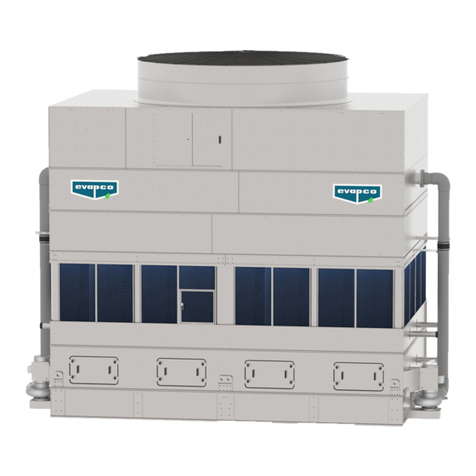

EVAPCO ATC-E User manual

Rigging and

Assembly nstructions

ATC-E, ATC-ES, ATWB, eco-ATWB and

eco-ATWB-E Evaporative Condensers and

Closed Circuit Coolers

Bulletin ATWB19RIG

Visit EVAPCO’s Website at: evapco.com

EVAPCO...SPECIALISTS IN HEAT TRANSFER PRODUCTS AND SERVICES.

EVAPCO Products are Manufactured Wordwide

EVAPCO, Inc. — World H adquart rs & R s arch/D v lopm nt C nt r

P.O. Box 1300 • Westminster, MD 21158 USA

410-756-2600 p • [email protected] • evapco.com

EVAPCO, Inc.

World H adquart rs

P.O. Box 1300

Westminster, MD 21158 USA

410-756-2600 p | 410-756-6450 f

Asia/Pacific

EVAPCO Asia/Pacific H adquart rs

1159 Luoning Road

Baoshan Industrial Zone

Shanghai 200949, P.R. China

(86) 21-6687-7786 p | (86) 21-6687-7008 f

Europ

EVAPCO Europ BVBA

Europ an H adquart rs

Heersterveldweg 19

Industrieterrein Oost

3700 Tongeren, Belgium

(32) 12-395029 p | (32) 12-238527 f

EVAPCO East

5151 Allendale Lane

Taneytown, MD 21787 USA

410-756-2600 p | 410-756-6450 f

EVAPCO East

Key Building

Taneytown, MD USA

410-756-2600 p

EVAPCO Midw st

Greenup, IL USA

217-923-3431 p

evapcomw@evapcomw.com

EVAPCO W st

Madera, CA USA

559-673-2207 p

EVAPCO Iowa

Lake View, IA USA

712-657-3223 p

EVAPCO Iowa

Sales & Engineering

Medford, MN USA

507-446-8005 p

EVAPCO N wton

Newton, IL USA

618-783-3433 p

evapcomw@evapcomw.com

EVAPCOLD

Greenup, IL USA

217-923-3431 p

evapcomw@evapcomw.com

EVAPCO-BLCT Dry Cooling, Inc.

Bridgewater, NJ 08807 USA

908-379-2665 p

EVAPCO-BLCT Dry Cooling, Inc.

Littleton, CO 80127 USA

908-379-2665 p

EVAPCO Pow r México S. d R.L. d C.V.

Calle Iglesia No. 2, Torre E

Tizapan San Ángel, Del. Álvaro Obregón

Ciudad de México, D. . México 01090

+52 (55) 8421-9260 p

R frig ration V ss ls & Syst ms Corporation

A wholl owned subsidiar of EVAPCO, Inc.

Bryan, TX USA

979-778-0095 p

EvapT ch, Inc.

A wholl owned subsidiar of EVAPCO, Inc.

Lenexa, KS USA

913-322-5165 p

Tow r Compon nts, Inc.

A wholl owned subsidiar of EVAPCO, Inc.

Ramseur, NC USA

336-824-2102 p

EVAPCO Alcoil, Inc.

A wholl owned subsidiar of EVAPCO, Inc.

York, PA USA

717-347-7500 p

EVAPCO Europ , S.r.l.

Milan, Italy

(39) 02-939-9041 p

EVAPCO Europ , S.r.l.

Sondrio, Italy

EVAPCO Europ GmbH

Meerbusch, Germany

(49) 2159 6956 18 p

EVAPCO Air Solutions

A wholl owned subsidiar of EVAPCO, Inc.

