Contents

Contents .....................................................................................................................................3

1. General notes on safety ......................................................................................................4

2. Preventing mechanical hazards .........................................................................................6

3. Preventing electrical hazards .............................................................................................6

4. Preventing dust hazards .....................................................................................................6

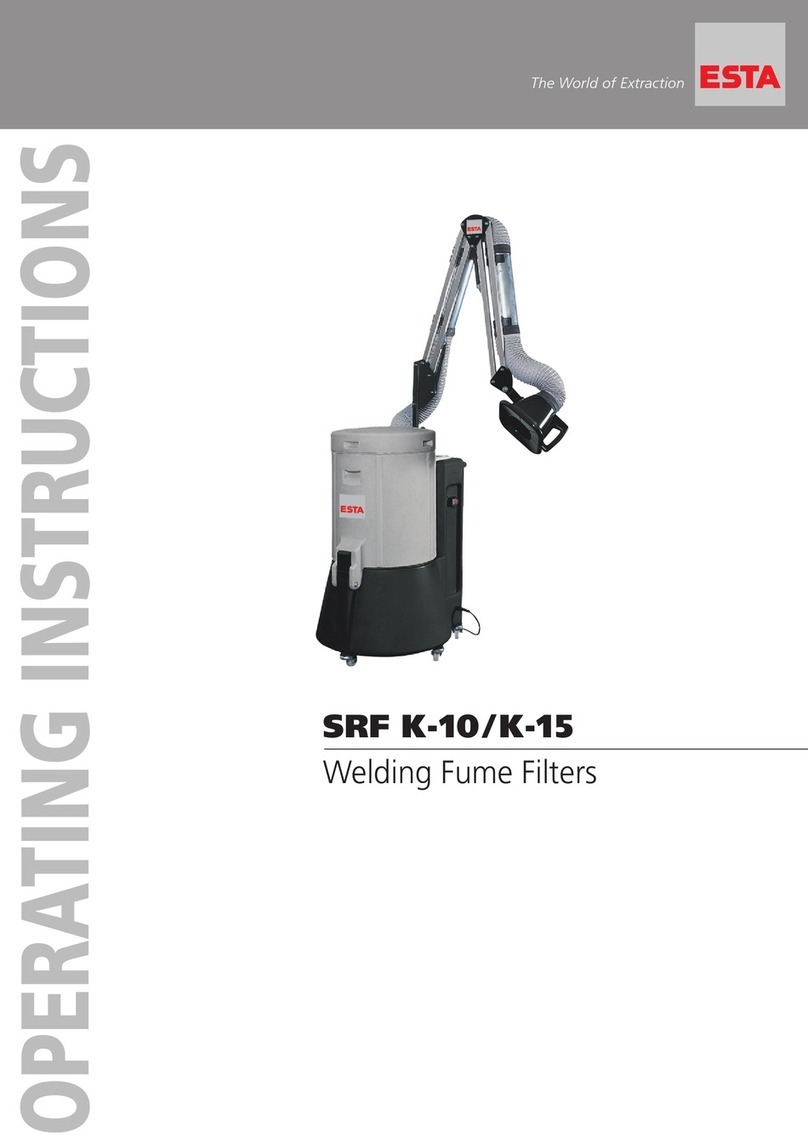

5. Intended use ........................................................................................................................7

6. Technical data and description ..........................................................................................8

6.1 Welding fume filter..............................................................................................................8

Technical changes reserved.....................................................................................................8

6.2 Function description ...........................................................................................................8

7. Delivery, assembly and commissioning............................................................................9

7.1 Delivery and transport ........................................................................................................9

7.2 Assembly............................................................................................................................9

7.3 Commissioning...................................................................................................................9

8. Maintenance and troubleshooting ...................................................................................10

8.1 Maintenance instructions.................................................................................................. 10

8.2 Inspection and maintenance intervals...........................................................................11

8.3 Troubleshooting................................................................................................................12

9. Monitoring the minimum air volume flow........................................................................ 13

10. Cleaning ............................................................................................................................. 13

10.1 Rotary cleaning system ..................................................................................................14

10.2 Changing the filter ..........................................................................................................14

...............................................................................................................................15

11. Disposal..............................................................................................................................15

11.1 Disposal of the collected dust.........................................................................................15

11.2 Disposal of the device ...................................................................................................15

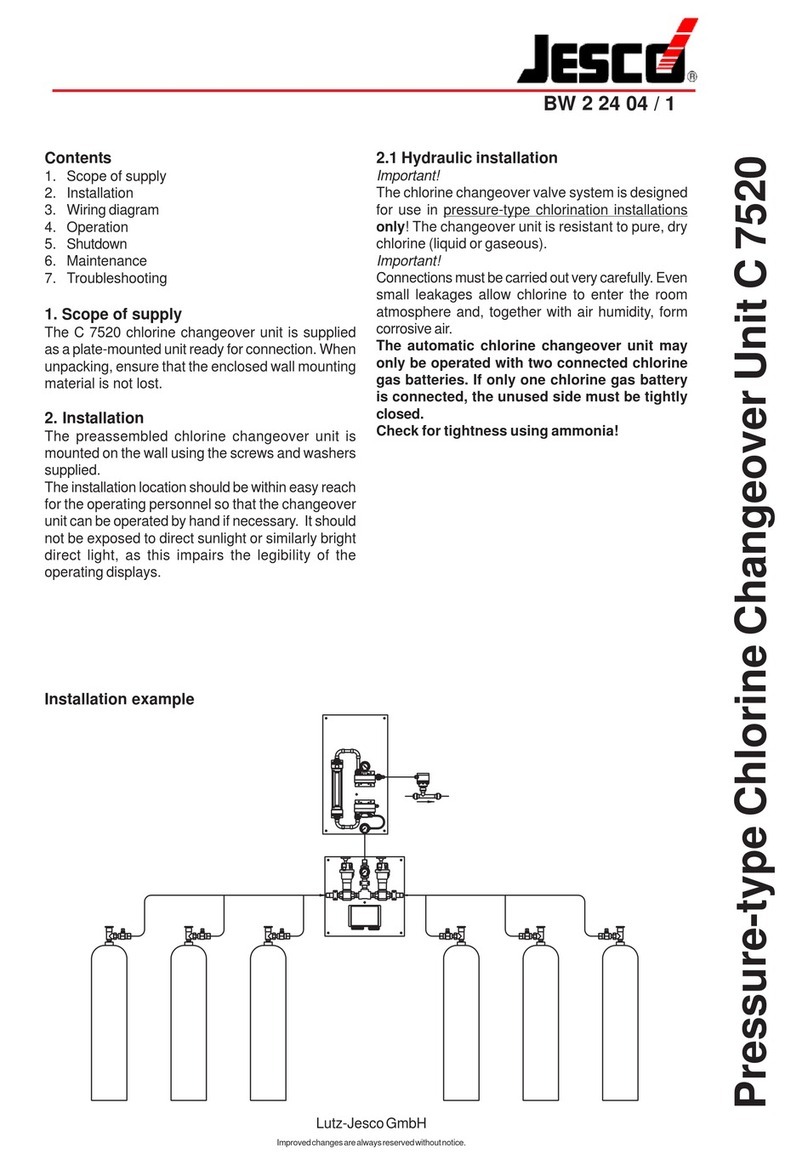

12. Device image...................................................................................................................... 16

13. Declaration of Conformity.................................................................................................17

Notes.........................................................................................................................................18

Notes.........................................................................................................................................19

Notes.........................................................................................................................................20