3 Bars indicates Battery is full (100%)

2 Bars indicates 50% of the battery life is left

1 Bar indicates 25% of the battery life is left

Blinking battery casing indicates the need to replace

batteries with fresh ones as specified by manufacturer

Electrode is not in contact with solution or electrode

is failing

Replacement sensor is not connected properly to the

tester during sensor replacement

mV calibration error while attempting to calibrate tester to a

value which is out of range

Self-Diagnostic Messages

Low battery

indicator

Or / UrOr / Ur

Or / UrOr / Ur

Or / Ur

Over range /

Under range

signal

ErEr

ErEr

Er.0.0

.0.0

.0

Error

Message

Electrode Replacement

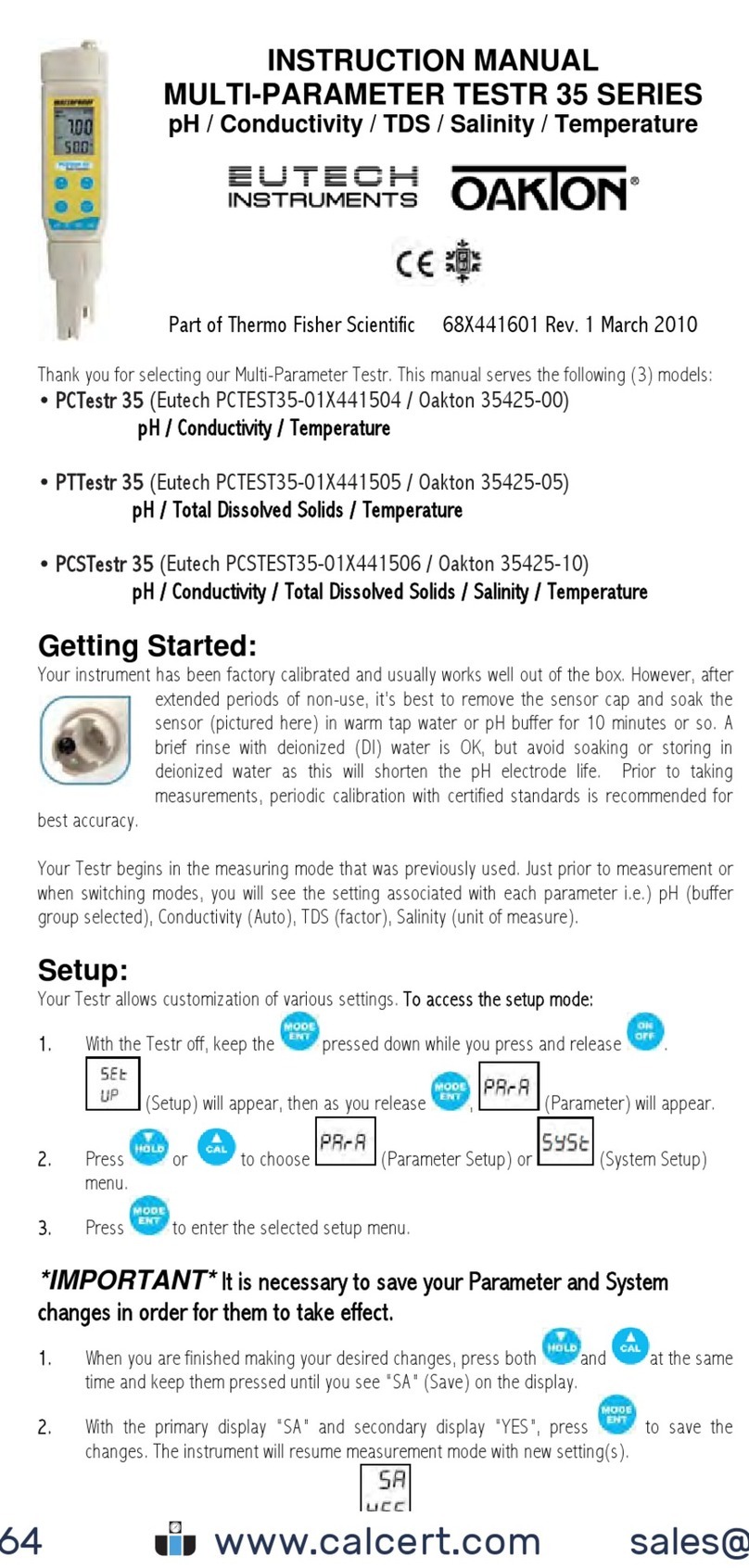

You can replace the electrode module at the fraction of the cost of a new tester.

