EVAPCO Eco-Air User manual

EVAPCO Controller Users Manual

Bulletin 1130

For EVAPCO Authorized Parts and Service, Contact Your Local EVAPCO

Representative or the Local Mr. GoodTower®Service Provider

EVAPCO...SPECIALISTS IN HEAT TRANSFER PRODUCTS AND SERVICES.

Visit EVAPCO’s Website at: www.evapco.com

EVAPCO, Inc. — Wo ld Headqua te s & Resea ch/Development Cente

EVAPCO, Inc. • P.O. Box 1300 • Westminster, MD 21158 USA

PHONE: 10-756-2600 • FAX: 10-756-6 50 • E-MAIL: [email protected]

EVAPCO, Inc.

Wo ld Headqua te s

P.O. Box 1300

Westminster, MD 21158 USA

Phone: 10-756-2600

Fax: 10-756-6 50

E-mail: marketing@evapco.com

EVAPCO Asia/Pacific

EVAPCO Asia/Pacific Headqua te s

1159 Luoning Rd. Baoshan Industrial Zone

Shanghai 2009 9, P.R. China

Phone: (86) 21-6687-7786

Fax: (86) 21-6687-7008

E-mail:

marketing@evapcochina.com

EVAPCO Eu ope

EVAPCO Eu ope BVBA

Eu opean Headqua te s

Heersteveldweg 19

Industrieterrein Oost

3700 Tongeren, Belgium

Phone: (32) 12-395029

Fax: (32) 12-238527

E-mail:

evapco.europe@evapco.be

EVAPCO East

5151 Allendale Lane

Taneytown, MD 21787 USA

410-756-2600 p | 410-756-6450 f

EVAPCO East

Key Building

Taneytown, MD USA

410-756-2600 p

EVAPCO Midwest

Greenup, L USA

217-923-3431 p

evapcomw@evapcomw.com

EVAPCO West

Madera, CA USA

559-673-2207 p

EVAPCO Iowa

Lake View, A USA

712-657-3223 p

EVAPCO Iowa

Sales & Engineering

Medford, MN USA

507-446-8005 p

EVAPCO ewton

Newton, L USA

618-783-3433 p

evapcomw@evapcomw.com

EVAPCOLD

Greenup, L USA

217-923-3431 p

evapcomw@evapcomw.com

EVAPCO-BLCT Dry Cooling, Inc.

1011 US Highway 22 West

Bridgewater, NJ 08807 USA

Phone: 1-908-379-2665

E-mail: [email protected]

EVAPCO-BLCT Dry Cooling, Inc.

7991 Shaffer Parkway

Littleton, CO 80127 USA

Phone: 1-908-379-2665

E-mail: [email protected]

Spare Parts Phone: 908-895-3236

Spare Parts e-mail: [email protected]

EVAPCO Power México S. de R.L. de C.V.

Calle glesia No. 2, Torre E

Tizapan San Ángel, Del. Álvaro Obregón

Ciudad de México, D.F. México 01090

Phone: +52 (55) 8421-9260

e-mail: [email protected]

Refrigeration Valves & Systems Corporation

A wh lly wned subsidiary f EVAPCO, Inc.

Bryan, TX USA

979-778-0095 p

EvapTech, Inc.

A wh lly wned subsidiary f EVAPCO, Inc.

Lenexa, KS USA

913-322-5165 p

Tower Components, Inc.

A wh lly wned subsidiary f EVAPCO, Inc.

Ramseur, NC USA

336-824-2102 p

EVAPCO Alcoil, Inc.

A wh lly wned subsidiary f EVAPCO, Inc.

York, PA USA

717-347-7500 p

EVAPCO Europe, S.r.l.

Milan, taly

(39) 02-939-9041 p

EVAPCO Europe, S.r.l.

Sondrio, taly

EVAPCO Europe GmbH

Meerbusch, Germany

(49) 2159 6956 18 p

EVAPCO Air Solutions

A wh lly wned subsidiary f EVAPCO, Inc.

Aabybro, Denmark

(45) 9824 4999 p

EVAPCO Air Solutions GmbH

Garbsen, Germany

(49) 5137 93875-0 p

Evap Egypt Engineering Industries Co.

A licensed manufacturer f EVAPCO, Inc.

Nasr City, Cairo, Egypt

2 02 24022866/2 02 24044997 p

EVAPCO S.A. (Pty.) Ltd.

A licensed manufacturer f EVAPCO, Inc.

sando 1600, Republic of South Africa

(27) 11-392-6630 p

EVAPCO (Shanghai) Refrigeration

Equipment Co., Ltd.

Baoshan ndustrial Zone Shanghai, P.R. China

(86) 21-6687-7786 p

Beijing EVAPCO Refrigeration

Equipment Co., Ltd.

Huairou District Beijing, P.R. China

010-6166-7238 p

EVAPCO Australia (Pty.) Ltd.

Riverstone NSW 2765, Australia

(61) 2 9627-3322 p

EVAPCO Composites Sdn. Bhd

Rawang, Selangor, Malaysia

(60-3) 6092-2209 p

EvapTech Asia Pacific Sdn. Bhd

A wh lly wned subsidiary f EvapTech, Inc.

Puchong, Selangor, Malaysia

(60-3) 8070-7255 p

EVAPCO No th Ame ica

EVAPCO South Ame ica

EVAPCO Brasil

Equipament s Industriais Ltda.

