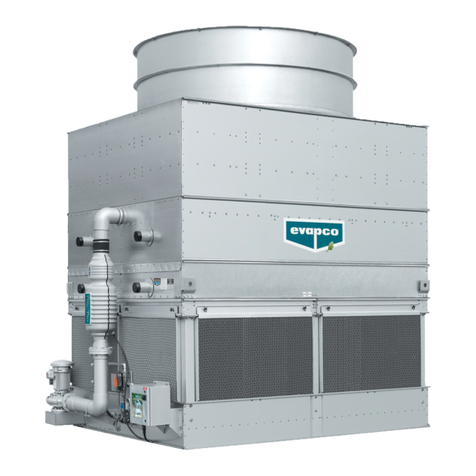

EVAPCO ESW4 User manual

Rigging and

Assembly Instructions

ESW4 CLOSE CIRCUIT COOLERS

Visit EVAPCO’s Website at: evapco.com

EVAPCO...SPECIALISTS IN HEAT TRANSFER PRODUCTS AND SERVICES.

EVAPCO Products are Manufactured Wordwide

Bulletin ESW419RIG

EVAPCO, Inc. — World H adquart rs & R s arch/D v lopm nt C nt r

P.O. Box 1300 • Westminster, M 21158 USA

410-756-2600 p • [email protected] • evapco.com

EVAPCO, Inc.

World H adquart rs

P.O. Box 1300

Westminster, M 21158 USA

410-756-2600 p | 410-756-6450 f

Asia/Pacific

EVAPCO Asia/Pacific H adquart rs

1159 Luoning Road

Baoshan Industrial Zone

Shanghai 200949, P.R. China

(86) 21-6687-7786 p | (86) 21-6687-7008 f

Europ

EVAPCO Europ BVBA

Europ an H adquart rs

Heersterveldweg 19

Industrieterrein Oost

3700 Tongeren, Belgium

(32) 12-395029 p | (32) 12-238527 f

EVAPCO East

5151 Allendale Lane

Taneytown, M 21787 USA

410-756-2600 p | 410-756-6450 f

EVAPCO East

Key Building

Taneytown, M USA

410-756-2600 p

EVAPCO Midw st

Greenup, IL USA

217-923-3431 p

evapcomw@evapcomw.com

EVAPCO W st

Madera, CA USA

559-673-2207 p

EVAPCO Iowa

Lake View, IA USA

712-657-3223 p

EVAPCO Iowa

Sales & Engineering

Medford, MN USA

507-446-8005 p

EVAPCO N wton

Newton, IL USA

618-783-3433 p

evapcomw@evapcomw.com

EVAPCOLD

Greenup, IL USA

217-923-3431 p

evapcomw@evapcomw.com

EVAPCO-BLCT Dry Cooling, Inc.

Bridgewater, NJ 08807 USA

908-379-2665 p

EVAPCO-BLCT Dry Cooling, Inc.

Littleton, CO 80127 USA

908-379-2665 p

EVAPCO Pow r México S. d R.L. d C.V.

Calle Iglesia No. 2, Torre E

Tizapan San Ángel, el. Álvaro Obregón

Ciudad de México, .F. México 01090

+52 (55) 8421-9260 p

R frig ration V ss ls & Syst ms Corporation

A wholl owned subsidiar of EVAPCO, Inc.

Bryan, TX USA

979-778-0095 p

EvapT ch, Inc.

A wholl owned subsidiar of EVAPCO, Inc.

Edwardsville, KS USA

913-322-5165 p

Tow r Compon nts, Inc.

A wholl owned subsidiar of EVAPCO, Inc.

Ramseur, NC USA

336-824-2102 p

EVAPCO Alcoil, Inc.

A wholl owned subsidiar of EVAPCO, Inc.

York, PA USA

717-347-7500 p

EVAPCO Europ , S.r.l.

Milan, Italy

(39) 02-939-9041 p

EVAPCO Europ , S.r.l.

Sondrio, Italy

EVAPCO Europ GmbH

Meerbusch, Germany

(49) 2159 6956 18 p

EVAPCO Air Solutions

A wholl owned subsidiar of EVAPCO, Inc.

Aabybro, enmark

(45) 9824 4999 p

EVAPCO Air Solutions GmbH

Garbsen, Germany

(49) 5137 93875-0 p

Evap Egypt Engin ring Industri s Co.

A licensed manufacturer of EVAPCO, Inc.

Nasr City, Cairo, Egypt

2 02 24022866/2 02 24044997 p

primacool@link.net / shady@primacool.net

EVAPCO Middl East DMCC

ubai, United Arab Emirates

+971 4 448 7242 p

EVAPCO S.A. (Pty.) Ltd.

A licensed manufacturer of EVAPCO, Inc.

Isando 1600, Republic of South Africa

(27) 11-392-6630 p

EVAPCO (Shanghai) R frig ration Equipm nt Co., Ltd.

Baoshan Industrial Zone Shanghai, P.R. China

(86) 21-6687-7786 p

B ijing EVAPCO R frig ration Equipm nt Co., Ltd.

Huairou istrict Beijing, P.R. China

010-6166-7238 p

EVAPCO Air Cooling Syst ms (Jiaxing) Company, Ltd.

Building 10, 1133 Taoyuan Road,

Jiaxing, Zhejiang, China

(86) 573 83119379 p

info@evapcoacs.cn

EVAPCO Australia (Pty.) Ltd.

Riverstone NSW 2765, Australia

(61) 2 9627-3322 p

EvapT ch Asia Pacific Sdn. Bhd

A wholl owned subsidiar of EvapTech, Inc.

Puchong, Selangor, Malaysia

(60-3) 8070-7255 p

North Am rica

South Am rica

EVAPCO Brasil

Equipamentos Industriais Ltda.

Al. Vênus, 151 – CEP: 13347-659

Indaiatuba –São Paulo – Brasil

(55+11) 5681-2000 p

Fan T chnology R sourc s

Cruz das Almas – Indaiatuba

São Paulo, Brasil 13308-200

55 (11) 4025-1670 p

fantr@fantr.com

2

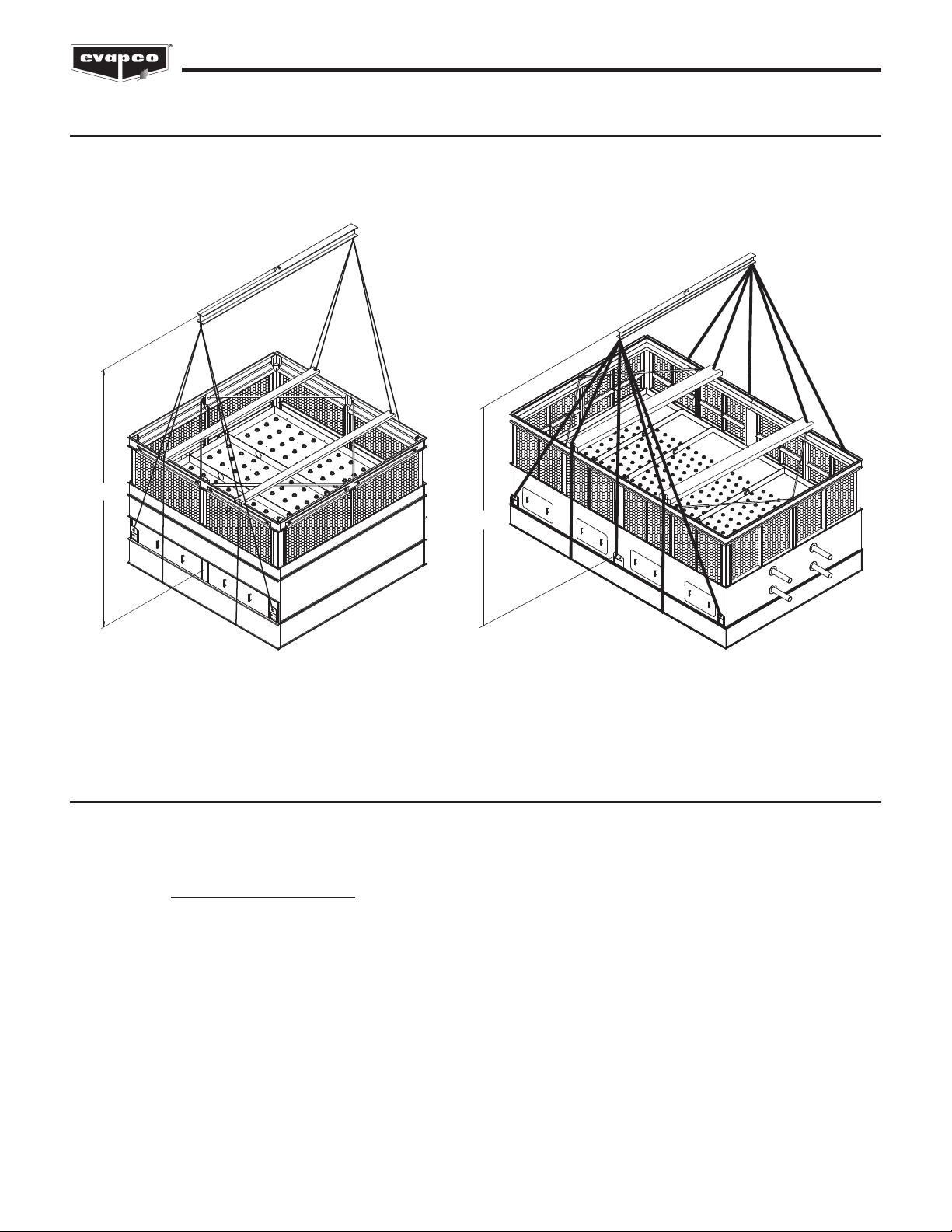

ESW4 Closed Circuit Coolers

Method of Shipment

ESW4 models are shipped with the top section(s) separate from the bottom section(s). These sections have mating flanges and

will join together in a waterproof joint when sealed and bolted together as described in the following instructions. Miscellaneous

items, such as sealer tape, hardware and any other required materials, are packaged and placed inside the pan for shipment.

