Etrel INCH DUO User manual

Document version: 1.4

Document date: 11. 11. 2021

Etrel INCH DUO | Electrical Installation Specifics

Technical

|

TABLE OF CONTENTS

1BASIC DESCRIPTION ....................................................................1

About this Document.........................................................................1

Site Preparation .................................................................................1

Permits...............................................................................................2

Location..............................................................................................3

Required Space ..............................................................................4

Charging Station Dimensions.........................................................4

Content, Optional and Extra Equipment............................................5

Tools...................................................................................................6

2PRODUCT DESCRIPTION ..............................................................7

Components Overview ......................................................................8

Base Specifications.............................................................................8

Grid Connection.................................................................................9

Connection to the Station Operator's Communication Network..9

Circuit Diagram ................................................................................11

External Signal..................................................................................12

Digital Inputs and Digital Outputs................................................12

3CABLE CROSS-SECTION SELECTION.............................................13

Minimum Cables Cross-Section .......................................................13

Other Consumption or Production of Electricity at the Location....17

4DIMENSIONING OF A CLUSTER ..................................................19

Cabling Route for the Connection of Multiple Charging Stations....20

Cluster Cables Cross-Section............................................................22

Examples of Connection ..............................................................28

5CONNECTING CHARGING STATION ............................................34

Insertion of Cables Through the Installation Pipe ...........................34

Preparation of Cables ......................................................................35

Power Supply Compartment............................................................35

Connection of the Protective Earthing (PE).................................38

Connection of the Power Cable...................................................39

Connection of the Communication Cable (UTP)..........................39

Finishing Work .................................................................................40

6ELECTRICAL MEASUREMENTS....................................................42

Earthing Conductor Continuity test.................................................42

Insulation Resistance Measurement ...............................................43

RCD Test...........................................................................................44

Effectiveness of the Protection Against Electric Shock....................45

Earth Electrode Resistance Measurement ......................................46

7OPERATION AND CHARGING PROCEDURE..................................50

First Power up..................................................................................50

First Charging Session ......................................................................51

8CONTACT INFORMATION ..........................................................57

1 | 57

Etrel INCH DUO | Electrical Installation Specifics

Technical

|

1 BASIC DESCRIPTION

ABOUT THIS DOCUMENT

The safety and installation instructions "Quick Start Guide" that comes

with the charging station should be read first and can also help with the

installation procedure:

•Etrel_INCH_DUO_QuickStartGuide.pdf

•Etrel_INCH_DUO_QuickStartGuide_Figures.pdf

The document in front of you contains information on the specifics of

electrical installation of the INCH DUO charging station. As it is necessary

to consider the physical installation, basic information about it is also

included.

More information about physical installation is available in the document

“Physical Installation”:

•Etrel_INCH_DUO_Physical_Installation.pdf

All the documents are available in the installation manuals section,

accessible from the INCH DUO product page, at the web page

https://etrel.com/charging-solutions/inch-duo/

SITE PREPARATION

CONFIRMATION OF READINESS

Before carrying out the installation, the client must confirm his readiness

usually with a statement, that all the requirements for the preparation of

the location and additional image material are met, which allows remote

checking of compliance.

ACCESS TO INSTALLATION SITE

An access to the location should be made possible to service vehicle for

installation and servicing of charging stations.

SUPPORT DURING INSTALLATION

The responsible staff for both electricity installations and IT

communications should be present on the location or available for

immediate remote support.

2 | 57

Etrel INCH DUO | Electrical Installation Specifics

Technical

|

EXTERNAL FACTORS

Installation cannot be carried out in the event of extremely rainy or snowy

weather or other external factors that can prevent safe mounting,

installation, and commissioning of charging stations. The charging station

installation should be cancelled under such circumstances.

INSTRUCTIONS VALIDITY

The client shall check with manufacturer for the latest valid version of

instructions before the preparation of location(s) for installation of

charging stations. Please make an inquiry with the point of contact at the

retailer or manufacturer’s support of your charging station to request the

latest instructions version when necessary.

PERMITS

LOCATION AND BUILDING PERMIT

The charging station is a simple object and there is usually no need to

acquire any building permits for its installation. If the installation site is a

part of municipal property, consent of the relevant authorities must be

acquired before the charging station can be installed. Installations must

be performed in accordance with possible additional requirements of the

national regulation.

CONNECTION TO THE GRID

The charging station must be connected to the low-voltage electricity

distribution network. No special permit is required to connect to an

existing network behind the metering point. The connection can be done

by any authorised electrician. Installations must be performed in

accordance with possible additional requirements of the national

regulation.

PARKING PERMITS

Parking must be possible in the direct vicinity of the station and permitted

by the operator or owner of the parking area. Estimated time for a full

charge depends on the current state of the battery and the vehicle's

charging power. Charging procedure usually takes between 30 minutes

and up to 8 hours. Installations must be performed in accordance with

possible additional requirements of the national regulation.

3 | 57

Etrel INCH DUO | Electrical Installation Specifics

Technical

|

LOCATION

Charging station should be installed in the vicinity of the parking spot that

will be used to park and charge electric vehicles. They can have charging

socket located in various positions. Consequently, cable length to connect

EV and charging station is important.

The sufficient cable length to easily connect the electric vehicle with the

charging station, regardless of where the EV’s charging socket is located,

should be between 3 and 7 m and depends on the charging station

location in comparison to parking spot. Shorter length cables are

recommended as they are easier to handle.

Make sure that in a typical connection scenario there are no obstructions

in the way of the charging cable. When in use, the charging cable should

be laid so that it will not be stepped on, tripped over, or otherwise

subjected to damage or stress.

Charging station should be mounted so that the plug of the charging

station is located approximately 120 cm above the ground. This height

enables averagely high user the easiest operation of charging station and

connection of charging cable. It also provides best view and operation of

the LCD screen.

