Estella 348DSC67 User manual

07/2020

348DSC67

17"W x 67"L Belt

348DSF78

19¾"W x 78¾"L Belt

348DSC78

19¾"W x 78"L Belt

348DSF94

24¾"W x 95"L Belt

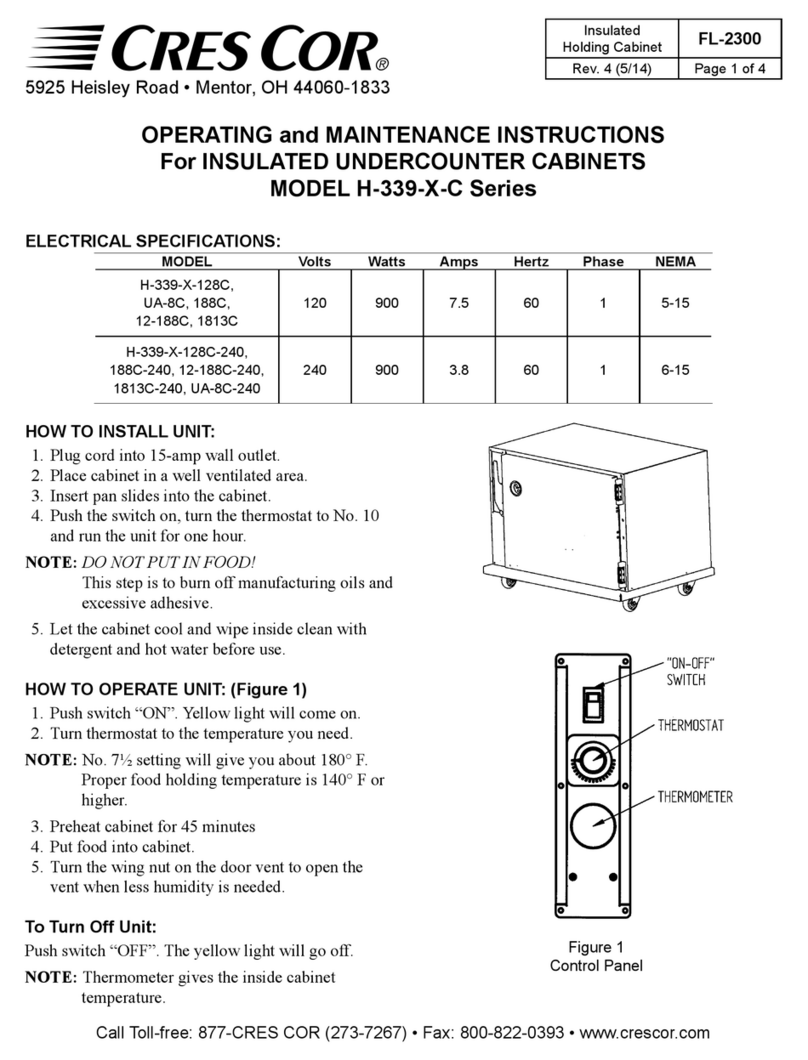

DOUGH SHEETERS

COUNTERTOP MODELS

FLOOR MODELS

USER MANUAL

Important Safety Information .....................................2

Setup...............................................................3

Safety Features ....................................................3

Operation .......................................................4-5

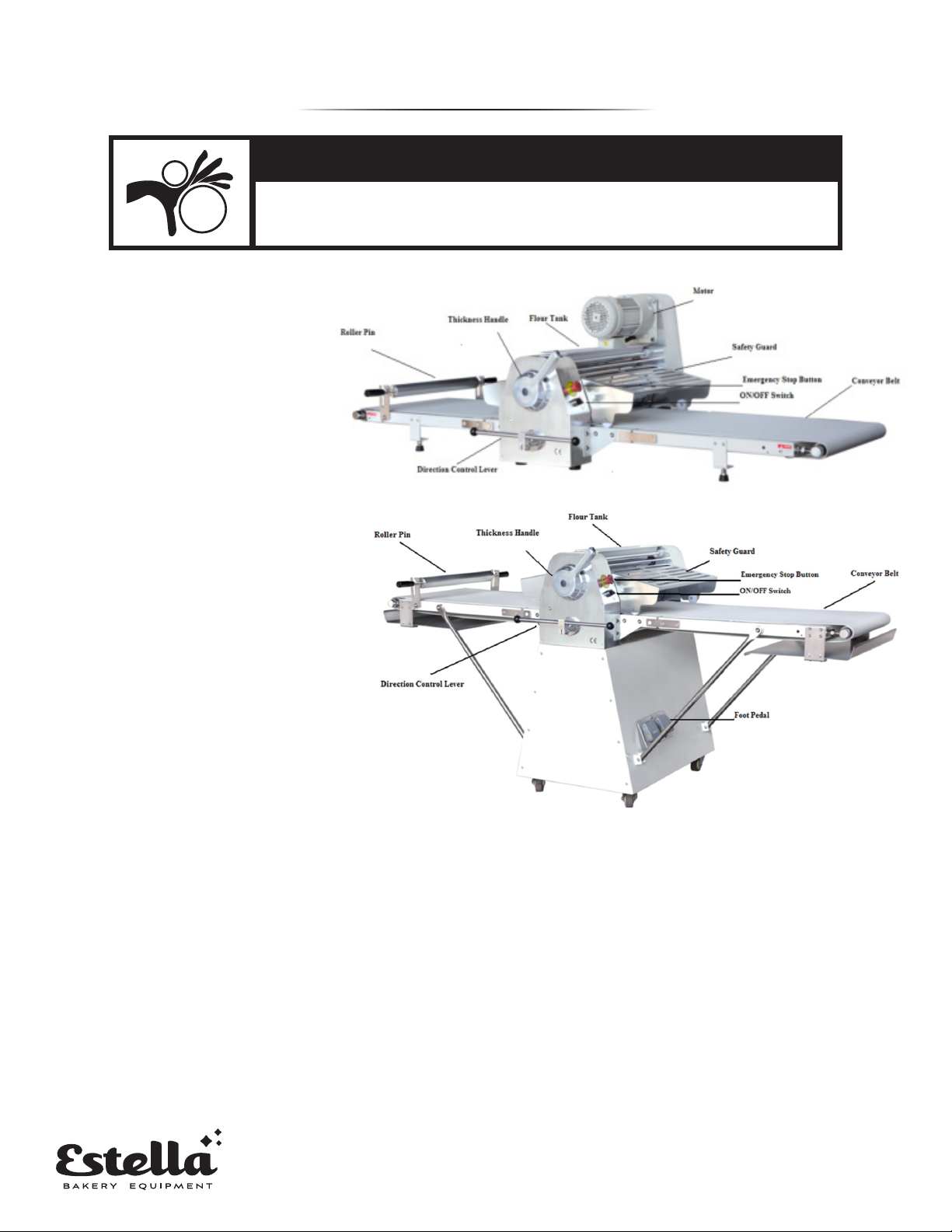

Circuit Diagram ....................................................6

Maintenance.......................................................6

Parts Diagrams.................................................7-16

Part Numbers ....................................................17

Troubleshooting .................................................17

Limited Warranty ................................................18

INDEX

1.

When using electrical appliances, basic safety precautions should always be followed,

including the following:

1. Keep the working around surrounding the machine clean and organized.

2. Consider environmental conditions surrounding the machine. Do not use the machine in humid,

wet or poorly lit environments. Do not use the machine close to flammable liquids or gas.

3. Keep machine away from children and non-authorized personnel. Do not permit them to go near

the machine or its working area.

4. Do not touch the switch or cable with wet hands.

5. Only utilize the machine with the correct voltage to achieve optimum results.

6. Do not wear low-hanging clothing or items that may get caught in the machine. Wear non-slip

shoes while working with the machine. For hygiene and safety, keep hair tied back and wear

protective gloves.

7. Do not tug on the cable to remove the plug from the outlet. Do not leave the cable near sharp

objects, water or solvents.

8. Remove the plug when the machine is not in use, you are cleaning the machine or need to move

the machine.

9. Check that the machine is not damaged prior to each use. Carefully check that all safety devices

are working, that the removable parts are not blocked, there are no parts damaged, that all the

parts have been set up correctly and that all conditions that could influence the regular function

of the machine are in working order.

10. If the machine is damaged or there are issues during its use, turn off the machine immediately

and contact the manufacturer for assistance or repair. Repairs should only be made by qualified

technicians, using the correct manufacturer parts. Non-compliance with these rules may void

the warranty.

NOTE: Save these instructions for future reference.

SAFETY

2.

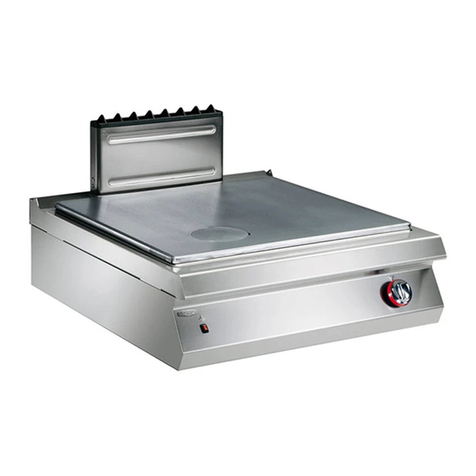

1. The surface where the machine will be used must be solid and

horizontally level.

2. The machine is very heavy. Check weight capacity of the table or

counter it is being used on before installing.

3. These models have 4 adjustable feet. Once you have placed the

machine on the counter, use a level on each side of the belt to ensure

level operation.