For 8.5’ (2.6m) wide units, the motors and drives are factory aligned and then shipped loose inside the basin section for mounting

during installation. Refer to the “External Motor Installation” section in this bulletin.

Storage

o not place tarps or other coverings over the top of the units if the units are to be stored before installation. Excessive heat can

build up if the units are covered, causing possible damage to the PVC eliminators, louvers or fill. For extended storage beyond six

months rotate the fan and fan motor shaft(s) monthly. Also, the fan shaft bearings should be purged and regreased prior to start-up.

International Building Code Provisions

The International Building Code (IBC) is a comprehensive set of regulations addressing the structural design and installation

requirements for building systems – including HVAC and industrial refrigeration equipment. As of June 2008, all 50 states plus

Washington .C have adopted the International Building Code. The code provisions require that evaporative cooling equipment

and all other components permanently installed on a structure must meet the same seismic design criteria as the building.

All items attached to the Evapco ESW4 Closed Circuit Cooler must be independently reviewed and isolated to meet applicable

wind and seismic loads. This includes piping, ductwork, conduit, and electrical connections. These items must be flexibly attached

to the Evapco unit so as not to transmit additional loads to the equipment as a result of seismic or wind forces.

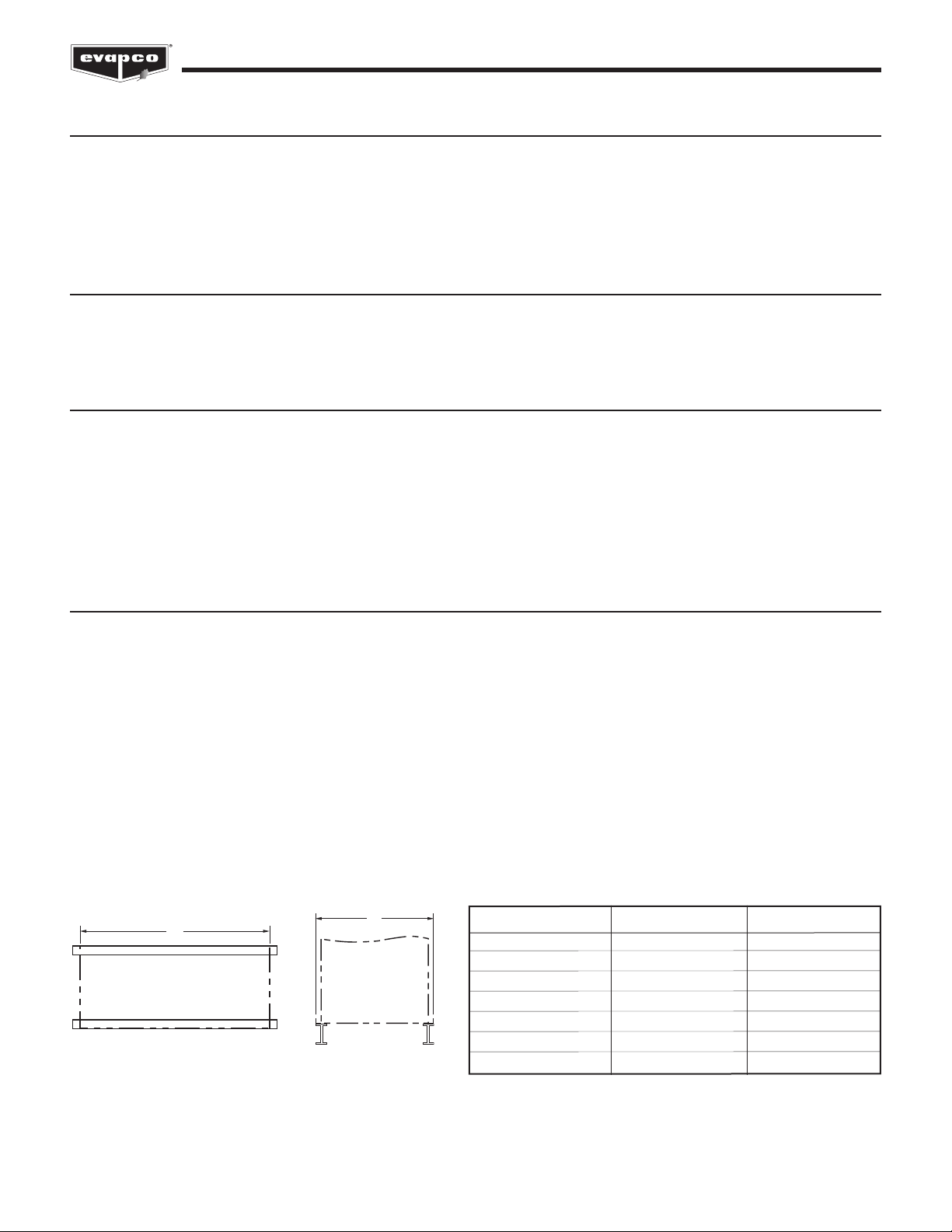

Structural Steel Support

Evapco recommends supporting the unit with two structural “I” beams that span the entire length of the unit*. These beams should

be located underneath the outer flanges of the unit. (See Figure 1). Mounting holes, 3/4” (19mm) in diameter, are located in the

bottom flange for bolting to the structural steel (see certified print for exact bolt hole location). Bolt the bottom section to the steel

support before rigging the top section.

Beams should be sized in accordance with accepted structural practices. Maximum deflection of the beam under the unit not to

exceed 1/2” (13mm). eflection may be calculated by using 55% of the operating weight as a uniform load on each beam (see

certified print for operating weight).

The supporting “I” beams should be level before setting the unit. o not level the unit by shimming between the bottom flange and

the beams as this will not provide proper longitudinal support.

Support beams and anchor bolts are to be furnished by others. Always refer to certified print for unit weights, dimensions and

technical data.

Note: Consult IBC for required steel support layout and structural design.

Figure 1A

Plan Views

Figure 1B

End Elevations

A

8.5' to 14' WIDE

MODELS

B

8.5' to 14'

WIDE

MODELS

* The Engineer of Record is ultimately responsible for the steel support design and may require additional cross beams based on loads.

Unit Footprint A B

8.5' x 6' (2.6m x 1.8m) 8' 5-1/2" (2,578mm) 5' 11-7/8" (1,826mm)

8.5' x 9' (2.6m x 2.7m) 8' 11-1/2" (2,731mm) 8' 5-1/2" (2,578mm)

8.5' x 12' (2.6m x 3.6m) 11' 11-3/4" (3,651mm) 8' 5-1/2" (2,578mm)

8.5' x 18' (2.6m x 5.5m) 18' 0" (5,486mm) 8' 5-1/2" (2,578mm)

12' x 12' (3.6m x 3.6m) 11' 11-3/4" (3,651mm) 11' 10" (3,607mm)

12' x 18' (3.6m x 5.5m) 18' 0" (5,486mm) 11' 10" (3,607mm)

14' X 22' (4.2m X 6.7m) 21' 11-3/4" (6,700mm) 13' 11-1/4" (4,250mm)