Aabybro, Denmark

(45) 9824 4999 p

EVAPCO Air Solutions GmbH

Garbsen, Germany

(49) 5137 93875-0 p

Evap Egypt Engin ring Industri s Co.

A licensed manufacturer of EVAPCO, Inc.

Nasr City, Cairo, Egypt

2 02 24022866/2 02 24044997 p

primacool@link.net / shady@primacool.net

EVAPCO Middl East DMCC

Dubai, United Arab Emirates

+971 4 448 7242 p

EVAPCO S.A. (Pty.) Ltd.

A licensed manufacturer of EVAPCO, Inc.

Isando 1600, Republic of South Africa

(27) 11-392-6630 p

EVAPCO (Shanghai) R frig ration Equipm nt Co., Ltd.

Baoshan Industrial Zone Shanghai, P.R. China

(86) 21-6687-7786 p

B ijing EVAPCO R frig ration Equipm nt Co., Ltd.

Huairou District Beijing, P.R. China

010-6166-7238 p

EVAPCO Air Cooling Syst ms (Jiaxing) Company, Ltd.

Building 10, 1133 Taoyuan Road,

Jiaxing, Zhejiang, China

(86) 573 83119379 p

info@evapcoacs.cn

EVAPCO Australia (Pty.) Ltd.

Riverstone NSW 2765, Australia

(61) 2 9627-3322 p

EvapT ch Asia Pacific Sdn. Bhd

A wholl owned subsidiar of EvapTech, Inc.

Puchong, Selangor, Malaysia

(60-3) 8070-7255 p

North Am rica

South Am rica

EVAPCO Brasil

Equipamentos Industriais Ltda.

Al. Vênus, 151 – CEP: 13347-659

Indaiatuba –São Paulo – Brasil

(55+11) 5681-2000 p

Fan T chnology R sourc s

Cruz das Almas – Indaiatuba

São Paulo, Brasil 13308-200

55 (11) 4025-1670 p

fantr@fantr.com

2

ATC-E, ATC-ES, ATWB, eco-ATWB and eco-ATWB-E Evaporative Condensers and Closed Circuit Coolers

Table of Contents

ntroduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Method of Shipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Structural Steel Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Rigging Basin Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Joining Multi-Cell Units Basin Sections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Equalizer Blank-Off Plate: Multi Cell Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Application of Sealer Tape . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Rigging Coil/Fan Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Extended Lifts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Assembly of the Coil/Fan Section to the Basin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Containerized Unit Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Assembly of the Fan Section to the Coil Section (Containerized) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Assembly of the Coil Section to the Basin (Containerized) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

nstalling Watertight Partitions & Firewalls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

External Motor nstallation – Belt Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Optional Motor & Gear Box Davit nstallation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Mounting Fan Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

