EVAPCO ESW Series User manual

Rigging and

Assembly Instructions

ESW CLOSED

CIRCUIT COOLERS

Bulletin 145-E Metric

EVAPCO, INC. (World Headquarters) P.O. Box 1300, Westminster, Maryland 21158 USA

Phone (410) 756-2600 Fax (410) 756-6450

EVAPCO products are manufactured worldwide:

EVAPCO Europe

Industrieterrein Oost 4010

3700 Tongeren, Belgium

Phone: (32) 12 395029

Fax: (32) 12 238527

EVAPCO Europe S.r.l.

Via Ciro Menotti 10

20017 Passirana di Rho (MI), Italy

Phone: (39) 02 9399041

Fax: (39) 02 93500840

EVAPCO Europe GmbH

Bovert 22

D-40670 Meerbusch, Germany

Phone: (49) 2159-6956-0

Fax: (49) 2159-6956-11

FOR EVAPCO AUTHORIZED PARTS AND SERVICE, CONTACT YOUR LOCAL

MR. GOODTOWER SERVICE PROVIDER OR THE EVAPCO PLANT NEAREST YOU.

2

ESW Closed Circuit Coolers

Method of Shipment

ESW models are shipped with the top section(s) separate

from the bottom section(s). These sections have mating

flanges and will join together in a waterproof joint when

sealed and bolted together as described in the following

instructions. Miscellaneous items, such as sealer tape, bolt

sets and any other required materials, are packaged and

placed inside th0e pan for shipment.

Storage

Do not place tarps or other coverings over the top of the

units if the units are to be stored before installation.

Excessive heat can build up if the units are covered,

causing possible damage to the PVC eliminators, PVC

louvers, or PVC fill. For extended storage beyond six

months, rotate the fan and fan motor shaft(s) monthly.

Also, the fan shaft bearings should be purged and

regreased prior to start-up.

Structural Steel Support

Two structural “I” beams running the length of the unit are

all that is required for support of the units. These beams

should be located underneath the outer flanges of the unit

(see Figure 1). Mounting holes, 19 mm in diameter, are

located in the bottom flange of the unit to provide for bolting

it to the structural steel (see certified print for exact bolt hole

location). Bolt the bottom section to the steel support before

rigging the top section.

Beams should be sized in accordance with accepted

structural practices. Maximum deflection of the beam under

the unit to be 1/360 of the unit length, not to exceed 13 mm.

Deflection may be calculated by using 55% of the operating

weight as a uniform load on each beam (see certified print

for operating weight).

The supporting “I” beams should be level before setting the

unit. Do not level the unit by shimming between the bottom

flange and the beams as this will not provide proper

longitudinal support.

Support beams and anchor bolts are to be furnished by

others. Always refer to certified print for unit weights,

dimensions and technical data.

Figure 1 - Structural Steel Support.