Table 1 – ESW4 Supporting Steel imensions

3

ESW4 Closed Circuit Coolers

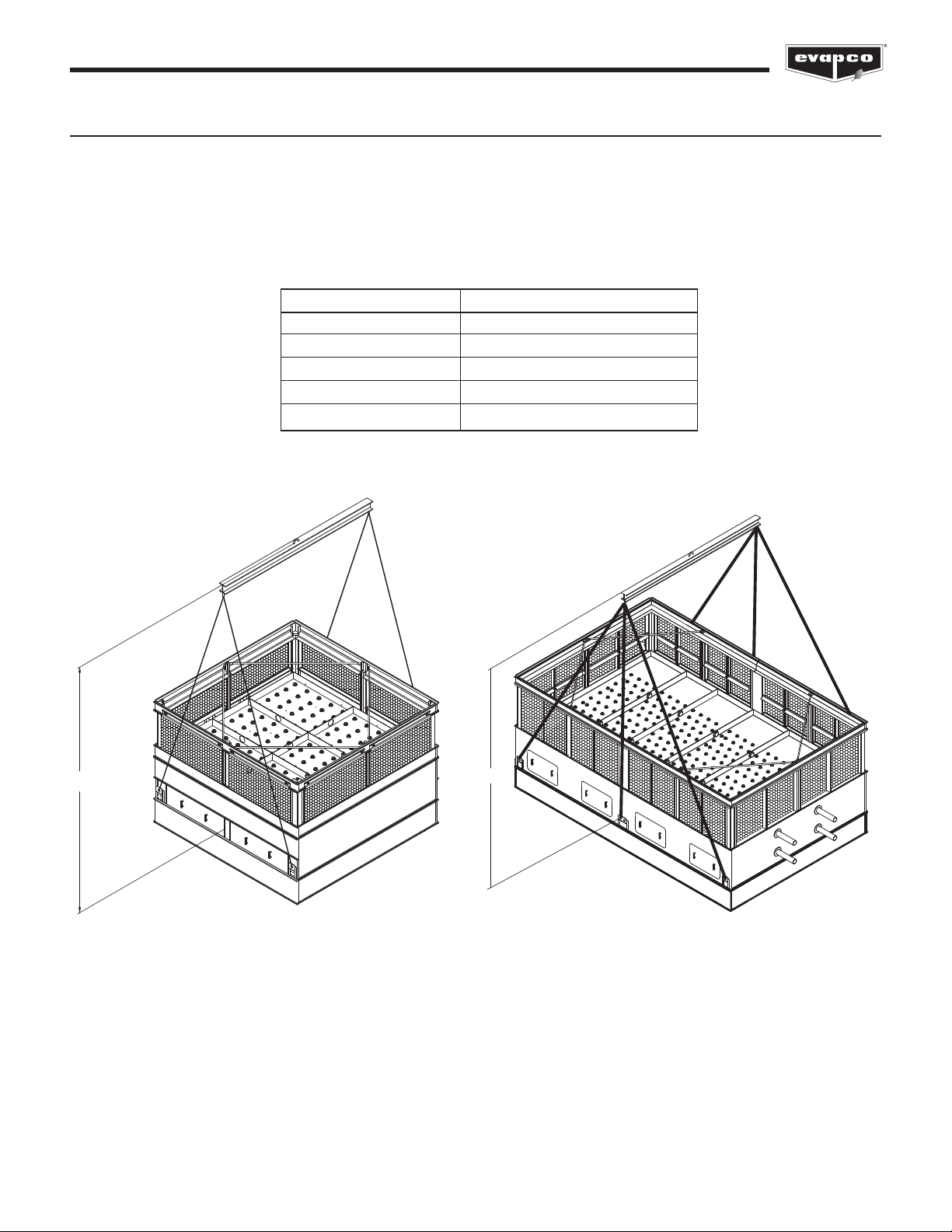

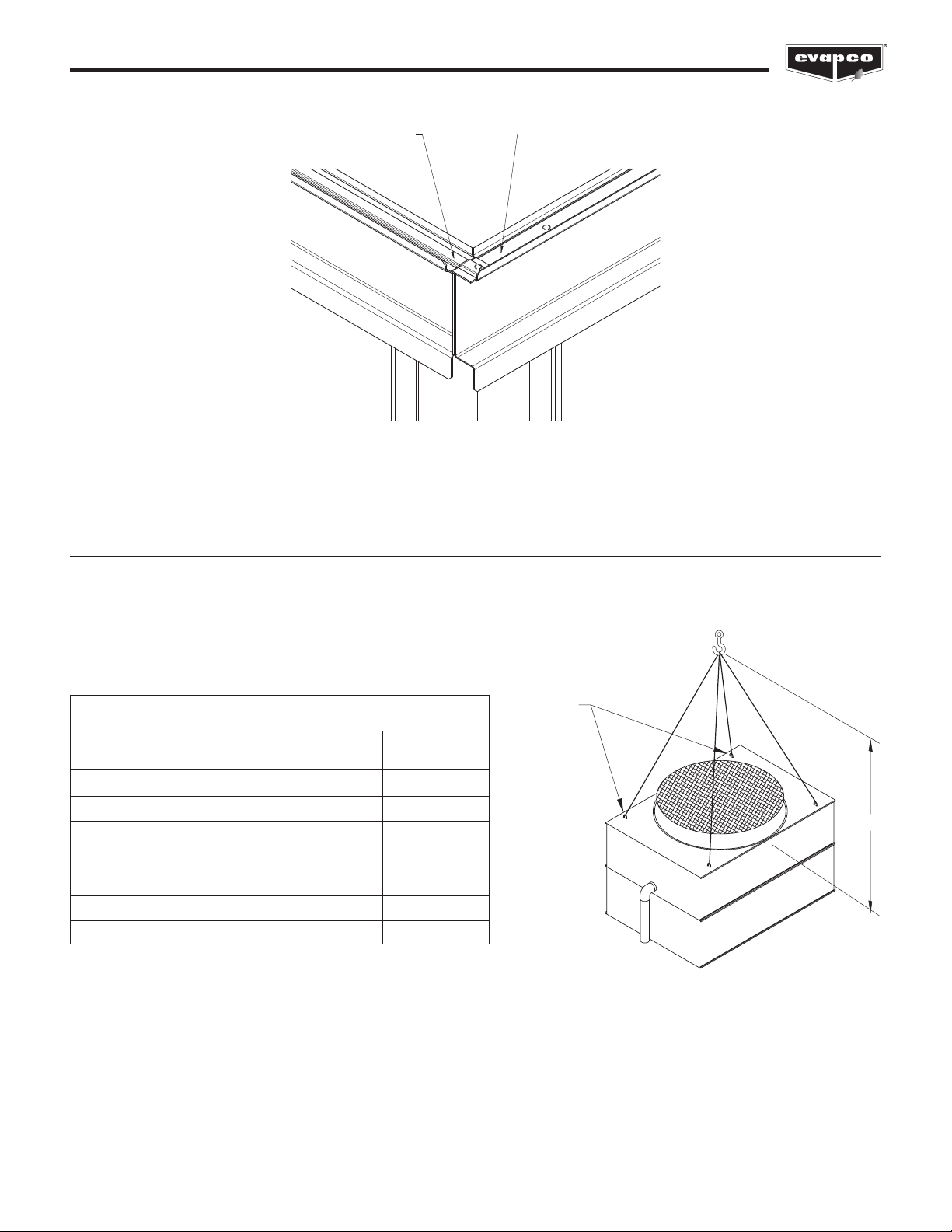

Basin Section Length in. “H” Dim. (above lift point)

8.5' (2.6m) 7' (2.1m)

9' (2.7m) 7' (2.1m)

12' (3.6m) 10' (3m)

18' (5.5m) 12' (3.6m)

22' (6.7m) 21' (6.4m)

Table 2 – Minimum “H” imension for Basin Sections

H

Rigging the Bottom Section: Standard Lift

Lifting devices are located in the lower corners of the unit as shown in Figures 2 and 3. The hook of the crane must be a minimum

dimension of “H” above the lift point to prevent undue strain on the lifting devices.

See Table 2 for the minimum “H” dimension. Bolt the bottom section to the steel support before rigging the top section of the unit.

The unit lifting devices should not be used for extended lifts or where any hazard exists unless safety slings are employed under

the section.

Figure 3 – ESW4 Bottom Section

18’ (5.5m) and 22’ (6.7m) 6 point rig

Important: The lifting devices should be used only for lifting where no danger exists and for final positioning of the

section. For extended lifts, safety slings should be provided under the section as described on page 4.