Etrel INCH charging station and its components (cable, casing, LCD

screen...) are developed to be installed in the outside area meaning that

charging station is resilient to the external actors (UV rays, rain, snow,

cold etc.). Installing it in the closed-up area, for example in garage, will

prolong the lifespan of the charging station and keep it in a pristine

condition for longer.

THERE IS NO FUNCTION OF VENTILATION IMPLEMENTED IN THE

CHARGING STATION.

Location of the charging station must meet the following criteria:

•The charging station must not be submersed in water or any other

fluid and should not be installed in flood risk areas.

•The operational temperature of the charging station is between

- 25°C and + 65°C.

For locations where the charging station will be exposed to direct

sunlight and high ambient temperatures during the day, it is

recommended to install protection from direct sunlight,

otherwise the temperature inside the station may exceed 65°C.

•Charging station must not be installed in explosion hazardous

areas (EX zone)

4 | 57

Etrel INCH DUO | Electrical Installation Specifics

Technical

|

REQUIRED SPACE

Basic installation of the charging station without arches requires an

excavation of minimal dimensions of 550 mm x 420 mm (floor plan) and

depth of 600 mm. If the charging station is installed together with two

safety arches, dimensions of the required dimensions are approximately

800 mm x 550 mm. Please find more information in chapter Construction

Works.

CHARGING STATION DIMENSIONS

Figure 1: INCH DUO dimensions

Additional considerations of dimensions:

•The height of the charging station is 1343 mm.

•Basic dimensions of the station's base: 272 mm x 200 mm.

•Free space needed:

o50 mm in the back.

o150 mm on the left and right side.

o500 mm at the front (140 mm for opening the station doors

and additional space to enable simple maintenance).

5 | 57

Etrel INCH DUO | Electrical Installation Specifics

Technical

|

Two air vents are built into the station, one on the top of the back side

and another in the middle of the back side. Air vents must not be blocked

or obstructed by other items or objects. When applicable, air vents must

be protected from being covered with snow.

The charging station is equipped with standard sockets (Type 2 according

to EN 61851 or EN 62196-2). Charging cables are not a part of the station's

equipment. It is expected that the users carry charging cables in their

vehicles. EV parking places must be placed within the reach of the

charging cable. Minimum length of the charging cable should be 2.5 m (in

the case of the most optimal EV parking to charge on both sockets).

CONTENT, OPTIONAL AND EXTRA EQUIPMENT

The table below shows the optional and extra equipment that can be

added to the charging station:

Optional / Extra

equipment

Use/Description

GPRS router with

network switch

GPRS router can be used for communication

for several chargers on the same location

(required for control centre connection

when local connection via Ethernet is not

possible). Network switch can be used to

connect several stations on the same

location with one router.

Safety arches

(Protective railing)

Protects the station from vehicle collisions.

Underground anchoring

structure

For safe installation of charging station and

safety arches.

Different graphical user

interface languages

Based on user identification, the station can

automatically adjust the language of the

user interface.

Visual customisation of

the station

Custom labels with client’s design,

logotypes, or promotions.

Connection of two sets

of supply wires

Special connection terminals can be used to

connect several stations in a row.

Etrel Load Guard

Enables management of charging current

based on settings in the control centre for

management of charging infrastructure.

Etrel Ocean

Control centre for management of charging

infrastructure.