Al. Vênus, 151 – CEP: 13347-659

ndaiatuba –São Paulo – Brasil

(55+11) 5681-2000 p

Fan Technology Resource

Cruz das Almas – ndaiatuba

São Paulo, Brasil 13308-200

55 (11) 4025-1670

fantr@fantr.com

For eco-Air™Air Cooled and Adiabatic Fluid Coolers and Condensers

2

Controller User Manual

Table of Content

ntroduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

EVAPCO Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

nstallation and Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Panel nstallation Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Temperature/Pressure Sensor nstallation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Wiring Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Operation and Servicing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Screen Navigation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Navigating the Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Modifying a Value . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Navigating the Scheduler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Operator nterface Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Welcome Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Standby Status Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Alarms Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Main Menu Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

On/Off Unit Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

View Setpoints Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Clock/Scheduler Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

nput/Output Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Error Log Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Board Switch Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Service Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Manufacturer Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

Terminology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

Alarm Event Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

3

Controller User Manual

Introduction

EVAPCO Controller

Congratulations on the purchase of your eco-Air unit with the EVAPCO Controller. The EVAPCO Controller will ensure that your

eco-Air unit is operating in the most efficient manner possible while using minimal resources. Along with proper eco-Air unit

maintenance, the EVAPCO Controller will ensure that your eco-Air unit provide years of service at peak efficiency.

The EVAPCO Controller serves as a single connection point for the eco-Air unit and contains all of the protection and logic devices

required to run the eco-Air unit in the most efficient manner possible.

n order to reduce downtime, Evapco recommends keeping a stock of spare fuses. Consult the wiring diagram for the quantity,

type, and fuse size required. Contact your local EVAPCO representative for replacement or spare parts.

This bulletin includes a description of the screens and parameters that are available through the display located on the front of the

EVAPCO Controller. Also included in this bulletin are the functions of the EVAPCO Controller. Please note that the screens

displayed on your EVAPCO Controller display may vary slightly from the images shown in this document.

Become familiar with the EVAPCO Controller by thoroughly reading and understanding the content of this bulletin. A detailed wiring

diagram can be found in the data pocket inside of the EVAPCO Controller.

f you should require any additional information about the operation or maintenance of this equipment, contact your local EVAPCO

representative. You may also visit www.evapco.com for more information.

In tallation and Wiring

Safety

Qualified personnel should use proper care, procedures, and tools when operating, maintaining, or repairing this equipment or any

other connected equipment in order to prevent personal injury and/or property damage. The warnings listed below are to be used

as guidelines only.

Warning: EVAPCO eco-Air units should never be operated without fan screens and access doors properly secured and

in place.

Warning: Avoid working on electrical circuits while they are live. Proper lock-out/tag-out and all applicable safety

practices must be followed prior to servicing any equipment.

Warning: Before opening the panel door, allow sufficient time for VFD’s to discharge after removing power. VFD’s contain

capacitive circuits which maintain a charge even after power is removed.

Warning: The three position selector switch is not intended to replace or act as a disconnect to disable the EVAPCO

eco-Air unit and/or de-energize the EVAPCO Controller. Be sure to follow lock-out/tag-out and all applicable

electrical safety practices before servicing any equipment.

Warning: Do not attempt to service or enter the eco-Air unit even if the unit status is indicated as being off. Unless power is

completely removed from the eco-Air unit, it may be possible for the eco-Air unit to start at any time without notice.

Be sure to follow lock-out/tag-out and all applicable electrical safety practices before servicing any equipment.

4

Controller User Manual

The following safety issues need to be addressed by those responsible for the installation, maintenance, and repair of the EVAPCO

Controller:

•Access to the control panel (including the disconnect switch(es)).

• Sizing and protection of electrical circuits feeding the control panel(s) and branch circuits feeding the controlled equipment.

• Proper grounding of electrical circuits.

• Qualification of persons who will install, maintain, and service the electrical equipment.

Panel In tallation Con ideration

When the EVAPCO Controller does not ship factory mounted on the eco-Air unit, the EVAPCO Controller should be placed in close

proximity to the eco-Air unit to reduce the wire lengths required. f the EVAPCO Controller is within sight of or mounted on the eco-

Air unit, the EVAPCO Controller may be used as the main electrical disconnect for the eco-Air unit. Otherwise, separate electrical

disconnects may be required. Consult applicable electrical codes to make this determination. Avoid mounting the EVAPCO

Controller with a southern exposure. This will minimize the amount of solar heat gain the system will experience and will make it

easier to view the operator interface.

Temperature/Pre ure Sen or In tallation

EVAPCO eco-Air fluid coolers are supplied with a thermowell (1/4” G threads) and a NTC temperature sensor. The thermowell and

temperature sensor should be installed in the common return pipework of the eco-Air fluid cooler unit. Thermowells must be

installed in the horizontal sections of the coil piping. A small amount of thermal paste should be added to the thermowell before the

NTC sensor is inserted to ensure a more accurate fluid temperature measurement.

Figure 1

The suggested temperature sensor location for fluid coolers. Piping shown by dashed lines provided and installed by others.

TEMPERATURE SENSOR TEMPERATURE SENSOR

EVAPCO eco-Air condensers are supplied with a pressure transducer (7/16”-20 UNF threads). The pressure transducer should be

located in the common compressor hot gas discharge pipework. t is recommended that a shut-off valve be located between the

pipework and the pressure transducer to allow the transducer to be more easily replaced should it become damaged.

When the EVAPCO Controller ships factory mounted to the eco-Air unit, the supplied temperature or pressure sensor must be

wired to the junction box location on the connection end of the eco-Air unit (Figure 3). f the EVAPCO Controller does not ship

factory mounted, the supplied temperature or pressure sensor must be wired to the EVAPCO Controller. Consult the supplied

wiring diagram for a determination if the junction box is supplied.

Each EVAPCO Controller is supplied with one ambient air sensor that is located on the bottom of the Controller enclosure. Should

the EVAPCO Controller be placed in a location where the ambient temperature (i.e. indoors) is not indicative of the ambient

temperature of the eco-Air unit, the ambient temperature sensor must be relocated to a more suitable location and the resulting

opening in the enclosure must be sealed with a Type 4 plug.

5

Controller User Manual

Figure 2

The suggested pressure sensor location for condensers. Piping shown by dashed lines provided and installed by others.

