4

Operating Instructions

Precision Single Limit Switches N01/NB01/SN01

Correct use

Precision single limit switches series N01/NB01/

SN01 are interlocking devices without guard locking

(with safety function). The actuator is uncoded (e.g.

dog). In combination with a movable safety guard

and the machine control, this safety component pre-

vents dangerous machine functions from occurring

while the safety guard is open. A stop command is

triggered if the safety guard is opened during the

dangerous machine function.

For general applications, snap-action switching

elements that are not positively driven are used. For

usage as safety switches, only the switching element

ES588 with positively driven NC contacts is allowed.

This means:

Starting commands that cause a dangerous ma-

chine function must become active only when the

safety guard is closed.

Opening the safety guard triggers a stop com-

mand.

Closing a safety guard must not cause automatic

starting of a dangerous machine function. A

separate start command must be issued. For

exceptions, refer to ENISO12100 or relevant

C-standards.

Devices from this series can be used as safe position

encoders.

Before the device is used, a risk assessment must

be performed on the machine, e.g. in accordance

with the following standards:

ENISO13849-1, Safety of machinery – Safety-re-

lated parts of control systems – Part 1: General

principles for design

ENISO 12100, Safety of machinery – General

principles for design – Risk assessment and risk

reduction

IEC62061, Safety of machinery – Functional

safety of safety-related electrical, electronic and

programmable electronic control systems

Correct use includes observing the relevant require-

ments for installation and operation, particularly

based on the following standards:

ENISO13849-1, Safety of machinery – Safety-re-

lated parts of control systems – Part 1: General

principles for design

ENISO14119, Safety of machinery – Interlocking

devices associated with guards – Principles for

design and selection

EN60204-1, Safety of machinery – Electrical

equipment of machines.

Important!

The user is responsible for the proper integration

of the device into a safe overall system. For this

purpose, the overall system must be validated,

e.g. in accordance with ENISO13849-2.

If the simplied method according to section 6.3

of ENISO13849-1:2015 is used for determining

the Performance Level (PL), the PL might be re-

duced if several devices are connected in series.

Logical series connection of safe contacts is

possible up to PLd in certain circumstances.

More information about this is available in

ISOTR24119.

If a product data sheet is included with the prod-

uct, the information on the data sheet applies

in case of discrepancies with the operating

instructions.

Safety precautions

WARNING

Danger to life due to improper installation or due

to bypassing (tampering). Safety components

perform a personal protection function.

Safety components must not be bypassed,

turned away, removed or otherwise rendered

ineffective. On this topic pay attention in partic-

ular to the measures for reducing the possibility

of bypassing according to ENISO14119:2013,

section 7.

Mounting, electrical connection and setup only

by authorized personnel possessing special

knowledge about handling safety components.

