3

1.0 INTRODUCTION

The rapid advancement in the electronics industry during the past decade has placed

increasing importance on the understanding of electrostatics and its effect on electronic

devices and systems. Electrostatic Discharge (ESD) is a common cause of

microelectronic circuit failure. Many of these devices can be seriously damaged or

destroyed by an electrostatic discharge below 30 Volts, or as a result of an electrostatic

field of only a few hundred Volts.

The static shielding bag was developed to provide a package that would protect static

sensitive components placed inside from external ESD events. Many different bag

constructions are now available that, when properly used, provide a Faraday cage

(electrostatic field attenuation) around the objects placed inside.

The most common bags are constructed from transparent polyethylene film with a

metalized layer of mylar laminated to either the outside or the inside of the bag. The

metalized side is either on the outside (metal out) or buried between the mylar and the

polyethylene film (metal in or buried metal layer). The metalized layer that provides the

shield is usually aluminum or nickel with a thickness limited to approximately 100

Angstroms to maintain bag transparency. Other constructions are available, however,

that consist of carbon grids or conductive fibers such as carbon or copper. Static

shielding is also provided by nontransparent bags that are either carbon loaded

polyethylene or foil laminated such as the MIL PRF 81705D Type I water vapor-proof

shielded bag.

In selecting the correct bag for a given application, consideration must be given to

whether the product being sensitive. The ability of the bag not to charge the object

inside and the ability of the bag to dissipate any charge on its surface in a timely

manner when grounded must also be taken into account.

Various commercial and military specifications and test standards now exist for

evaluating the different electrical and physical characteristics of the bag and/or its

material. The static dissipative characteristics of the bag material is determined by

measuring the surface resistance is accordance with Electrostatic Discharge

Association test standard ANSI/ESD STM11.11. The antistatic (ability to resist

tribocharging) characteristic is determined using procedures outlined in ESD ADV

11.21. The Electronics Industries Association Test Standard EIA 541-1988 "Packaging

Material Standards - For The Protection Of ESD Sensitive Items" currently references

similar test methods. However, ESD Association test standards are now specified.