4. Ensure the machine is close enough to a 120V outlet. Contact a

qualified electrician if unsure of your electrical supply.

The potentially most dangerous area of these machines is the two superimposed

cylinders with convergent rotation movements. So, there are safety bars that

obstruct the entry in this area. Those safety bars are completely built in stainless

steel and designed in a way to allow the user to watch the dough.

The machine can only begin its work if the security bars are in working position, that is, completely

down. The machine has an electric protection system that does not allow the machine to work if the

bars are not completely down.

It is forbidden to remove, modify or damage the security bars of the machine.

1. These models sit on 4 casters with brakes.

2. Ensure that the installation location is close enough to a 120V outlet.

Contact a qualified electrician if unsure of your electrical supply.

3. Keep the machine away from potential hazards like fryers, grills, or any

other piece of equipment that can splash hot oil or water onto it.

4. Unfold the belts down for use and sure enough working clearance. Use a

level on the belts to ensure that the machine is on a level surface.

COUNTERTOP MODELS

FLOOR MODELS

SETUP

NOTE: The manufacturer is not responsible for any damages caused by improper installation.

NOTE: The machine should be ran with a batch of test dough first that will not be used for consumption.

This is necessary to remove any lubricants that are on the rollers/belts from the new machine.

SAFETY FEATURES

3.

4.

1. Ensure the machine is plugged

in to a 120V outlet and the

working space is clear of any

potential hazards.

2. Locate the on off switch. Turn

on the power switch. (Before

start the switch, you need to

check whether the emergency

stop switch is turned on and safety

nets are all put down.

3. The thickness adjustment handle

can now be adjusted to your

desired dough thickness. Swing

the handle to the corresponding

scale to adjust the pressure roller

spacing.

4. Once that is set, prepare the belt

with flour as needed to prevent

sticking and add your dough to the belt. It is

recommended to start on the highest thickness

setting and work your way down. If you try to

force a large piece of dough into a small setting,

the rollers will not accept it.

5. Use the directional control to work the dough

through the rollers as many times as needed. Tabletop Model(s): Swing the left and right

levers to change the direction of the conveyor belt. Floor model(s) Use foot pedals to change

the direction of the conveyor beltKeep hands away from rollers and keep the safety guards

down. The machine will shut off immediately if safety guard is lifted.

6. Once done, return the direction control lever parallel to the floor and shut the machine off.

7. If Cleaning the machine, turn the power off and unplug it.

OPERATION

WARNING: MOVING PARTS CAN CRUSH & CUT

Keep hands, feet and all objects away from the rollers

prior to turning on the machine!

Swing the handle to the corresponding

scale to adjust the roller spacing of the

pressing surface.

Swing the left and right levers to change

the belt conveying direction.

Don't open this cover.

When the safety net is opened, the

machine will be stopped immediately,

and when it is put down, the machine

will continue to work.

TT-D18A

Dough Sheeter

Emergency stop

switch

Power switch

Operating Steps:

1. Turn on the power switch. (Before start the switch, you need to check whether the emergency stop switch is turned on and safety nets are

all put down)

2. Swing the handle to the corresponding scale to adjust the pressure roller spacing.

3. Swing the left and right levers to change the direction of the conveyor belt.

4. When the machine is running, if the safety protection net is opened, the machine will stop immediately. And then when the net is put down,

the machine will continue to work.

5. If meeting the emergency, please press the emergency stop immediately.

6. When the operation is completed, swinging the left and right levers to the horizontal, and then turning off the power switch.

Swing the handle to the corresponding

scale to adjust the roller spacing of the

pressing surface.

Swing the left and right levers to change

the belt conveying direction.

Stepping on the foot switch to jog the

conveyor belt (turn left and right)

Power switch

Emergency stop switch

When the safety net is opened, the machine

will be stopped immediately, and when it is

put down, the machine will continue to work.

Don't open this cover.

TT-D19A-1

Dough Sheeter

Operating Steps:

1. Turn on the power switch. (Before start the switch, you need to check whether the emergency stop switch is turned on and safety nets are all

put down)

2. Swing the handle to the corresponding scale to adjust the pressure roller spacing.

3. Swing the left and right levers to change the direction of the conveyor belt.

4. When the machine is running, if the safety protection net is opened, the machine will stop immediately. And then when the net is put down, the

machine will continue to work.

5. If meeting the emergency, please press the emergency stop immediately.

6. When the operation is completed, swinging the left and right levers to the horizontal, and then turning off the power switch.

Estella sheeters are designed to be used by qualified people in the pastry and bakery’s business. Other

uses will be considered improper. The manufacturer is not responsible for any machine damages or

personal injuries due to improper use of the machine

IMPROPER USE OF THIS MACHINE

Don't open this cover.

Power Switch

Emergency Power Switch

Swing the left and right levers to

change the belt conveying direction.

Swing the handle to the

corresponding scale to adjust the

roller spacing of the pressing surface.

When the safety net is opened, the

machine will stop immediately. When it

is put down, the machine will resume.

Swing the handle to the

corresponding scale to adjust the

roller spacing of the pressing surface.

Swing the left and right levers to

change the belt conveying direction.

Don't open this cover.

When the safety net is opened, the

machine will stop immediately. When it

is put down, the machine will resume.

Power switch

Emergency stop switch

Stepping on the foot switch to jog

the conveyor belt (turn left and right)

5.

• Before performing any sort of maintenance on the machine, first remove the

plug from the outlet.

• The machine must be cleaned every day that it is in use, especially areas that

contact dough.

• DO NOT use knives, hard brushes, or tools to clean the cylinders. use plastic tools

and/or soft sponges. Use a soft brush to clean the canvas.

• DO NOT use toxic products or abrasive agents as they could damage the machine.

CIRCUIT DIAGRAM

MAINTENANCE

1. Using a proper brush and a wooden palate, first clean any flour residue and dough

off the machine.

2. To open the machine for cleaning, first lift the safety guards and adjust the roller

thickness to the largest setting.

3. You now have access to clean the rollers.

4. Rinse thoroughly and dry with an absorbent wipe. Wipe down all of the surfaces that

come into contact with the dough and then clean the entire machine with a smooth

cloth and a foodservice-safe disinfectant such as Nobles 147QUIKSAN.

5. Dry thoroughly before next use.

6.

7.