H

Figure 2 – ESW4 Bottom Section

4 point rig

4

ESW4 Closed Circuit Coolers

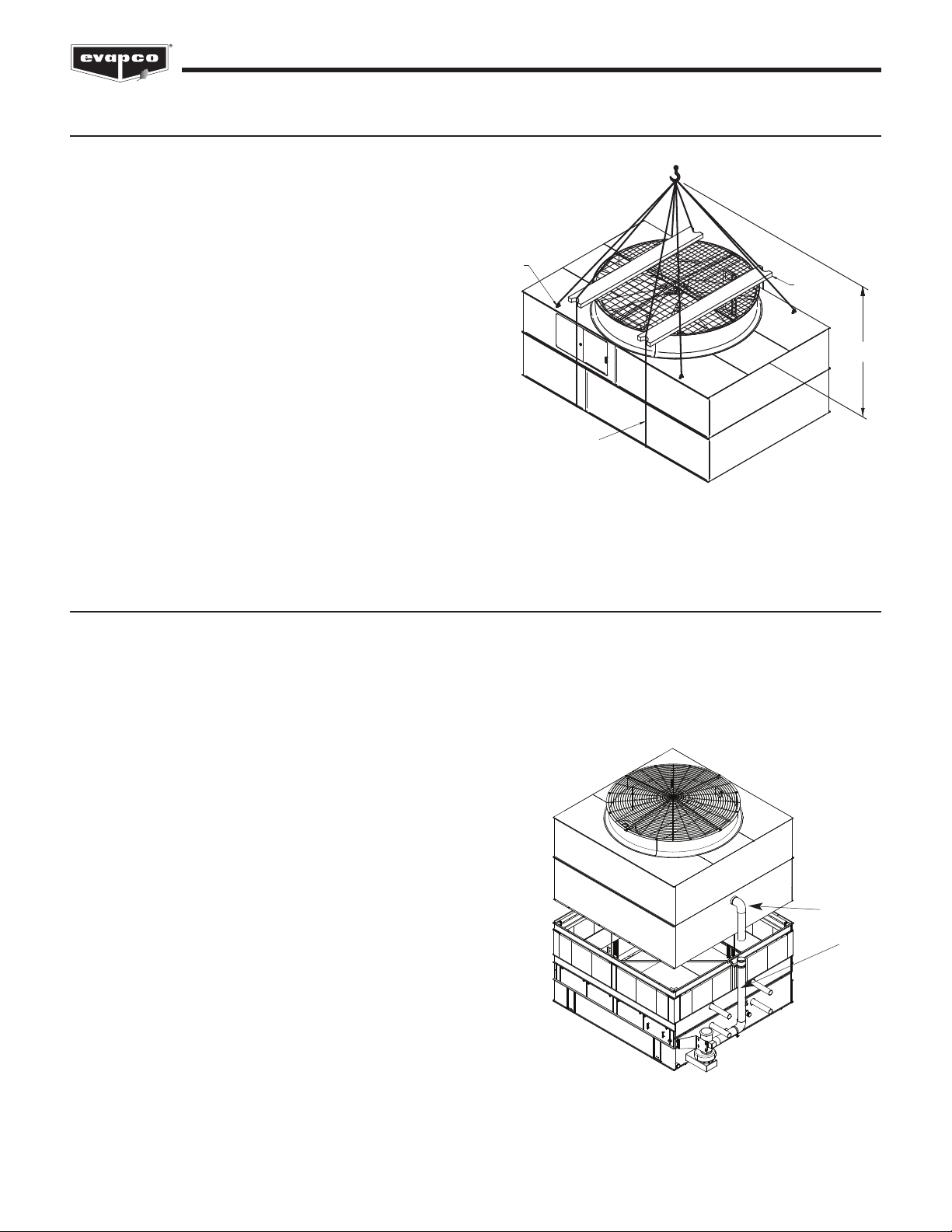

Rigging the Bottom Section: Extended Lifts

The preferred method for extended lifts is to use slings under the unit as shown in Figures 4 and 5. Spreader bars should always

be used between the cables at the top of the section to prevent damage to the upper portion of the basin. Safety slings and skids

should be removed before final positioning of the unit. See Table 2 on page 3 for minimum “H” dimensions.

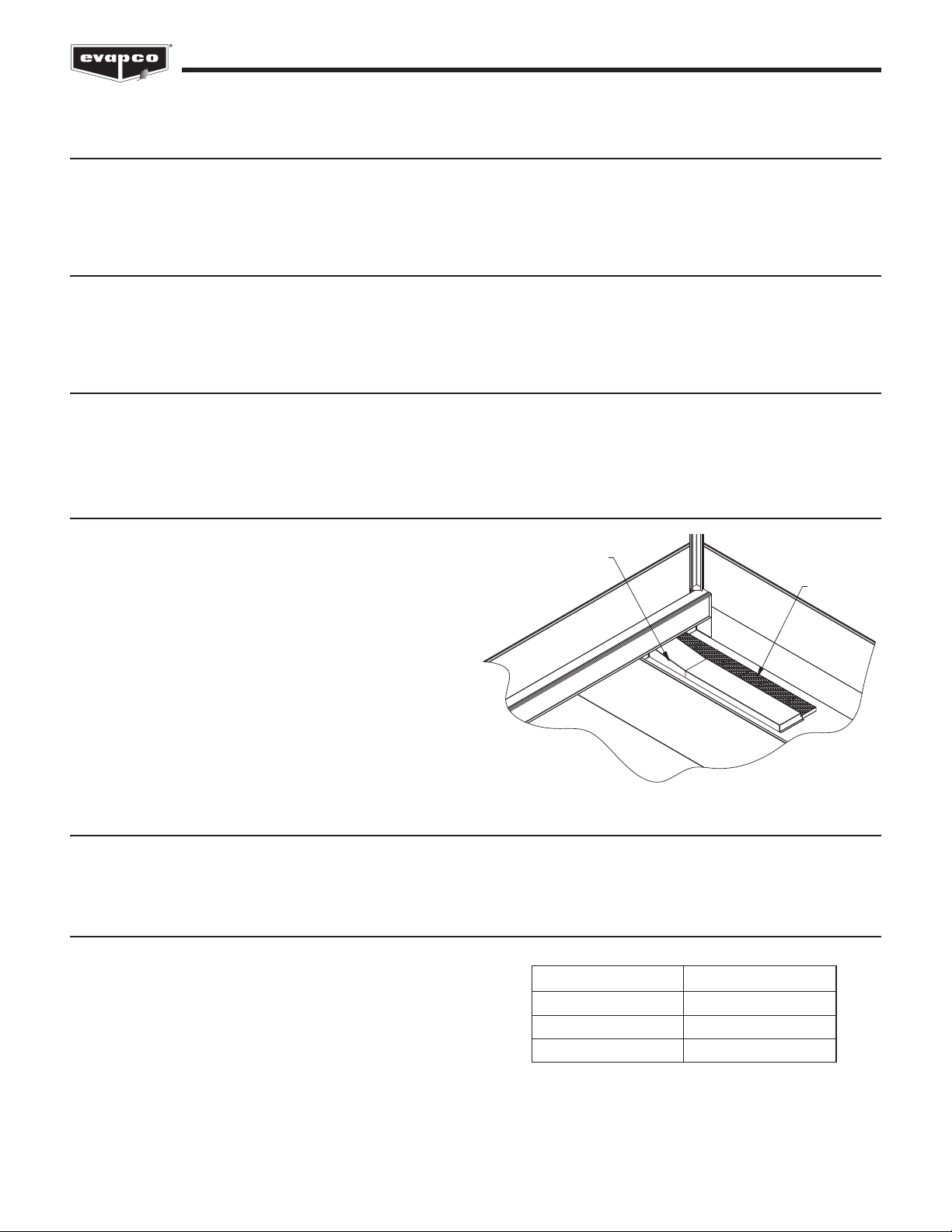

Application of Sealer Tape

Once the bottom section has been set on the supporting steel and bolted in place, the top flanges should be wiped down to remove

any dirt or moisture. Sealer tape should be placed over the mounting hole centerline on the side flanges along the entire length of

all sides. Apply two strips of sealer tape, one partially overlapping the other, on the entire length of the end flanges.

The sealer tape should overlap on the corners as shown in Figure 6. o not splice the sealer tape along the end flanges and

preferably not on the side flanges if it can be avoided.

Always remove the paper backing from the sealer tape.

H

Figure 5 – Proper Rigging Method for Extended Lifts

18’ (5.5m) and 22’ (6.7m) long

H

Figure 4 – Proper Rigging Method for Extended Lifts

ESW4 Closed Circuit Coolers

5

Rigging the Top Section: Standard Lift (2-Piece Shipment)

“U” bolts are provided in the four corners of the top section for lifting and final positioning (See Figure 7). The hook of the crane

must be a minimum dimension “H” above the top of the section being lifted to prevent undue strain on the “U” bolts. See Table 3 for

the minimum “H” dimension.

H

“U” BOLTS

Figure 7 – ESW4 Top Section

Important: The “U” Bolts should be used only for lifting where no danger exists and for final positioning of the section.

For extended lifts, safety slings should be provided under the section as described on page 6.

2OVERLAPPING LAYERS

OF SEALER TAPE

ON THE ENDS

1LAYER OF SEALER TAPE

CENTERED OVER THE

MOUNTING HOLES

END SIDE

Figure 6 – Sealer Tape on Flange of Bottom Section

inumum “H” Dim.

(above fan deck)

Box Size Standard Super Low

Fan Sound Fan

8.5' x 6' (2.6m x 1.8m) 7' (2.1m) 8' (2.4m)

8.5' x 9' (2.6m x 2.7m) 9' (2.7m) 12' (3.6m)

8.5' x 12' (2.6m x 3.6m) 12' (3.6m) 12' (3.6m)

8.5' x 18' (2.6m x 5.5m) 17' (5.2m) 20' (6m)

12' x 12' (3.6m x 3.6m) 12' (3.6m) 15' (4.6m)

12' x 18' (3.6m x 5.5m) 17' (5.2m) 19' (5.8m)

14' X 22' (4.2m x 6.7m) 18' (5.5m) 18' (5.5m)

Table 3 – Minimum “H” imension for Top Sections

6

ESW4 Closed Circuit Coolers

Assembly of the Top Section to the Bottom Section

Before assembling the top section to the bottom section, remove any loose parts shipped in the pan. Apply sealer tape as shown in

Figure 6 on page 5.