Figure 3

The junction box is highlighted and circled.

PRESSURE SENSOR PRESSURE SENSOR

6

Controller User Manual

Wiring Con ideration

Consult the supplied wiring diagram for detailed wiring information. All field wiring is indicated by dashed lines on the wiring

diagram.

All wiring in and out of the EVAPCO Controller should be with copper conductors and wire lengths must be kept as short as

possible. Consult the detailed wiring diagram for field wiring connections of each device. Applicable electrical codes for the

location should be followed during the sizing and installation of the field wiring. All fittings attached to the EVAPCO Controller

must be Type 4. All wiring must be through the bottom of the EVAPCO Controller. Top entry into the EVAPCO Controller is

not permitted. Any damage caused to any component within or connected to the EVAPCO Controller due to a top entry

connection is not warrantable!

For wiring the EVAPCO Controller to each NEMA fan motor, Belden®VFD cable 295XX (XX denotes gauge) or equivalent should

be used. The shield of the VFD cable needs to be bonded to ground at both ends of the cable.

While the EVAPCO Controller does provide provisions for connection to a BAS, this connection is not required for the EVAPCO

Controller to operate.

Operation and Servicing

On eco-Air units equipped with NEMA fan motor(s), the EVAPCO Controller contains a three position selector switch (Bypass-Off-

Auto) located behind the HM door. The operation of each position is as follows:

Auto: The Auto position allows the EVAPCO Controller to operate the eco-Air unit based on the logic programmed into the

Controller. Note that the unit must be switched on before the eco-Air unit will begin to operate. Please see the On/Off Unit

Screen section of this document for more information.

Off: n the Off position, the EVAPCO Controller will be powered; however, output commands will not be sent to any of the

attached equipment. This position is used for programming the VFD.

Bypass: n the Bypass position, the logic program is bypassed which allows the fan motor(s) to energize independent of

sensor temperature or setpoints. Power is routed around the VFD and thus the fan motor(s) will operate at full power, across-

the-line. The VFD will still be energized when the selector switch is in the Bypass position.

The door protecting the HM must be shut unless an operator is using the HM interface. This will protect the HM interface from

contamination and increase the life of the HM .

The EVAPCO Controller is supplied with air filters that must be inspected every 90 days. Depending on the installation

environment, more frequent inspection and/or replacement may be required. A dirty filter can cause the internal panel temperature

to increase and may cause component failure. Permanently removing the filter will allow dirt and particulates to enter the enclosure

and may cause premature failure.

Please consult the proper Operation and Maintenance nstructions for start-up and maintenance guides for the eco-Air unit

attached to the EVAPCO Controller.

7

Controller User Manual

ALARM button. Direct shortcut to the Alarms Screen. This button will flash red if there is an active alarm.

PRG button (Program). Direct shortcut to the Main Menu Screen.

ESC button. Leaves a menu or an entry field without changing the value.

UP button. Scrolls up in the menu or changes a value.

E T button. Goes to the selected submenu or accepts a modified value.

DOW button. Scrolls down in the menu or changes a value.

Screen Navigation

Navigating the Di play

The operator interface contains a LED display and six buttons that allow the user to navigate the various screens as well as view

and modify several setpoints that affect the operation of the eco-Air unit.

Table 1

A description of the buttons located on the operator interface.

Button Function

Figure 4

The operator interface of the EVAPCO Controller.