When the tester fails to calibrate or gives fluctuating readings in calibration standards,

you need to change the electrode.

1. With dry hands, grip the ribbed tester collar with electrode facing you. Twist

the collar counter clockwise (see picture A). Save the ribbed tester collar and

O-ring for later use.3. Align the four tabs on the new module so that they

match the four slots on the tester (see picture B).

2. Pull the old electrode module away from the tester.

3. Align the four tabs on the new module so that they match the four slots on the

tester (see picture B).

4. Gently push the module onto the slots to sit it in position. Push the smaller

O-ring fully onto the new electrode module. Push the collar over the module

and thread it into place by firmly twisting clockwise.

Note: It is necessary that you recalibrate your tester prior to measurement after an

electrode replacement.

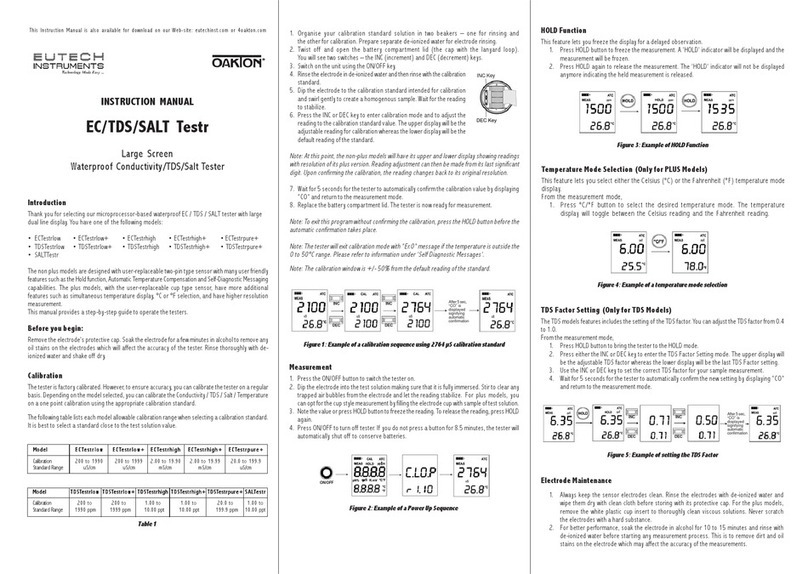

SpecificationsSpecifications

SpecificationsSpecifications

Specifications

Large Screen TesterLarge Screen Tester

Large Screen TesterLarge Screen Tester

Large Screen Tester ORPTestr10 / ORP Testr 10BNCORPTestr10 / ORP Testr 10BNC

ORPTestr10 / ORP Testr 10BNCORPTestr10 / ORP Testr 10BNC

ORPTestr10 / ORP Testr 10BNC

Range -999 mV to +1000 mV

Resolution 1mV

Accuracy ±2mV

Calibration Window Offset adjustment up to ± 150mV

Auto Off After 8.5 minutes from last key press

User Reset Yes

Non Volatile Memory Backup Yes

LCD Display Dual

Power Requirement 4 x 1.5V “A 76” micro Alkaline Batteries

Battery Life More than 500 hours

Operating Temperature 0 – 50 °C

Tester Dimension 6.5 “L x 1.5”dia. (165 x 38 mm)

Boxed: 220 x 60 x 50 mm

Weight 3.25 oz (90 gm)

Electrode Maintenance

1. Rinse the electrode with tap water or electrode storage solution after each

measurement.

2. In aggressive chemicals, dirty or viscous solutions, and solutions with heavy

metals or proteins, take readings quickly and rinse electrode immediately afterward.

3. If possible, keep a small piece of paper or sponge in the electrode cap – moistened

with clean water or electrode storage solution (NOT de-ionized water) – and close

the cap over the electrode.