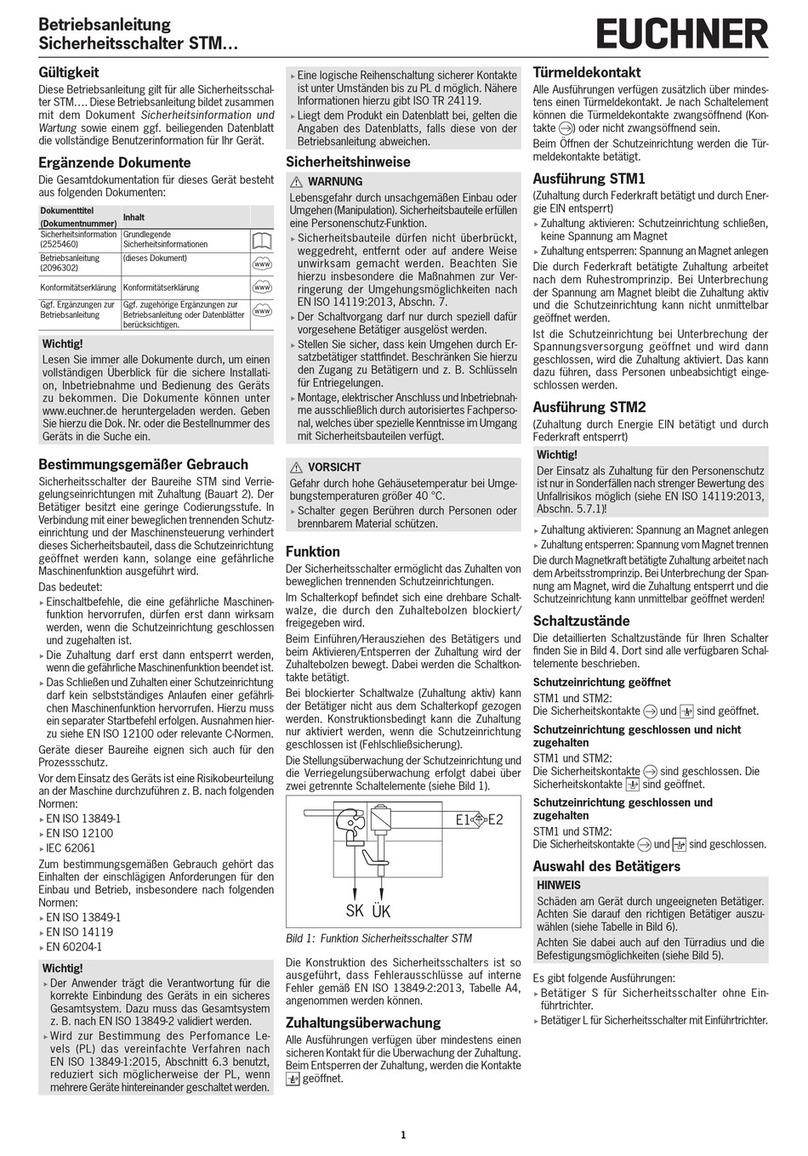

Function

Precision single limit switches are used for posi-

tioning and control applications in mechanical and

systems engineering.

The switching elements are actuated by means of

plungers. Different plunger types and trip dogs are

used depending on the application (operating point

accuracy and approach speed) (see Figure 2).

In general applications the plunger is actuated by

trip dogs in accordance with DIN 69639 which

are mounted with an interference t in trip rails in

accordance with DIN 69638.

The switching contacts are actuated when the actu-

ating element is moved from the free position to the

end position. The safety contacts are positively

opened in this process.

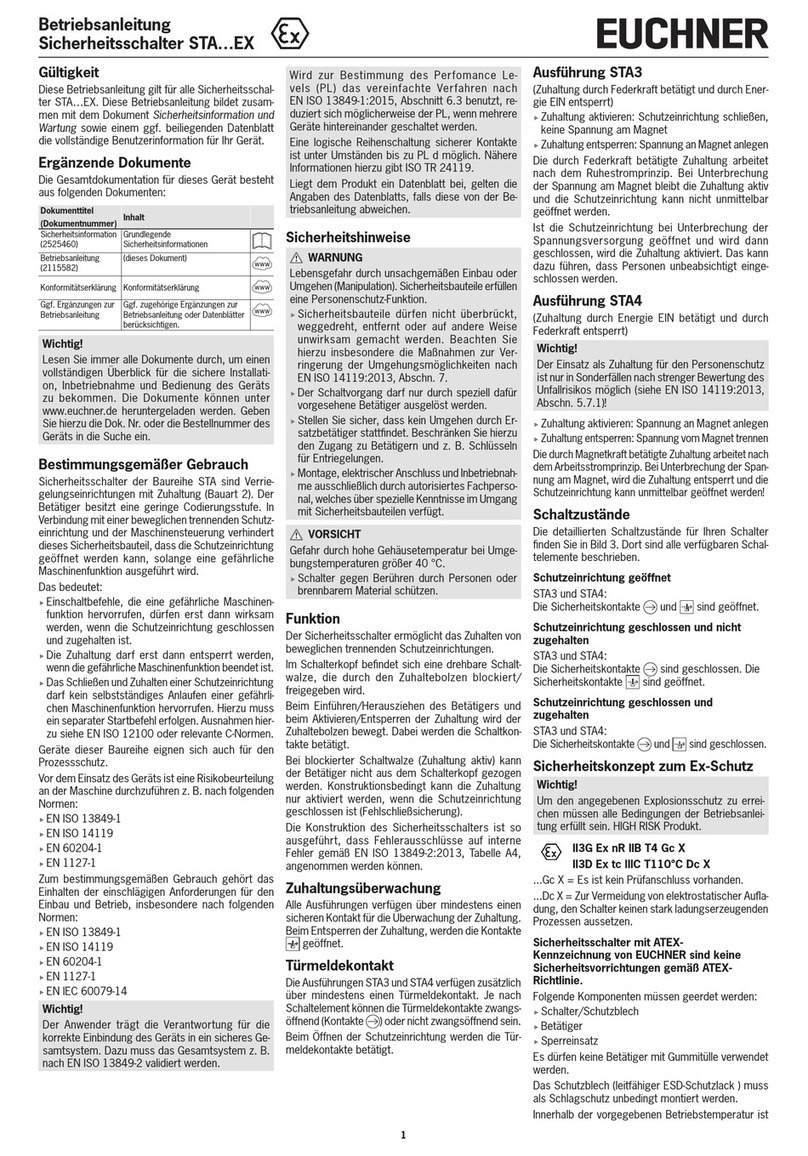

Switching states

The detailed switching states for your switch can be

found in Figure 11. All available switching elements

are described there.