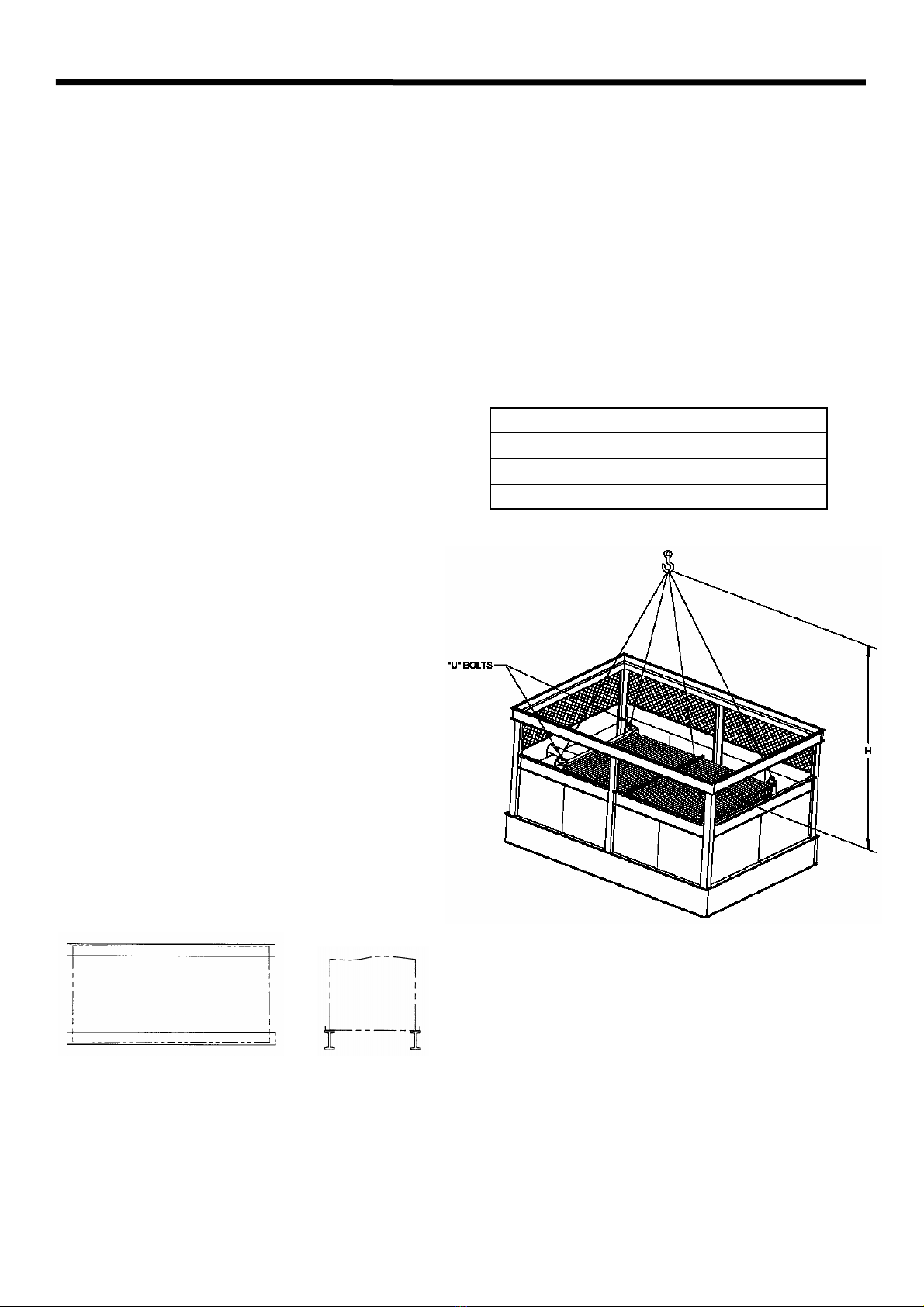

Rigging Bottom Section

Lifting devices are located in the upper corners of the coil as

shown in Figure 2. The hook of the crane must be a

minimum dimension of “H” above the top of the coil to

prevent undue strain on the lifting devices.

See Table 1 for the minimum “H” dimension. These lifting

devices should not be used for extended lifts or where any

hazard exists unless safety slings are employed under the

section. (See “Extended Lifts” on page 4 for proper

arrangement.) Bolt the bottom section to the steel support

before rigging the top section.

Table 1 - Minimum H Dimension for Bottom Sections.