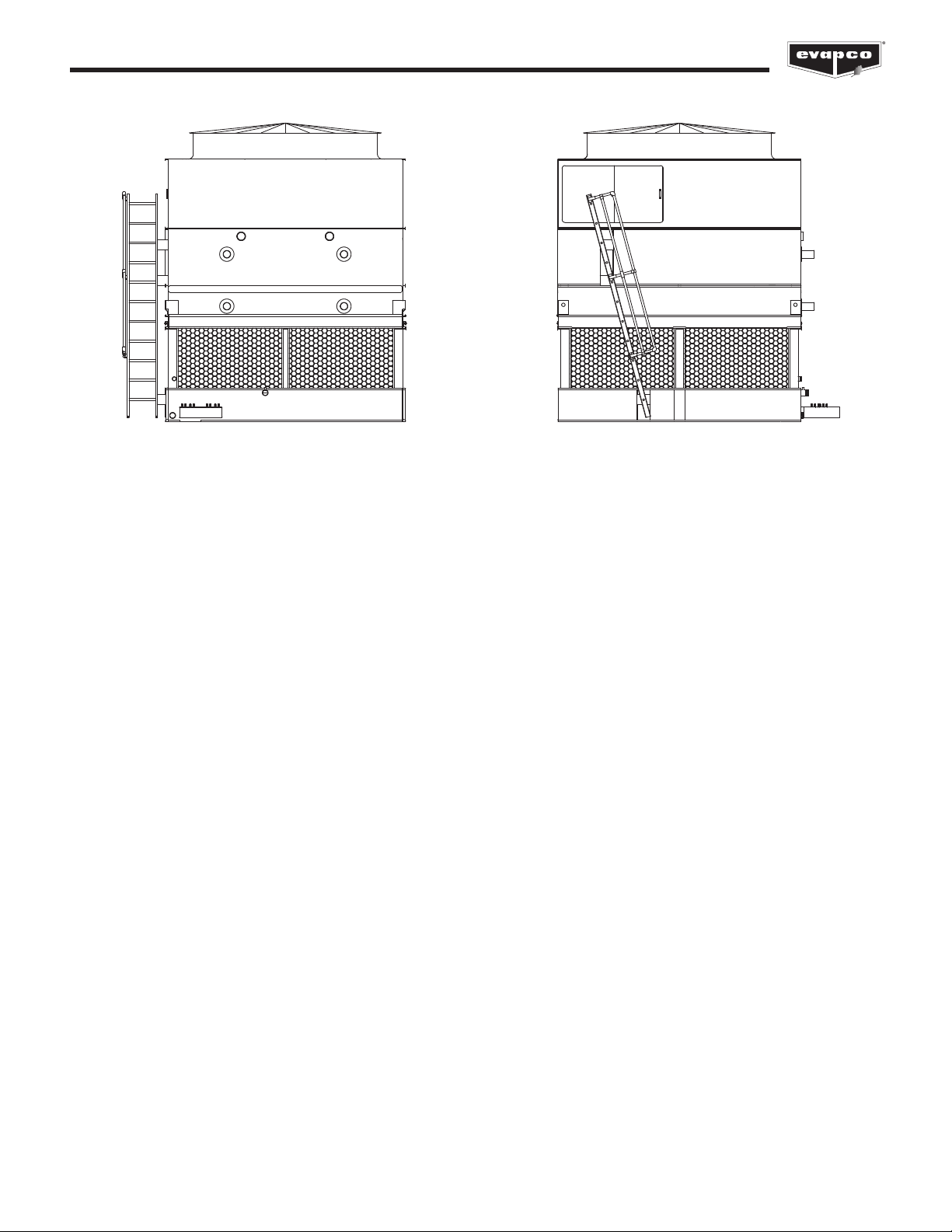

Sloped Ladder nstallation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

External Platform and Vertical Ladder nstallation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

3

ATC-E, ATC-ES, ATWB, eco-ATWB and eco-ATWB-E Evaporative Condensers and Closed Circuit Coolers

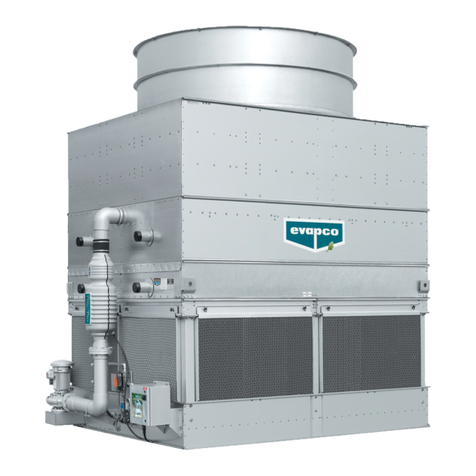

Introduct on

This manual provides instructions and recommendations to safely and correctly install all ATC-E, ATC-ES, ATWB, eco-ATWB and eco-

ATWB-E Evaporative Condensers and Closed Circuit Coolers. It is recommended that all the instructions provided in this manual be

reviewed in detail prior to rigging and assembly. If at any point, specific circumstances not covered by this manual arise, please contact

your local EVAPCO representative for assistance.

Proper care must be taken by all parties involved in handling and assembling the equipment to ensure that safe and thorough

installation practices are implemented to prevent damage or injury to the equipment, persons and environment involved.