Actuating element in free position

The safety contacts are closed.

Actuating element in end position

The safety contacts are open.

Mounting

NOTICE

Device damage due to improper mounting and

unsuitable ambient conditions.

Safety switches and actuators must not be used

as an end stop.

Observe ENISO14119:2013, sections 5.2 and

5.3, for information about fastening the safety

switch and the actuator.

Observe ENISO 14119:2013, section 7, for

information about reducing the possibilities for

bypassing an interlocking device.

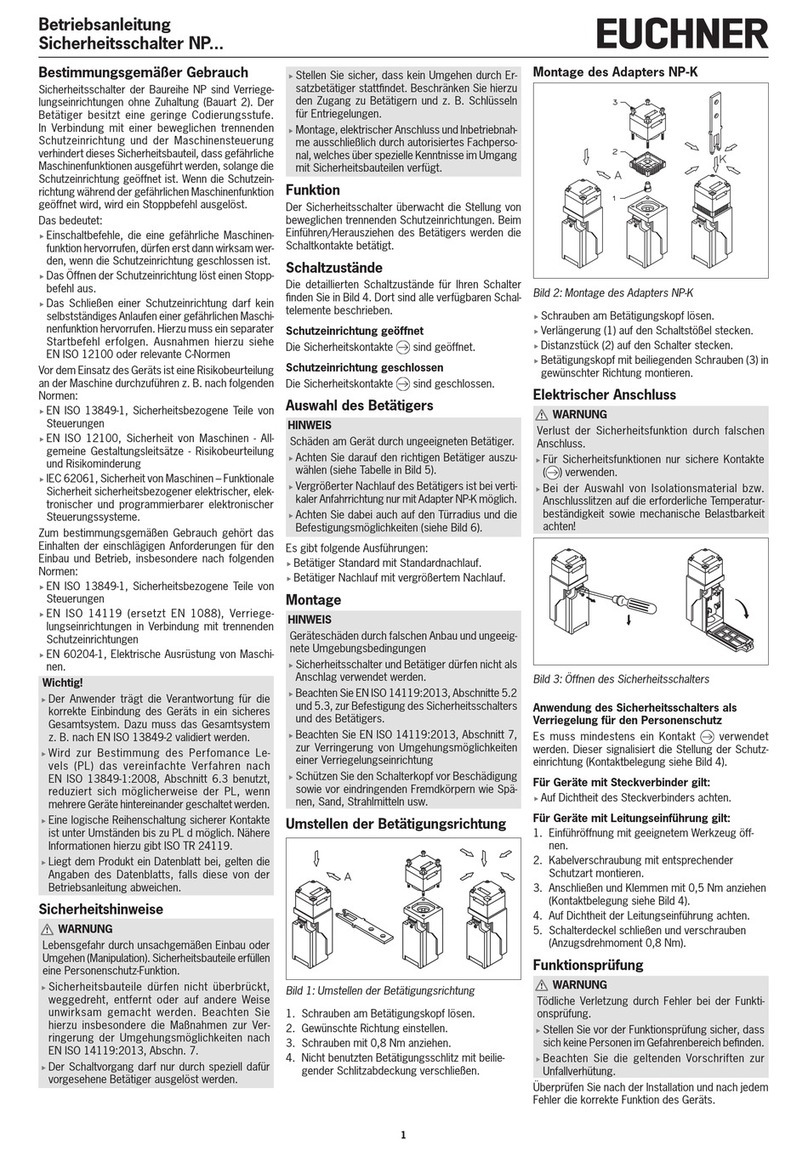

It is imperative that dimension

-0,5 (distance

from switch reference surface to trip dog, see

Figure 3) is maintained in safety circuits to ensure

safe contact opening.

Protect the switch head against damage.

Protection against environmental

inuences

Safety venting valves (see Figure 3, for example)

are used to compensate for the pumping action of

the plungers. They must not be sealed with paint.

Mask plunger, plunger guide, safety venting valves

and rating plate during painting work!

