carried in the air is moistened with water and thickens in the water to

become sludge.

A capacitative sensor automatically controls the state of the water and makes sure

that there is always enough water in the device.

There is a droplet separator between the fan and the swirl chamber. The droplet

separator separates the agitated droplets that are still in the air. The water-bound

dust sinks as sludge into the flange-mounted pail.

For easier disposal and maintenance, there are two drain spigots on the sludge

pail.

8 NA-K 45603-52-01

6. Delivery and assembly

The NA-K wet separator is delivered lying on a pallet. After the protective covering

is removed, it can be set up using a crane. The upper part of the NA-K has two

loops for this purpose.

Never use the fan to lift the NA-K!

The wet separator must be set up in such a way that in the front and on the right

side (control module) the device has at least 2 m of free space. The distance from

the ceiling must be at least 50 cm. Further details are in point 8.2 (environmental

conditions) of this operating manual.

After connecting the energy supply, secure the water supply.

Before setting up the cable connection between the device and the power

grid, you must check to make sure the operating voltage shown on the

manufacturer’s plate is the same as that of the grid.

The dust extractor must be set up in such a way that the system’s intake

and discharge openings are secure against foreign objects falling in or

being sucked in. The device must be placed on a level surface with a load

capacity of at least 1,000 kg. To improve stability, bolt the device to the

floor.

Dust extractors and collection containers must never be set in direct

sunlight.

There should be an open distance of 2 metres around the device to provide

enough room for maintenance.

The maintenance doors must be freely accessible. The dust extractor must

be set up to allow easy inspection and cleaning (such as removing dust

build-up on the fan wheel).

When operating the device, the legal requirements of the clean air act and

the immission control act.

Disposal of packaging: The wet separator is delivered on a EURO wooden pallet

and is protected from dirt by a PE film.

Both materials must be disposed of or recycled according to local regulations.

45603-52-01 NA-K 9

6.1 Connecting processing machines

To correctly exhaust a dust-producing machine, the pipe or hose connection and

the electrical connection must be created between the processing machine to be

exhausted and the NA-K.

The diameters of the hoses and pipes must be chosen so as to ensure a

minimum interior air speed of 20 m/s.

If several processing machines are connected to the NA-K, the total volume flow

is divided among the individual devices. Find out the volume flow necessary for

exhaust from the machine’s manufacturer.

The data shown in the chart can be taken as reference values:

Pipe or hose diameter Airflow volume at

20 m/s

50 mm 141 m³/h

70 mm 277 m³/h

80 mm 362 m³/h

100 mm 566 m³/h

125 mm 884 m³/h

140 mm 1,108 m³/h

160 mm 1,448 m³/h

180 mm 1,832 m³/h

200 mm 2,262 m³/h

225 mm 2,863 m³/h

250 mm 3,534 m³/h

280 mm 4,434 m³/h

300 mm 5,090 m³/h

10 NA-K 45603-52-01

7. Start-up

Check the fan’s direction of rotation as it operates.

Before starting a device with three-phase drive, please make sure that the drive

motor’s direction of rotation is correct.

Proceed as described below:

1. The device must be ready to operate (enough water, main switch at the “I”

position).

2. Turn on the fan.

3. Wait 5 seconds.

4. Turn off the fan.

5. Check to see that the motor fan wheel is moving in the direction of the

arrow.

When the direction of rotation is wrong, the device gets impermissibly hot,

and performance suffers.

For devices that are delivered ready to connect with CEE plugs, the rotating field

can be changed using the rotating pole pins in the phase inverter. Use an

appropriate screwdriver to press lightly while turning the pole pins and change

their sequence.

For devices that are connected to the electrical grid without plug

connections, the phase swap must be performed by a trained electrical

specialist.

Before start-up, all of the dust extractor’s maintenance openings must be

closed. Sudden closing of the suction port during operation must always be

avoided.

To start up the NA-K, the red-yellow main switch on must first be turned to position

“I”. For devices with a control cabinet: The red and green button for turning the fan

wheel on and off is on the front of the switch box. The green signal light goes on

when the fan motor is running.

If the level control’s signal light goes on, the device’s water level is too low

and no suction can occur.

45603-52-01 NA-K 11

The water level control is active as soon as the main switch is activated. Because

the water pressure at the NA-K’s inlet valve can vary from place to place, the time

necessary for water filling also varies. Therefore the device’s controls must be

adapted to the water supply network at the place where it is set up. For this

purpose, the time between the response of the capacitative sensor and the

attainment of target water level is stopped. The target water level is about 2 cm

above the minimum mark. The sensor’s response can be seen on the level control

(the red light goes out). The stop time is set at the K2T time relay.

The operator of the NA-K must see to it that, if the device is defective, the

escaping water causes no damage to persons, machines, fixtures, buildings

or the environment!

One possible way of preventing damage from escaping water is setting the

device up in a water-tight catch basin with an automatic simultaneous alarm

sent to an appropriate person (maintenance person, gatekeeper, etc.).

12 NA-K 45603-52-01

8. Repair and maintenance

8.1 Routine tasks

Check daily:

Is there damage to the device or its parts?

Is there mechanical damage to the power cable?

Is the fill level sensor’s measurement impaired by dirt on the

inspection window?

Check monthly:

Is the seal between the sludge pail and the device housing

perfect?

Does the water fill level control work properly? Drain the

water while the fan is running. If the water goes below the

minimum mark on the inspection glass, open the water

intake valve.

Is the swirl chamber or gas deflector damaged (by

corrosion) or is its diameter changed by build-up?

Is the droplet separator contaminated?

Is there corrosion anywhere inside the device?

If heavily soiled, the device interior must be cleaned.