6 | 57

Etrel INCH DUO | Electrical Installation Specifics

Technical

|

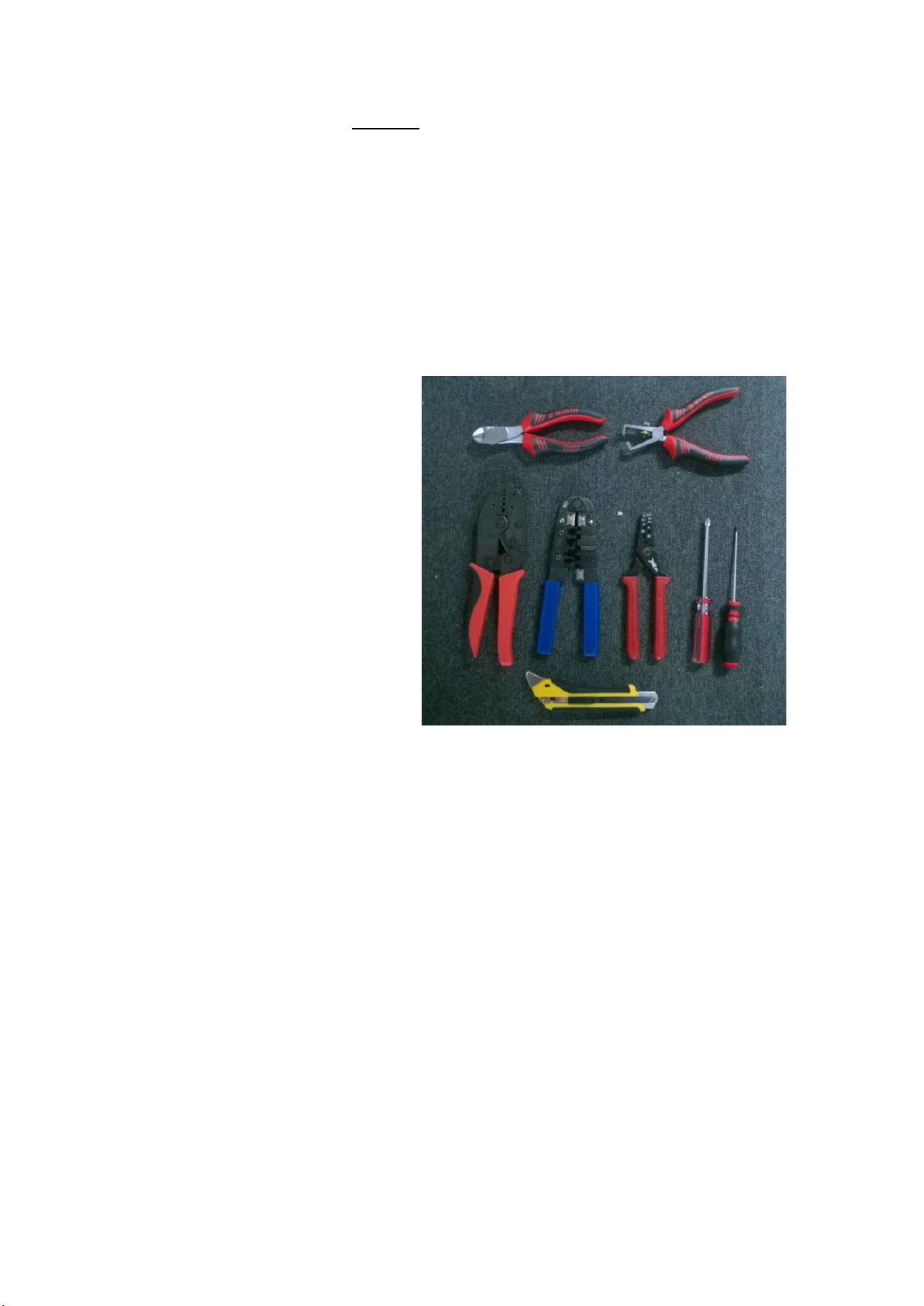

TOOLS

To execute the installation of charging station multiple tools are needed:

•Screwdriver,

•Hex screwdriver (if charging station without key lock on

maintenance doors),

•Utility knife,

•Self-adjusting crimping pliers for cables' end sleeves,

•Wire trippers and

•Cable rippers.

Figure 2: Equipment used for the installation of charging station

7 | 57

Etrel INCH DUO | Electrical Installation Specifics

Technical

|

2 PRODUCT DESCRIPTION

The Etrel’s public charging station INCH DUO is highly configurable and

can be tailored to the client’s specific needs. It allows simultaneous

charging of two vehicles with power of up to 2 x 22,08 kW and is equipped

with standard Type 2 sockets (EN 61851 or EN 62196-2).

The actual number of maximal charging power can differentiate the exact

value for one charging spot considering voltage of 230 V is 22,08 kW.

Charging is limited to 32 A, however voltage specified as 230 V, can be

between 207 V and 253 V (+- 10 %). This means that the actual charging

power can be lower or higher of the specified 22,08 kW.

Another factor heavily influencing what is the charging power is the power

factor (cos Fi), which is determined by the internal charger in the electric

vehicle. This factor is always lower than one, meaning that all power is not

active, there is also reactive component. The correct designation of

charging power would therefore be 2 x 22,08 kVA (or 44,16 kVA).

No matter the specifics, the charging power of Mode 3 charging spot is

commonly referenced as 22 kW (or 44 kW for charging station with two

charging spots). This simplification is used in this document as well.

Charging station comes with the LCD screen that guides through the

charging process and provides important charging information. Charging

station comes with several connectivity options (including LTE and

Ethernet) and open protocol support and can be seamlessly integrated in

the smart home system.

Certified utility-grade meters as well as all optional utility feeder

equipment are embedded in the station. The station can be equipped

with an RFID identification module, which prevents unauthorized use and

is necessary to enable different billing and reservation processes and

other advanced functionalities. The station also supports remote

identification with SMS or other external identification means.

The casing of the charging station is robust enough to withstand any

unfavourable weather conditions and potential damage which may occur

in open public areas. The compact dimensions of the charging station

allow its installation in a small area, for example close to the edge of the

pavement or roadside curb.

Modular design allows simple replacement of key components that can

become damaged due to wear and tear or vandalism (especially the

charging sockets). The station's service doors use a special three-point

locking mechanism. The doors open outwards and to the side to simplify

the work of maintenance staff.

8 | 57

Etrel INCH DUO | Electrical Installation Specifics

Technical

|

COMPONENTS OVERVIEW

The Etrel INCH DUO public charging station contains the following

components:

•Casing of the station,

•two charging spots (Type 2 sockets, single- or three-phase),

•main controller of the station,

•LCD display that guides user through the charging process,

•user identification module with RFID card reader,

•ethernet communication connection point,

•built-in smart energy meters for each charging spot,

•electrical protection of each socket,

•three-phase grid connection point equipped with standard safety

protection.

1

Figure 3: Arrangement of equipment inside the station

BASE SPECIFICATIONS

•Input: 2x230/400V~; 3W+N+PE; 50/60 Hz; 32 A max.

•Output: 2x230/400V~; 3W+N+PE; 50/60 Hz; 32 A max.

•Maximum charging power: 2 x 22 kW (3-phase)

•Device power consumption:

oFrom 5 W, depending on the actual configuration.

1) Grid connection of the charging

station, which contains terminals for

all supply wires (L1, L2, L3, N and

PE).

2) Energy meters for each socket. For

normal functioning of the station, a

working communication connection

between the main station controller

and the energy meters is required.

3) Differential and overcurrent

protection of each socket.

4) Module for communication with

electric vehicle (compliant with the

IEC 61851 standard), socket voltage

monitoring components, socket

contactors.

5) Main station controller with RFID

reader, RFID antenna and LCD

display, control circuit power supply,

and communication modules

(Ethernet or GPRS router).

9 | 57

Etrel INCH DUO | Electrical Installation Specifics

Technical

|

GRID CONNECTION

The charging station can be connected directly to the electricity

distribution network or to an existing electrical installation nearby. Supply

power depends on the charging power of each socket (according to the

configuration of the charging station).

The following supply power is required:

•44 kW (64 A): 2 x three-phase charging spots, for each Type 2

socket is the maximum current 32 A per phase.

