Estate Swing E-S 1600 Series User manual

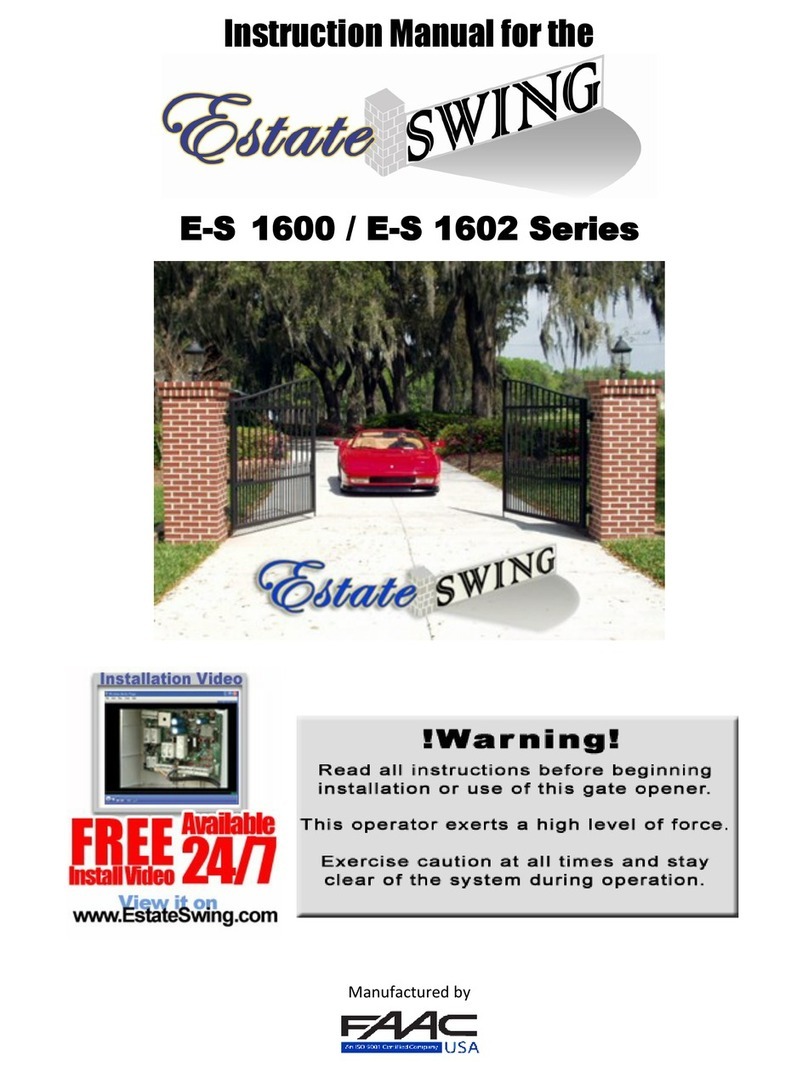

Instruction Manual for the

E-S 1600/ E-S 1602 / E-S 1600L /

E-S 1602L Series

CE DECLARATION OF CONFORMITY OF MACHINES

(Directive 89/392/EEC, Annex II, Part B)

Manufacturer: FAAC S.p.A.

Address: Via Benini, 1 – 40069 Zola Predosa Bologna – Italy

Declares that: 409 A.K.A. Estate Swing (USA) mod operator

Is built to be integrated into a machine or to be assembled with other machinery to create a machine under the provisions

of Directive 89/392/EEC, and subsequent amendments 91/368/EEC, 93/44/EEC.

Conforms to the essential safety requirements of the following EEC directives:

o73/23/EEC and subsequent amendment 93/68/EEC, 89/336/EEC and subsequent amendment 92/31/EEC and

93/68/EEC.

oAnd also declares the it is prohibited to put into service the machinery until the machine in which it will be

integrated or of which it will become a component has been identified and declared as conforming to the

conditions of Directive 89/392/EEC and subsequent amendments assimilated under national laws under DPR

#459 of July 24, 1996.

Bologna, January 1, 2002

Managing Director

A. Bassi

Warnings for the installer

General safety obligations

Abassi

1. Attention! To ensure the safety of people, it is important that you read all the following instructions. Incorrect installation or incorrect

use of the product could cause serious harm to people.

2. Carefully read the instructions before beginning to install the product.

3. Store these instructions for future reference.

4. This product was designed and built strictly for the use indicated in the documentation. Any other use, not expressly indicated here,

could compromise the good condition/operation of the product and/or be a source of danger.

