9 / 16

7-SETTING AUTORECOGNIZED CAPACITOR BANK:

a) The controller must be set on MANUAL operation and all capacitors must be OFF.

b) Press the button for 5 seconds.

c) The display will show 6

d) The LED and will flash with intermittent of 500ms.

e) Press the button until the display show the parameters value

.

f) Press the button for 10 seconds until display will show

and start the automatic recognition of steps kvar.

This operation can take some minutes, at the end the display show

.

Warning, the load must be stable during recognition, or wrong values of steps will be set.

However, when recognition is over, you can check and set the steps manually if values are wrong.

g) Press the button for scroll through the steps and see the banks acquired.

h) If the value is wrong press the button to increase or to decrease.

i) Now press the button to save all data, the display will show

and exit the Basic set-up Menu.

All LEDs will flash for a few seconds.

ATTENTION: Capacity below 100VAR are recognized as 0.

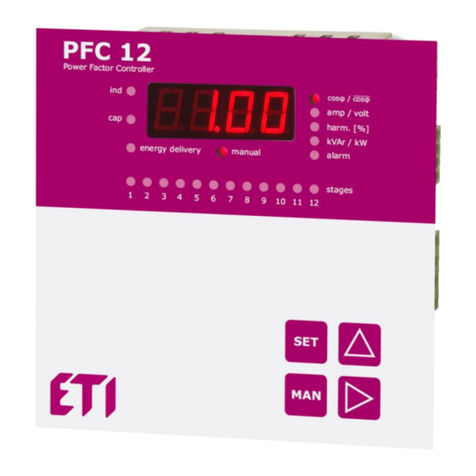

8 - MEASUREMENTS FUNCTIONS:

a) In operation mode the display shows the CosMof the installation and, if the load are inductive or capacitive .

On CosMvalue indication, if the decimal point on first digit (from left) is flashing, this is because the system working as

Generator and the sense of current is inverted (verify correct CT connection or modify parameter

.

).

b) Press the button to scroll on available measurements indicated by the related LED.

c) If a value is above 1000, the decimal point will flash. If the value is below 1000 the decimal point light is fixed.

d) Select measure, the display will show the kvar needed to achieve the CosMadjustment.

Pressing the button the display will show the correct value measured by the controller of the minimum capacitor

step set on

.

Pressing the button , the display will show the numbers of minimum step capacitor (programmed on

.

) that will

be needed to reach the desired CosM.

e) If the ∆kvar LED is ON, the installation is inductive and needs to switch on the capacitor to reach the value of CosM

programmed.

f) If the ∆kvar LED is ON, the CosMof the installation is capacitive and needs to switch off the capacitor to reduce the

CosMto the value programmed.

g) Press the button to verify the equivalent number of steps that must be switched ON (load inductive) or OFF (load

capacitive) to reach the CosMprogrammed.

h) If no button is pressed for 30 seconds, the display will return to show the CosMof the installation.

ETI Elektroelement d.d. - Slovenija

Tel.: 03/56-57-570- Fax: 03/56-74-077