4.1 Intended use

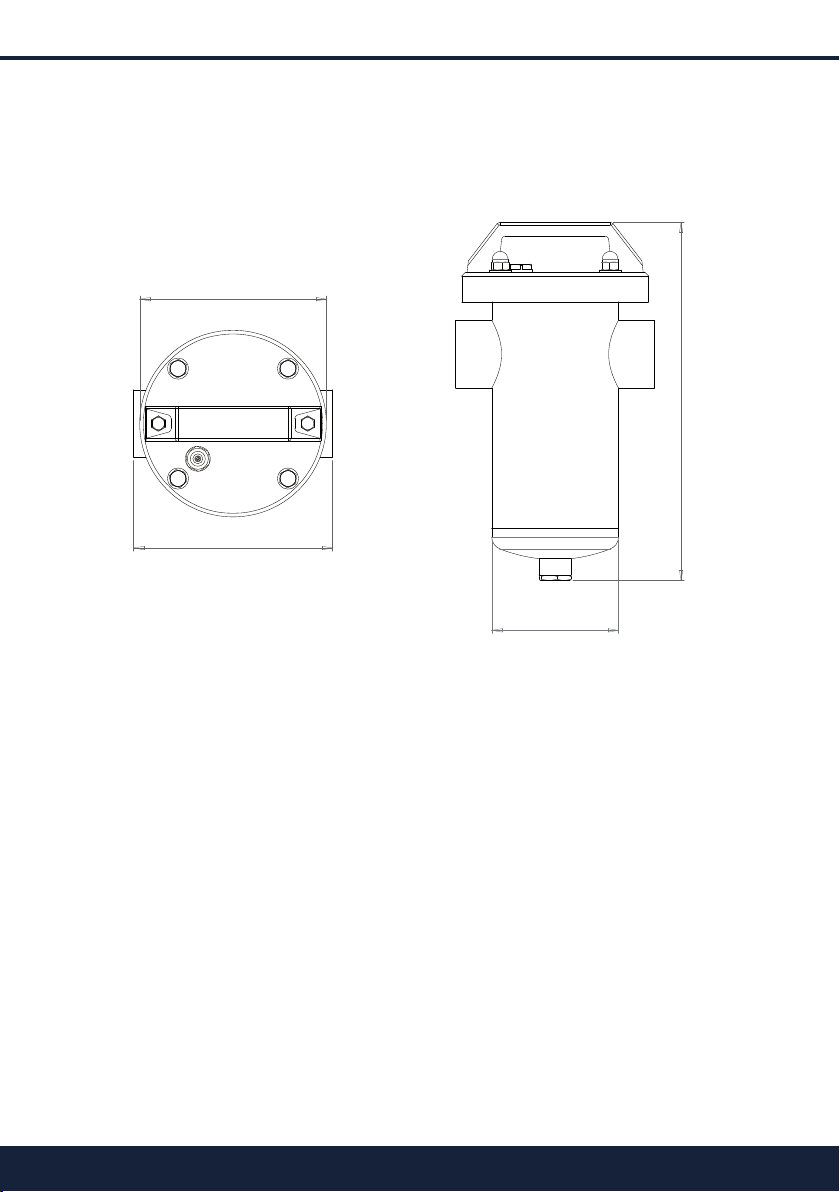

The BoilermagXL filter is designed for installation into systems working at up to 12 bar (10

bar if using automatic air vent). All connections are to be installed accurately and sealed to

prevent the loss of pressure/product. The lid seal is to be maintained in a good condition.

To ensure that the supplied magnets maintain their high level of performance, attention must

be paid to the following conditions:

1. NO temperatures above the specific operating temperature

2. NO oscillating vibrations

3. NO impacts

4. NO strong external flux fields

5. Pay attention to the cleaning and maintenance of the system

4.2 General preventative measures

The rod is constructed with strong magnets. The handling of ferrous tools (e.g. with

maintenance or cleaning) etc. can cause risk of injury for the personnel due to the magnetic

attraction. Special measures regarding the presence of ferrous items have to be considered

when handling magnetic material.

4.3 Dangers during neglect of the safety notes

Using this equipment in a manner not intended can present safety hazards.

4.4 Safety notes for operation and maintenance

Maintenance work is to be executed only by qualified personnel.

With work on pneumatic, hydraulic, pressurised or electrical services the supply lines are to

be isolated prior to any cleaning or maintenance actions.

Prior to any maintenance work being carried out, the process, equipment used and personnel

must be risk assessed and deemed suitable to conduct that task. All work is to be carried out

in accordance with local and legislative regulations.

WARNING! This system incorporates strong permanent magnetic materials. Please pay

attention to the safety notes in order to avoid personal injury or material-damage:

• Operators fitted with heart pace-maker’s shall not come within 1m of the equipment.

• Oppositional poles of magnets attract each other with high clamping forces.

• Do not use steel/iron tools or other ferrous parts in the flux field of the system.

• Data carriers, credit cards, computer drives etc can be erased by the influence of the magnetic

field. Keep electronic and sensitive mechanical units (i. e. watches) away from the magnet.

• Please contact our service department before welding or drilling works on the unit.

4 Safety

www.boilermag.com