5. FAAC declines all liability caused by improper use or use other than that for which automated system was intended.

6. Do not install the equipment in an explosive atmosphere; the presence of inflammable gas or fumes is a serious danger to safety.

7. The mechanical parts must conform to the provisions of Standards EN 12604 and EN 12605.

For non-EU countries, to obtain an adequate level of safety, the standards mentioned above must be observed, in addition to national

legal regulations.

8. FAAC is not responsible for failure to observe Good Technique in the construction of the closing elements to be motorized, of for any

deformation that may occur during use.

9. The installation must conform to Standards EN 12453 and EN 12445.

The safety level of the automated system must be C+D.

10. Before attempting any job on the system, cut out electrical power and disconnect the batteries.

11. The main power supply of the automated system must be fitted with an all-pole switch with contact opening distance of 3 mm or great-

er. Use of a 6A thermal breaker will all-pole circuit break is recommended.

12. Make sure that a differential switch with threshold of 0.03 A is fitted upstream of the system.

13. Make sure that the earthing system is perfectly constructed, and connect metal parts of the means of the closure to it.

14. The automated system is supplied with an intrinsic anti-crushing safety device consisting of a torque control. Nevertheless, its tripping

threshold must be checked as specified in the Standards indicated at point 10.

15. The safety devices (EN 12978 standard) protect any danger areas against mechanical movement risks, such as crushing, dragging, and

shearing.

16. Use of at least one indicator-light (e.g. FAACLIGHT 12VDC) is recommended for every system, as well as a warning sign adequately

secured to the frame structure, in addition to the devices mentioned at point “15”.

17. FAAC declines all liability as concerns safety and efficient operation of the automated system, is system components not produced by

FAAC are used.

18. For maintenance, strictly use original parts by FAAC.

19. Do not in any way modify the components of the automated system.

20. The installer shall supply all information concerning manual operation of the system in case of an emergency, and shall hand over to

the user the warnings handbook supplied with the product.

21. Do not allow children or adults to stay near the product while it is operating.

22. Keep remote controls or other pulse generators away from children, to prevent the automated system from being activated involuntari-

ly.

23. Transit through the leaves is allowed only when the gate is fully open.

24. The user must not attempt any kind of repair or direct action whatever and contact qualified personnel only.

25. Do not short-circuit the poles of the batteries and do not try to recharge the batteries with power supply units other than Primary or

Secondary cards.

26. Do not throw exhausted batteries into containers for other waste but dispose them in the appropriate containers to enable them to be

recycled.

27. Anything not expressly specified in these instructions is not permitted.

Estate Swing Summary of Functions

The Estate Swing is only to be used for vehicular swing gates in a Class I

setting.

Class I: A vehicular gate opener (or system) intended for use in a home of

one-to-four single family dwelling, or a garage or parking area associated

therewith.

The FAAC Estate Swing automated system was designed and built for controlling

vehicle access. Do not use for any other purpose.

The external automation with an electro-mechanical non-reversing linear arm

automates residential swing-leaf gates with leaves of up to 16’ in length. It

consists of an irreversible electro-mechanical operator with built in opening and

closing limits and utilizes a worm screw system. The irreversible system ensures

the gate is mechanical locked when the motor is not operating. A lock still needs to

be installed if security or high winds are a concern. A manual release makes it

possible to move the gate in the event of a power-cut or fault.

Keep this manual safely stored after

installation.

Serial Number__________________________

Date of Purchase_______________________

Place of Purchase______________________

Have this information on hand while handling all

service and warranty issues.

This manual and its contents are produced by Web Direct Brands, Inc.

Table of Contents

The table of contents are listed to assist you locating a desired section. We do howev-

er strongly suggest studying every page of the instruction manual before attempting

installation.

SECTION:

Review of specifications, warnings, and tools 1

Specifications of the Estate Swing and Components 1.1

Parts List 1.2

System Overview & Preliminary Checks 1.3

Tools Needed for Installation 1.4

Installation 2

Manual Operation, Restoring Automation 2.1

READ FIRST: Determining Push or Pull to Open 2.2

IMPORTANT: Determining Setback—Pull to Open 2.3

Installation of Operator—Pull to Open 2.4-.7

IMPORTANT: Determining Setback—Push to Open 2.8

Installation of Operator—Push to Open 2.9-.12

Easy Wiring Under Driveway 2.13

For Your Convenience 2.14

Wiring, Jumpers and Receiver 3

Wiring Operator Arm(s) - Pull to Open 3.1-.3

Wiring Operator Arm(s) - Push to Open 3.4-.5

Temporary Safety Jumpers and Dip Switch Settings 3.6

Power 3.7

Limit Switches 4

Fine Tune Limit Switch - Pull to Open 4.1-.2

Fine Tuning Limit Switch - Push to Open 4.3

Table of Contents

Marks pages with opener or usage warnings. Although we have marked these as very

important warnings, please read the entire manual. Every step is important to the

correct installation of your gate opener.