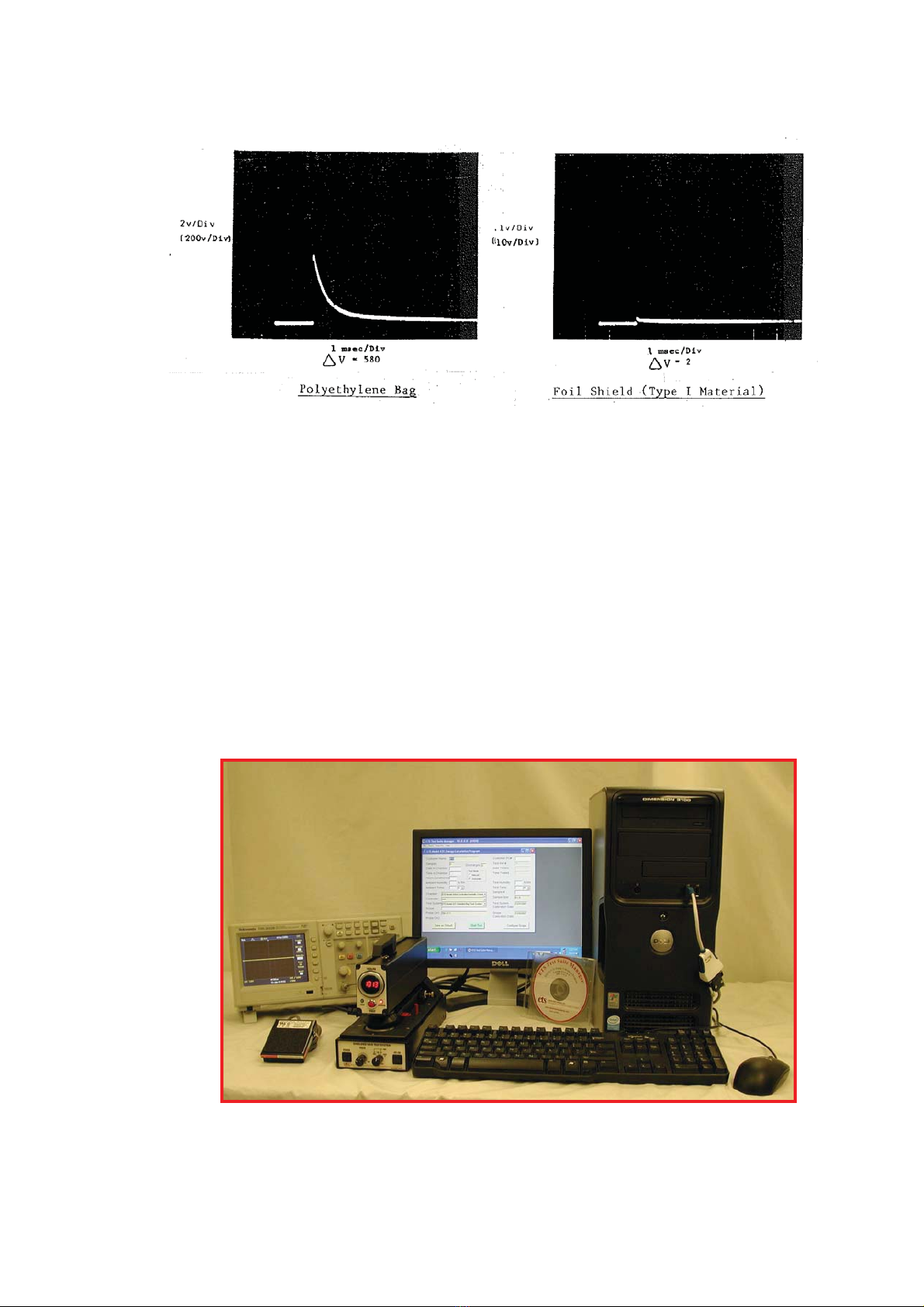

The shielding effectiveness of the bag was previously evaluated using the voltage

