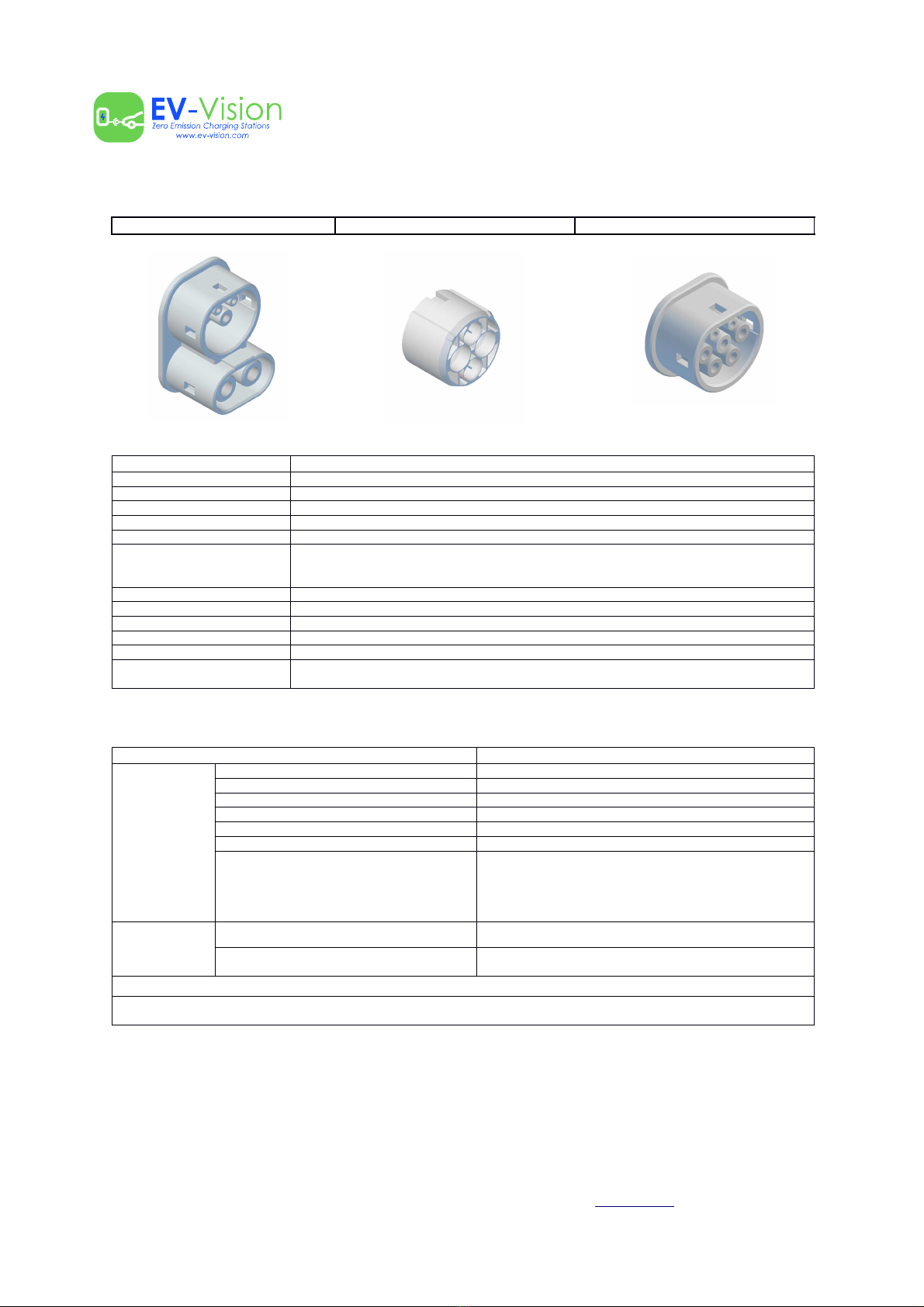

EXP120K1-HT 120KW DC Charger

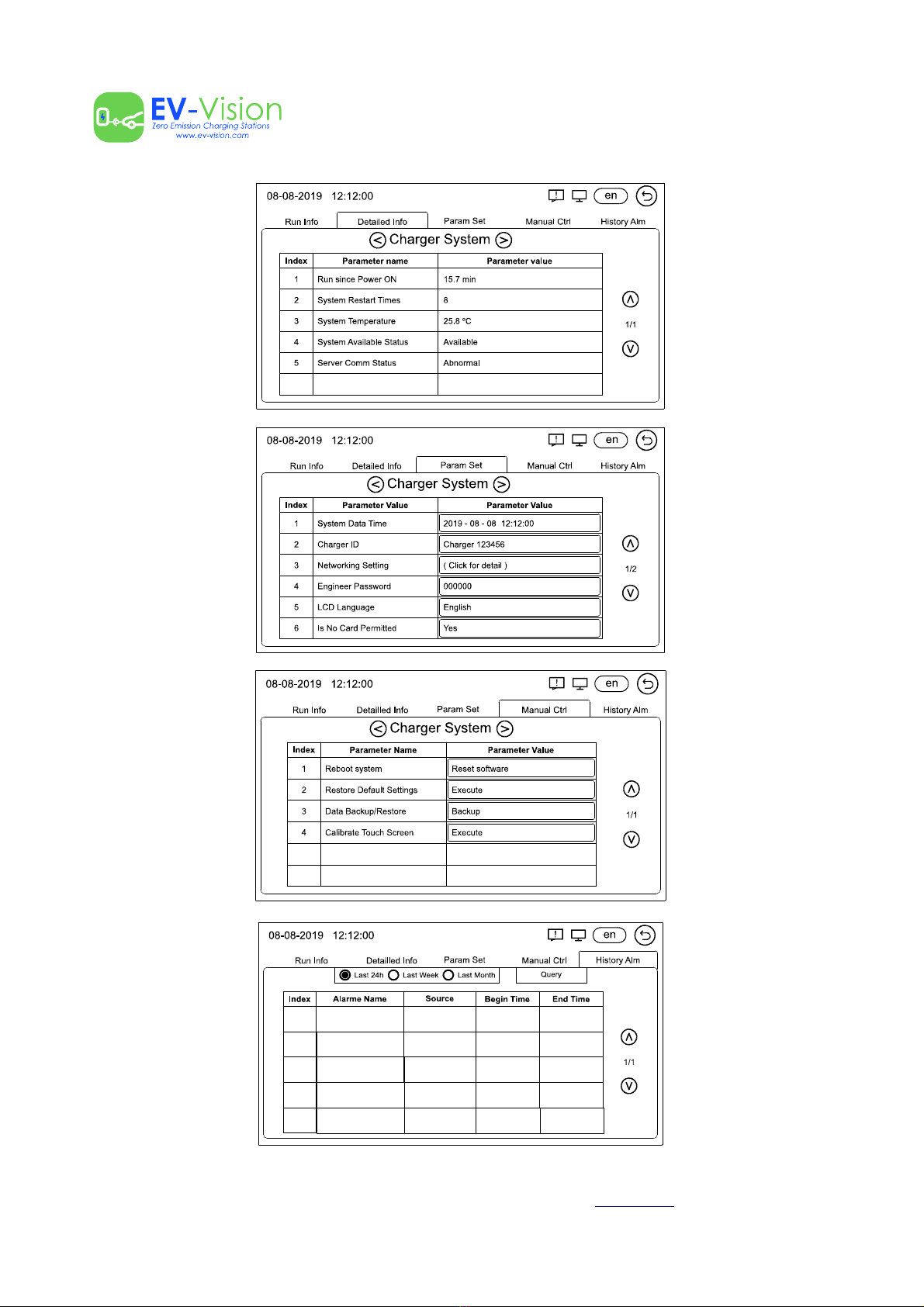

1.4 Performance indicators

Indicators Description Observations

Input number of phases Three-phase and four-line + PE

Input voltage range 400 VAC (+/-10%)

Input frequency 50 Hz/ 60Hz

Max input power 120KW + 20kW

Max input current 233A

System efficiency Total charge ≥94%

Power factor ≥0.99

Harmonic current ≤3% (under certain operating conditions)

Output current accuracy ≤±0.5%

Output current accuracy ≤±0.5%

Ripple coefficient ≤±0.2%

Current sharing ≤±3%

Ground detection ≤30mA

Noise ≤65dB (nominal input / output power, environment temperature

25°C.)

Minimum ingress protection IP 65

Operating mode Vertical operation

Maintenance access Front maintenance access for system and right-side

maintenance access for power modules.

RoHS The system meets R5 requirements in the RoHS directive

Hot plug

The system power modules are quick-connect and do not

need to restart the entire system, however the DC output must

be turned off during the entire power module exchange. After

disconnecting a power module, a break os at least 10 seconds

must be given before reconnecting it. Care should be taken