Wipe the flanges on the bottom of the top section. Check to see that the water distribution connection on the top section is in the

correction position relative to the bottom section (see certified unit drawing). Units are also provided with match markings on each

section (i.e. A1 of bottom section should match up with A1 of top section).

Lower the top section to within several inches of the bottom

section making sure the two sections do not touch and the

sealer tape is not disturbed. Using suitably sized drift pins to

assure proper alignment, lower the top section down onto the

bottom section.

Place nuts and bolts in all four corner bolt holes. Then continue

to install the rest of the nuts and bolts working from the corners

toward the center. Nuts and bolts must be installed in every

hole on the side flanges and end flanges. Cut off extra sealer

tape once the section is bolted into place.

Rigging the Top Section: Extended Lifts

The preferred method for extended lifts is to use slings under

the unit as shown in Figure 8. Spreader bars should always be

used between the cables at the top of the section to prevent

damage to the upper flanges or fan cylinder. Safety slings and

skids should be removed before final positioning of the unit.

See Table 3 on page 5 for minimum “H” dimensions.

H

“U” BOLTS

SPREADER

BARS

SAFETY SLINGS

Figure 8 – Proper Rigging Method for Extended Lifts

Figure 9 – Mating Upper Section to Bottom Section.

WATER

ISTRIBUTION

CONNECTIONS

7

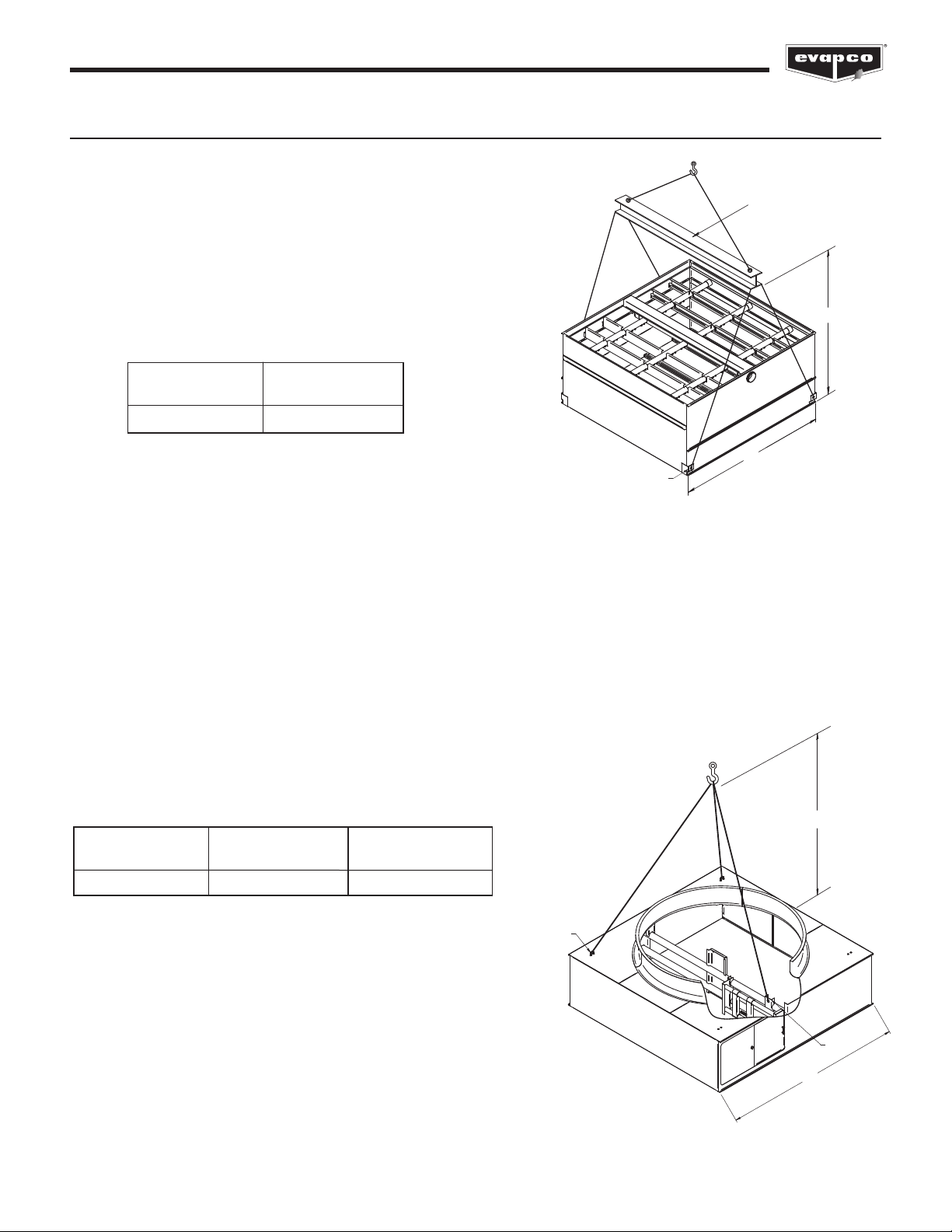

ESW4 Closed Circuit Coolers

3-Section Shipments

In some cases, a unit is shipped in 3 sections (Fan, Casing and

Basin) in lieu of the standard 2 sections (Fan + Casing, and Basin).

This is often done to reduce the shipping height of each individual

section, which in turn may reduce the size of the crane required to

rig the unit.

Casing Section Rigging

All casing sections will be rigged as a four-point lift as shown in

Figure 9a.

H

L

LIFTING EAR

SPREADER BAR

Section inimum "H"

Length Dimension

14' (4.2m) 14' (4.2m)

Table 4 – Minimum “H” imension for

Four-Point Lift of Cooler Casing Sections

Figure 9a – Four-Point Rigging of Tower Casing

Section with Added Lifting Ears

H

“U” BOLTS

LIFTING

EAR

L

Fan Section Rigging

When lifting the fan section separate from the casing section, the center of gravity of the fan section is heavily biased towards the

location of the fan motor and major drive components. In order to avoid lifting the fan section at a lopsided angle, a three-point lift is

necessary.

In such a case, an additional lifting ear is provided by the factory on the mechanical bearing support assembly. The “U” bolts on the

fan deck which are located close to the fan motor are removed.

Figure 10 shows the proper three-point lifting method for the fan section. The hook of the crane must be a minimum dimension “H”

above the top of the section being lifted to prevent undue strain on the “U” bolts.

See Table 5 below for minimum “H” dimension to safely lift the fan section during a three-point lift.

Figure 10 – Three-Point Lift

Section inimum "H" inimum "H"

Length Standard Fan Dimension SLSF

14' (4.2m) 13' (4m) 13' (4m)

Table 5 – Minimum “H” imension for Three-Point Lifts

8

ESW4 Closed Circuit Coolers

Prior to lowering the fan section onto the casing section, the side flanges on the casing sections must be cleaned by the installer

and have sealer tape applied to them. The ends will need to have 2 overlapping layers of sealer tape applied to them. Follow

instructions from the “Application of Sealer Tape” section of this manual.

rift pins should be used to align the fan section with the casing section. The installer will need to attach the fan section end panels

to the casing section end panels and the fan section side panels to the casing section side panels with self-threading tappers

(galvanized units) or bolts (stainless units).

Note: Fan screen and fan screen support will be shipped loose in the event of a 3-section shipment. Both these items

need to be installed after rigging.

Assembly of the Top Section to the Bottom Section

Before securing the upper section to the bottom section, remove any loose parts shipped in the basin.

Wipe the flanges on the bottom of the upper section. Check to see that the water distribution connection on the top section is in the

correct position relative to the bottom section (see unit certified drawing). Units are also provided with match markings on each

section (i.e. A1 of bottom section should match up with A1 of top section).

Lower the upper section to within several inches of the bottom section making sure the two sections do not touch and the sealer

tape is not disturbed. Fasten all four corners. Make use of drift pins to simplify the fastening process.

Install the remaining fasteners, working from the corners towards the center. Fasteners must be installed in every hole in the side

flanges. No fasteners are required on the end flanges.

Use of Drift Pins for Final Positioning

rift pins are tools used to align holes in the flanges of the upper and lower sections of the unit prior to final fastening. By the time

drift pins are needed, the lower section of the unit has already been anchored to its support structure. The sealer tape has been

laid down on the lower section’s flanges, and the upper section is now hovering over the lower section.

A drift pin should be driven in to each of the corner bolt holes such that the upper and lower flanges are aligned as best as possible

with sideways motion restricted.

On units which are longer than 12’ (3.6m) (“L” > 12’ (3.6m)), a drift pin should be used at an intermediate pair of bolt holes in the

rigging seam to allow for proper alignment.

Notes:

Bolts can be driven upward through the mating flanges if access is restricted.