Supply power of the charging station must be dimensioned appropriately

to enable simultaneous charging of two vehicles.

Charging power of each charging spot can be limited in the settings of the

charging station on the scale between 6 A and 32 A. The charging station

can also be set up to allow local power management so that when two

vehicles are connected at the same time, the available maximum power

is divided between the two vehicles. Power management can also be

setup for a cluster of charging stations.

In the execution phase of the grid connection project, the following

requirements need to be met:

•Selectivity of the functioning of protection devices needs to be

ensured:

oThe main overcurrent protection should be at least one class

greater than the one used for the protection of the charging

station or have a higher delay.

oDifferential protection (RCD) which is used in the charging

station operates at a low current (ΔI 30 mA, without delay).

The selectivity of this protection on the level of facility is

achieved with a higher delay or a greater current differential.

•Five wires are routed to the station, including three phase wires,

grounding wire, and the neutral wire (when connecting to an

existing installation). For single phase connection (slow charging

option), only one phase wire with sufficient diameter can be

routed to the station, together with neutral and earthing

conductor. Dimensioning of the wires is determined in the project

documentation. Grounding wire must be connected to the main

grounding busbar.

CONNECTION TO THE STATION OPERATOR'S

COMMUNICATION NETWORK

The charging station uses network connection to communicate with the

Control centre to cyclically send information about its status, perform

10 | 57

Etrel INCH DUO | Electrical Installation Specifics

Technical

|

identification of users (on the Control centre level), forward events that

occur during its operation and execute billing for the services performed.

The connection also enables communication from the Control centre

towards the charging station, which enables remote access to the station

for needs of maintenance or remote control.

The charging station could require a connection to the station operator's

WAN network (charging infrastructure control centre). To access the WAN

network via an internet connection, some additional security

requirements need to be observed.

Network connection can be executed in several different ways:

•Direct connection to the station operator's WAN network.

Connection can be established directly with a UTP cable or a fibre

optic converter.

•Wireless connection. The station connects to an existing LTE

2G/3G/4G mobile network with an GPRS/UMTS router built into

the station.

Specification of frequency bands and transmitting power (it is possible

that not all modules are part of an actual device).

LTE module

Frequency bands:

LTE-FDD: B1 (2100 MHz), B3 (1800

MHz), B5 (850 MHz), B7 (2600 MHz),

B8 (900 MHz), B20 (800 MHz)

LTE-TDD: B38 (2600 MHz), B40 (2300

MHz), B41 (2500 MHz)

WCDMA: B1 (2100 MHz), B5 (850

MHz), B8 (900 MHz)

GSM/EDGE: B3 (1800 MHz), B8 (900

MHz)

Transmitting power:

33dBm±2dB for GSM

24dBm+1/-3dB for WCDMA

23dBm±2dB for LTE-FDD

23dBm±2dB for LTE-TDD

LTE Router

Frequency bands:

4G (LTE-FDD): B1 (2100 MHz), B3

(1800 MHz), B5 (850 MHz), B7 (2600

MHz), B8 (900 MHz), B20 (800 MHz)

4G (LTE-TDD): B38 (2600 MHz), B40

(2300 MHz), B41 (2500 MHz)

3G: B1 (2100 MHz), B5 (850 MHz), B8

(900 MHz)

2G: B3 (1800 MHz), B8 (900 MHz)

Transmitting power:

21.9 dB

RFID module

Frequency band:

13.56 MHz (HF)

Transmitting power:

up to 8 dBm

11 | 57

Etrel INCH DUO | Electrical Installation Specifics

Technical

|

CIRCUIT DIAGRAM

12 | 57

Etrel INCH DUO | Electrical Installation Specifics

Technical

|

EXTERNAL SIGNAL

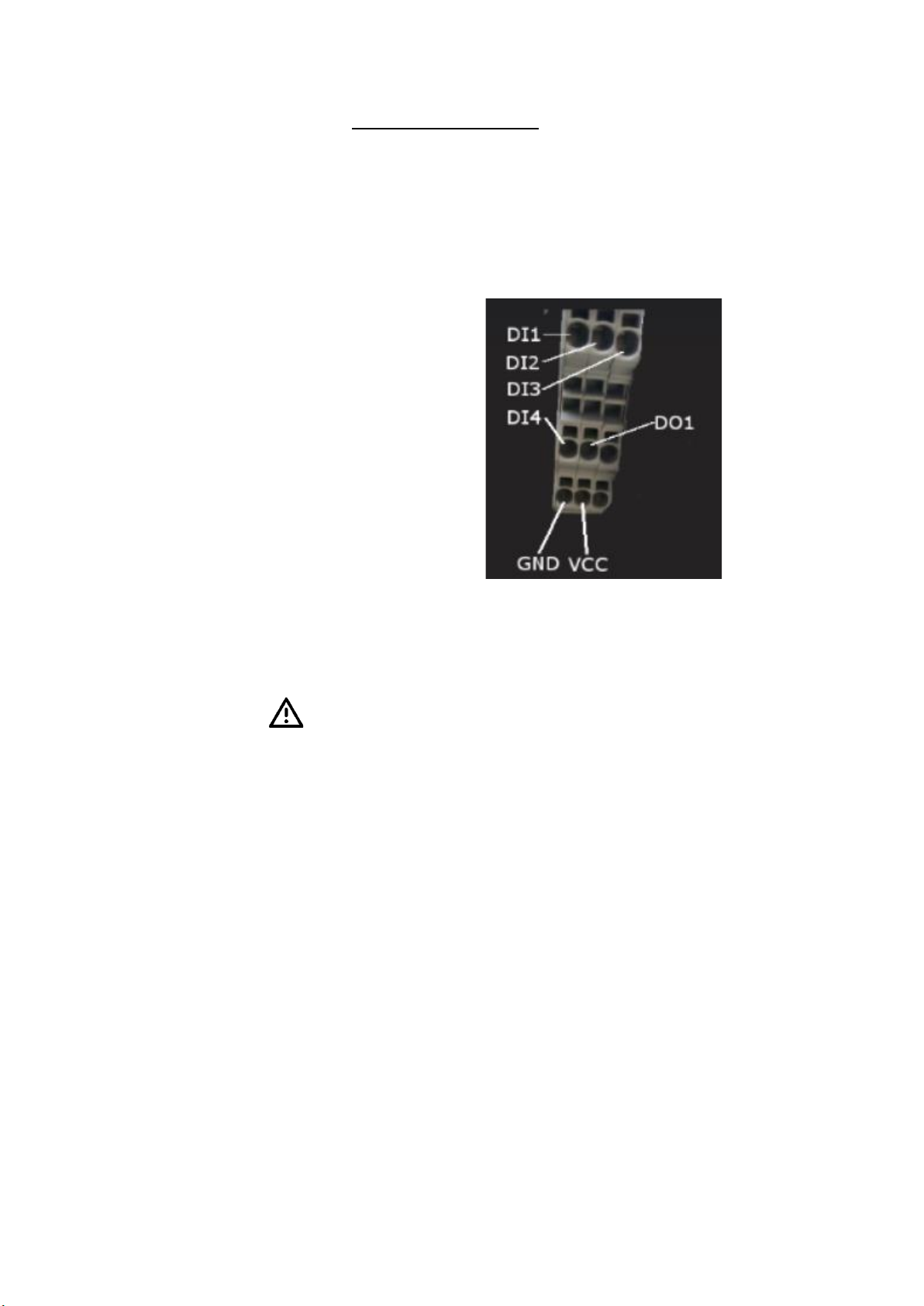

DIGITAL INPUTS AND DIGITAL OUTPUTS

Charger supports connecting four digital inputs and one digital output.

Inputs and output are operating on 12 VDC, and maximal allowed load is

100 mA. Check pinout on the image below.

Figure 4: Pins of connector for digital inputs and output

The use and logic of these digital input and outputs is settable via web

interface of the charging station.

Do not use external 12 VDC or 5 VDC for power supply. Digital output

allows maximal load of 100 mA! Be careful not to make short circuit,

which could be dangerous to persons and could also damage the

charging station.

13 | 57

Etrel INCH DUO | Electrical Installation Specifics

Technical

|

3 CABLE CROSS-SECTION SELECTION

The required cable cross-section is determined considering the maximum

current, the allowable voltage drop and the expected short-circuit

current. Cross-section can be determined by calculation or from a table,

in the usual way, in accordance with IEC 60364-5-52.

When determining the cross-section of the cables, it is also necessary to

include the method of installation, the material of the conductors and the

insulation material. The temperature conditions at the location and the

length of the cable also have an impact.

In general, the cable cross-section for the INCH DUO connection is around

10 - 25 mm2, dependant on the installation method. Larger distances or

clustering of several charging stations could require cables with larger

cross-section. Direct connection of INCH DUO is possible for cables of

cross-section of up to 50 mm2. With use of additional clamps, it is possible

to connect cables with cross-section of up to 95 mm2.

We recommend that at least the specified cable cross-section is selected

for all phase conductors, for the neutral conductor and for the protective

conductor. When choosing cables with a larger cross-section, the losses

will be smaller, which is especially important for longer cable routes.

MINIMUM CABLES CROSS-SECTION

The calculation of necessary cables cross-sections should be part of

electrical project and should consider the specifics of the actual location.

The plan of installation should be prepared by licensed electrician or

electrical planner in accordance with national legislation. Values given in

this chapter are only informational.

The cables cross-sections are determined by three criteria:

•Continuous operating current.

•Voltage drop.

•Short circuit withstand.

CONTINUOUS OPERATING CURRENT

The cross-section of cables must be large enough that continuous

charging with maximal current is safe and does not damage the cables.

Different installation options and environmental conditions are possible.

In the following table, the installation method can be checked for the

minimum cable cross-section when connecting one INCH DUO charging

station. These values apply for copper conductors with XLPE insulation at

reference air temperature of 35 ° C. For installation of cables in the

ground, temperature of the ground is set as 25 ° C and soil thermal

resistivity as 2.5 K*m/W. Charging current of 64 A is being considered.