8

Controller User Manual

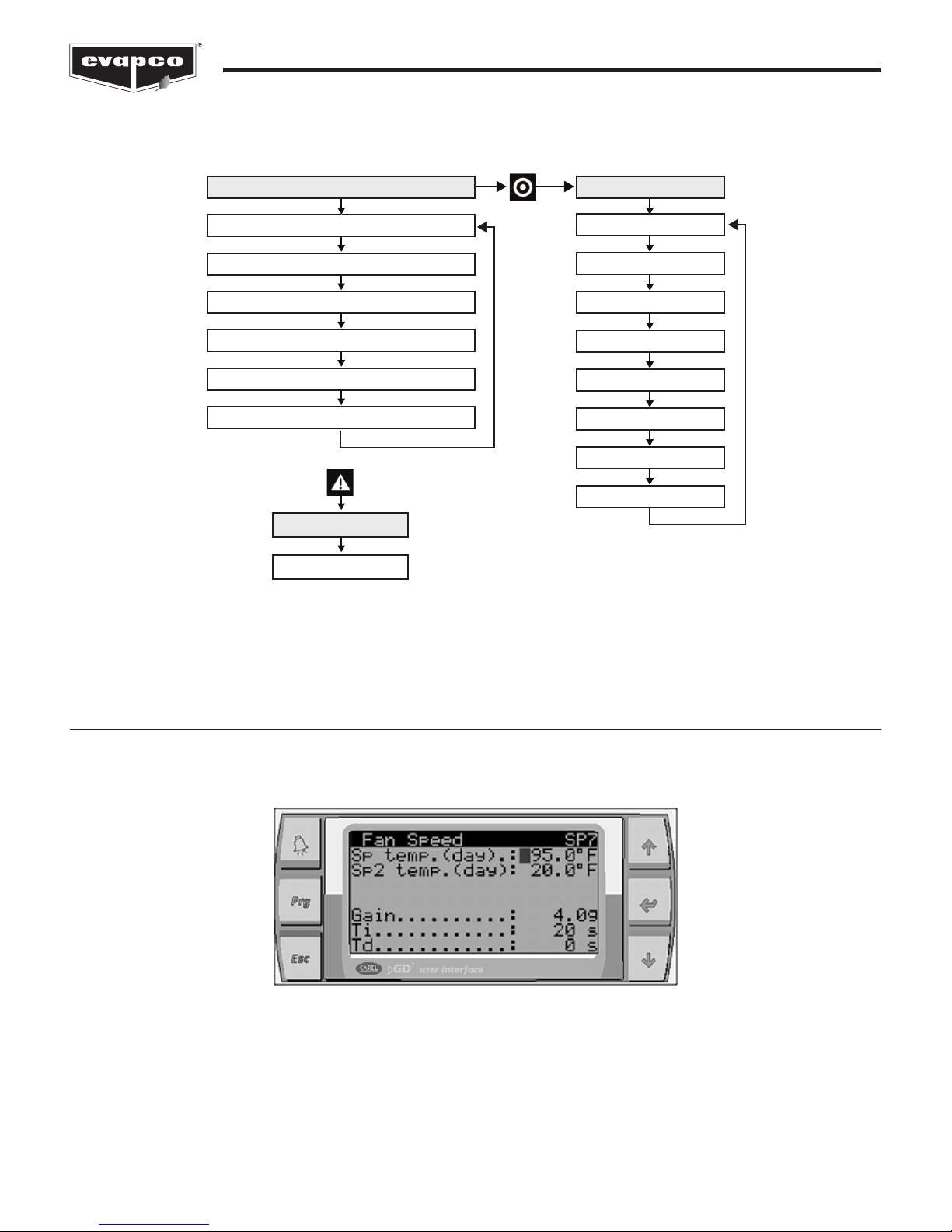

Figure 5 provides an overview of the various screens and menus of the EVAPCO Controller.

Active Alarms

Pre-Cooling Stage Rotation Screen

Flush Timer Screen

Pre-Cooling Minimum On Time Screen

Pre-Cooling Increment/Decrement Screen

Fan Motor Status Screen

Alarms Screen

Standby Screen

Standby Status Screens Main Menu Screens

A. On/Off Unit

B. View Setpoints

C. Clock/Scheduler

D. Input/Output

E. Error Log

F. Board Switch

G. Service

H. Manufacturer

Figure 5

Controller screen flowchart.

Modifying a Value

To change a parameter on a given screen, first navigate to the desired screen. n this example, the setpoint temperature will be

modified. Once at the desired screen, press the E T button.

Figure 6

The cursor next to the setpoint temperature.

9

Controller User Manual

As seen in Figure 6, the cursor (the shaded block) is next to the setpoint value. To change the value, press the UP or DOW

button. To accept the value, press the E T button.

Figure 7

The cursor moved to the next setpoint. Note that the first setpoint value has changed.

Next, press the ESC button to return to the previous menu or repeatedly press the E T button until the cursor moves to the top of

the screen.

Figure 8

The cursor is located in the top left of the screen.