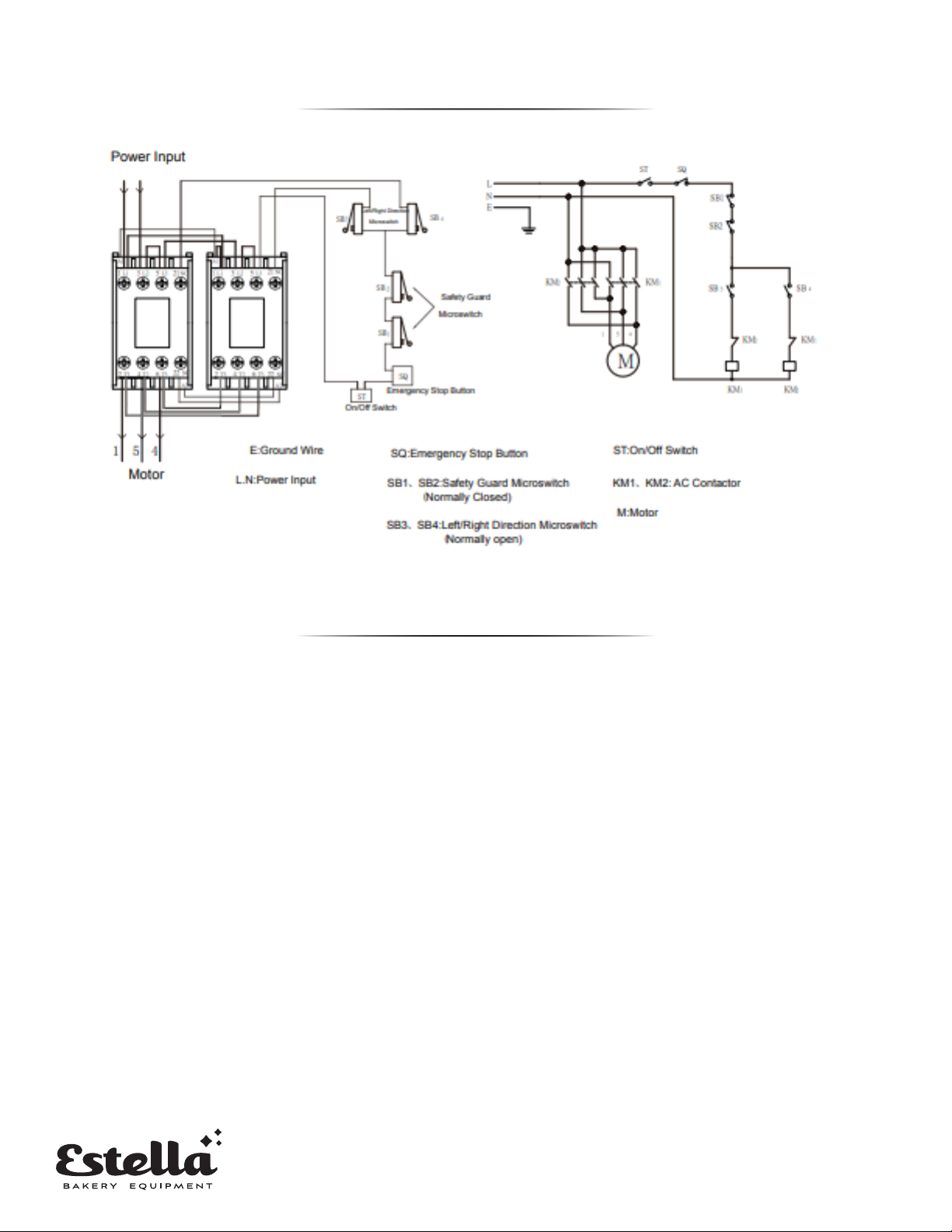

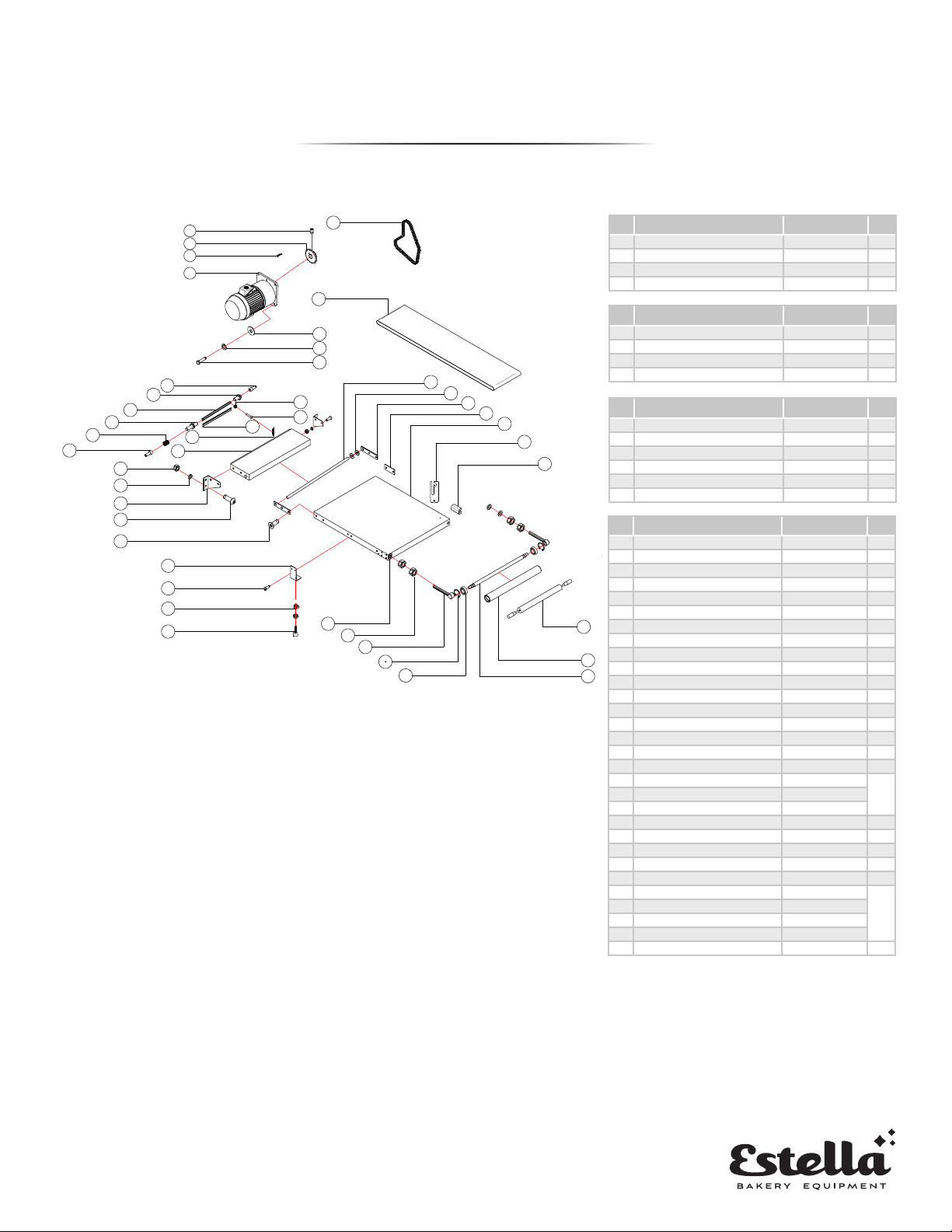

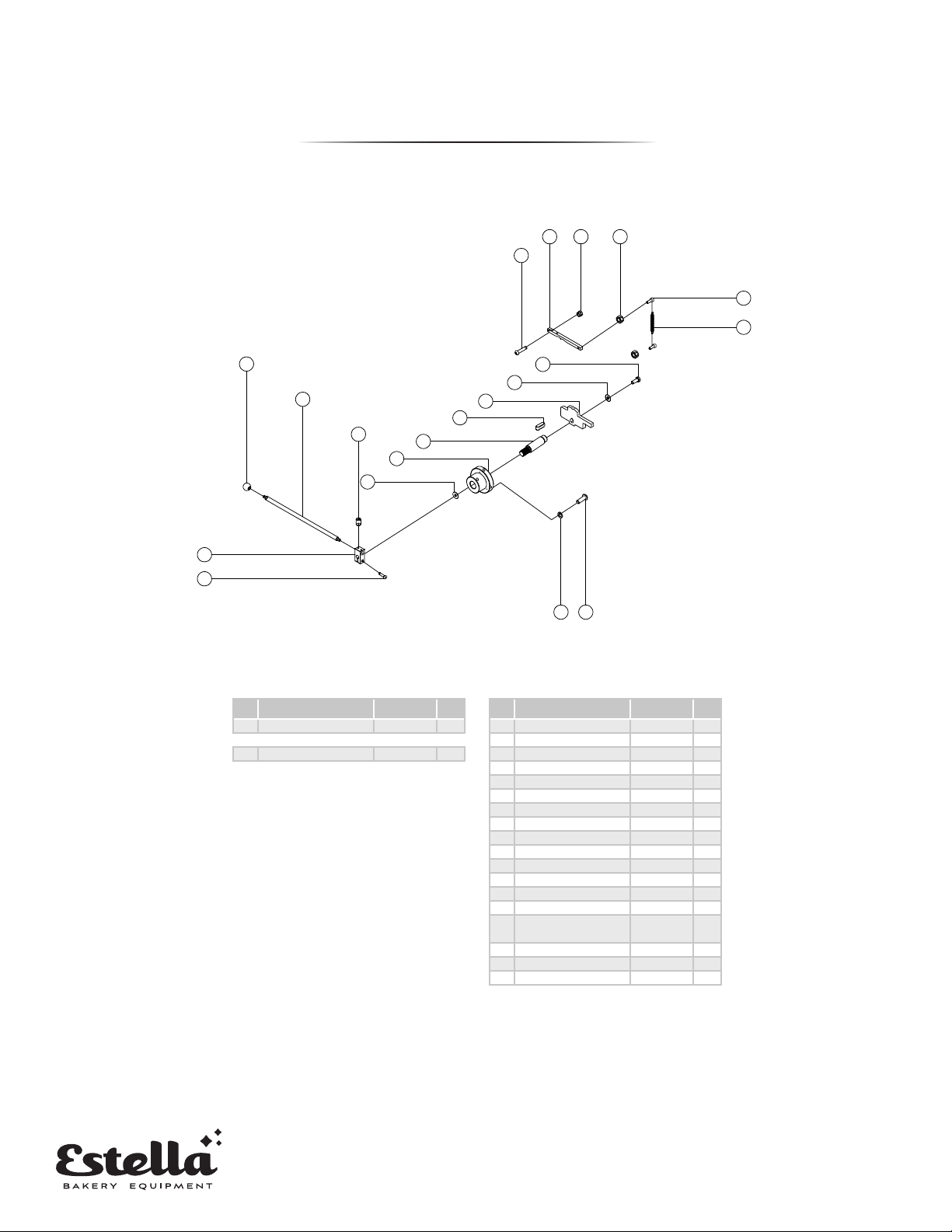

COUNTERTOP MODEL

PARTS DIAGRAMS

No Description Code

Qty

1 Hexagon screw M8x20L 1

28 at pad 1

3 Gear 15T TT520290 1

4 Gear 27T TT520280 1

5 Gasket TT520300 1

6 51108 Thrust Bearing 1

7 Bearing sleeve TT520320 1

8 6004 bearing 1

9C type 5x5x30L at key 1

10 Axis TT520310 1

11 Conveyor wheel bearing

sleeve TT520410

1 Set

12 6003 bearing

13 51103 Thrust Bearing

14 Aluminum blocks on both

sides of the roller

15 Roller shaft

16 Belt roller TT520420

17 Bearing sleeve TT520470

18 Adjusting bolt M20x50*2 1

19 Plastic head screw M10x78x30 1

20 M10 nut 1

21 10 spring pad 1

22 Fixed shaft TT450920 1

23 35 hole circlip 1

1

10

100

2

3

4

5

6

7

8

9

11

12

13

14

15

17

18

16

32

28

29

30

31

33

34

35

37

36

38

39

40

41

42

43

44

45

91

92

93

94

95

96

97

98

99

104

101

105

106

107

108

102

103

109

110

19

20

21

22

23

24

25

26

27

:

:

:

:

:

:

SECTION NAME

DRW No.