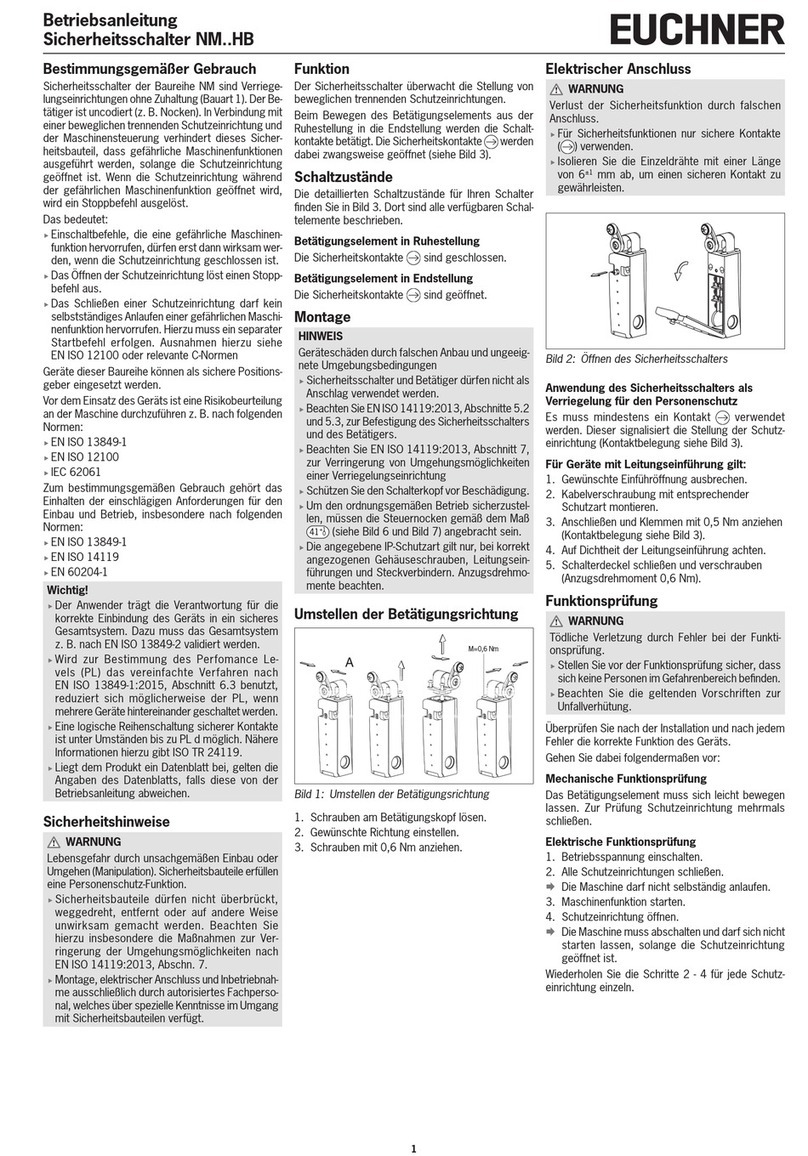

Changing the actuating direction

90°

Figure 1: Changing the actuating direction

1. Unscrew the locking screw.

2. Set the required direction.

3. Screw in the locking screw again.

Electrical connection

WARNING

Loss of the safety function due to incorrect

connection.

Use only safe contacts ( ) for safety functions.

Use of the safety switch as an interlocking

device for personnel protection

At least one contact must be used. This signals

the position of the safety guard (for terminal assign-

ment, see Figure 11).

The following information applies to devices

with plug connector:

Check that the plug connector is sealed.

The following information applies to devices

with cable entry:

1. Use a suitable tool to open the desired inser-

tion opening.

2. Fit the cable gland with the appropriate degree

of protection.

3. Connect and tighten the terminals (for terminal

assignment, see Figure 11; for tightening

torque values, see technical data).

4. Check that the cable entry is sealed.

5. Close the switch cover and screw in place

(tightening torque 0.5 Nm).

Function test

WARNING

Fatal injury due to faults during the function test.

Before carrying out the function test, make sure

that there are no persons in the danger area.

Observe the valid accident prevention regula-

tions.

Check the device for correct function after installa-

tion and after every fault.

Proceed as follows:

Mechanical function test

The actuating element must move easily. Close the

safety guard several times to check the function.

Electrical function test

1. Switch on operating voltage.

2. Close all safety guards.

The machine must not start automatically.

3. Start the machine function.

4. Open the safety guard.

The machine must switch off and it must not be

possible to start it as long as the safety guard

is open.

Repeat steps 2 - 4 for each safety guard.

Inspection and service

WARNING

Danger of severe injuries due to the loss of the

safety function.

In safety circuits, the entire switch must be re-

placed in case of damage or wear. Replacement

of individual parts or assemblies is not permitted.

Check the device for proper function at regular

intervals and after every fault. For informa-

tion about possible time intervals, refer to

ENISO14119:2013, section 8.2.

Inspection of the following is necessary to ensure

trouble-free long-term operation:

correct switching function

secure mounting of all components

precise adjustment of trip dog in relation to single

limit switch

damage, heavy contamination, dirt and wear