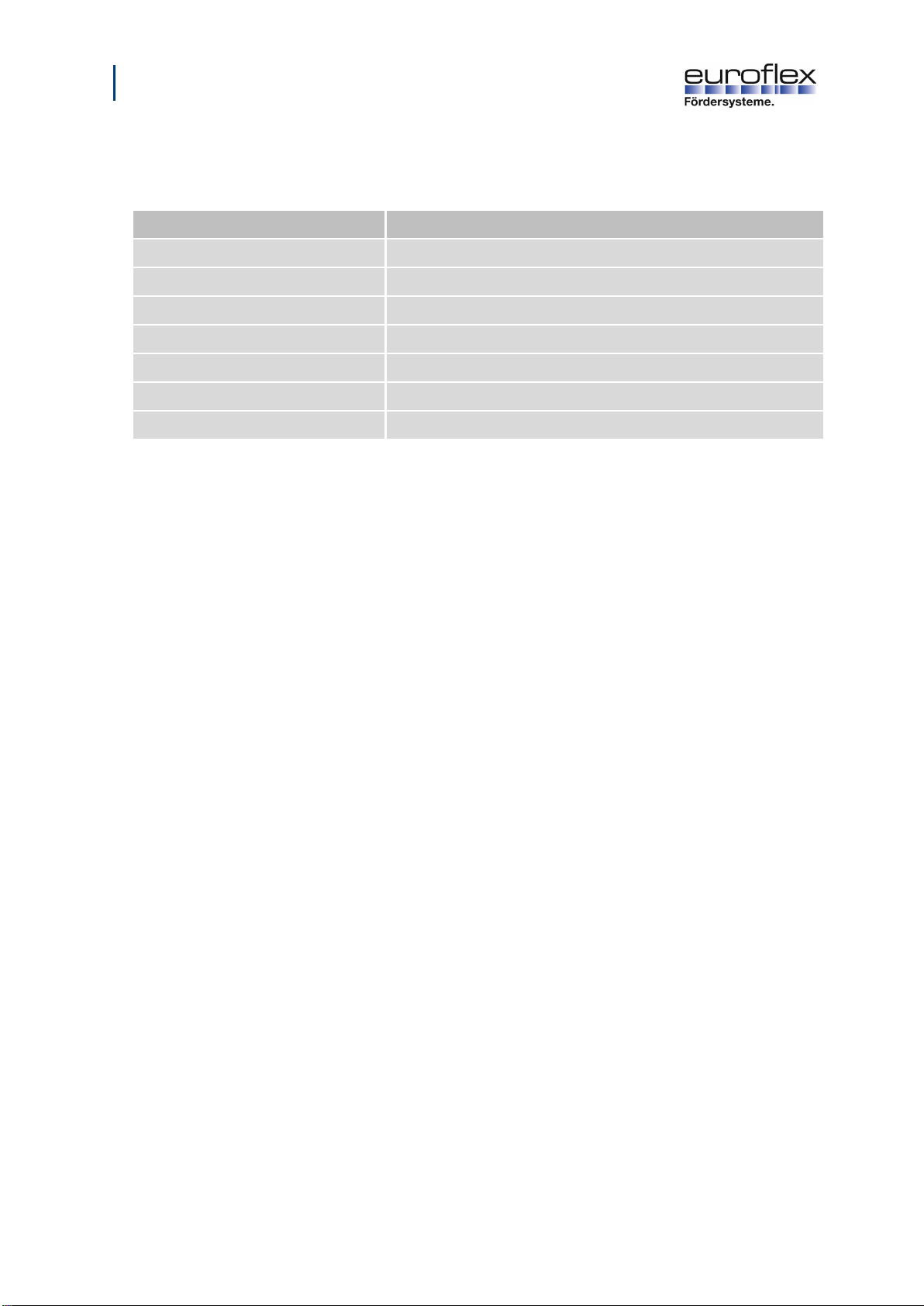

1Reader information .................................................................................................4

1.1 Target group ........................................................................................................................... 4

1.2 Customer service....................................................................................................................4

1.3 Copyright protection................................................................................................................ 4

2Safety .......................................................................................................................5

2.1 Owner...................................................................................................................................... 5

2.2 Obligations of the owner......................................................................................................... 5

2.3 Instruction of the personnel .................................................................................................... 6

2.4 Qualification requirements...................................................................................................... 6

2.4.1 Specially trained personnel.......................................................................................6

2.4.2 Operating personnel ................................................................................................. 6

2.4.3 Maintenance personnel............................................................................................. 6

2.4.4 Qualified specialist personnel ................................................................................... 6

2.4.5 Electricians................................................................................................................7