The table of contents are listed to assist you locating a desired section. We do howev-

er strongly suggest studying every page of the instruction manual before attempting

installation.

SECTION:

Diagnostics 5

First Run & Parameters 5.1-.2

Plug-in Receiver 5.3-.4

Maintenance and Trouble Shooting

Bracket Maintenance 6.1

Troubleshooting 6.2-.5

Accessories 7

Control Board Overview 7.1-.4

Accessories 7.5-.6

MODEL Estate Swing

Power Supply

Rated Absorbed Power (W)

Current (A)

Travel (in.)

Cycles per hour

Operating Ambient Temp

Protection class

Gate leaf max length (ft.)

Gate leaf max weight (lbs.)

Operator overall dimensions LxHxD(in.)

Operator Weight

115V AC/ 24V AC

70

3

11

Continuous Duty / Aprox. 75

-4 to 131 F

IP44

Up to 14 (L-series: up to 20)

Up to 800 (L-series: up to 1000)

See below

18 lbs (L-series: 19 lbs)

Specifications

1.1

E-S 1600L arm

E-S 1600 arm

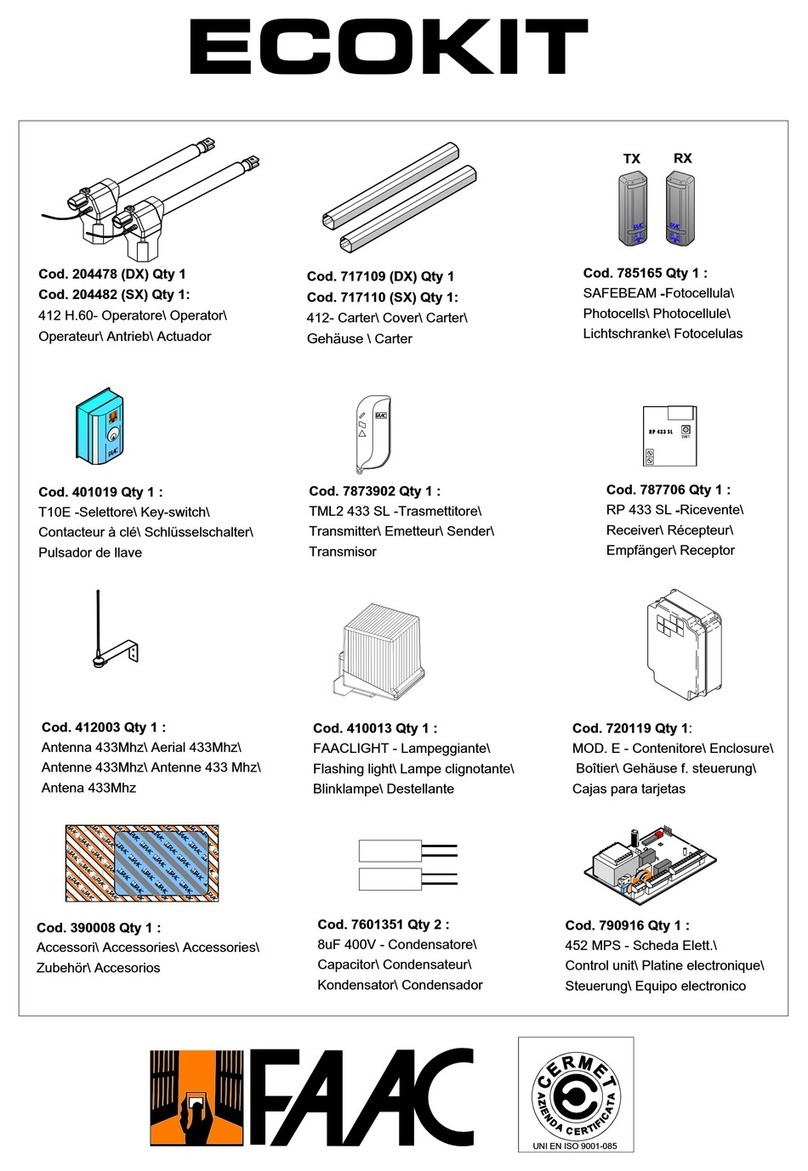

1.2

Estate Swing Parts List

B. Operator Arm with 33' (45')

of 5 Conductor Wire

G. Gate Mounting Bracket

H. Post Mounting Brackets

I. Mounting Hardware

1 - 3/8”x1 1/2” Hex bolts, washer,

nut 1 - 5/16”x1 1/2” Hex bolt,

washer, nut 2 - 3/8”x2” Carriage bolt,

washers, nut 1 - 1/4”x2” Hex bolt,

washers, nut

Secondary Operator (If Applicable)

A. Control Box

B. Operator Arm with 6' of 5 Conductor Wire and

Key

C. Control Board

D. Transmitter

E. Receiver

F. Transformer

G. Gate Mounting Bracket

H. Post Mounting Brackets

I. Mounting Hardware

1 - 3/8”x1 1/2” Hex bolts, washer, nut

1 - 5/16”x1 1/2” Hex bolt, washer, nut

2 - 3/8”x2” Carriage bolt, washers, nut

1 - 1/4”x2” Hex bolt, washers, nut

Primary or Single Operator

Standard System

Overview and Safety Zones

The system display to the below is a

recom-mended standard system. Other

approved accessories can be installed.

Photo sensors and a flashing light

indicating gate move-ment is

recommended for safety purposes.

IMPORTANT

Preliminary Checks:

To ensure safety and an efficiently operating automated system, make sure the

following condi-tions are observed.

The gate and post must be suitable for being automated. Check that the structure is

sufficiently strong and rigid, and its dimensions and weights conform to those

indicated on page 1.

Make sure the leaves move smoothly without any irregular friction during entire travel.

Make sure the hinges are in good condition. Ball bearing hinges are ideal for gates

weighing over 200 lbs. or over 10’ in length.

Make sure the gate is plumb and level.

The fence post must be secured in the ground with concrete. This will