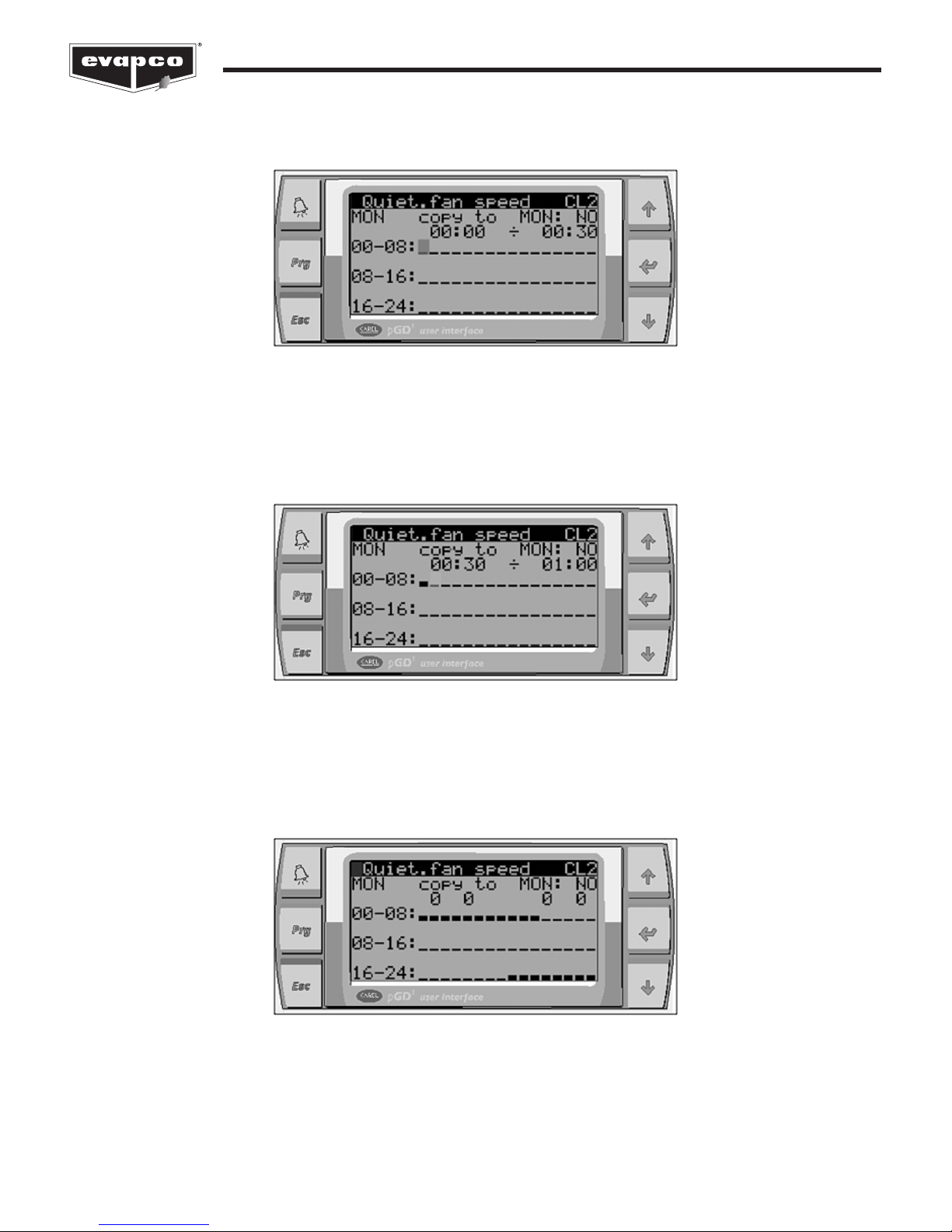

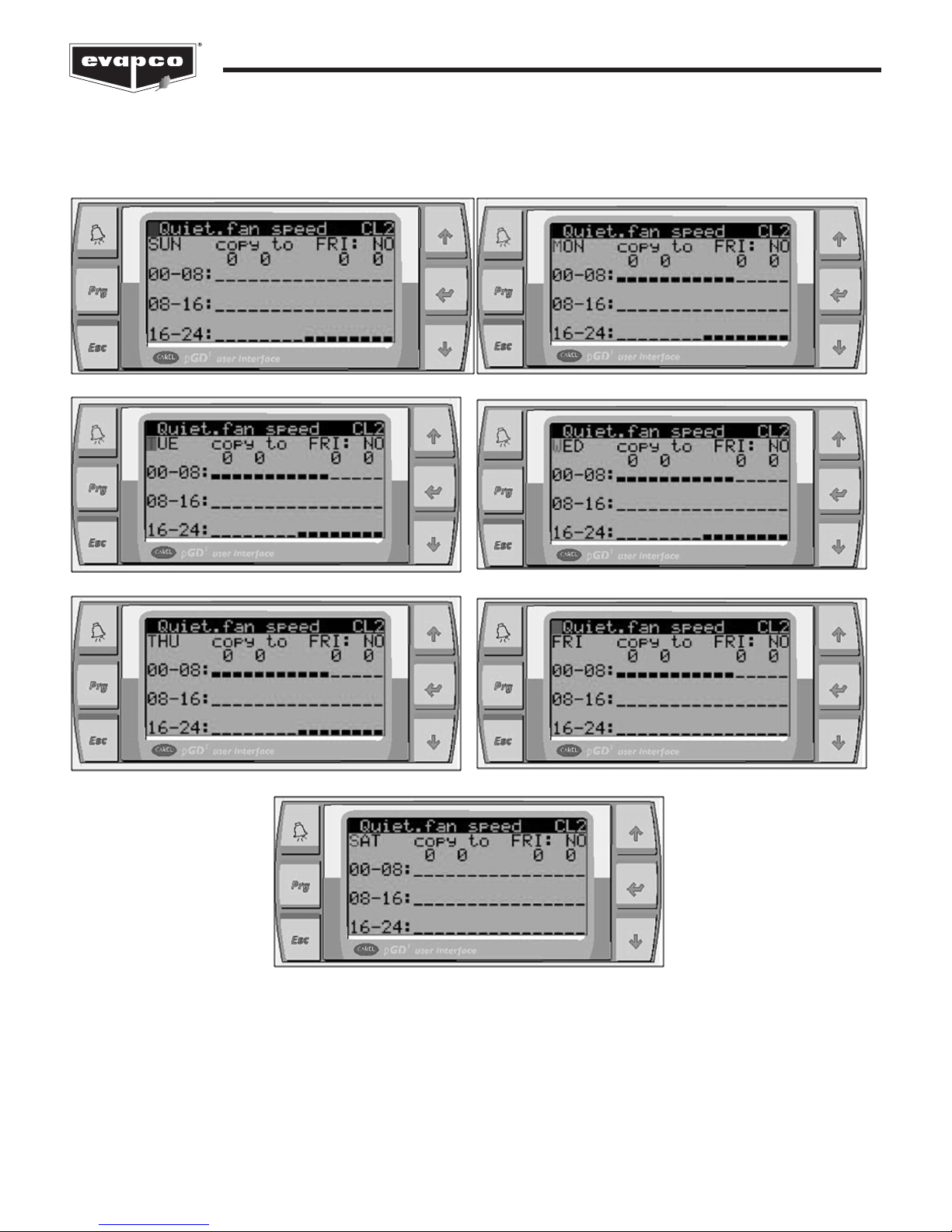

Navigating the Scheduler

Several functions of the EVAPCO Controller are able to be scheduled to operate during certain periods of the year or at certain

times of the day. n this example, consider a noise restriction from 8:00pm to 5:30am starting Sunday night and ending Friday

morning. During the noise restriction hours, the fan speed will be limited to 85% via the Quiet Mode. After navigating to the proper

scheduler, the screen shown in Figure 9 will be displayed. The day of the week is indicated in the upper left corner.

Figure 9

The Scheduler Screen.

10

Controller User Manual

Each block represents a half hour period of time. First, press the E T button four times until the first block is highlighted by the

cursor. Note that this first block represents 12:00am to 12:30am.

Figure 10

The 12:00am to 12:30am block is selected.

Press the UP or DOW button to enable the Quiet Mode during the selected period of time. The selected block will become raised

indicating that the Quiet Mode will be active. Press the E T button to move to the next half hour period (12:30am to 1:00am).

Figure 11

Quiet Mode will be active from 12:00am to 12:30am.

Continue the steps above until the desired blocks are raised. As shown in Figure 12, the Quiet Mode will be active from 12:00am to

5:30 am and 8:00pm to 12:00am on Monday.

Figure 12

Quiet Mode is active from 12:00am to 5:30am and 8:00pm to 12:00am on Monday.

11

Controller User Manual

Figure 15

Tuesday’s schedule is now the same as Monday after the copy.

This schedule for Monday now may be copied to the other days of the week. Press the E T button to place the cursor after the

c py t text shown on the display.

Next, use the UP or DOW button to change the NO to YES and press the E T button. After a few seconds, the YES will change

back to a NO, indicating that the copy was successful. Place the cursor next to the text that says MON. Press the UP or DOW

button to change the day to TUE, and press the E T button. The scheduler for Tuesday should be identical to Monday.