All rigging hardware is provided by EVAPCO. Drift pins are by others.

9

ESW4 Closed Circuit Coolers

Mounting Fan Screens

12’ (3.6m) and 14’ (4.2m) wide units will be shipped with the fan screens in the basin. Under these circumstances use the following

procedures to mount the fan screen on the discharge cylinder.

WARNING: DO NOT WALK ON THE FAN SCREENS

AT ANY TI E!

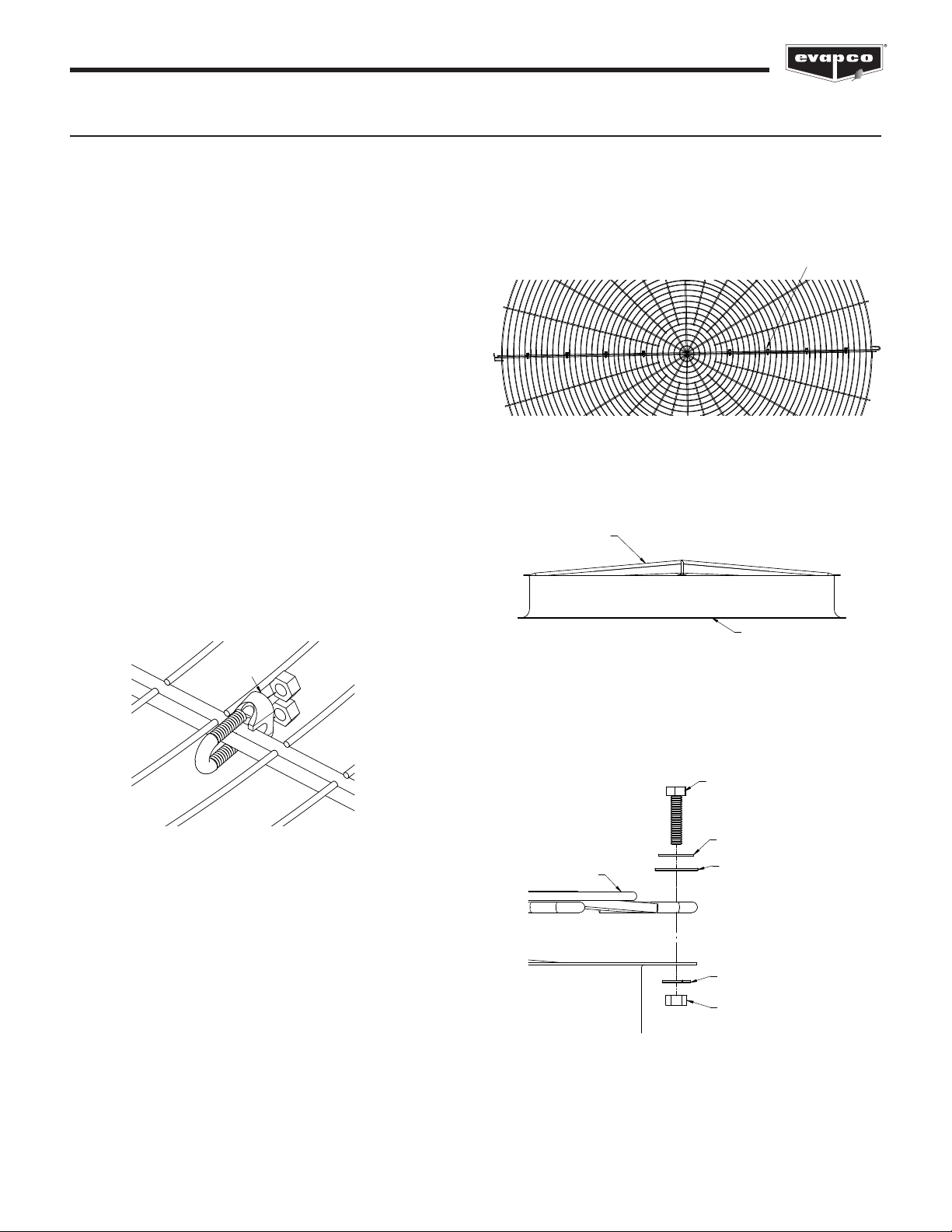

1. Lay both halves of the fan screen on the ground. Join the

two screen halves with wire clips (Figure 11). There should

be 4 wire clips on each side of the fan screen for 12’

(3.6m) and 14’ (4.2m) wide units. Space the wire clips

evenly across the radius of the fan screen as shown in

Figure 12.

2. The fan screen is supported from underneath by an “X”

shaped support frame. Set the support frame across the

top of the discharge cylinder (See Figure 13), and fasten to

cylinder with 3/8” (10mm) bolts.

3. Place the fan screen on top of the support frame and

discharge cylinder. Each half will be tagged to match

markings on the cylinder. Align the eyelets of the fan

screen with the holes on the perimeter of the discharge

cylinder.

4. At each hole, attach the fan screen to the discharge

cylinder as shown in Figure 14.

5/8" (16mm) FLATWASHER

1/2" (13mm) BOLT

1/2" (13mm) FLATWASHER

FAN SCREEN

1/2" (13mm) LOCKWASHER

1/2" (13mm) HEX NUT

Figure 12 – Wire Clip Spacing

WIRE

CLIPS

FAN SCREEN

SUPPORT

FAN

CYLINDER

Figure 14 – Attaching Fan Screen to Cylinder

Figure 11 – Wire Clip Arrangement

U-BOLT

ASSEMBLY

Figure 13 – Support Frame Installation

10

ESW4 Closed Circuit Coolers

External Motor Installation (applicable to 8.5’ (2.6m) wide models only)

8.5’ (2.6m) Wide odels

1. Study Figure 15 before installing the motor base on the unit.

2. Insert the lifting device into “U” bolt Aon motor base B.

3. Lift the motor base and insert the pivot pin Cdown into

hole Eand pivot pin Finto hole D.

4. Install washer and nut (do not overtighten) on pivot pins.

Install jam nut on pivot pin C.

5. Insert “J” bolts Ginto holes H. Install flat washers and

cotter pins. Place nuts and washers on threaded portion of

“J” bolts. These will be behind the motor base installed in

the next step.

6. Insert “J” bolts into holes Jin the motor base. Install flat

washers, lock washer and nuts. Remove lifting device from

the “U” bolt on the motor base. Position motor base toward

casing of unit for belt installation.

7. Install Powerband belt K(Figure 15) around fan sheave

and motor sheave. Tighten belt by adjusting nuts on “J”

bolts. o not over tighten the belts. The center of the belt

should deflect approximately 3/4” (19mm) with moderate

hand pressure.

8. Measure to see that the top and bottom of the motor base

are the same distance out from the casing of the unit. This

should ensure that the sheaves are properly aligned as

they have been pre-set at the factory.

9. As a final check, lay a straight edge from sheave to

sheave. There should be four point contact (See Figure

16). Adjust the position of the motor sheave as necessary.

10. To install Motor Guard L, match up hinges and install hinge

pins (See Figure 16).

11. Close Motor Guard and install two (2) wing bolts N.

J

J

C

G

G

H

F

E

B

D

H

A

Figure 15 – External Motor Installation

N

K

M

L

N

Figure 16 – Motor Guard and Powerband Belt Installation

FAN SHEAVE

ADJUST POSITION

OF MOTOR SHEAVE

(only if necessary)

