Estate Swing E-S 1000D Series User manual

Other manuals for E-S 1000D Series

1

Other Estate Swing Gate Opener manuals

Estate Swing

Estate Swing E-S 1000H Series User manual

Estate Swing

Estate Swing E-SC 1600 Series User manual

Estate Swing

Estate Swing E-S 1600 Series User manual

Estate Swing

Estate Swing E-S 1000H Series User manual

Estate Swing

Estate Swing E-S 1600 Series User manual

Estate Swing

Estate Swing E-S Allegiant Series User manual

Estate Swing

Estate Swing Classic Series User manual

Estate Swing

Estate Swing Classic Series User manual

Estate Swing

Estate Swing E-SC 400 User manual

Estate Swing

Estate Swing E-S 1600L Series User manual

Popular Gate Opener manuals by other brands

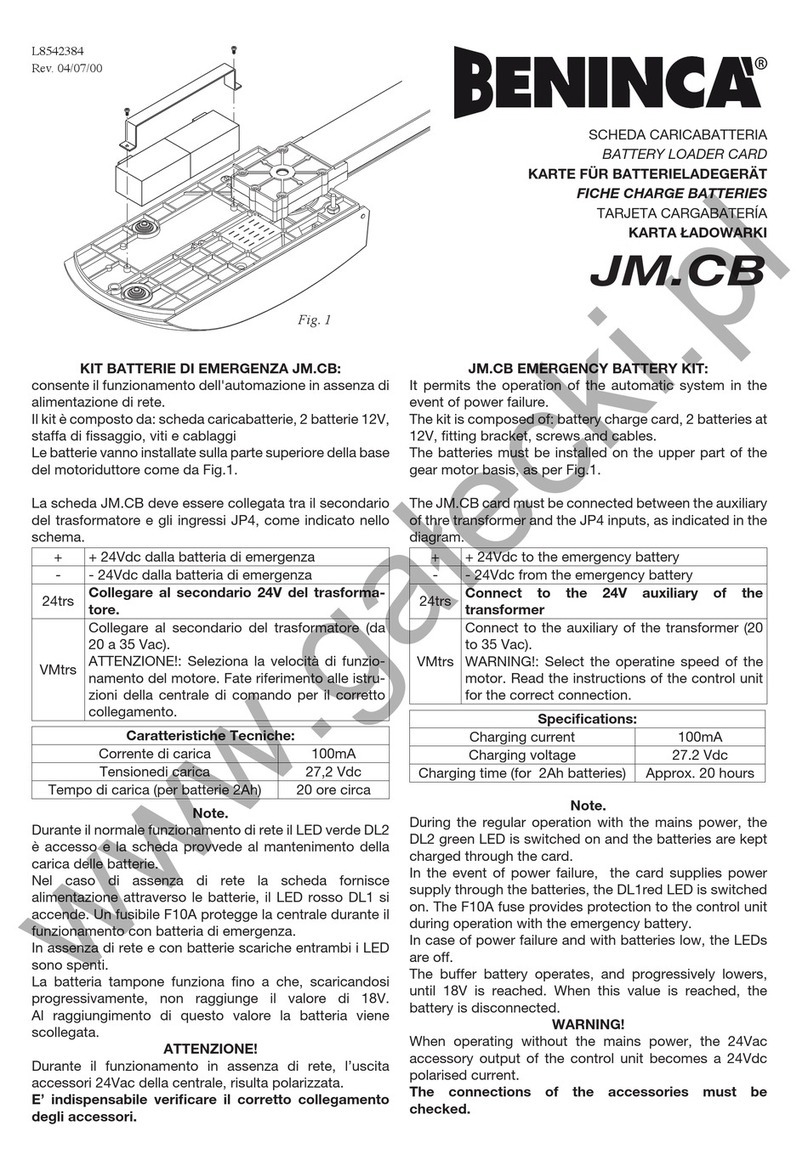

Beninca

Beninca JM.CB quick start guide

RIB

RIB JOLLY ONE manual

Polaris Automatic Gate Operators

Polaris Automatic Gate Operators Predator 500 user manual