Figure 13

The day to copy to the current schedule to is highlighted by the cursor.

Use the UP button to change the c py t date to Tuesday and press the E T button.

Figure 14

After Selecting YES, Monday’s schedule will be copied to Tuesday.

12

Controller User Manual

Repeat the steps above until the desired scheduled is set. Below is what the schedule of each day of the week should be for this

example.

Figure 16

The Quiet Mode weekly schedule for the presented example.

13

Controller User Manual

Operator Interface Screen

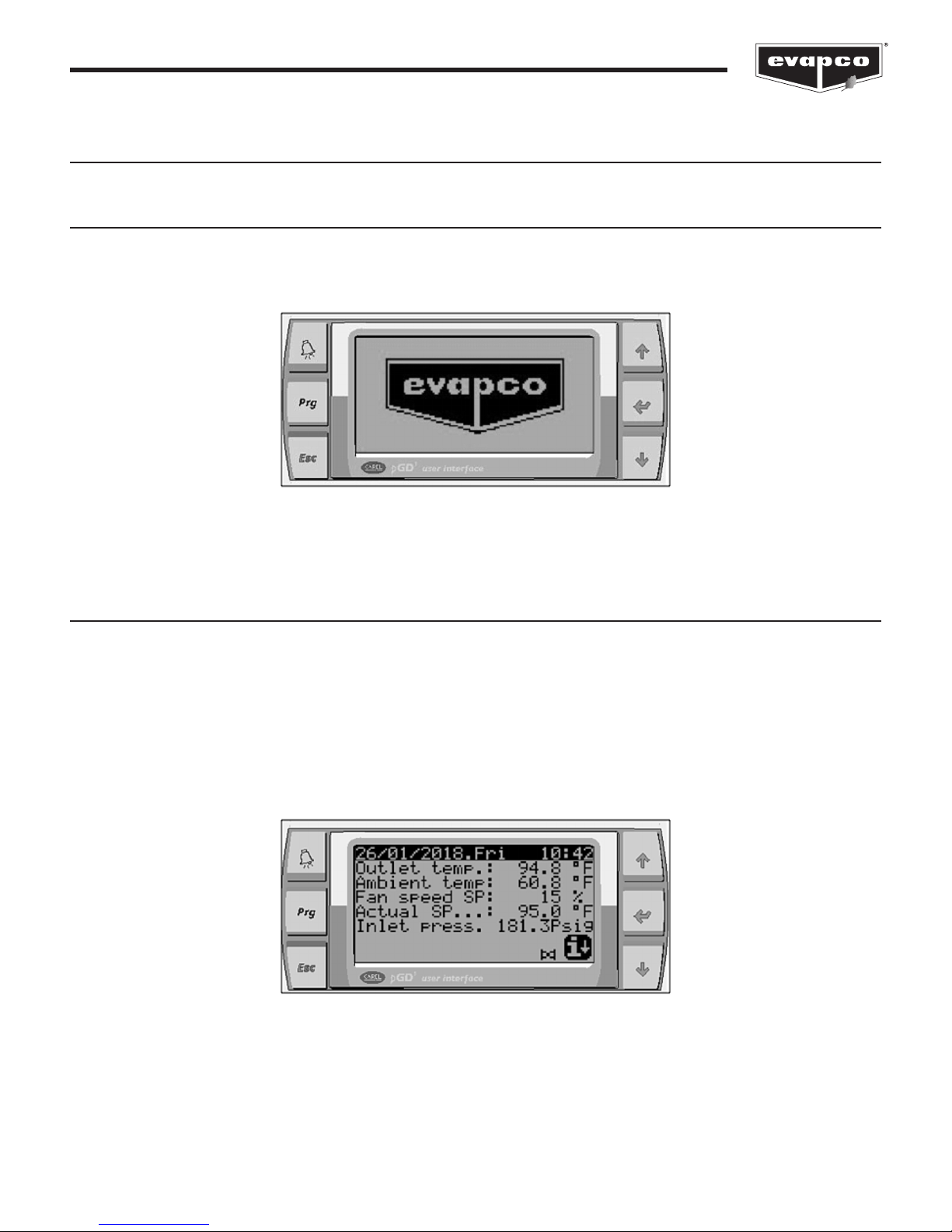

Welcome Screen

When the EVAPCO Controller is first energized, the system will do a self-diagnostic test and load all of the interface screens. When

the EVAPCO logo (Figure 17) appears, loading is complete. Press the ESC button to proceed to the Standby Status Screens.

Standby Statu Screen

The Standby Status Screens provide real time status of the various components of the eco-Air unit such as solenoid valves and

fans as well as live data of parameters such as sensor probe values, setpoints, and timer values. Note that all values shown on the

Standby Status Screens are read only. To view additional status screens, use the UP or DOW buttons located on the operator

interface.

The Standby Screen shown in Figure 18 displays the process temperature, ambient temperature, command fan speed, active

setpoint, and the process pressure. Note that the process pressure is only shown if the eco-Air unit is a condenser. Also, if the eco-

Air unit is a condenser, the process or Outlet Temperature will be a temperature derived from the temperature versus pressure

relationship of the refrigerant (see the Service Screens section for more information).

f the eco-Air unit is equipped with a pre-cooling system, the status of the solenoid valve is shown at the bottom of the screen as

shown in Figure 18.

Figure 17

The EVAPCO Controller Welcome Screen.

Figure 18

The Standby Screen.

Controller User Manual

14

Pre-cooling system is inactive (solenoid valve is closed).

Pre-cooling system is active (solenoid valve is open).

Image Description

Table 2

The states of the pre-cooling system status indicator.