12 3 4

Figure 17 – Sheave Alignment Check

11

ESW4 Closed Circuit Coolers

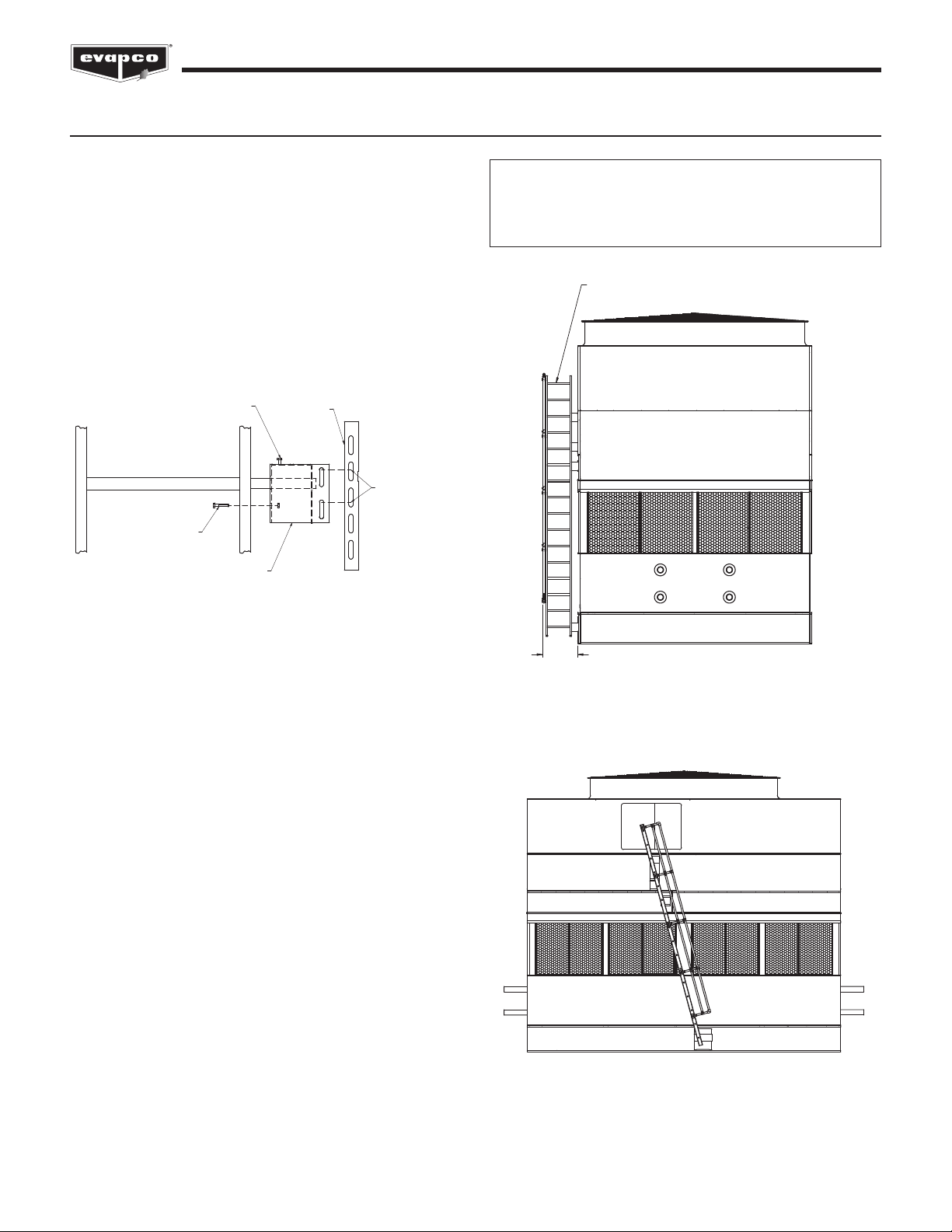

Optional Motor Davit

This accessory is available to aid in the removal of fan motors and gear boxes. The assembly consists of a davit and a mounting

base/channel that is attached to the side of the unit next to the access door (Figure 18). Both of these items will ship loose in the

unit’s basin.

Use the following procedure to install the mounting channel:

1. Place the mounting channel on the factory-installed

mounting brackets near the access door.

2. At each hole, attach the mounting channel to the bracket

using 3/8” (10mm) hardware as shown in Figure 19.

Optional Heater Pac age

This accessory is available to prevent the basin water from

freezing during winter operation. The heater package consists

of a heater, a low water cutout switch and a thermostat. The

heater is installed at the factory. The low water cutout switch is

shipped loose in the rigging box and will need to be screwed

into the screw tight fitting installed in the unit. The thermostat is

attached to the side of the unit at the factory. The bulbwell for

the thermostat is shipped loose in the rigging box and will also

need to be screwed into the screw tight fitting installed in the

unit. See Figure 20 for heater package location diagrams.

M

MOUNTING

BRACKET

MOUNTING

BRACKET

MOUNTING

BRACKET

MOUNTING CHANNEL

(SHIPS LOOSE)

ACCESS

DOOR

Figure 18 – ual-Point avit Arrangement

MOUNTING BRACKET

MOUNTING CHANNEL

BOLT

FLAT WASHER

FLAT WASHER

LOCK WASHER

NUT

Figure 19 – Attaching Mounting Channel to Mounting Bracket

LOW

WATER

CUTOUT

SWITCH

BULB WELL

LWCO

COVER PLATE

(INSIDE UNIT)

THERMOSTAT

HEATER

CONTROL

PANEL

(OPTIONAL)

IMMERSION

HEATER

Figure 20 – Heater Component Location

12

ESW4 Closed Circuit Coolers

Optional Sloped Ladders

When sloped ladders are supplied with a unit, they are shipped

in the basin section, if there is room. One sloped ladder will be

provided for each cell. Assembly is identical for each cell.

Sloped ladders are attached at a minimum of three points.

Taller units will have four attachment points. At each point of

attachment, the ladder will be fitted with a ladder bracket

assembly. The ladder bracket assembly looks like a metal box

and is shown in detail (component #4) in Figure 21 below. The

upper two assembly brackets are factory mounted to the ladder

and are not adjustable. These two brackets define the slope of

the ladder. The lower brackets are adjustable. See Figures 22

and 23 for drawing of the final ladder assembly.

To install the ladder assembly, follow the steps outlined below

which refer to Figure 21:

1. Remove the ladder bracket mounting bolts (A) from the

ladder mounting channels (B) on pan and casing sections.

2. Loosen, but do not remove, the ladder bracket and

assembly bolts (C).

3. Slide the ladder bracket assembly (D) over the ladder

mounting channel (B) located on the unit panels. o not

remove the ladder bracket assembly (D) from the ladder.

4. Align the bolt holes and reinstall the ladder bracket

mounting bolts (A) through the ladder bracket assembly

and the ladder mounting channels (B).

5. Tighten all bolts.

6. Tighten the adjusting screw (E) in the adjustable mounting

bracket where applicable.

LADDER

MOUNTING

CHANNEL (b)

ADJUSTING SCREW (e)

(WHEN APPLICABLE)

LADDER BRACKET

MOUNTING BOLTS (a)

LADDER BRACKET

ASSEMBLY BOLTS (c)

LADDER BRACKET

ASSEMBLY (d)

Figure 21– etail of Ladder, Ladder Bracket Assembly

and Mounting Channel

NOTE: Upper Section of Unit Must Be Properly Oriented

with Respect to Lower Section. All Mounting Brackets Must

be on Same Side of Unit. Refer to Certified Print For Proper

Orientation.

LADDER SHIPS LOOSE FOR

FIELD MOUNTING (BY OTHERS)

Figure 22 – End View of Ladder Assembly

ACCESS

DOOR

Figure 23 – Side View of Ladder Assembly

13

ESW4 Closed Circuit Coolers

Optional Wor ing Platform and Ladder

The working platform and ladder will either be shipped in the basin or shipped separately due to basin accessories that interfere

with storage. The platform is partially assembled prior to shipment for minimal field assembly.

The platform and ladder assembly should be attached after the unit is fully rigged. Follow the instructions below.

7,7/(

&87

1&

'5$:1

*$ 5$:

3$5712 5(912

$//¡+2/(66+28/'%(¡

86(67$,1/(6667((/1&6(7836+((7

67$,1/(6667((/237,21

3$5712 5(912

5(9,6,216

3$57

1(;7

6,=(

,1)2

%<

$66( %/<

$7/

12 $7/

5$:

127(

(9$3&2,1&

'$7(

&+.'

%<

&21),'(17,$/

7KLVGRFXPHQWLVWKHSURSHUW\RI(YDSFR,QF,WVKRXOGQRW

EHFRSLHGRUGLVFORVHGZLWKRXWSULRUZULWWHQDXWKRUL]DWLRQ

6&$/(

127(6

3/$7)25 *5$7,1*1276+2:1

)25&/$5,7<

$'(7$,/$

%'(7$,/%

'

'(7$,/'

(

'(7$,/(

&

'(7$,/&

6(&85(',$*21$/

683325772'(&.

683325786,1*

*5$'(+$5':$5(

'(&.

6833257

',$*21$/

6833257

6(&85('(&.6833257

72&211(&7,213/$7(6

86,1**5$'(

+$5':$5(

'(&.

6833257

&211(&7,21

3/$7(

6(&85('(&.683325772

&211(&7,213/$7(686,1*

*5$'(+$5':$5(

',$*21$/

6833257

&211(&7,21

3/$7(

6(&85(5$,/,1*),77,1*

72)521772(3/$7(86,1*

*5$'(+$5':$5(

5$,/,1*

),77,1*

)5217

72(3/$7(

/2:(5

&+$11(/

$66<

/$''(5

&+$11(/

6(&85(/$''(5

&+$11(/672/2:(5

&+$11(/$66( %/<

2181,786,1*

*5$'(+$5':$5(

5()

)52 723

2)72(3/$7(

727232))7*

),77,1*621/$''(5 $<

1(('72%($'-867('

,1),(/'

6(1'7+,6'5$:,1*727+(6+,33,1*'(3$570(17

72%(3/$&(',17+(5,**,1*3$&.$*(

),(/'$66<3/$7)25 *(1$55

176

1/1 *$

*$

5(3/$&('6$)(7<

&+$,16:6:,1**$7(

$ *

Y

Figure 23 – Ladder Assembly

14

ESW4 Closed Circuit Coolers

General Information - Start-up & Maintenance Start-up Details

Shipping Choc s and Debris

Remove any chocks that have been placed inside the unit for shipping purposes. Be sure to remove the chocks from between the

fan and fan guard if applicable. Clean all debris from the basin prior to start-up. Clean and secure all access doors.