Designer

Check

Review

Scale

Date

LEFT ROLLER

ASSEMLY

AND

TOP ROLLER

ASSEMBLY

-- --

-- --

-- --

-- --

-- --

-- --

-- --

-- --

-- --

-- --

-- --

-- --

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

DESCRIPTION

VERSION DESRIPTION DATE

1st Drawing 2019/05/19A

B

C

D

E

F

DES IGNER

PRODUCT NAME

TABLE TOP

DOUGH SHEETER

TT-D18A

TT-D18B

LEFT ROLLER ASSEMBLY

AND TOP ROLLER

ASSEMBLY

LEFT ROLLER ASSEMBLY AND TOP ROLLER ASSEMBLY

No Description Code

Qty

24 6202 bearing 1

25 Sprocket TT520930 1

26 15 axis circlip 1

27 Hexagon socket head cap

screws M10x40L 1

28 Socket head bolt M6x20L 1

29 Cover TT450040 1

30 25 circlip 1

31 Sprocket 21T TT520500 1

32 6205 bearing 1

33 52 hole circlip 1

34 Washer 3mm 1

35 Eccentric block TT520210 1

36 Wheel adjustment block TT520101 1

37 Flat pad 3mm 1

38 Washer 6mm TT520770 1

39 Arm TT450020 1

40 M10 nut 1

41 10 spring pad 1

42 10x596 dental rod 1

43 Rubber sleeve TT520720 1

44 Fixed rod TT520710 1

45 Axis TT520450 1

46 Arm TT520010 1

No Description Code

Qty

91 Hex bolts M8x80L 1

92 8 spring pad 1

93 M8 nut 1

94 Tension spring 1.6x16x64 1

95 8 spring pad 1

96 M8 hat 1

97 Set screw M8x12L 1

98 C type 6x6x25 at key 1

99 Upper roller sprocket TT520510 1

100 6205 bearing 1

101 A type 6x6x18 at key 1

102 A type 6x6x18 at key 1

103 C type 6x6x30 at key 1

104 M5 nut 1

105 Hexagon pan head screws M5x20L 1

106 Roller (top) TT520440 1

107 6205 bearing 1

108 Wheel adjustment block TT520110 1

109 6205 bearing 1

110 20 axis circlip 1

8.

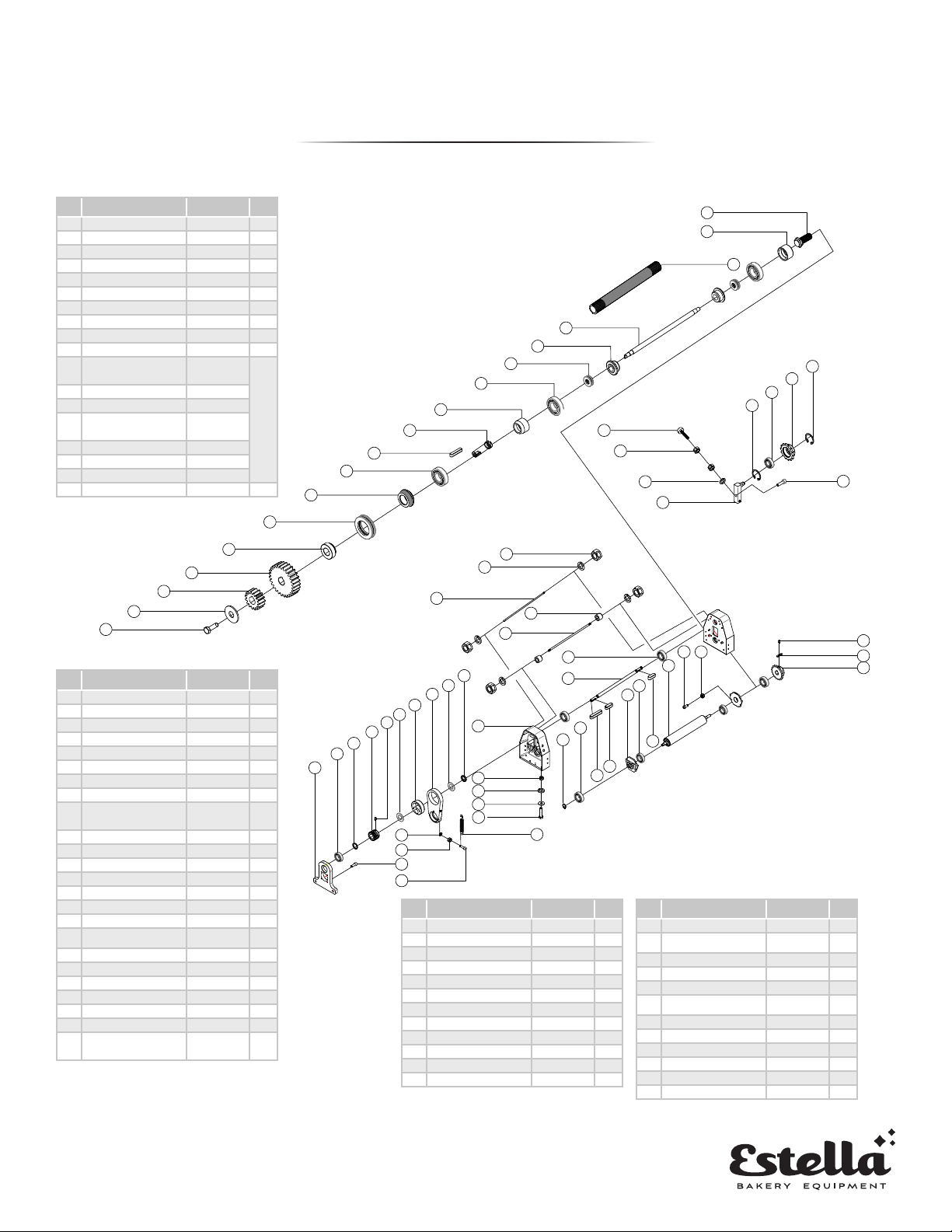

STARTER LEVER AND THICKNESS ASSEMBLY

46

47

48

49

50

51

52

53

54

55

56

59

60

57

58

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

111

112

113

114

115

116

118

119

117

:

:

:

:

:

:

SECTION NAME

DRW No.

Designer

Check

Review

Scale

Date

-- --

-- --

-- --

-- --

-- --

-- --

-- --

-- --

-- --

-- --

-- --

-- --

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

DESCRIPTION

VERSION DESRIPTION DATE

1st Drawing 2019/05/19A

B

C

D

E

F

DES IGNER

PRODUCT NAME

TABLE TOP

DOUGH SHEETER

TT-D18A

TT-D18B

START LEVER

AND THICKNESS

ASSEMBLY

START LEVER AND

THICKNESS ASSEMBLY

No Description Code

Qty

46 Arm TT520010 1

47 Washer 6mm TT520770 1

48 Flat pad 3mm 1

49 Wheel adjustment block TT520100 1

50 Eccentric block TT520210 1

51 Flat pad 3mm 1

52 Set screw M8x12L 1

53 Brake gear TT521870 1

54 Washer 3mm TT520770-1 1

55 6005 bearing 1

56 Brake bearing xing seat TT521820 1

57 Rotary shaft of brake TT521860 1

58 Brake xing seat TT521830 1

59 ¢ 10 spring pad 1

60 Hex bolts M10x30L 1

61 Brake cylinder TT521890 1

62 Socket head bolt M6x15L 1

63 M6 nut 1

64 Socket head bolt M6x20L 1

65 5x30 cotter pin 1

66 Socket head bolt M5x15L 1

67 5 spring pad 1

68 Brake gear TT521880 1

69 washer 22x¢32x3mm 1

70 6005 bearing 1

No Description Code

Qty

71 C type 6xx6x30 at key 1

72 A type 6x6x12 at key 1

73 A type 6x6x35 at key 1

74 Spring 0.9x9x14 1

75 Brake TT521840 1

76 24 axis circlip 1

77 Cover TT520030 1

78 A type 6x6x18 at key 1

79 Brake rotating disc TT521850 1

80 Fixed dial TT521910 1

81 Sealing ring TT521920 1

82 handle TT520050 1

83 Headless screw M10x35L 1

84 ¢ 10 at pad 1

85 M10 hat 1

86 HP-25 button plug 1

No Description Code

Qty

111 M12 nut 1

112 12 spring pad 1

113 12 Flat pad 1

114 Big foot pad TT450950 1

115 8 spring pad 1

116 M8 nut 1

117 Socket head bolt M6x16L 1

118 Socket head bolt M8x30L 1

119 Tension spring 1.6x16x76.8 1

COUNTERTOP MODEL

PARTS DIAGRAMS

9.

87

88

89

90

158

159

160

161

167

168

169

170

171

172

185

186

187

188

189

190

191

192

193

194

195

196

197

198

199

200

201

202

203

204

205

206

207

208

209

210

211

214

213

212

-- --

-- --

-- --

-- --

-- --

-- --

-- --

-- --

-- --

-- --

-- --

-- --

:

:

:

:

:

:

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

DESCRIPTION

VERSION DESRIPTION DATE

1st Drawing 2019/05/19A

B

C

D

E

F

DES IGNER

PRODUCT NAME

SECTI ON NAME

DRW No.