differential test method specified in EIA 541. However, the energy test method

specified in ANSI/ESD STM11.31 is now the preferred method. MIL PRF 81705D

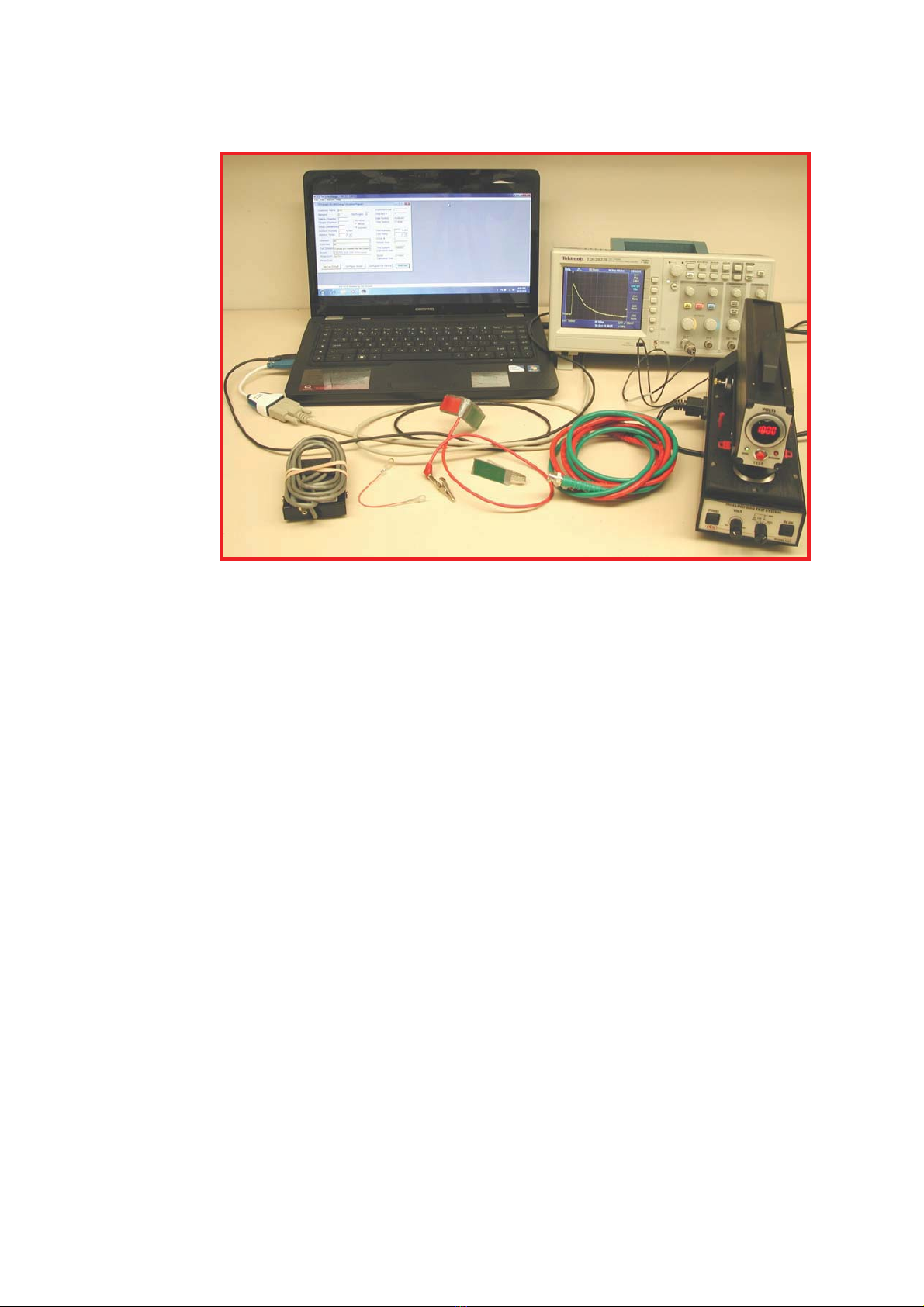

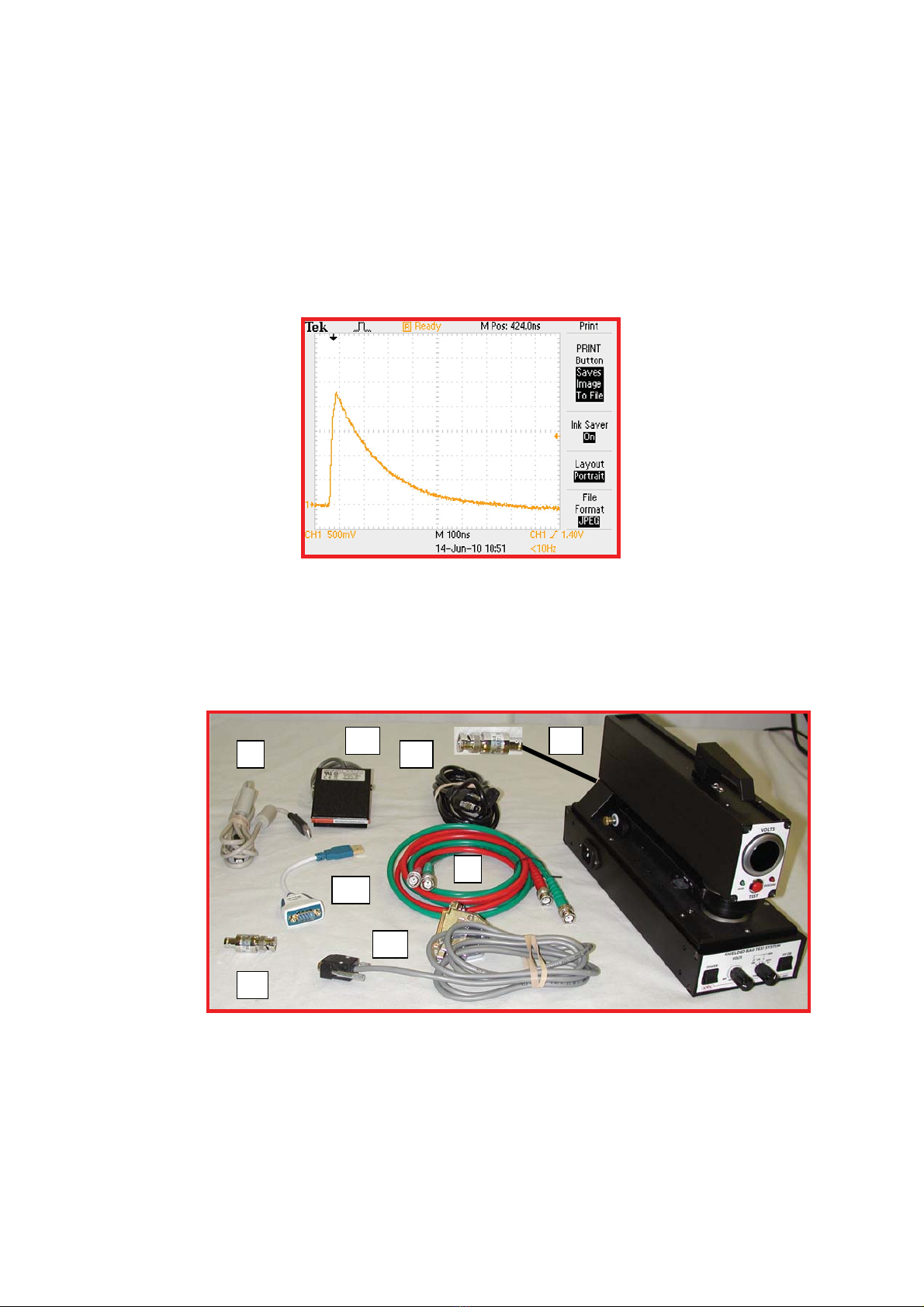

specifies the ANSI/ESD STM11.31 test. The ETS Model 4431-EV Shielded Bag Test

System meets the requirements of both test standards while the Model 4431-V

performs only the EIA 541 Voltage Differential Test. The Model 4431-EV replaces

the Model 431. Any reference in this manual that refers to the Model 431 also applies

to the Model 4431 or EV or V, unless otherwise noted.