Pump Discharge Line

Connect the riser pipe from the pump discharge on the basin section to the riser pipe on the coil/fan section using the flexible

connection and hose clamps provided.

Bleed-off Line

A bleed-off line and valve are installed on the unit when shipped with a pump. On units shipped without a pump (remote sump

applications) make sure a bleed-off line and valve are properly sized and installed on the discharge side of the pump and

connected to a convenient drain. In either case, the bleed-off valve should be fully open.

Strainer

Check the strainers, if applicable, in the basin section to make

certain they are in the proper location over the pump suction,

along side of the anti-vortex hood. (See Figure 24.)

Screens

Protective fan screens are provided across the top of the fan cylinders of all models. Check and tighten all bolts.

Float Valve Adjustment

The float valve is pre-set at the factory; however, adjustment

should be checked after rigging. The float valve should be

adjusted so that the centerline of the float is at the

measurement shown in Table 6 from the basin bottom. Raise

or lower the float by using the wing nuts on the vertical

threaded rod only. o not adjust the horizontal rod.

SUCTION HOOD

STRAINER

Figure 24 – Strainer Location

Unit Width Level

8.5’ (2.6m) 9” (23cm)

12’ (3.6m) 10” (30cm)

14’ (4.2m) 9” (23cm)

Table 6 – Recommended Water Level

15

ESW4 Closed Circuit Coolers

Starting Sequence

Before starting the unit, check that all access openings, safety screens and covers are in place. Start the unit as outlined below:

1. Fill the pan to the overflow level.

2. Bump start and check the spray water pump(s) for proper rotation. irectional arrows are found on the pump impeller housing.

3. Bump start and check the fan(s) for proper rotation. irectional arrows are placed on the side of the fan cylinder.

Maintenance

Once the installation is complete and the unit is turned on, it is important that it be properly maintained. Maintenance is not difficult

or time-consuming but must be done regularly to assure full performance of the unit. Refer to the operation maintenance

instructions enclosed with the unit for proper maintenance procedures.

Freeze Protection

Proper freeze protection must be provided if the unit is located in a cold climate. Refer to the operation maintenance instructions as

well as product bulletins for further information.

EVAPCO, Inc. • P.O. Box 1300 • Westminster, M 21158 USA

PHONE: 410-756-2600 • FAX: 410-756-6450 • E-MAIL: [email protected]

©2020 EVAPCO, Inc.

Printed on recycled paper

using soy-based ink

Accessories can ship in a variety of locations depending on the type of accessory, the size of the unit and the other accessories

purchased with the unit. See Table 7 for a guide to accessory location.

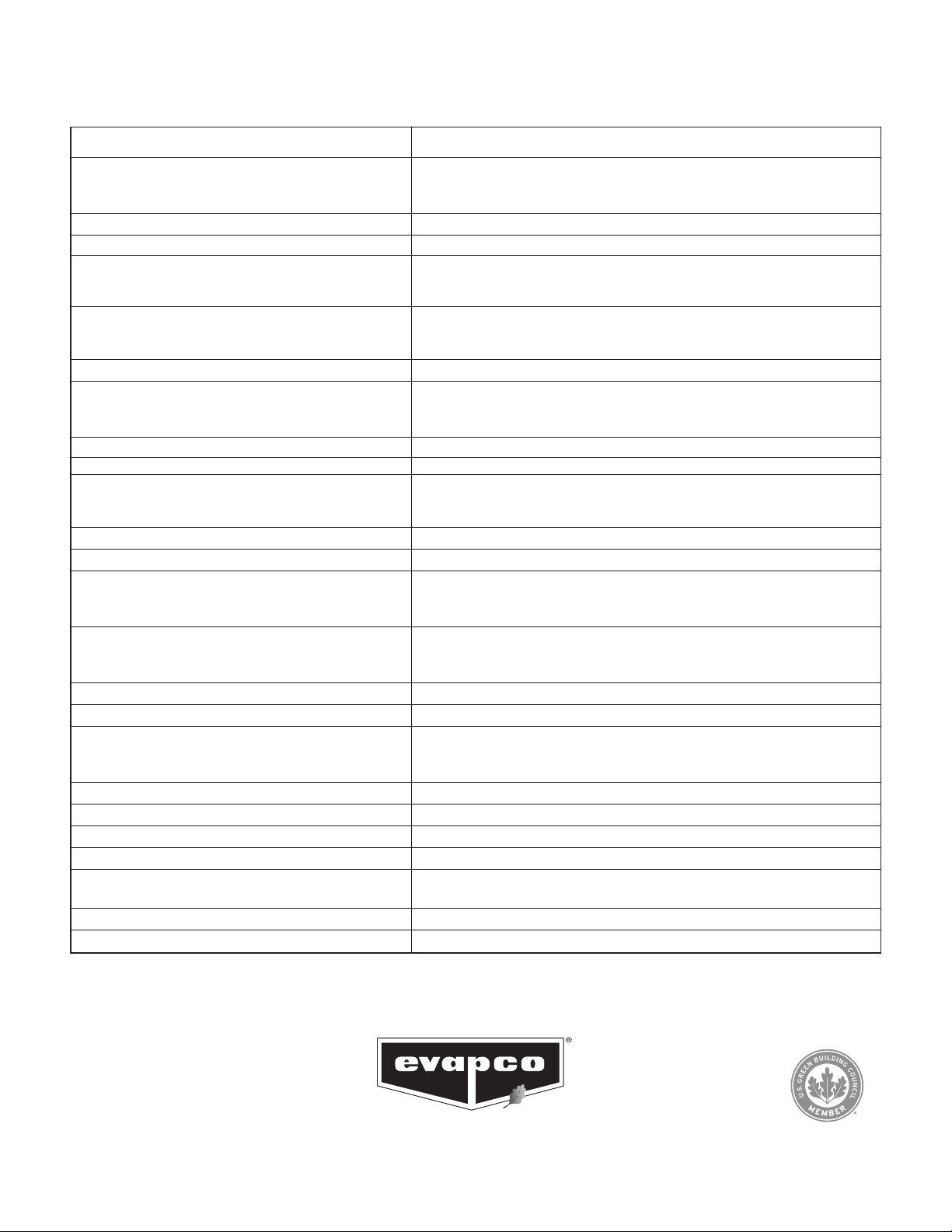

Unit Accessories Shipping Location

Aluminum Ladder Shipping Location is Unit and Accessory ependent

- If Space is Available: Strapped Inside Unit Basin

- If No Space is Available: Shipped Separately on Truck Bed

rip Channels for Multi Cell Units Strapped Inside Unit Basin

ischarge Attenuation Mounted Loosely Bolted on Basin Section

Shipping Location is Unit ependent

Electric Basin Heater - End Mounted Heater: Installed in Unit Basin

- Side Mounted Heater: Strapped Inside Basin Section

Shipping Location is ependent on Control Panel Size

Electric Basin Heater Control Panel - If Space is Available: Mounted on Unit Basin

- If No Space is Available: Boxed, Wrapped and Wire Tied Inside Basin Section

Electric Basin Heater Low Water Cutout Shipped in Rigging Box

Shipping Location is Unit ependent

Electric Basin Heater Thermostat - End Mounted Thermostat: Mounted on Basin Section

- Side Mounted Thermostat: Shipped in Rigging Box

Electronic Water Level Control Probes Mounted in PVC standpipe

Electronic Water Level Control PVC Standpipe Strapped Inside Unit Basin

Shipping Location is Unit and Accessory ependent

External Service Platform with Ladder - If Space is Available: Strapped Inside Basin Section

- If No Space is Available: Crated and Shipped Separately on Truck Bed

Factory Mounted Crossover Piping Welded to Coil Connections

Fan Motor Shipped Loose on 8.5’ (2.6m) Wide Units

Shipping Location is Unit and Accessory ependent

Fan Screens (If not mounted) - If Space is Available: Strapped Inside Basin Sections

- If No Space is Available: Crated and Shipped Separately on Truck Bed

Shipping Location is Unit and Accessory ependent

Fan Screen Supports (If not mounted) - If Space is Available: Strapped Inside Basin Section

- If No Space is Available: Crated and Shipped Separately on Truck Bed

Hot Water or Steam Coil Installed in Unit Basin

Low Water Cutoff for Pump Shipped in Rigging Box

Shipping Location is Unit and Accessory ependent

Motor avit and Base - If Space is Available: Strapped Inside Basin Section

- If No Space is Available: Crated and Shipped Separately on Truck Bed

Remote Sump Trash Screen Installed In Unit Basin

Rigging Hardware Shipped in Rigging Box

Safety Cage Attached to the Ladder

Sealer Tape Shipped in Rigging Box

Sump Sweeper Piping with and without

High Flow Eductors Installed in Unit Basin

Vibration Switch Mounted in Fan Section

Water Level Indicator Strapped Inside Unit Basin

Table 7 – Unit Accessory Shipping Location

Other EVAPCO Accessories manuals