prevent alteration of alignments and leveling during installation and

during cycles.

1.3

1,2 Estate Swing Operator

3 Photocells (not included)

4 Control board

5 N/A

6 Push button opening device (not included)

7 Receiver extension (not included)

8 12Vdc flashing lamp (not included)

9 Positive stop

10 DC transformer

Notes:

1) When laying electrical cables, use appropriate rigid and/or

flexible tube.

2) Do not run any wires in the same conduit as 110 AC

power that may be in the area. This will cause unwanted

interference.

Tools Needed

Power Drill

Crescent Wrench

Flat Head Screwdriver

Hacksaw

Phillips Head

Screwdriver

C-Ring Pliers

Tape Measure

Level

Wire Strippers

C-clamps

3/8”, 1/4”, 5/16” Drill Bits

Other items that may be needed prior to commencing installation. Bolded items are

necessary to all applications.

Start and stop post, bracket or door stop. Although the FAAC Estate swing 1600

features built in limit switches some may choose to use positive stops:

16, 14 or 12 gauge, 2 conductor stranded direct burial low voltage wire will be

required to run power to your operator. Length is deter mined by distance

between transfor mer power supply and the control box.

4 - 3/8” Bolts will be needed to connect the 2 “L” shaped brackets to the

post. Length will be determined by the size of your posts.

A metal support bracket may be needed to achieve the appropriate desired setback.

The metal support bracket will be bolted or welded to your post to give a larger

amount of space to mount the provided mounting bracket.

A voltage meter and digital camera will be necessary to run diagnostic checks.

If your transformer is going to be plugged into an outdoor outlet you will need to

weatherproof that outlet and transformer. Electrical boxes or plug covers can be

obtained from a local hardware store to accommodate both the plug and transformer.

Hardware to attach the control box to a post or fence.

Connectors for running wires into the control box.

Protect all ingoing and outgoing wires with a surge suppressor. Consult your local

dealer for more information.

1.4

Manual Operation Mode

1)

2) Remove rubber cover

3) Insert key and turn it 90 degrees.

4) Flip release lever up.

To exit manual mode, reverse the above steps.

2.1

The following section is instructions on

mounting your gate opener. Your gate can

be mounted one of two ways:

Pull-To-Open: With the gate opener on the inside of the

property, the gate will swing in towards the property. The

gate opener will be extended in the gate’s closed

position and as the opener retracts it PULLS the gate

open.