2.4.6 Specialist pneumatic personnel................................................................................ 7

2.4.7 Specialist hydraulic personnel ..................................................................................7

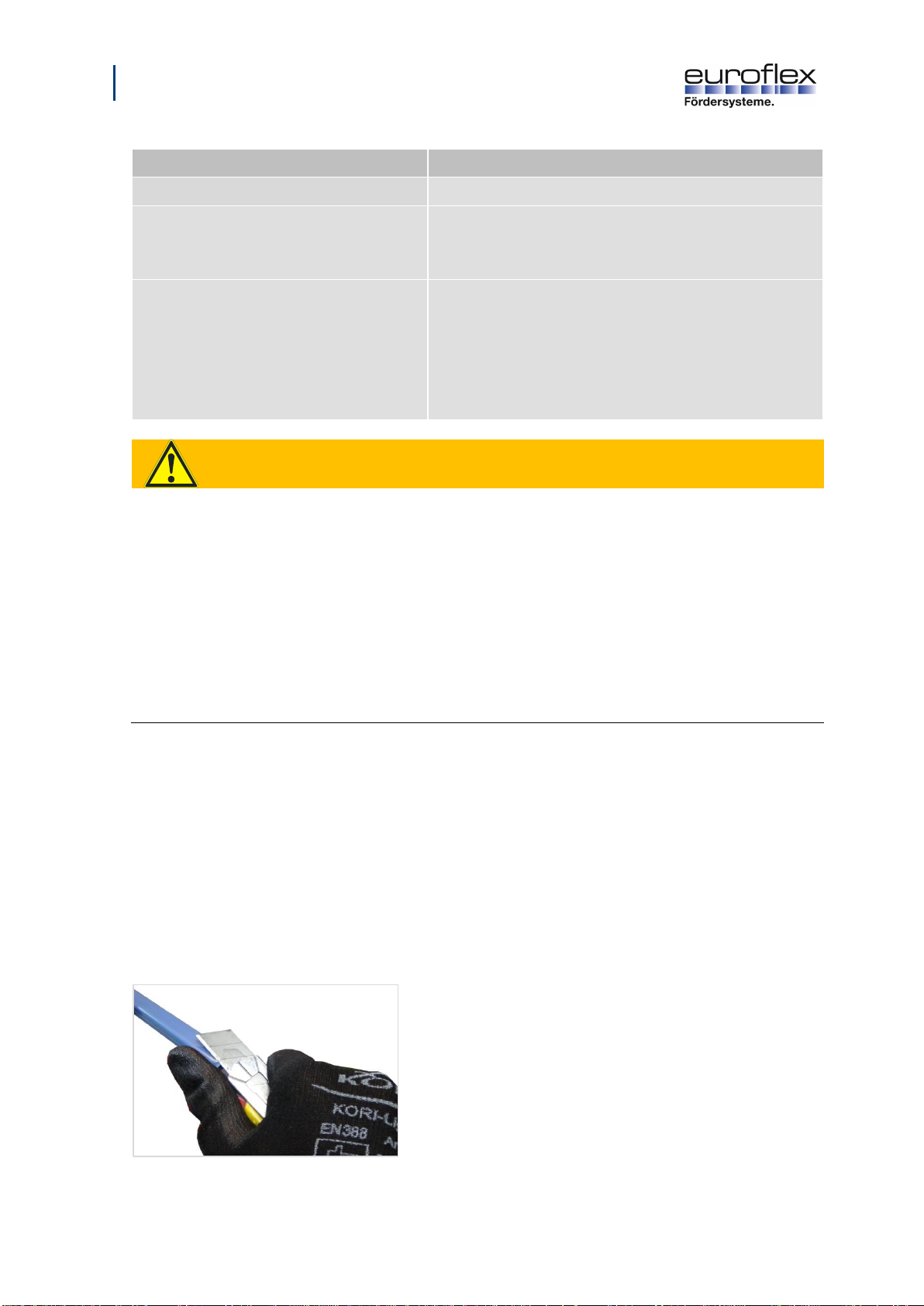

2.5 Personal protective equipment ............................................................................................... 7

2.6 Protective enclosure/Protective cover ....................................................................................7

2.7 Spare parts and their purchase .............................................................................................. 8

3Assembly.................................................................................................................9

3.1 Overview of MB-flex S aluminium........................................................................................... 9

3.2 Assembly the slide profiles on the holding profiles...............................................................10

3.2.1 Assembly the slide rails on the modular belt conveyor...... Fehler! Textmarke nicht

definiert.

3.3 Assembling the modular chain belt.......................................................................................13

4Cleaning.................................................................................................................15

4.1 Personnel and Protective equipment....................................................................................15

4.2 Selection of the cleaning agent.............................................................................................15

4.3 Preparation ...........................................................................................................................16

4.4 Execution ..............................................................................................................................16

5Maintenance ..........................................................................................................18

5.1 Lubrication ............................................................................................................................18

5.2 Maintenance plan..................................................................................................................19

5.3 Maintenance log....................................................................................................................21

5.4 Repair ...................................................................................................................................21

5.4.1 Conveyor chain: Repair or adjust the chain tension...............................................22

6Table of figures .....................................................................................................25