14 | 57

Etrel INCH DUO | Electrical Installation Specifics

Technical

|

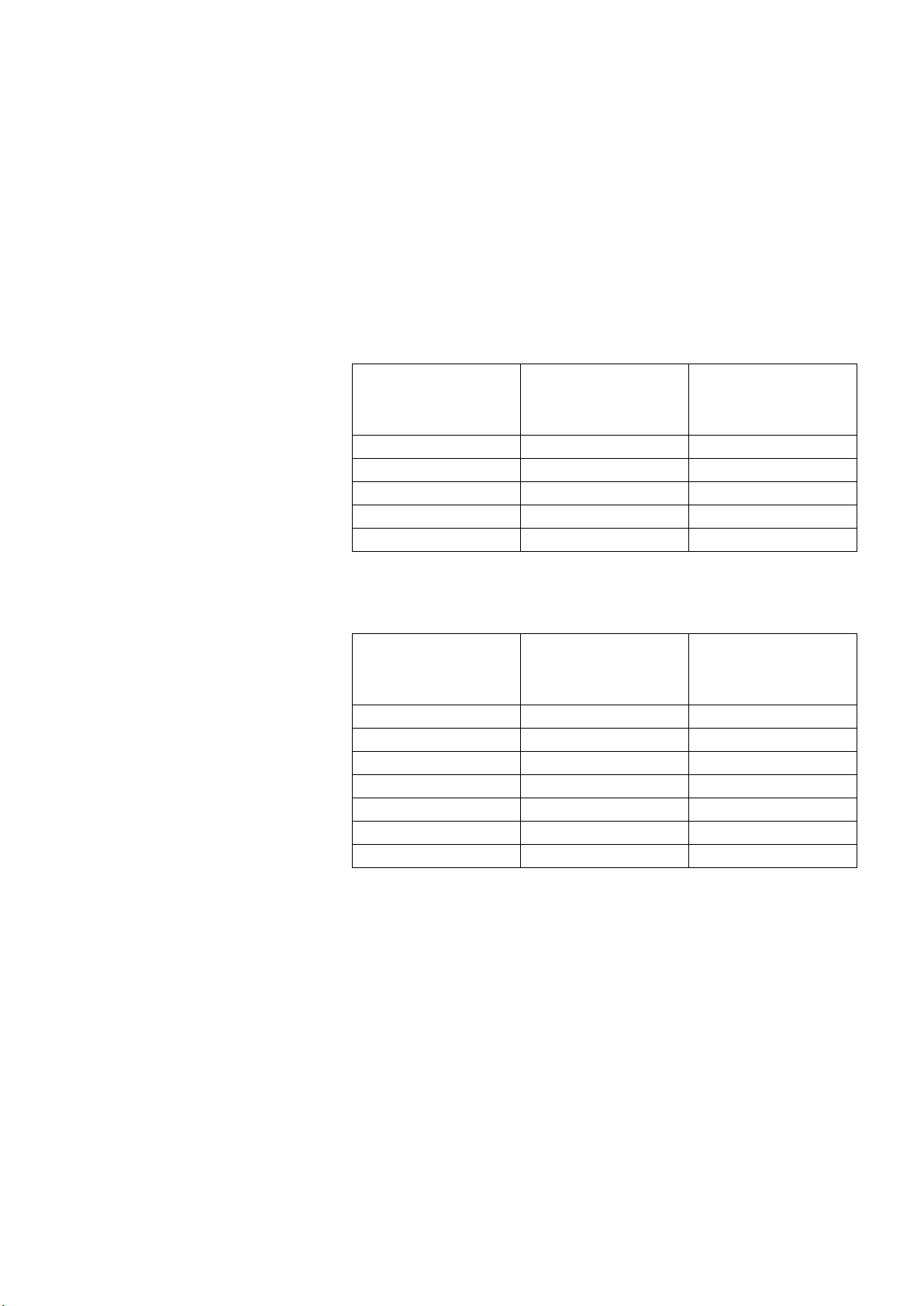

Table 1: Minimum cable cross-section for continuous operating current of 64 A.

A1 - Insulated single core conductors in conduit in a

thermally insulated wall

A2 - Multicore cable in conduit in a thermally insulated wall

This method also applies to single core or multicore cables

installed directly in a thermally insulated wall (use methods

A1 and A2 respectively), conductors installed in mouldings,

architraves and window frames.

A1, A2:

16 mm2

B1 - Insulated single core conductors in conduit on a wall

B2 - Multicore cable in conduit on a wall

This method applies when a conduit is installed inside a wall,

against a wall or spaced less than 0.3 x D (overall diameter

of the cable) from the wall. Method B also applies for cables

installed in trunking / cable duct against a wall or suspended

from a wall and cables installed in building cavities.

B1, B2:

16 mm2

C - Single core or multi-core cable on a wooden wall

This method also applies to cables fixed directly to walls or

ceilings, suspended from ceilings, installed on unperforated

cable trays (run horizontally or vertically), and installed

directly in a masonry wall (with thermal resistivity less than

2 K·m/W).

C:

10 mm2

D1 - Multicore or single core cables installed in conduit

buried in the ground

D2 - Multicore or single core cables buried directly in the

ground

D1, D2:

16 mm2

E - Multicore cable in free-air

This method applies to cables installed on cable ladder,

perforated cable tray or cleats provided that the cable is

spaced more than 0.3 x D (overall diameter of the cable)

from the wall. Note that cables installed on unperforated

cable trays are classified under Method C.

E:

10 mm2

F - Single core cables touching in free-air

This method applies to cables installed on cable ladder,

perforated cable tray or cleats provided that the cable is

spaced more than 0.3 x D (overall diameter of the cable)

from the wall. Note that cables installed on unperforated

cable trays are classified under Method C.

F:

25 mm2

G - Single-core cables laid flat and spaced in free-air

This method applies to cables installed on cable ladder,

perforated cable tray or cleats provided that the cable is

spaced more than 0.3 x D (overall diameter of the cable)

from the wall and with at least 1 x D spacings between

cables. Note that cables installed on unperforated cable

trays are classified under Method C. This method also

applies to cables installed in air supported by insulators.

G:

25 mm2

At sites, where the cross-section of already existent cables is smaller than

recommended minimum, the limitation of maximal current can be made

in the charging station’s web interface to allow the connection of charging

station, without the need to replace all the cables.

15 | 57

Etrel INCH DUO | Electrical Installation Specifics

Technical

|

VOLTAGE DROP

The requirement for the maximum voltage drop of the installation can be

different across different countries. Usually, it is required that the voltage

drop of the installation is below 4 % (or in some cases below 5 %).

The length of the conductors and charging current are major factors

determining the adequacy of cables cross-section, however voltage drop

occurs on other components or devices as well. Because of it, some

reserve should be considered when selecting cables cross-section.