when replacing the module, inserting it slowly to avoid

mechanical damage to the pins that make the module contact

to the rest of the equipment.

AC output power 22KW

AC output voltage 400 VAC (+/- 10%)

AC output current 32A

AC connection – 1 piece Mode-3 type 2

DC output power 120KW

DC output default voltage 600Vdc (when REG75030G power module is use )

500Vdc (when REG50040G power module is use )

DC output voltage range

150Vdc~750Vdc, tolerance ± 1Vdc (when REG75030G power

module is use)

150Vdc~550Vdc, tolerance ± 1Vdc (when REG50040G power

module is use)

DC output current

Maximum load current ≤200A (when REG75030G power

module is use)

Maximum load current ≤200A (when REG50040G power

module is use)

DC connection – 2 units 2 x CCS COMBO 2 or 1 x CCS COMBO 2 + 1 x CHAdeMO

DC distribution voltage drop ≤500mV (a 25°C ambient temperature)

General IEC 61851-1-2017

IEC 62196-1-2012

Security (LV) IEC 60950-1

EMC IEC 61851-21-2

EV Vision – Porto – Portugal – www.ev-vision.com – Support service: (+351) 229 999 230

All rights reserved. This manual may be changed without prior notice. - V 1.0 – 2019/08/10 – Pag. 8 de 25

Power distribution unit

Standards System indicators