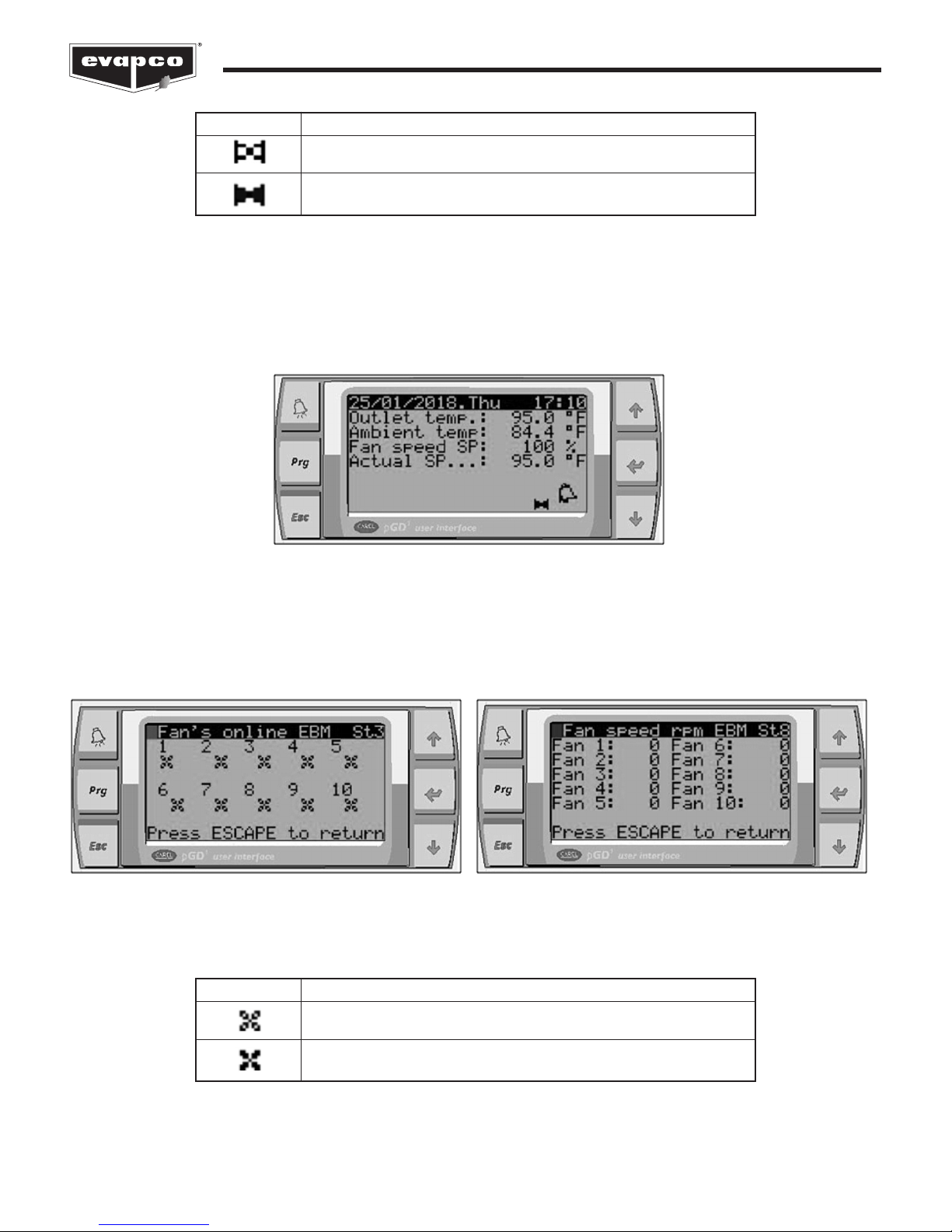

A bell icon in the lower right corner of the standby screen (see Figure 19) indicates that there is an active alarm. Press the ALARM

button to go directly to the Alarms Screen.

When the eco-Air unit is equipped with EC fan motors, the status and current speed of the fan motors may be viewed by pressing

the DOW button.

Figure 19

Standby Screen with an active alarm.

Figure 20

The left screen displays the status of the fan motors. The right screen displays the live fan motor speeds in rpm.

EC fan motor is off or is not communicating with the controller.

EC fan motor is online and communicating with the controller.

Image Description

Table 3

The states of the EC fan motor status indicator.

15

Controller User Manual

Figure 21

The increment and decrement timers of the pre-cooling system.

When the eco-Air unit is equipped with a pre-cooling system, several additional status screens indicate the various timers

associated with the control of the pre-cooling system. Figure 21 though Figure 24 will not be displayed unless the eco-Air unit is

equipped with a pre-cooling system. Figure 21 displays incremental timers which indicate if the pre-cooling system is getting ready

to activate (increase) or deactivate (decrease) based on the process temperature. For example, if the process setpoint is 95°F and

the process temperature rises past the setpoint, the increase timer will begin to count up. Once the timer reaches a predetermined

value, the pre-cooling system will activate. Conversely, if the process temperature falls below the process setpoint while the pre-

cooling system is active, the decrease timer will begin to count up until a predetermined value is reached. Once the value is

reached, the pre-cooling system will stop.

Figure 22

The Stage Minimum On Time Status Screen.

Also, once activated, the pre-cooling system remains active for a predetermined amount of time. The times shown on the Stage

Minimum On Time Status Screen begin to count up until it reaches a predetermined value. The pre-cooling system will remain

active until the minimum on time is satisfied.

Figure 23

The Flush Timers Status Screen.

When scheduled or manually enabled, the pre-cooling system will undergo a flushing and drying sequence for a predetermined

about of time. Each cycle remains active until the timers shown on the flush timers status screen reach the appropriate duration.

16

Controller User Manual

Figure 24

The Stage Rotation Status Screen. n this case, stage four will activate first as indicated by the number one.