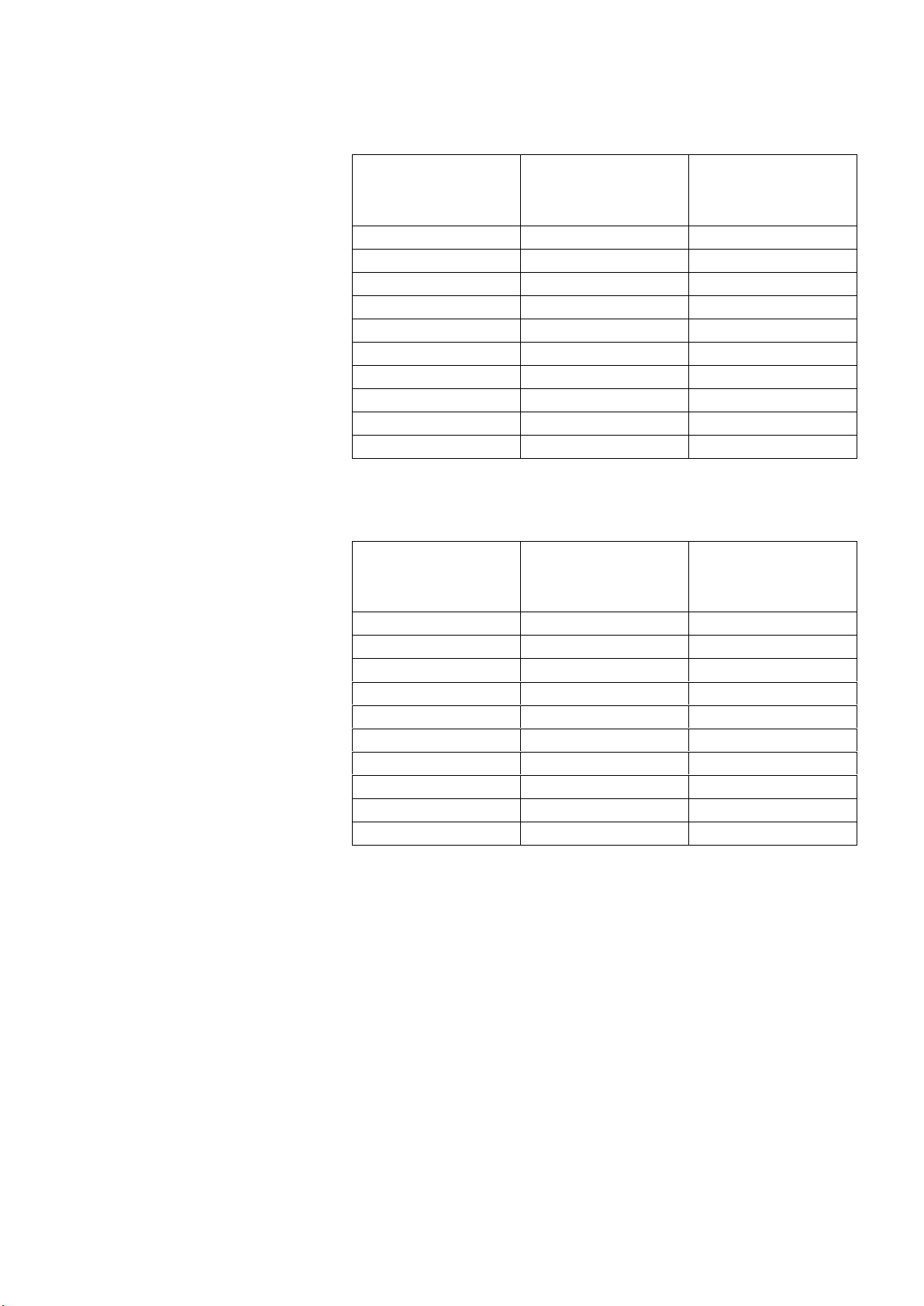

Table 2: Voltage drop in conductors with 10 mm2cable cross-section and charging

current of 64 A.

Charging current

Conductor

Conductor

64 A

10 mm2

10 mm2

Single phase

Three phase

L - length [m]

Voltage drop [%]

Voltage drop [%]

10

1,09

0,94

20

2,18

1,88

30

3,26

2,83

40

4,35

3,77

Table 3: Voltage drop in conductors with 16 mm2cable cross-section and charging

current of 64 A.

Charging current

Conductor

Conductor

64 A

16 mm2

16 mm2

Single phase

Three phase

L - length [m]

Voltage drop [%]

Voltage drop [%]

10

0,69

0,60

20

1,38

1,19

30

2,07

1,79

40

2,75

2,39

50

3,44

2,98

60

4,13

3,58

Lower voltage drop also means that the power losses of charging process

will be lower. The life cycle assessment and calculation of benefit of using

cables with larger cross-section could help mitigate the higher cost of

investment.

16 | 57

Etrel INCH DUO | Electrical Installation Specifics

Technical

|

Table 4: Voltage drop in conductors with 25 mm2cable cross-section and charging

current of 64 A.

Charging current

Conductor

Conductor

64 A

25 mm2

25 mm2

Single phase

Three phase

L - length [m]

Voltage drop [%]

Voltage drop [%]

10

0,45

0,39

20

0,90

0,78

30

1,35

1,17

40

1,80

1,56

50

2,25

1,95

60

2,70

2,33

70

3,14

2,72

80

3,59

3,11

90

4,04

3,50

Table 5: Voltage drop in conductors with 35 mm2cable cross-section and charging

current of 64 A.

Charging current

Conductor

Conductor

64 A

35 mm2

35 mm2

Single phase

Three phase

L - length [m]

Voltage drop [%]

Voltage drop [%]

40

1,31

1,13

50

1,64

1,42

60

1,97

1,70

70

2,29

1,99

80

2,62

2,27

90

2,95

2,55

100

3,28

2,84

110

3,60

3,12

120

3,93

3,40

SHORT CIRCUIT WITHSTAND

Charging station INCH DUO has already installed miniature circuit

breakers which protect against overload and short circuit. This protection

can also be part of installation with different tripping characteristics.