Designer

Check

Review

Scale

Date

TABLE TOP

DOUGH SHEETER

TT-D18A

TT-D18B

TRANSMISSION

AND

CONVEYOR

ASSEMBLY

TRANSMISSION

AND

CONVEYOR

ASSEMBLY

TRANSMISSION AND CONVEYOR ASSEMBLY

No Description Code

Qty

87 Set screw M8x12L 1

88 Sprocket 24T TT520520 1

89 C type 7x8x30 at key 1

90 Motor GV28-550-17S 1

No Description Code

Qty

158 10 at pad 1

159 10 spring pad 1

160 Hex bolts M10x35L 1

161 08A 50HZ / 08A 60HZ 88/86 1

No Description Code

Qty

167 Hexagon socket head cap screws M10x16L 1

168 Positioning pin TT52066-1 1

169 Lower knife cover TT520680 1

170 Positioning pin TT52066-3 1

171 Compression spring 1.0x10.4x22 1

172 Hexagon socket head cap screws M10x16L 1

No Description Code

Qty

185 Bracket foot pad TT450970 1

186 M8 nut 1

187 Hexagon pan head screws M6x10L 1

188 Tripod TT450960 1

189 Cross countersunk head screws M10x25L 1

190 Hexagon pan head screws M10x25L 1

191 Fixed plate (left and right) TT520530 1

192 10 spring pad 1

193 M10 nut 1

194 Pallet TT520540 1

195 Tension spring 1.5x10x80 1

196 Lower blade TT520690 1

197 M6 nut 1

198 Phillips pan head screws M6x10L 1

199 Fixed rod TT520550-1 1

200 Gasket 16x30x1.5 1

201 Connector TT520560 1

202 Support plate reinforced plate TT520570-4

1 Set203 Bracket plate TT520570

204 Bracket plate xing seat TT520570-2

205 Rolling pin xing seat TT520790 1

206 conveyor 2160x500 1

207 16 at pad 1

208 M16 nut 1

209 Rolling surface xing rod TT520580 1

210 20 axis circlip

1 Set

211 6004 bearing

212 Roller lever TT520610

213 Conveyor belt roller TT520600

214 Rolling pin 1

COUNTERTOP MODEL

PARTS DIAGRAMS

10.

120

121

122

123

124

125

126

127

128

129

130

131

132

133

134

135

136

137

145

146

:

:

:

:

:

:

SECTION NAME

DRW No.

Designer

Check

Review

Scale

Date

-- --

-- --

-- --

-- --

-- --

-- --

-- --

-- --

-- --

-- --

-- --

-- --

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

DESCRIPTION

VERSION DESRIPTION DATE

1st Drawing 2019/05/19A

B

C

D

E

F

DES IGNER

PRODUCT NAME

TABLE TOP

DOUGH SHEETER

TT-D18A

TT-D18B

DIRECTION

HANDLE

ASSEMBLY

DIRECTION HANDLE

ASSEMBLY

DIRECTION HANDLE ASSEMBLY

No Description Code

Qty

120 M5 nut 1

121 M8 hat 1

122 Cam strip TT520150 1

123 Hexagon pan head screws M8x35L 1

124 M6x6 set screw 1

125 Adjustment lever TT520370 1

126 plastic ball TT520320 1

127 Left and right adjustment seat TT520360 1

128 Socket head bolt M8x30L 1

129 Hexagon pan head screws M8x20L 1

130 8 spring pad 1

131 16 large at pads 1

132 Fixed seat TT520070 1

133 axis TT520140 1

134 A type 6x6x12 at key 1

135 Adjustment lm TT520080 1

136 8 at pad 1

137 Hex bolts M8x20L 1

No Description Code

Qty

145 Tension spring 1.4x11x88 1

146 Socket head bolt M5x20L 1

138

139

140

141

142

143

144

147

148

149

150

151

152

153

154

155

156

157

162

163

164

165

166

174

173

175

176

177

178

179

180

181

182

183

184

:

:

:

:

:

:

SECTI ON NAME

DRW No.

Designer

Check

Review

Scale

Date

BOTTOM

ROLLER

ASSEMBLY

-- --

-- --

-- --

-- --

-- --

-- --

-- --

-- --

-- --

-- --

-- --

-- --

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

DESCRIPTION

VERSION DESRIPTION DATE

1st Drawing 2019/05/19A

B

C

D

E

F

DES IGNER

PRODUCT NAME

TABLE TOP

DOUGH SHEETER

TT-D18A

TT-D18B

No Description Code

Qty

138 Hex bolts M10x20L 1

139 10 at pad 1

140 52 hole circlip 1

141 6005 bearing 1

142 Adjustment block TT520090 1

143 M10 nut 1

144 10 spring pad 1

No Description Code

Qty

147 Plastic gear shaft (top) TT520230 1

148 Gear M3 15T TT520250 1

149 13 Retaining ring 1

150 Upper blade TT520670 1

151 Positioning pin TT52066-2 1

152 Upper knife cover TT520660 1

153 6 spring pad 1

154 M6 nut 1

155 Cross pan head bolt M6x30L 1

156 Tension spring 1.6x12x43 1

157 Roller (below) TT520430 1

BOTTOM ROLLER ASSEMBLY

No Description Code

Qty

162 6206 bearing 1

163 Set screw M8x12L 1

164 Sprocket 1

165 C type 6x6x25 at key 1

166 A type 6x6x35 at key 1

No Description Code

Qty

173 Gear M3 24T TT520270 1

174 Washer 6mm TT520770 1

175 Gear M3 10T TT520260 1

176 Plastic gear shaft (below) TT520240 1

177 Plastic head screw M8x37L 1

178 M8 nut 1

179 8 spring pad 1

180 Micro switch sleeve TT520760 1

181 10 at pad 1

182 Protection net TT520740 1

183 Protection net rubber wheel TT520750 1

184 Hexagon socket head cap

screws M6x15L 1

COUNTERTOP MODEL

PARTS DIAGRAMS

11.