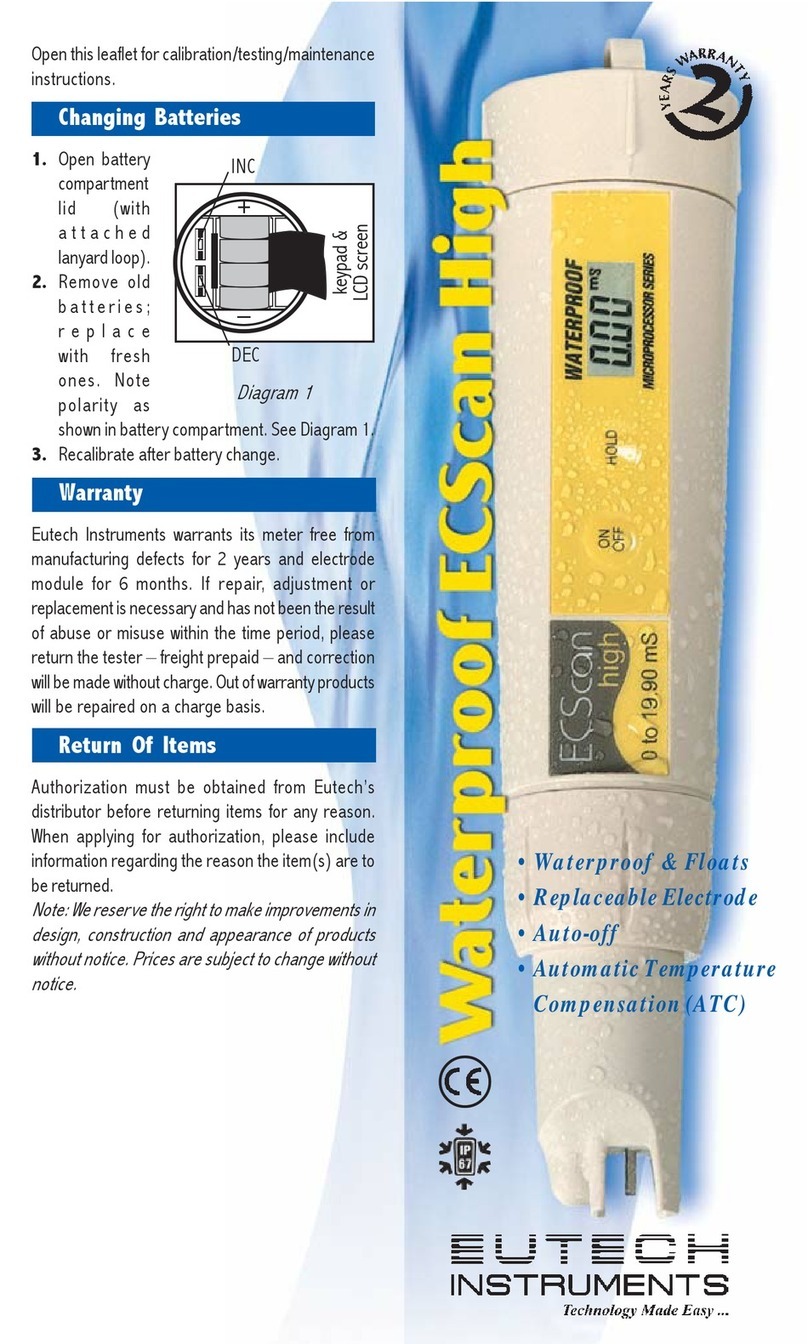

Changing Batteries

1. Open battery compartment lid (with attached lanyard loop).

2. Remove old batteries; replace with fresh ones. Note polarity.

(shown in diagram below)

Applications

Water quality testing • pools • spas • cooling towers • water purification • chromate

reduction • cyanide oxidation • boilers • pulp bleaching • ozone systems • water and

wastewater treatment • and more!

Warranty

The waterproof ORPTestr10DJ and ORPTestr10BNC are warranted to be free from

manufacturing defects for 2 years and electrode module for 6 months. If repair, adjustment

or replacement is necessary and has not been the result of abuse or misuse within the

time period, please return the tester – freight prepaid – and correction will be made

without charge. Out of warranty products will be repaired on a charge basis.

Return of Items

Authorization must be obtained from your distributor before returning items for any

reason.

When applying for authorization, please include information regarding the reason the

item(s) are to be returned.

Note: We reserve the right to make improvements in design, construction and appearance

of products without notice. Prices are subject to change without notice.

68X068043 01/04 Rev 0

Rlbbed collar

Rotate collar

away from you

Insert Electrode Module

Electrode Module

Large

O-ring

Small O-ring Small Tab Large Tab