Short circuit protection lowers the possible short-circuit and its duration

that downstream installed devices can be subjected to. Normally, 2 kA

short circuit of 10 ms duration could be considered for calculations of

cables cross-section to withstand short circuit.

Cable with cross-section of 6 mm2is enough to withstand 5 kA, 20 ms.

This value suggests that short-circuit withstand will not be the strictest

criterion.

17 | 57

Etrel INCH DUO | Electrical Installation Specifics

Technical

|

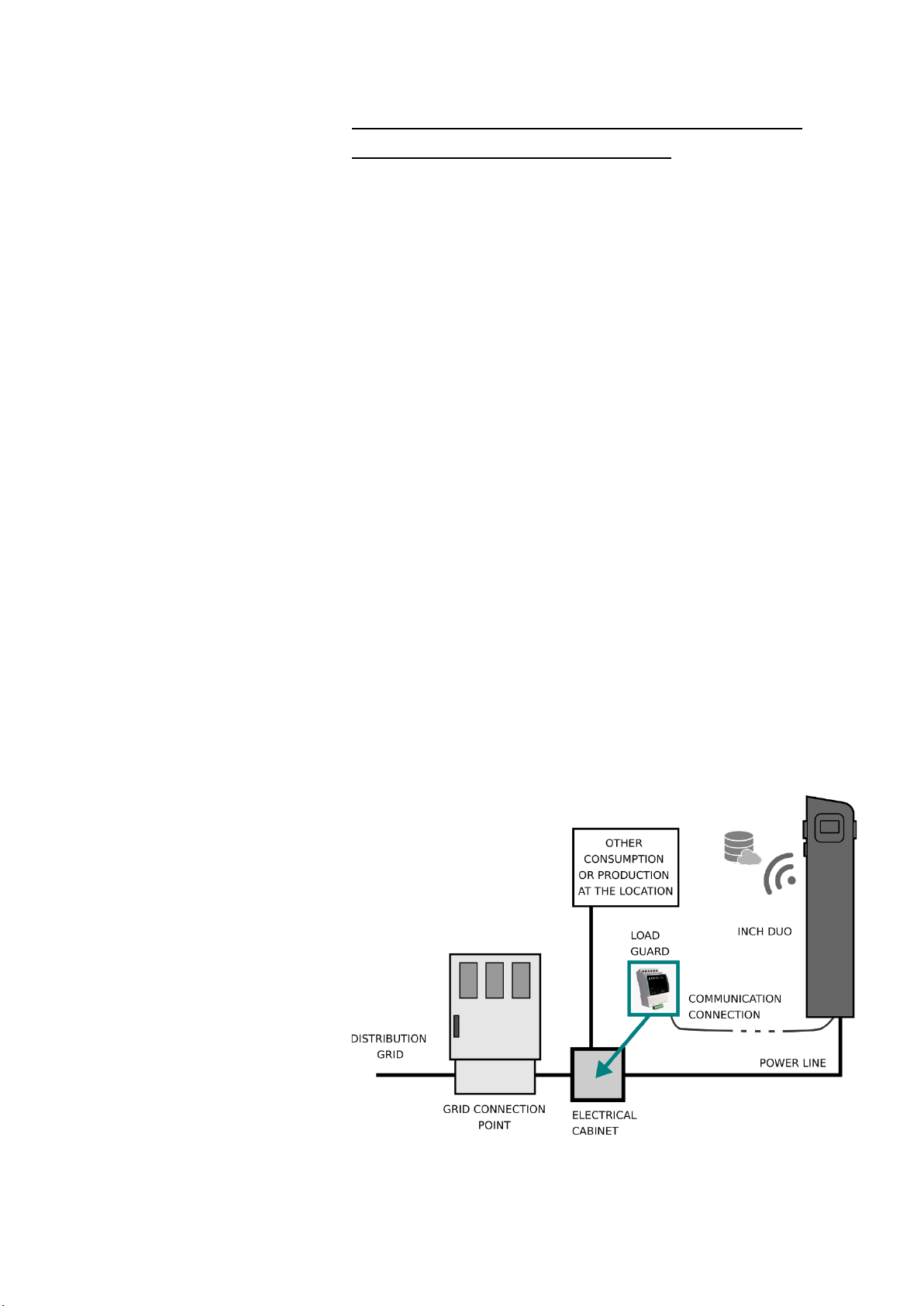

OTHER CONSUMPTION OR PRODUCTION OF

ELECTRICITY AT THE LOCATION

In cases, where there are other loads at the location and there is a

possibility that the total load (other loads + charging) overcomes the

limitation of the grid connection point, the charging should be controlled.

Because the charging station needs information of other loads (or

production) to be able to react appropriately, Etrel Load Guard device can

be used.

LOAD GUARD

By using Load Guard device, other loads or production can be measured

and used in overload prevention algorithms:

•Static limit of maximum allowed charging current per phase.

•Static limit of maximum allowed charging current per phase in

case connection with Load Guard sensor or with Back-End System

is lost.

•Detection and visualisation of available supply and automatic

adjustment of charging power.

•Detection and visualisation of surplus energy returned to the grid

(Production from renewable energy sources).

When the user connects EV to charger, and prior to beginning of charging,

the charger determines the current available for charging as the

difference between the rated current of the main fuse (reduced by a

safety margin that can be pre-set by the user via charger’s web interface)

and the last measurement received from Load guard.

Figure 5: Use of additional consumption data to prevent overload

18 | 57

Etrel INCH DUO | Electrical Installation Specifics

Technical

|

When there is local production of energy present at the location (e.g.,

photovoltaics), the available charging current can be higher, and the use

of Load Guard make possible to always charge with maximum available

current.

Figure 6: Use of additional consumption and production data to prevent overload

Other manuals for INCH DUO

1

Table of contents

Other Etrel Batteries Charger manuals