A log is to be kept of the monthly inspection. It must document the date of

inspection, deficiencies determined and the name of the inspector.

When necessary, of course, the device must be repaired.

45603-52-01 NA-K 13

8.2 Environmental conditions

Ambient temperature:

5 ≤≤45 °C

Air humidity:

Max. 80%

Before a long downtime, make sure that the wet separator is cleaned.

8.3 Troubleshooting

In an emergency (fire, etc.), the device must be turned off at the emergency shut-

off switch.

During repairs to the device, make absolutely sure that the red-yellow main

switch is turned to the “0” position and is secured with a padlock against

unintentional reactivation.

The following chart describes possible malfunctions that may arise during

operation of NA-K models, their cause and possible solutions.

Problem Cause Solution

The level control’s main

signal light stays on.

The water is too low.

See if the water intake is

correct, and if necessary

turn the spigot further.

14 NA-K 45603-52-01

9. Cleaning

9.1 Cleaning the wet separator

The device must be cleaned at regular intervals — at least once a month.

Water is the recommended cleaning agent.

For correct operation of the device, clean surroundings are necessary. Therefore

make sure that dust build-up is removed from the surface of the dust extractor.

9.2 Cleaning the droplet separator

The NA-K is equipped with a droplet separator. Its purpose is to separate the

droplets still remaining in the cleaned air, before they leave the device. After

extended use, dirt settles in the droplet separator’s channels. This causes higher

internal air resistance in the device, reducing suction performance.

If this occurs, the droplet separator must be thoroughly cleaned.

The droplet separator must be cleaned or maintained as follows:

1. Open the upper doors on the wet separator by turning the star grip clockwise.

2. Pull the droplet separator out using the front grips.

3. Now the droplet separator can be properly cleaned (with a steam jet).

4. Slide the cleaned droplet separator back into the device.

5. Close the doors and lock them by turning the star grip. The NA-K is ready to

work.

45603-52-01 NA-K 15

10.Disposal

10.1 Disposing of and replacing the contaminated water

With time, the water in the NA-K gets used up and must be completely changed.

For this, two drain spigots are mounted on the device. Drain the lightly

contaminated water in the upper part of the NA-K through the upper spigot, and

the rest of the water with the lower spigot mounted on the sludge pail. For better

cleaning, use the four quick-tension locks to disconnect the sludge pail from the

device. It is best to clean the device thoroughly before filling it with fresh water.

This increases the useful life of the water. Before refilling with water, the sludge

pail must be reconnected to the device, and the drain spigots must be closed.

Dispose of the contaminated water and the sludge build-up in an

environmentally sound manner, according to local regulations.

With some dusts, the water tends to foam.

In that case, an anti-foaming agent (such as soda) should be added to the

water.

10.2 Dismantling or disposing of the device

Instructions on dismantling, packaging and loading

Before any necessary dismantling, the electricity and water must be disconnected

and the water and sludge should be drained. Do this as in the cleaning procedures

described in 8.4 and 8.5.

To transport the device, use the loops at the top of the NA-K to set it on a pallet,

and cover it with film against dirt.

Never use the fan to lift the NA-K!

Disposing of or returning the device

After removal of the water and sludge, and after all connections have been

removed, the device can undergo the standard disposal process. Explicitly comply

with regulations.

The device cannot be returned to ESTA.

16 NA-K 45603-52-01

11.Device diagram from declaration of conformity

1. Motor

2. Exhaust release

3. Fan

4. Gas deflector

5. Droplet separator

6. Raw gas intake port

7. Swirl chamber

8. Water

9. Device cone

10.Sludge pail

11.Drain spigots

45603-52-01 NA-K 17

12.Declaration of conformity

EC Conformity declaration for machines

Name of manufacturer: ESTA APPARATEBAU GmbH & Co. KG

Address of manufacturer: Gotenstraße 2 – 6,

89250 Senden

Person in charge of Ramona Pflum

documentation: Gotenstr. 2 - 6

89250 Senden

We hereby declare that the design of the machine

Machine: Dust extractor for exhausting dust

Series: NA-K

Model: NA-K 1800, NA-K 3600, NA-K 6000

conforms to the applicable directives:

2006/42/EG - EG Machine directive,

2004/108/EC Directive on Electromagnetic Compatibility

Reconciled norms used:

EN 12100 Safety of machinery - basic concepts,

general propositions (part 1 and part 2)

EN 13857 Safety of machinery, devices and systems;

safety distances for avoiding

hazard zones

EN 349 Safety of machinery; minimum distances for preventing

body parts from being crushed

EN 60 204-1 Machine safety - Electrical

machinery equipment,

EN 61 000-6-3 Electromagnetic compatibility

Emitted interference in domestic applications.

Senden, 03.05.2012 Dr. Peter Kulitz

CEO

18 NA-K 45603-52-01

Notes

ESTA Apparatebau GmbH & Co. KG

Gotenstraße 2 - 6

89250 Senden / Ay

Tel.: +49 (0) 7307 804 - 0

Fax: +49 (0) 7307 804 - 500

www.esta.com

Table of contents

Other Esta Vacuum Cleaner manuals

Esta

Esta MOBEX P-24 User manual

Esta

Esta EUROSOG-W/N User manual

Esta

Esta DDE 1500 User manual

Esta

Esta NA-K B/VA User manual

Esta

Esta EUROSOG - ATEX User manual

Esta

Esta DUSTOMAT-160 S User manual

Esta

Esta DUSTOMAT 4 ATEX User manual

Esta

Esta DUSTOMAT-21 User manual

Esta

Esta DUSTOVAC 5.5 FM User manual

Esta

Esta WHISPERSOG User manual