Instructions are pages 2.3 - 2.7

Push-To-Open: With the gate opener on the inside of the

property, the gate will swing out away from the property

towards the street. The gate opener will be

retracted in the gate’s closed position and as the opener

extends it PUSHES the gate open.

Instructions are pages 2.8 - 2.12

After deciding which method you will use

to automate your gate, make an X across

the pages of the installation method you

will

not

be using.

This will prevent mistakenly using the wrong instructions

for your installation as the two sections look very similar.

2.2

IMPORTANT: Determining Correct Setback

2.3

PULL TO OPEN - Standard operation. This means the gate operator is

mounted on the inside of the property and pulls your gate in towards the property.

To determine the position of the gate

mounting bracket (above is for the post

mounting bracket) re-fer to step 9 in the

section “Installation of operator”

A B a

6” 6” 90o

5.5” 5.5” 100o

There are 4 factors to keep in mind when finding the setback mounting:

1) The (A) measurement is perpendicular from the gate in the CLOSED position.

2) There must be clearance for your gate opener to attach to the gate in the closed position.

This is most commonly an issue on columns. Re-positioning of the hinges or Push-To-Open

operation may be required to achieve clearance.

3) The brackets do not and must not move after installation.

4) The "L" shape brackets can be mounted anywhere on the post or column. They can be

mounted on a separate post or fence as well. The only factor of importance is that when

mounting of the brackets is done the hole in the boomerang bracket that the gate opener mounts

on matches the setback on this page.

It is best to C-Clamp brackets on and test arm movement clearance before permanently attaching

them.

Installation of Operator—Pull-to-Open

2.4

2. Cut off the excess

length (if any) of the

angled brack-et using a

hacksaw.

3. Position the angled

brack-et between the two

“L” shaped brackets in the

same position as when

the setback was found.

Clamp the 3 brackets

together. Drill through the

angled bracket using the

pre-drilled holes in the “L”

shaped brackets us-ing a

3/8” drill bit. Drill through

all three brackets using a

5/16” drill bit in a position

behind the first hole.

4. Insert a 3/8” x 1” bolt

in the center hole and a

5/16” bolt in the rear

hole. Secure them using

the provided nuts and

lock washers.

1. Find the proper set back for your operator (from

previous page). Do this by holding the bottom “L”

shaped bracket against the post. Marking its horizontal

positioning on the post using a vertical line up from the

middle of the bracket. Also mark your angled bracket

for positioning on the “L” shaped bracket. The hole on

the end of the angled bracket should be in the setback

position.

HINT: Trace the bracket on cardboard and use the

cardboard to make a template.

Before permanently attaching any brackets, be sure to test

arm motion and clearance.

For full capacity, the amount of stainless steel showing retracted shovel be

between 2 1/4 - 3 inches and 15 1/4 - 16 1/2 inches when extended (L-series: 20

- 21 1/4 inches when extracted).

5. Temporarily position the gate side

mounting bracket. (horizontal position

does not matter, vertical position on

the gate is the position you are

matching to the post bracket.) Position

your assembled gate mounting along the

previouslydrawn vertical line and level the

angled piece with the horizontal piece of

the gate mounting bracket using a level.

Mark your holes, drill and attach the

brackets using (4) 3/8” carriage bolts.

6. Assemble the rear fitting to the operator as shown below

2.5

7. Run the 5 wires from the arm(s) to the control board as seen in section 3.

8.Set the operator for manual operation. And extend the operator arm to a near full

extended position.

2.6

9. Extend the operator arm so the measurement between the center of the pivot hole

on the rear bracket and the center of the pivot hole in the front mounting measures 51

1/4 inches (63 inches for L-series). After finding the measurement relock your

operator arm.

This is your closed mounting position.

10.Assemble the front gate mounting bracket as shown below. (bottom ring can

be left off if security is not a concern)

11.Attach the operator to the post mounting bracket using the supplied pins as shown

below, support the arm to prevent dropping and breakage of the rear fitting. (bottom ring

can be left off if security is not a concern)

E-S 1600 arm

E-S 1600L arm

2.7

Manually test the gate by completely

opening and closing it, checking for

smooth operation.

Gate in Closed position

12. Close the gate leaf. With the operator attached on the post side, move the end of

the arm to the gate and, keeping the gate operator in a perfectly horizontal position,

determine the gate mounting position. The arm should already be in it’s full closed length

that was determined in step 9

13. Attach the gate mounting bracket

using carriage bolts, nuts, and washers.