Figure 2 - ESW Bottom Section

Basin Section Length - m MIN. H (Above Coil) - m

2,7 2,1

3,6 3,0

5,4 4,2

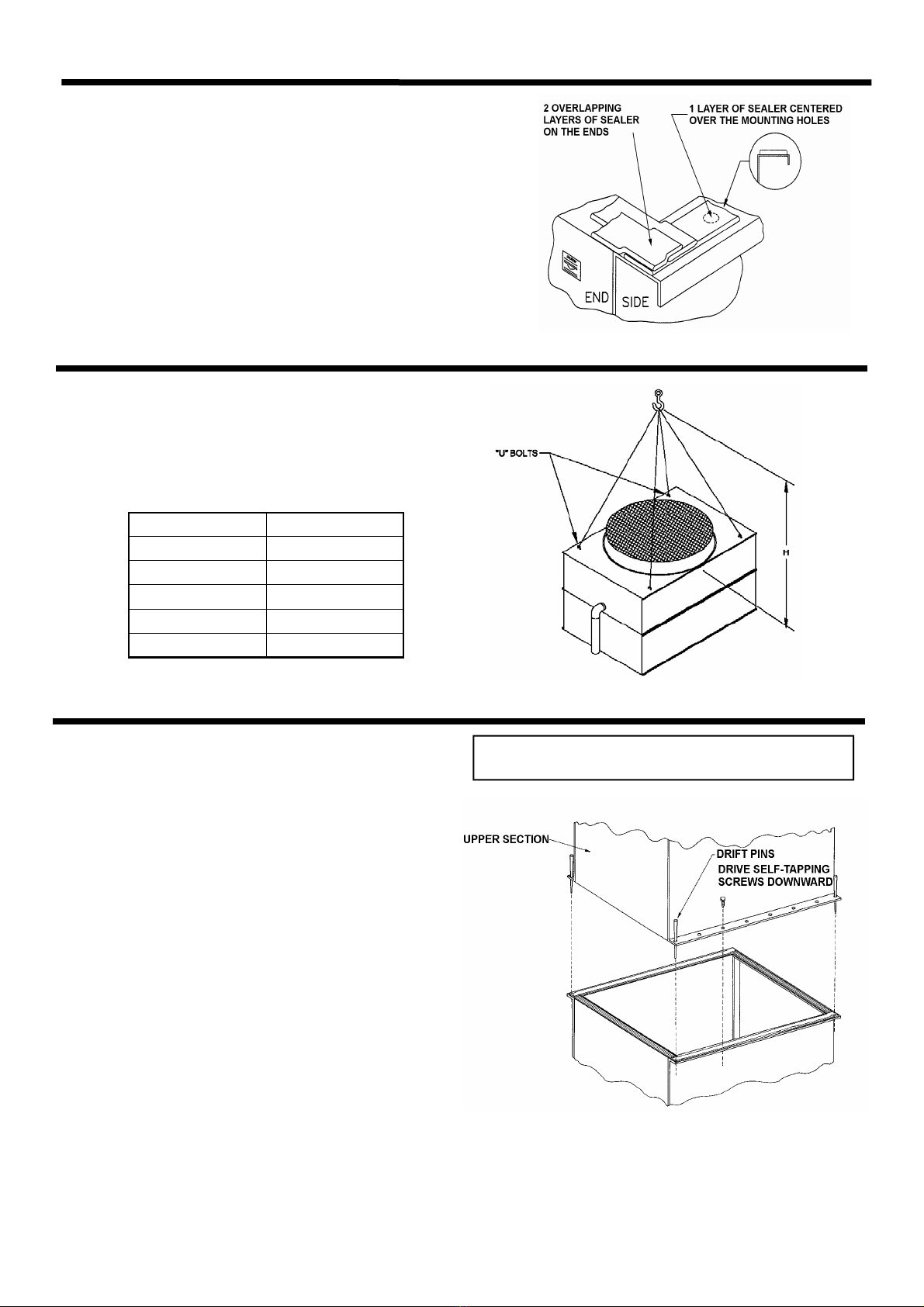

Applying Sealer Tape

Once the bottom section has been set on the supporting steel and

bolted in place, the top flanges should be wiped down to remove any

dirt or moisture. Sealer tape should be placed over the mounting hole

centerline on the side flanges. Apply two strips of sealer tape, one

partially overlapping the other, on the end flanges.

The sealer tape should overlap on the corners as shown in Figure 3.

Do not splice the sealer tape along the end flanges and preferably not

on the side flanges if it can be avoided. Always remove the paper

backing from the sealer tape.

Figure 3 - Proper Sealer Tape Application

Top Section

“U” bolts are provided in the four corners of the top section

for lifting and final positioning (See Figure 4). The hook of

the crane must be a minimum dimension “H” above the top

section being lifted to prevent undue strain on the “U” bolts.