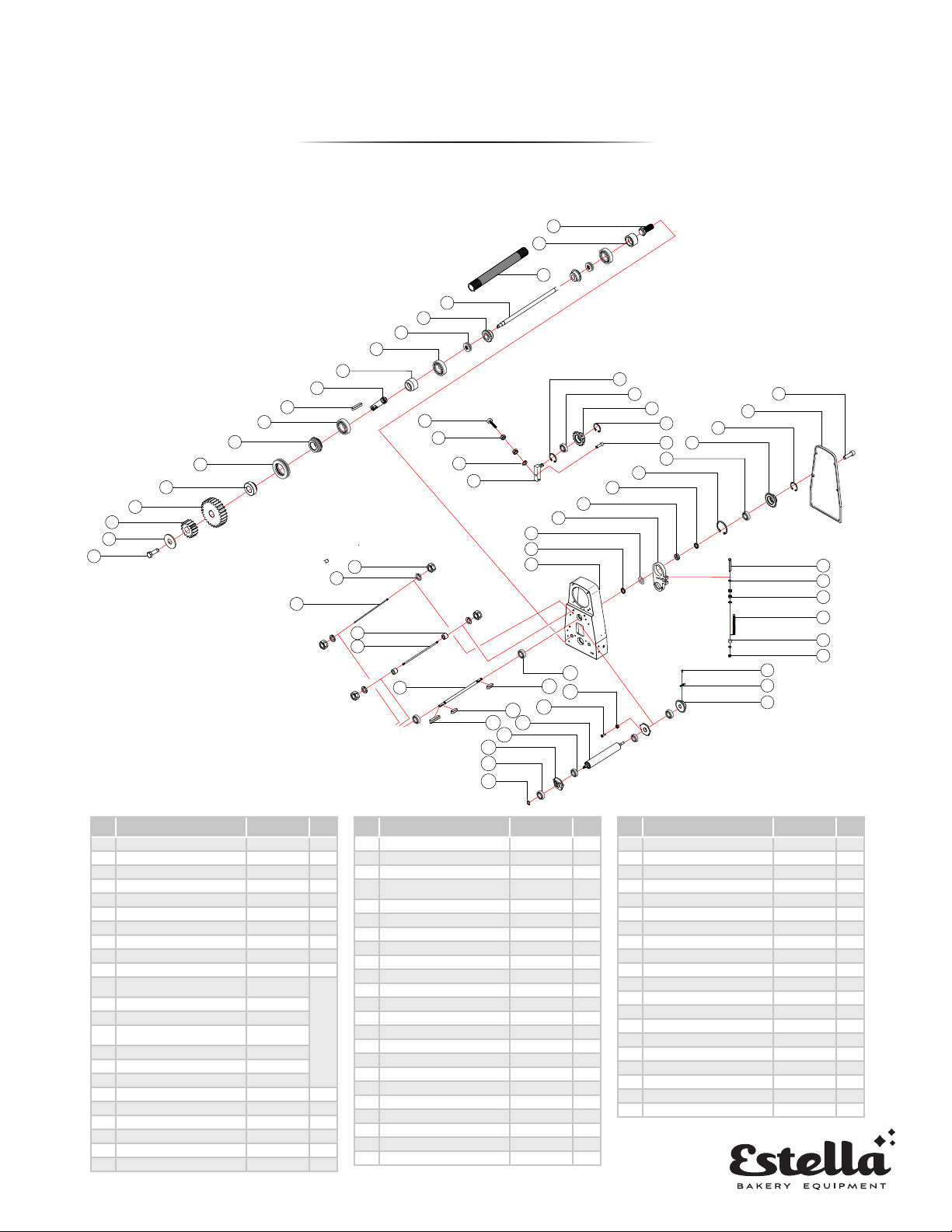

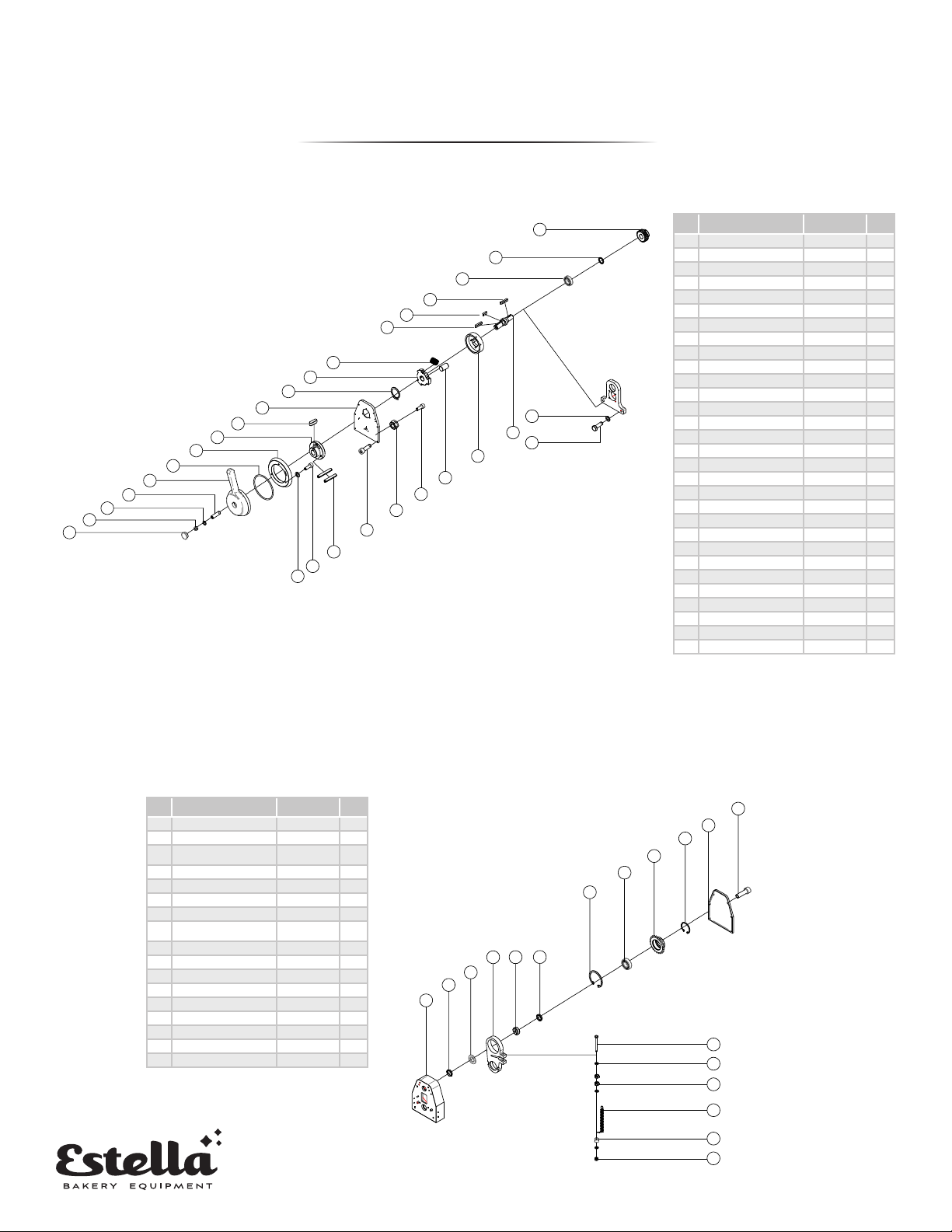

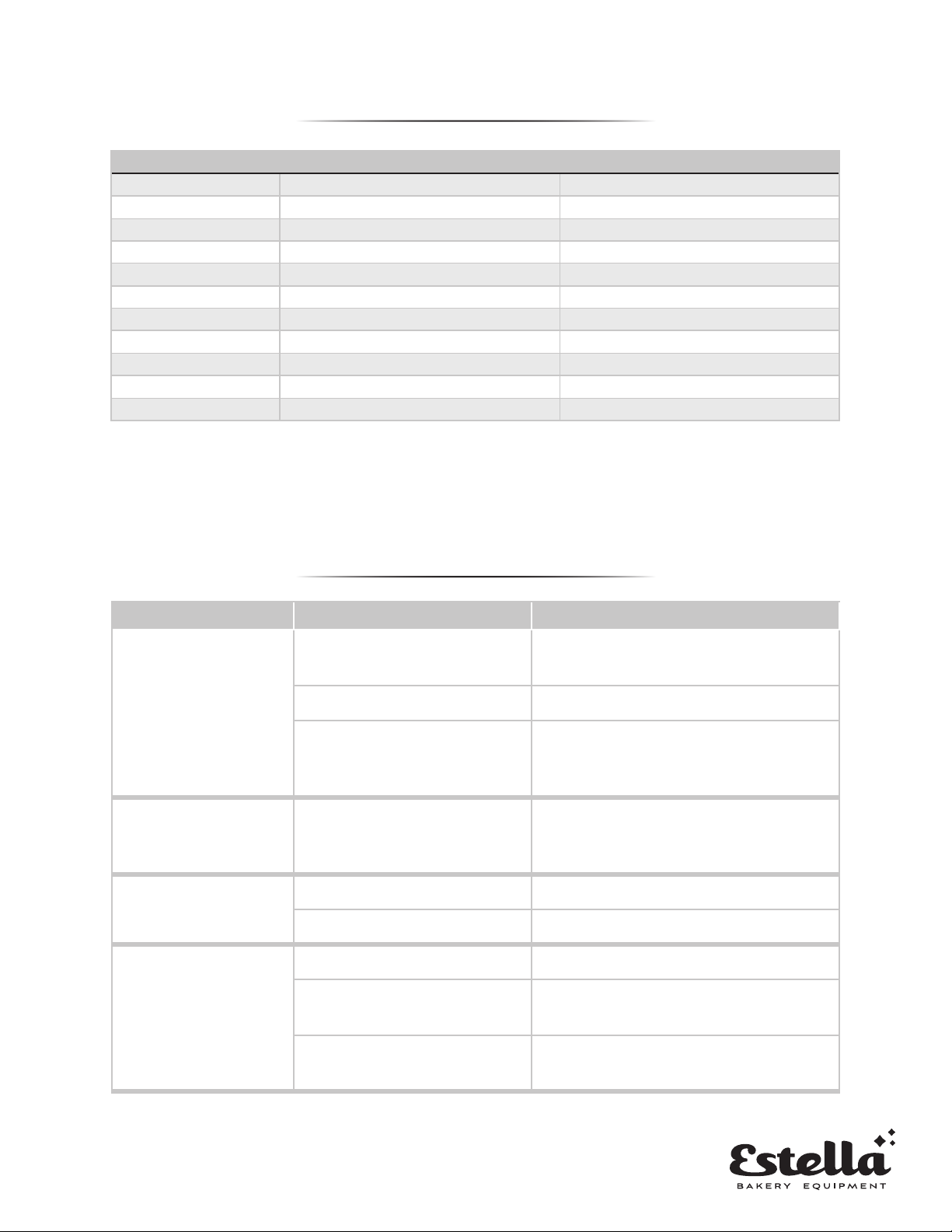

FLOOR MODEL

PARTS DIAGRAMS

LEFT ROLLER ASSEMBLY AND TOP ROLLER ASSEMBLY

No Description Code

Qty

1 Hexagon screw M8x20L 1

28 at pad 1

3 Gear 15T TT520290 1

4 Gear 27T TT520280 1

5 Gasket TT520300 1

6 51108 Thrust Bearing 1

7 Bearing sleeve TT520320 1

8 6004 bearing 1

9C type 5x5x30L at key 1

10 axis TT520310 1

11 Conveyor wheel

bearing sleeve TT520410

1 Set

12 6003 bearing

13 51103 Thrust Bearing

14 Aluminum blocks on

both sides of the roller

15 Roller shaft

16 Belt roller TT520420

17 Bearing sleeve TT520470

18 Adjusting bolt M20x50*2 1

28

29

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

18

30

31

32

42

41

40

39

38

37

36

35

34

33

17

74

76

75

73

77

81

80

79

78

82

83

84 112113

114

116

117

120

121

119

118

115

105

104

103

19

20

21

23

24

25

26

22

27

:

:

:

:

:

:

SECTION NAME

DRW No.

Designer

Check

Review

Scale

Date

-- --

-- --

-- --

-- --

-- --

-- --

-- --

-- --

-- --

-- --

-- --

-- --

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

DESCRIPTION

VERSION DESRIPTION DATE

1st Drawing 2019/05/19A

B

C

D

E

F

DES IGNER

PRODUCT NAME

LEFT ROLLER

ASSEMBLY

AND

TOP ROLLER

ASSEMBLY

FLOOR TYPE

DOUGH SHEETER

TT-D19A-1

TT-D19B-1

LEFT ROLLER ASSEMBLY

AND

TOP ROLLER

ASSEMBLY

No Description Code

Qty

19 Plastic head screw M10x78x30 1

20 M10 nut 1

21 10 spring pad 1

22 Fixed shaft TT450920 1

23 35 hole circlip 1

24 6202 bearing 1

25 Sprocket TT520930 1

26 15 axis circlip 1

27 Hexagon socket head

cap screws M10x40L 1

28 M10 nut 1

29 10 spring pad 1

30 10x596 dental rod 1

31 Rubber sleeve TT520720 1

32 Fixed rod TT520710 1

33 Washer 6mm TT520770 1

34 Flat pad 3mm 1

35 Wheel adjustment

block TT520100 1

36 Eccentric block TT520210 1

37 Flat pad 3mm 1

38 Set screw M8x12L 1

39 Brake gear TT520870 1

40 Washer 3mm TT520770-1 1

41 6005 bearing 1

42 Brake bearing xing

seat TT521820 1

No Description Code

Qty

73 Socket head bolt M8x30L 1

74 Socket head bolt M6x16L 1

75 M8 nut 1

76 8 spring pad 1

77 Tension spring 1.6x16x76.8 1

78 Hex bolts M12x50L 1

79 12 Flat pad 1

80 12 spring pad 1

81 M12 nut 1

82 Arm TT520010 1

83 Axis TT520450 1

84 6205 bearing 1

No Description Code

Qty

112 M5 nut

113 Hexagon pan head

screws

114 Roller (top)

115 A type 6x6x18 at key

116 6205 bearing

117 Wheel adjustment

block

118 A type 6x6x18 at key

119 C type 6x6x30 at key

120 6205 bearing

121 ¢ 20 axis circlip

109 6205 bearing 1

110 20 axis circlip 1

12.