14. Release the gate operator once

more.

2.8

IMPORTANT: Determining Correct Setback

PUSH TO OPEN - This operation is commonly used if you driveway slopes up

after the gate, preventing it from swinging in. This means the gate operator is

mounted on the inside of the property and pushes your gate out away from the

property.

A B a

6” 6” 90o

5.5” 5.5” 100o

To determine the position of the

gate mount-ing bracket (above is

for the post mounting bracket) refer

to step 9 in the section

“Installation of operator - PTO”

There are 4 factors to keep in mind when finding the setback mounting:

1) The (A) measurement is perpendicular from the gate in the CLOSED position.

2) There must be clearance for your gate opener to attach to the gate in the closed position.

This is most commonly an issue on columns. Re-positioning of the hinges or Push-To-Open

operation may be re-quired to achieve clearance.

3) The brackets do not and must not move after installation.

4) The "L" shape brackets can be mounted anywhere on the post or column. They can be

mounted on a separate post or fence as well. The only factor of importance is that when

mounting of the brackets is done the hole in the boomerang bracket that the gate opener

mounts on matches the setback on this page.

It is best to C-Clamp brackets on and test arm movement clearance before permanently attaching

them.

Installation of Operator—Push-to-Open

1. Find the proper set back for your

operator (from previous page). Do this by

holding the bottom “L” shaped bracket

against the post. Marking its horizontal

positioning on the post using a vertical line

up from the middle of the bracket. Also mark

your angled bracket for posi-tioning on the

“L” shaped bracket. The hole on the end of

the angled bracket should be in the setback

position.

HINT: Trace the bracket on cardboard

and use the cardboard to make a

template.

Before permanently attaching any brackets, be sure to test arm

motion and clearance.

2.9

4. Insert a 3/8” x 1” bolt

in the center hole and a

5/16” bolt in the rear

hole. Secure them using

the provided nuts and

lock washers.

3. Position the angled

brack-et between the two

“L” shaped brackets in the

same position as when

the setback was found.

Clamp the 3 brackets

together. Drill through the

angled bracket using the

pre-drilled holes in the “L”

shaped brackets using a

3/8” drill bit. Drill through

all three brackets using a

5/16” drill bit in a position

behind the first hole.

2. Cut off the excess

length (if any) of the

angled brack-et using a

hacksaw.

For full capacity, the amount of stainless steel showing retracted shovel be

between 2 1/4 - 3 inches and 15 1/4 - 16 1/2 inches when extended (L-series: 20

- 21 1/4 inches when extracted).

5. Temporarily position the gate side

mounting bracket. (horizontal

position does not matter, vertical

position on the gate is the position

you are matching to the post

bracket.) Position your assem-bled

gate mounting along the previously

drawn vertical line and level the angled

piece with the horizontal piece of the

gate mounting bracket using a level.

Mark your holes, drill and attach the

brackets using (4) 3/8” carriage bolts.

6. Assemble the rear fitting to the operator as shown below.

7. Run the five wires from the arm(s) to the control board as seen in section 3.

8. Set the operator for manual operation. And extend the operator arm slightly

past the full retracted position..

2.10

2.11

9. Retract the operator arm so the measurement between the center of the pivot hole

on the rear bracket and the center of the pivot hole in the front mounting measures 36

inches (41 inches for L-series). After finding the measurement relock your operator

arm.

10. Assemble the front gate mounting bracket as shown below. (bottom ring can be left

off if se-curity is not a concern)

11.Attach the operator to the post mounting bracket using the supplied pins as shown

below, support the arm to prevent dropping and breakage of the rear fitting. (bottom

ring can be left off if security is not a concern)

This is your closed mounting position.

E-S 1600L

E-S 1600

Other manuals for E-S 1600 Series

1

This manual suits for next models

3

Table of contents

Other Estate Swing Gate Opener manuals

Estate Swing

Estate Swing E-S 1600 Series User manual

Estate Swing

Estate Swing E-SC 400 User manual

Estate Swing

Estate Swing Classic Series User manual

Estate Swing

Estate Swing E-S Allegiant Series User manual

Estate Swing

Estate Swing E-S 1600L Series User manual

Estate Swing

Estate Swing E-S 500 User manual

Estate Swing

Estate Swing E-S 1000D Series User manual

Estate Swing

Estate Swing Classic Series User manual

Estate Swing

Estate Swing E-S 300 User manual

Estate Swing

Estate Swing E-SC 1600 Series User manual