See Table 2 for the minimum “H” dimension.

Table 2 -Minimum H Dimension for Top Sections.

UNIT NO. MIN. H - m

ESW 72 models 2,7

ESW 96 models 3,6

ESW 142 models 5,1

ESW 144 models 3,6

ESW 216 models 5,1

Figure 4 - ESW Top Section.

ESW Closed Circuit Coolers

Assembly of the Top Section to the Bottom

Section

Before assembling the top section to the bottom section,

remove any loose parts shipped in the pan.

Wipe the flanges on the bottom of the top section. Check to

see that the water distribution connection on the top section is

in the correct position relative to the bottom section (see

certified unit drawing). Units are also provided with match

markings on each section (i.e. A1 of bottom section should

match up with A1 of top section).

Lower the top section to within several inches of the bottom

section making sure the two sections do not touch and the

sealer is not disturbed. Using suitably sized drift pins to

assure proper alignment, lower the top section down onto the

bottom section. Fasten all four corners. Install the remaining

fasteners, working from the corners toward the center, using

drift pins to align the holes. Fasteners must be installed in

every hole on the side flange. None are required on the end

flanges. Galvanized units will use 5/16” self tapping screws

and stainless steel units will use 8 mm nuts, bolts and

washers. See Figure 5.

Note: 8 mm stainless steel nuts, bolts and washers are

used on stainless steel models.

Figure 5 - Mating Upper Section to Bottom Section.

3

4

Extended Lifts

Important: The lifting devices and “U” bolts should be

used for final positioning only and for lifting where no

danger exists. If they are used for extended lifts, safety

slings should be provided under the sections.

The preferred method for extended lifts is to use slings

under the unit (see Figures 5, 6, 7). Spreader bars should

always be used between the cables at the top of the section

to prevent damage to the upper flanges or fan cylinders.

Safety slings and skids should be removed before final positioning of the unit.

ESW Closed Circuit Coolers

Figure 8 - Proper Rigging Method for Extended Lifts. (5,4 m long units)

Figure 6 -ESW Top Section

Figure 7 - Proper Rigging Method for Extended Lifts. (2,7 & 3,6 m long units)

Figure 9 - Attaching Fan Screen to Cylinder

5

ESW Closed Circuit Coolers

Mounting Fan Screens

3,6 m Wide Models

In certain situations some units may be shipped with the fan

screens in the basin. Under these circumstances, use the

following procedures to mount the fan screen on the discharge

cylinder.

WARNING: DO NOT WALK ON THE FAN SCREENS AT

ANY TIME!

1. Place both halves of the fan screen on top of the

discharge cylinder. Each half will be tagged to match

markings on the cylinder. Align the eyelets of the fan

screen with the holes tha\t can be found on the

perimeter of the discharge cylinder.

2. At each hole, attach the fan screen to the discharge

cylinder as shown in Figure 9.

3. Join the two screen halves with wire clips (Figure 10).

There should be 3 wire clips on each side of the fan

screen. Space the wire clips evenly across the

radius of the fan screen as shown in Figure 11.

Figure 10 - \\\Wire Clip Arrangement

Figure 11- Wire Clip Spacing

Mounting Fan Screens

3,6 m Wide by 5,4 m Long Models

On these models, the fan screen is supported from underneath

by an “X” shaped support frame.

1. Set the support frame across the top of the discharge

cylinder (See Figure 12).

2. Place both halves of the fan screen on top of the support

frame. Each half will be tagged to match markings on the

cylinder. Align the eyelets of the fan screen with the holes

on the cylinder perimeter.

3. Join the two screen halves with wire clips (See Figure 10).

There should be four clips on either side of the fan screen.

Space them evenly as shown in Figure 11.

4. At each hole, attach the fan screen to the discharge

cylinder as shown in Figure 9. At the four points where the

support frame meets the cylinder, bolt the support frame to

the cylinder together with the fan screen.

Figure 12 - Support Frame Installation

Other manuals for ESW Series

1

This manual suits for next models

5

Table of contents

Other EVAPCO Accessories manuals