STARTER LEVER AND THICKNESS ASSEMBLY

FLOOR MODEL

PARTS DIAGRAMS

44

43

45

46

47

48

70

49

50

68

69

51

52

53

55

56

57

58

59

60

61

54

67

66

65

64

63

62

71

72

:

:

:

:

:

:

SECTION NAME

DRW No.

Designer

Check

Review

Scale

Date

-- --

-- --

-- --

-- --

-- --

-- --

-- --

-- --

-- --

-- --

-- --

-- --

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

DESCRIPTION

VERSION DESRIPTION DATE

1st Drawing 2019/05/19A

B

C

D

E

F

DES IGNER

PRODUCT NAME

START LEVER

AND THICKNESS

ASSEMBLY

FLOOR TYPE

DOUGH SHEETER

TT-D19A-1

TT-D19B-1

START LEVER

AND THICKNESS

ASSEMBLY

No Description Code

Qty

43 Brake gear TT521880 1

44 washer 22x32x3mm 1

45 6005 bearing 1

46 C type 6xx6x30 at key 1

47 A type 6x6x12 at key 1

48 A type 6x6x35 at key 1

49 spring 0.9x9x14 1

50 brake TT521840 1

51 24 axis circlip 1

52 Cover TT520030 1

53 A type 6x6x18 at key 1

54 Brake rotating disc TT521850 1

55 Fixed dial TT521910 1

56 Sealing ring TT521920 1

57 handle TT520050 1

58 Headless screw M10x35L 1

59 10 at pad 1

60 M10 hat 1

61 HP-25 button plug 1

62 5 spring pad 1

63 Socket head bolt M5x15L 1

64 5x30 cotter pin 1

65 Socket head bolt M6x20L 1

66 M6 nut 1

67 Socket head bolt M6x15L 1

68 Brake cylinder TT521890 1

69 Brake xing seat TT521830 1

70 Rotary shaft of brake TT520101 1

71 Hex bolts M10x30L 1

72 10 spring pad 1

RIGHT ROLLER ASSEMBLY

No Description Code

Qty

85 Washer 6mm TT520770 1

86 Flat pad 3mm 1

87 Wheel adjustment

block TT520101 1

88 Eccentric block TT520210 1

89 Washer 6mm 520770 1

90 52 hole circlip 1

91 6205 bearing 1

92 Adjusting shaft

sprocket M3 21T TT520500 1

93 25 axis circlip 1

94 Cover TT520040 1

95 Socket head bolt M6x20L 1

96 Hex bolts M8x80L 1

97 8 spring pad

98 M8 nut

99 Tension spring 1.6x16x64

100 8 spring pad

101 M8 hat

85

86

87 88 89

90

91

92

93

94

95

96

97

98

99

101

100

238

:

:

:

:

:

:

SECTION NAME

DRW No.

Designer

Check

Review

Scale

Date

-- --

-- --

-- --

-- --

-- --

-- --

-- --

-- --

-- --

-- --

-- --

-- --

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

DESCRIPTION

VERSION DESRIPTION DATE

1st Drawing 2019/05/19A

B

C

D

E

F

DES IGNER

PRODUCT NAME

RIGHT ROLLER

ASSEMBLY

FLOOR TYPE

DOUGH SHEETER

TT-D19A-1

TT-D19B-1

RIGHT ROLLER

ASSEMBLY

13.

FLOOR MODEL

PARTS DIAGRAMS

BOTTOM ROLLER ASSEMBLY

122

111 110 109 108 107 106

102

123

124

125

126

127

128

129

130

132

134

135

136

162

161

160

177

174173

167

166

:

:

:

:

:

:

SECTION NAME

DRW No.

Designer

Check

Review

Scale

Date

-- --

-- --

-- --

-- --

-- --

-- --

-- --

-- --

-- --

-- --

-- --

-- --

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

DESCRIPTION

VERSION DESRIPTION DATE

1st Drawing 2019/05/19A

B

C

D

E

F

DESIGNER

PRODUCT NAME

BOTTOM

ROLLER

ASSEMBLY

FLOOR TYPE

DOUGH SHEETER

TT-D19A-1

TT-D19B-1

BOTTOM

ROLLER

ASSEMBLY

No Description Code

Qty

102 Sprocket (double row) TT521490 1

No Description Code

Qty

106 6206 bearing 1

107 Roller (below) TT520430 1

108 Tension spring 1.6x12x43 1

109 Cross pan head bolt M6x30L 1

110 M6 nut 1

111 6 spring pad 1

122 Upper knife cover TT520680 1

123 Positioning pin TT52066-2 1

No Description Code

Qty

160 8 spring pad 1

161 M8 nut 1

162 Plastic head screw M8x37L 1

No Description Code

Qty

166 Plastic gear shaft (below) TT520240 1

167 Gear M3 10T TT520260 1

No Description Code

Qty

173 Gear M3 24T TT520270 1

174 A type 6x6x35 at key 1

No Description Code

Qty

177 C type 6x6x25 at key 1

No Description Code

Qty

124 Upper blade TT520670 1

125 13 Retaining ring 1

126 Gear M3 15T TT520250 1

127 Plastic gear shaft (top) TT520230 1

128 10 spring pad 1

129 M10 nut 1

130 Adjustment block TT520090 1

132 6005 bearing 1

134 52 hole circlip 1

135 10 at pad 1

136 Hex bolts M10x20L 1

14.

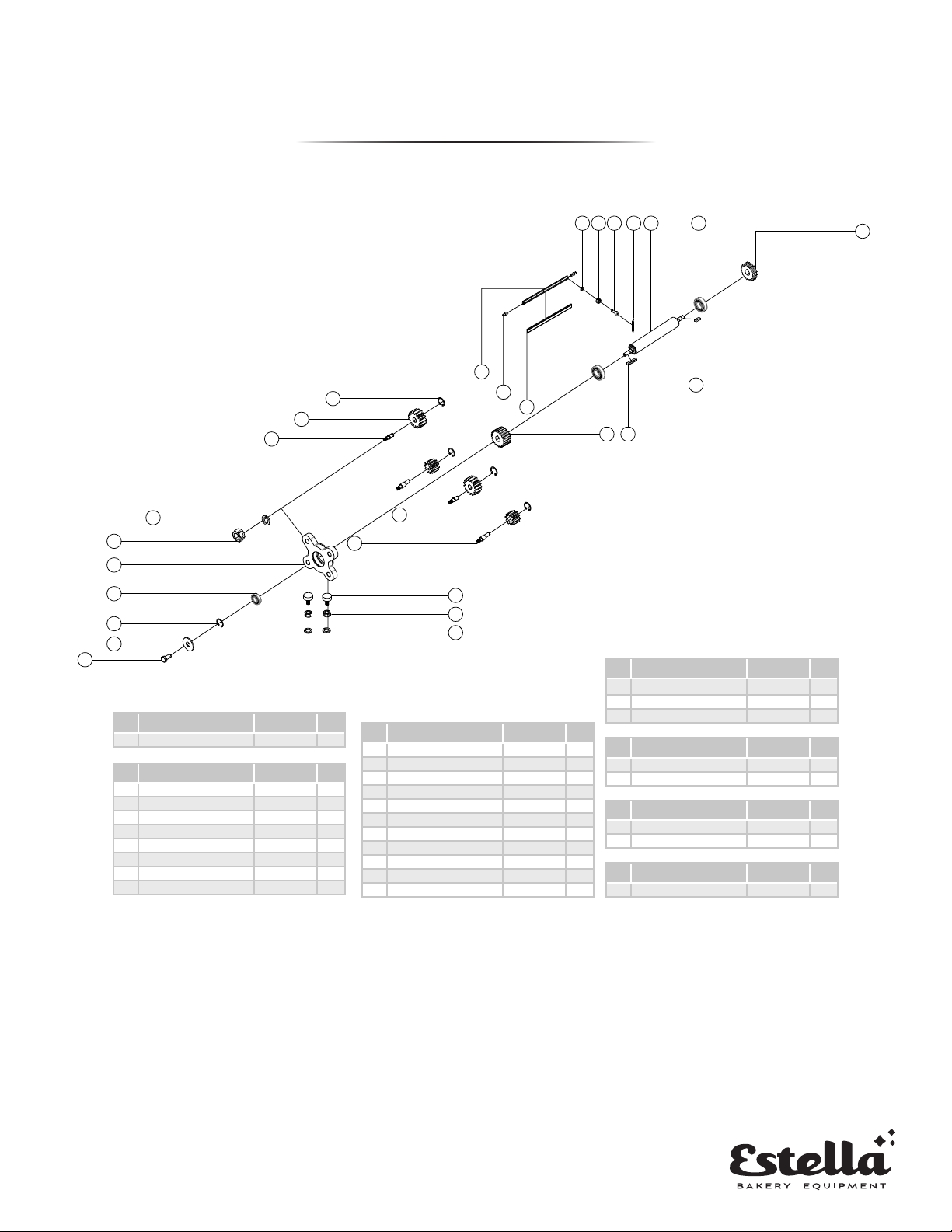

DIRECTION HANDLE ASSEMBLY

FLOOR MODEL

PARTS DIAGRAMS

131

133

137139 138

140

141

142

143

144

145

146

148

149

150

151

152

154153

147

:

:

:

:

:

:

SECTION NAME

DRW No.