When the pre-cooling system contains multiple stages or solenoid valves, the solenoid or pre-cooling section that enables first will

change after all stages are switched off. For example, if the eco-Air unit contains two stages, the first time the pre-cooling system

activates, stage one will be activated first followed by stage two. After both stages are switched off, the next time the pre-cooling

system is activated, stage two will be activated first followed by stage one.

Figure 26

Press the E T button at this screen to view the alarm log.

All alarms are logged and are viewable by pressing the E T button while at the screen shown in Figure 26. For more information

about this screen, please see the Error Log Screen section of this document.

Alarm Screen

The Alarms Screen displays all active alarms. Navigate the alarms by pressing the UP and DOW buttons on the operator

interface. Refer to the Alarm Event Description for a description of the possible alarms. To dismiss alarms, press and hold the

ALARM button for several seconds.

Figure 25

The Alarms Screen. n this example, there is an electrical valve fault.

Figure 28

The On/Off Unit Screen.

17

Controller User Manual

Main Menu Screen

The Main Menu Screen is available by touching the PRG button on the operator interface. The Main Menu Screen is used to

navigate to additional screens that allow users to modify the current operation of the system or to view additional monitoring

information. To navigate between the different menu items, use the UP or DOW arrow buttons on the operator interface. To select

a menu, place the black bar on the desired menu and press the E T button.

Figure 27

The Main Menu Screen.

On/Off Unit Screen

The On/Off Unit Screen shows and allows the operator to set the current operational status of the eco-Air unit. When the eco-Air

unit is not controlled via an external source (i.e. BAS), the On/Off Unit Screen is the only way to disable the eco-Air unit without

removing power. Note that the EVAPCO Controller must be switched on locally before the unit will operate even if the EVAPCO

Controller is being controlled via a BAS or digital input.

Unit is operational.

Unit is being controlled via a BAS and may be enabled by sending an enable signal

to the EVAPCO Controller.

Unit is being controlled via a digital input and may be enabled by sending an

enable signal to the EVAPCO Controller.

Unit is turned off manually and may only be enabled via the On/Off Unit Screen.

Status

Description

Table 4

The operational states of the unit and their descriptions.

The various operational states of the eco-Air unit are explained in the following table:

UnitOn

OFFbyBMS

OFFbyD N

OFFbyKEY

18

Controller User Manual

View Setpoint Screen

The View Setpoints Screen allows viewing of all setpoint parameters. For a detailed description of the setpoints and instructions

on how to change the various setpoints and options, please see the Service Screens section of this document.

Clock/Scheduler Screen

The Clock/Scheduler Screens allows the internal clock of the EVAPCO Controller to be set as well as the scheduling of several

routines. f enabled, the following routines may be programmed during certain periods of certain days:

Figure 29

One of the screens that allows viewing, but not editing of setpoints and options.

Limits the maximum fan speed to

the value set for quiet operation.

Switches the active setpoint to an

alternate value.

The pre-cooling system is activated

to run water over the adiabatic pads.

There is noise restriction during night time periods

due to close proximity of residences.

The cooling load is for an office building which

does not require as much cooling during off hours.

The unit installation site is located next to a field.

The flush routine runs at night to rinse any debris

that may have been sucked onto the adiabatic

pads during unit operation.

Routine

FunctionExample Use

Table 5

The various functions that may be scheduled hourly.

Quiet Mode

Setpoint 2

Flush

For instructions on setting the scheduler, please see the avigating the Scheduler section of this document. Note that unless

the desired routine is set to run via the scheduler (except the flush routine), the scheduler screen for that particular routine will

not be shown.

f equipped with a pre-cooling system, the pre-cooling system may be set to run only during certain dates. n climates that are

subject to freezing temperatures or if there is a reduced cooling load during certain periods of the year, the scheduler may be used

to disable the pre-cooling system. ote that all pipework that is susceptible to freezing must be heat traced in order to avoid

damage. When the scheduler is enabled, the pre-cooling system will only operate during the dates shown in the screen. Note that

the date format for the period start and stop is day/month. When in the Released state, the pre-cooling system will activate when

required as long as all conditions (e.g. enabled for scheduler, ambient is above lower limit, etc.) are satisfied. When changed to

L cked, the pre-cooling system will not activate even if additional cooling is required.

19

Controller User Manual

Figure 30

The pre-cooling system scheduler. n this example, the pre-cooling system will only run from April 1st though October 31st.

Figure 31

The pre-cooling system flushing parameters.

The amount of time that water flows

over the adiabatic pads.

The amount of time that the fans run in

reverse during the flushing routine.

The fan speed (reverse) during the dry

cycle of the flushing routine.

0 minutes

0 minutes

0%

Parameter

DescriptionDefault

Table 6

The flushing routine parameters.

Flushing Time

Drying Time

Fan Speed

The pre-cooling system flush routine parameters may be adjusted via the screen shown in Figure 31. All parameters may be

adjusted from the factory defaults. Note that only EC fan motors have the capability of spinning in reverse.

20

Controller User Manual

Figure 32

The Clock Adjustment Screen.

The internal clock of the EVAPCO Controller may be set in the screen shown in Figure 32. f any of the scheduler functionality of

the EVAPCO Controller is used, it is vital that the clock be set to the proper time. Also, the clock is used to add timestamps to

alarms. Note that the date is in a dd/mm/yy format.

Figure 33

The daylight savings clock adjustment parameters.

n order to ensure proper time keeping, the daylight savings adjustment must be accurate. Any adjustments to the daylight

savings transition parameters may be done on the screen shown in Figure 33.

Input/Output Screen

Figure 34 displays the current status of all digital inputs, digital outputs, analog inputs, and analog outputs of the EVAPCO

Controller. This screen is primarily used for troubleshooting and start-up purposes to determine if the correct signals are being sent

to and from the EVAPCO Controller.

Figure 34

The Digital nput Status Screen. n this example, the controller is receiving a signal to instruct the unit to operate in quiet mode.

Table of contents

Other EVAPCO Accessories manuals