South Bend, Indiana USA | networketi.com FPT-130 INSTALLATION MANUAL | PART NO. 25165 REV E

7

OPERATION

The FPT 130 can maintain temperatures at setpoints of

30 °F, 38 °F, 45 °F, or 50 °F (−1.1 °C, 3.3 °C, 7.2 °C, or

10 °C). The heater will energize when the temperature

drops below the designated setpoint. The heater will de-

energize when the temperature reaches 2 °F (1 °C) above

the setpoint.

The FPT 130 features ETI’s patented self–testing GFEP,

which switches the system off when it detects excessive

ground current leakage (unless Fire Protection Mode is

on). The GFEP eliminates the extra expenses associated

with having to provide external GFEP.

The FTP 130 also features a Low Current Alarm, which

switches the system off when it detects a load current

below 0.1 amps (unless Fire Protection Mode is on). The

load current is checked during each ground fault test,

and whenever the load is on. Note: the low-current alarm

takes ve seconds of low current to activate.

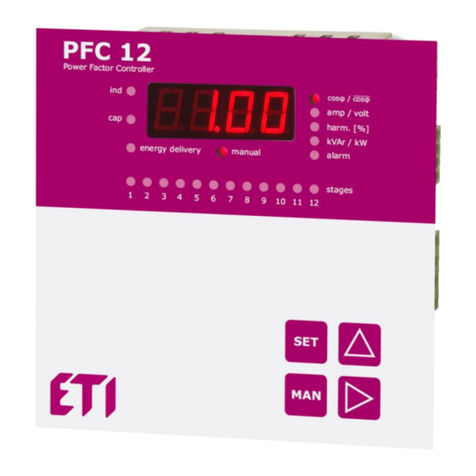

FPT 130 Front Panel

Indicator Lights (See Figure 8.)

• POWER indicator – This green LED lit solid indicates that

the FPT 130 is receiving power.

– Blinking indicates a calibration error.

• HEAT indicator – This yellow LED lit solid indicates when

the heater is energized.

– Blinking asymmetric (1/2 sec off × 1–1/2 sec on) – Low

Current Alarm, heater relay closed.

– Blinking asymmetric (1/2 sec on × 1–1/2 sec off) – Low

Current Alarm, heater relay open.

– Blinking fast – Stuck relay.

• LOW TEMP indicator – This blue LED lit solid indicates

when the temperature falls to 32 °F (0 °C) for all

setpoints except the 30 °F (-1.1 °C) setpoint. For the 30

°F (-1.1 °C) setpoint the LOW TEMP alarm will indicate

when the temperature drops to 28 °F (-2.2 °C).

– Blinking indicates sensor fault.

– Blinking fast – indicates High Temperature alarm.

• ALARM indicator – This red LED lit solid indicates when

there is a high ground fault current.

– Blinking indicates a GFEP circuit failure (this light will

also blink while system is preforming a self–test).

Pushbuttons

• TEST/RESET pushbutton – This red pushbutton has the

following functions:

– To test the ground fault detector circuit itself AND

to test for a ground fault when the heat load is not

energized (the heater will energize during the test).

Note: whenever the heat is on, the unit is continuously

checking for a ground fault.

– To reset the system after a ground fault. If the ground

fault no longer exists, then normal operation will resume.

– To reset the low-current alarm. If the load current is

still below 0.1 amps then the alarm will recur in ve

seconds. Note: the low-current alarm takes ve

seconds of low current to activate.

– Energizes heater for system testing or troubleshooting.

Pressing this pushbutton for ve seconds will energize

the heater for ve minutes. Pressing the push

button again will de-energize the heater and resume

normal operation.

Note: Because the unit has no ON/OFF power switch,

power runs to the unit as soon as facility power is

connected to it. When the unit has power, the green

POWER indicator will be lit.

FIGURE 8. FPT 130 front panel