Designer

Check

Review

Scale

Date

-- --

-- --

-- --

-- --

-- --

-- --

-- --

-- --

-- --

-- --

-- --

-- --

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

DESCRIPTION

VERSION DESRIPTION DATE

1st Drawing 2019/05/19A

B

C

D

E

F

DESIGNER

PRODUCT NAME

DIRECTION

HANDLE

ASSEMBLY

FLOOR TYPE

DOUGH SHEETER

TT-D19A-1

TT-D19B-1

DIRECTION HANDLE

ASSEMBLY

No Description Code

Qty

131 Socket head bolt M5x20L 1

133 Tension spring 1.4x11x88 1

No Description Code

Qty

137 M5 nut 1

138 M8 hat 1

139 Cam strip TT520150 1

140 Hexagon pan head screws M8x35L 1

141 Hex bolts M8x20L 1

142 8 at pad 1

143 Adjustment lm TT520080 1

144 A type 6x6x12 at key 1

145 axis TT520140 1

146 Fixed seat TT520070 1

147 16 large at pads 1

148 M6x6 set screw 1

149 Adjustment lever TT520370 1

150 plastic ball TT520320 1

151 Left and right adjustment

seat TT520360 1

152 Socket head bolt M8x30L 1

153 ¢ 8 spring pad 1

154 Hexagon pan head screws M8x20L 1

15.

FLOOR MODEL

PARTS DIAGRAMS

UPPER BODY MACHINE ASSEMBLY

158

157

155

156

159

163

164

165

214

215

216

217

210

211

212

213

204

205

206

207

208

209

218

:

:

:

:

:

:

SECTION NAME

DRW No.

Designer

Check

Review

Scale

Date

-- --

-- --

-- --

-- --

-- --

-- --

-- --

-- --

-- --

-- --

-- --

-- --

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

DESCRIPTION

VERSION DESRIPTION DATE

1st Drawing 2019/05/19A

B

C

D

E

F

DESIGNER

PRODUCT NAME

UPPER

MACHINE

BODY

ASSEMBLY

FLOOR TYPE

DOUGH SHEETER

TT-D19A-1

TT-D19B-1

UPPER MACHINE

BODY ASSEMBLY

No Description Code

Qty

155 Cover TT520130 1

156 Phillips pan head screws M6x10L 1

157 Base plate TT520120 1

158 Noodle stick xing seat (left and right) TT520120-7 1

159 Motor (380V) GH28-550-17S 1

No Description Code

Qty

163 C type 7x8x30 at key 1

164 Sprocket 24T TT520520 1

165 Set screw M8x12L 1

No Description Code

Qty

204 M12 nut 1

205 ¢ 12 spring pad 1

206 ¢ 12 Flat pad 1

207 Hexagon Screw M12x40L 1

208 Motor mount TT520120-4 1

209 Fixed frame (reinforcement) TT520120-5 1

210 Brake caster 1

211 ¢ 8 at pad 1

212 ¢ 8 spring pad 1

213 Hex bolts M8x35L 1

214 M8 hat 1

215 Support frame TT520120-1 1

216 Phillips pan head screws M6x15L 1

217 Hex bolts M8x60L 1

218 Bottom plate TT520120-3 1

16.

CONVEYOR ASSEMBLY

FLOOR MODEL

PARTS DIAGRAMS

183

182

181

180

176

175 187

188

179

178

172

171

170

169

168

202

201

200

199

198

203

226

224

223

222

221

220

219

230

231

232

233 234 235 236 237

197 196 195 194 193 192

189

229

228

225

227

239 240

241

186

185

191

190

184

:

:

:

:

:

:

SECTION NAME

DRW No.

Designer

Check

Review

Scale

Date

-- --

-- --

-- --

-- --

-- --

-- --

-- --

-- --

-- --

-- --

-- --

-- --

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

DESCRIPTION

VERSION DESRIPTION DATE

1st Drawing 2019/05/19A

B

C

D

E

F

DES IGNER

PRODUCT NAME

CONVEYOR

ASSEMBLY

FLOOR TYPE

DOUGH SHEETER

TT-D19A-1

TT-D19B-1

CONVEYOR

ASSEMBLY

No Description Code

Qty

168 Cross countersunk

head screws M10x25L 1

169 Hexagon pan head

screws M10x25L 1

170 Fixed plate (left and

right) TT520530 1

171 10 spring pad 1

172 M10 nut 1

No Description Code

Qty

175 Hexagon socket

head cap screws M10x16L 1

176 Compression spring 1.0x10.4x22 1

No Description Code

Qty

178 Pallet TT520540 1

179 Tension spring 1.5x10x80 1

180 Positioning pin TT52066-3 1

181 Lower knife cover TT520680 1

182 Positioning pin TT52066-1 1

183 Hexagon socket

head cap screws M10x16L 1

184 Protection net TT520740 1

185 Protection net

rubber wheel TT520750 1

186 Hexagon socket

head cap screws M6x15L 1

187 M6 nut 1

188 Phillips pan head

screws M6x10L 1

189 Lower blade TT520690 1

190 Micro switch sleeve TT520760 1

191 10 at pad 1

192 conveyor 2160x500 1

193 Bracket plate xing

seat TT520570-2

1 Set

194 Bracket plate TT520570

195 Support plate

reinforced plate TT520570-4

196 Connector TT520560 1

197 Fixed rod TT520550-1 1

198 M10 hat 1

199 10 at pad 1

200 Upper movable pole

seat 1

201 Hexagon pan head

screws M10x40L 1

202 Movable rod TT520640 1

203 Fixed rod TT520630 1

No Description Code

Qty

219 Sheng material plate aluminum pad 1

220 Sheng block xed block (left and right) TT520580-1 1

221 Hexagon pan head screws M8x10L 1

222 M8 hat 1

223 Hexagon pan head screws M8x10L 1

224 08A 50HZ / 08A 60HZ 70/68 1

225 Powder tank TT520730 1

226 08A 62 1

227 Powder shield TT520810 1

228 Panel rubber wheel 1

229 Hexagon socket head cap screws M6x30L 1

230 Sheng material board TT520620 1

No Description Code

Qty

231 16 at pad 1

232 M16 nut 1

233 Rolling surface xing rod TT520580 1

234 20 axis circlip

1 Set

235 6004 bearing

236 Roller lever TT520610

237 Conveyor belt roller TT520600

239 Gasket TT520790 1

241 Rolling pin 1

TROUBLESHOOTING

Issue Cause Solution

The machine won’t start

The machine is not plugged in or

connected to a source of power

Check the general switch, the plug, and the

feeding cable

The voltage input is incorrect Use the proper voltage

There is another issue with the

machine

Stop using the machine immediately and

contact the manufacturer for assistance

The machine causes an

electric shock

Wires are touching the structure

of the machine

Check the wires, conrming that they are

not touching the structure of the machine

Only one set of rollers

is working

The belt is broken Change the belt

The worm wheel is worn out Change the worm wheel

The machine is making a

loud noise

Lubrication needed Check all lubrication points and add

Loose chain Check that the transmission chain is

connected. Replace if damaged

Worn out bearings Check machine bearings for any wear/tear.

Replace if damaged

7.

ITEM # COMPATIBLE ITEM # PART DIAGRAM #

348PDS67UBLD 348DSC67 Countertop Model #150

348PDS78UBLD 348DSC78 & 348DSF78 Countertop Model #150 & Floor Model #124

348PDS94UBLD 348DSF94 Floor Model #124

348PDS67LBLD 348DSC67 Countertop Model #196

348PDS78LBLD 348DSC78 & 348DSF78 Countertop Model #196 & Floor Model #189

348PDS94LBLD 348DSF94 Floor Model #189

348PDS67TANK 348DSC67 Countertop Model #215

348PDS78TANK 348DSC78 & 348DSF78 Countertop Model #215 & Floor Model #225

348PDS94TANK 348DSF94 Floor Model #225

348PDSUSPRNG 348DSC67, 348DSC78, 348DSF78, 348DSF94 Countertop Model #156 & Floor Model #108

348PDSLSPRNG 348DSC67, 348DSC78, 348DSF78, 348DSF94 Countertop Model #195 & Floor Model #179

PART NUMBERS

Other manuals for 348DSC67

2

This manual suits for next models

3

Table of contents

Other Estella Commercial Food Equipment manuals

Popular Commercial Food Equipment manuals by other brands

Igloo

Igloo SANTIAGO BEMAR Series user manual

Bartscher

Bartscher 900 SERIES Installation, use and maintenance

Studio 54

Studio 54 DAIQUIRI ECO Instructions for use

Structural Concepts

Structural Concepts GHSS476HRD.5718 user manual

Angelo Po

Angelo Po 191BR1G Use and installation manual

Hendi

Hendi THERMOSYSTEM user manual