SOMFY

SOMFY Axovia 400C NS installation guide

Relcross Door Controls

Relcross Door Controls 9130 installation instructions

SEA

SEA FLIPPER Fitting instructions

Motorline professional

Motorline professional KFM User's and installer's manual

WALKY

WALKY WL1024 Instructions and warnings for installation and use

DYNACO

DYNACO Slimline Series Technical manual

Cardin

Cardin BLTOW24 Series instruction manual

Nice Apollo

Nice Apollo 72001K installation manual

BFT

BFT KUSTOS BTA manual

Actuall

Actuall DoorLIFT DL-6 installation guide

RAMSET

RAMSET RAM 300 UL instruction manual

Chamberlain

Chamberlain LA400UL installation manual

Mighty Mule

Mighty Mule Silver-HD Dual 25th annivesary series installation manual

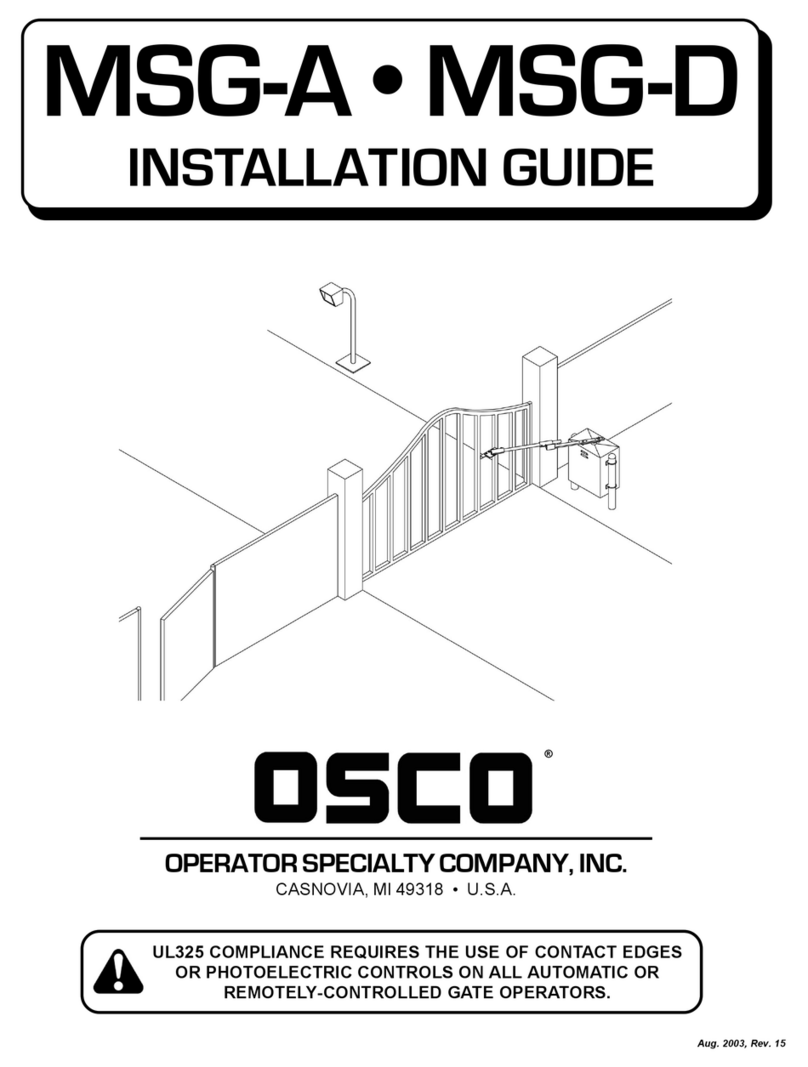

OSCO

OSCO MSG-A installation guide

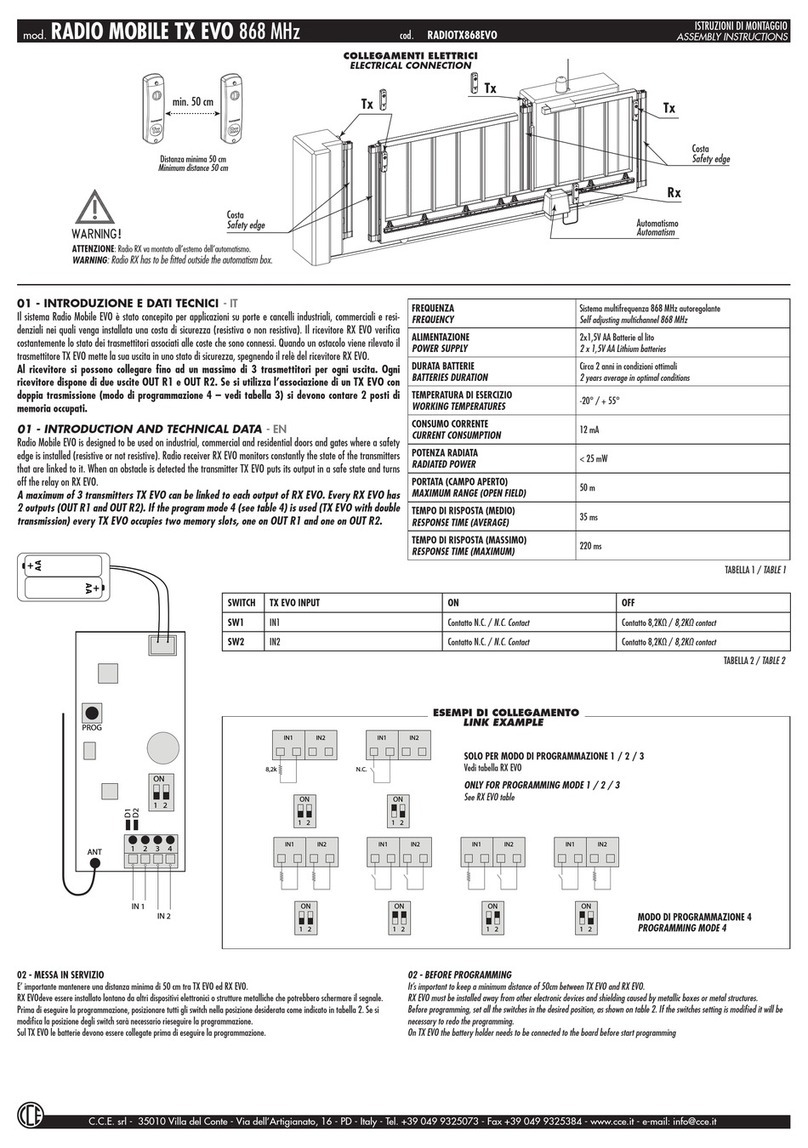

C.C.E.

C.C.E. RADIO MOBILE TX EVO Assembly instructions