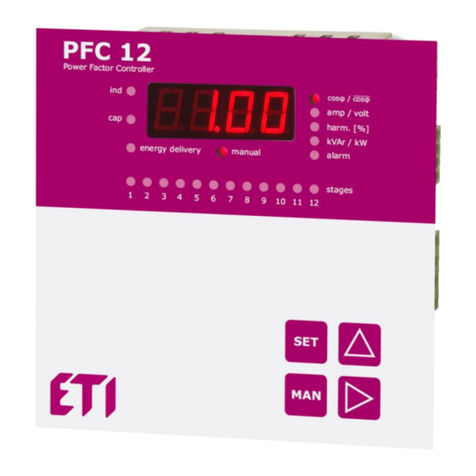

Table 3. Configuration menu

Note

Overdrive is activated by permanent pressing of button ▲or ▼.

6.1 Target cosφ setting (CoS)

Press the button SET at least for 5 second for entering service mode. On the display will appear parameter symbol

CoS. After another pressing of button SET display will show set value. Via buttons ▲, ▼ set new requested value

in the limits from 0,8 inductive to 0,8 capacitive. Another pressing of button SET saves new value to the memory

and on display it will appear again symbol CoS.

6.2 Current transformer ratio setting (Itr)

If service mode is activated, move by buttons ▲, ▼ to the parameter Itr. After pressing button SET, the set value

will appear on the display. Via buttons ▲, ▼ is possible to change value of transformer ratio. Another press of

button SET saves new value to the memory and on display, symbol Itr will appear again.

It is important to have in mind that the value which is set, is ratio itself. It means that, for example, if primary

nominal current of transformer is 50 A and secondary is 5 A then set parameter value is Itr = 10.

Caution

Measurement range of the current inputs is from 5 mA to 6 A. Maximum of the adjustable current transformer ratio is 5000

/ 5 A. If the secondary current value rises over 5,3 A, alarm will start, in the case it is enabled.

6.3 Automatic detection of compensation stages

(Aut)

Another parameter in the menu is function Aut. After pressing of button SET, the display will show oFF. Via buttons

▲, ▼ change to the value on. After the pressing of button SET automatic detection will start to detect connected

stages. The symbol Con will appear on the display, and first capacitor stage will be switched on and off 6 times in

the cycle of 20 seconds.

Detection of controller connection to the system is followed by detection of power of connected capacitor stages.

During detection, the measured values of each stage are shown on the display. Measured values are being

rounded on 0,5 kvar. After the detection is finished, the regulator will switch parameter Aut back to oFF.

Important

In some cases controller is not able to make automatic detection and in place of measured power shows zeros. It can

happen in places with very fast changes of network parameters, where measured values will not be correct. In this case

regulator shows Er1 and it is necessary to set parameters manually, after detailed network measurements.

6.4 Deceleration of regulation at over compensation (Sht)

This parameter is represented by symbol Sht. This function is used for slowing down the regulation during over-

compensation. At under-compensation regulation is slowed down according to average power factor. This function

assures reduction of switch on/off operation of contactor stages. After pressing the button SET, display will show

set value of deceleration. By buttons ▲, ▼ it is possible to change value and button SET saves this into the

memory. Current situation of regulation deceleration during over-compensation is shown under parameter Sht, in

the menu of measured values.

6.5 Manual setting of compensation stages (StP)

Entering the parameter StP by pressing button SET will open sub menu, where it is necessary to select the step,