Method of Sh pment

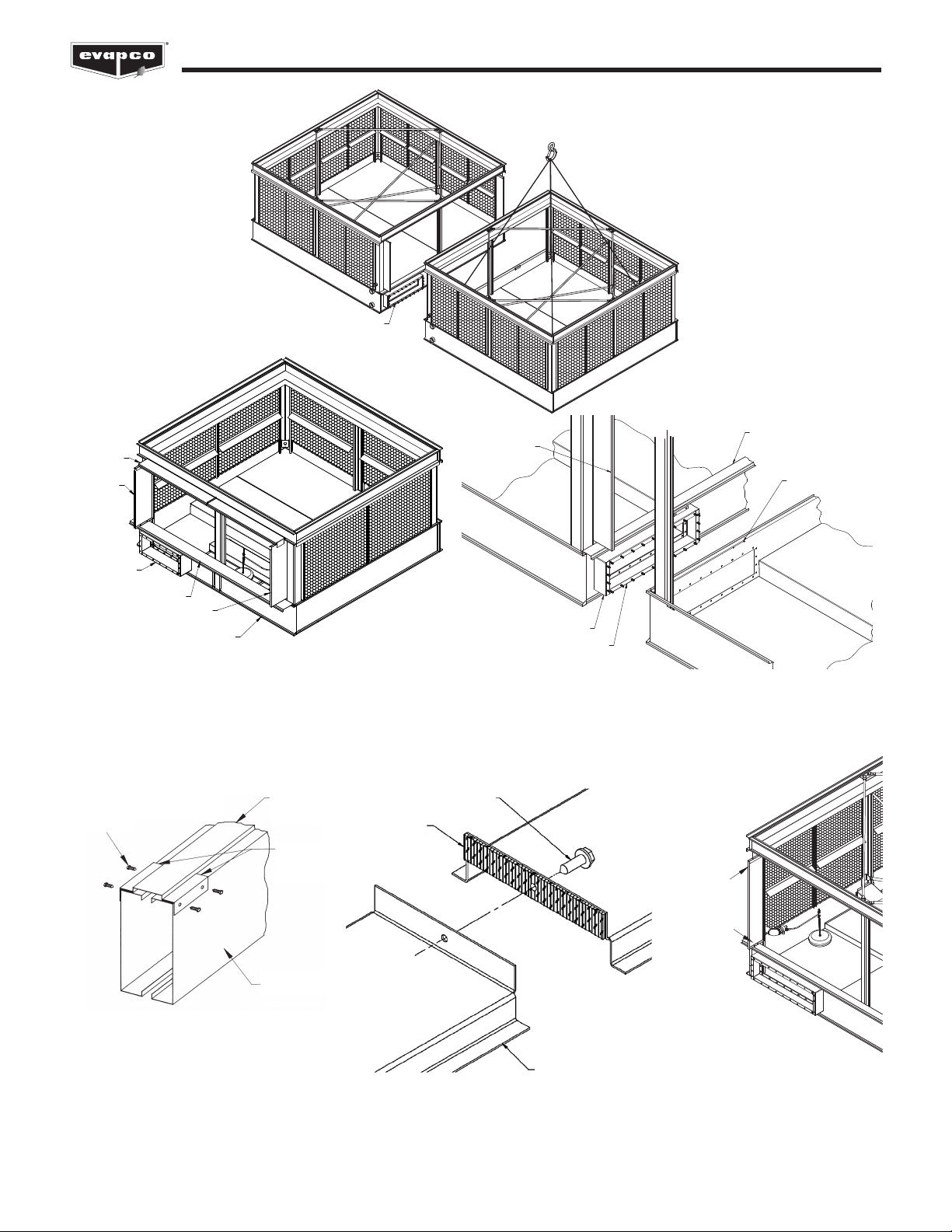

Induced draft coil products are shipped with the top section(s) separate from the bottom section(s). These sections have mating flanges

and will join together in a waterproof joint when sealed and bolted together as described in the following instructions. Miscellaneous

items, such as sealer, self-tapping screws and any other required materials, are packaged and placed inside the pan for shipment. or

units consisting of multiple cells, drip channels and splash guards will ship loose in the basin for field installation.

or 7' and 8.5' (2.2 m and 2.6m) and 14' and 17' (4.3m and 5.2m) wide units, the motors and drives are factory aligned and then

shipped loose inside the basin section for mounting during installation. Refer to the “External Motor Installation” section in this bulletin.

NOTE: All casing sections are factory inspected prior to shipment to verify proper fit for rigging. Please take extra care to handle and rig

unit section per the instructions of this manual to avoid possible distortion and poor casing alignment. It is advisable to check each

section upon receipt and during each lift to ensure that the factory alignment has not been altered. Should the field inspection indicate the

section alignment (“square”) has been altered, please contact the factory or your local EVAPCO representative for additional instructions

to obtain proper section fit.

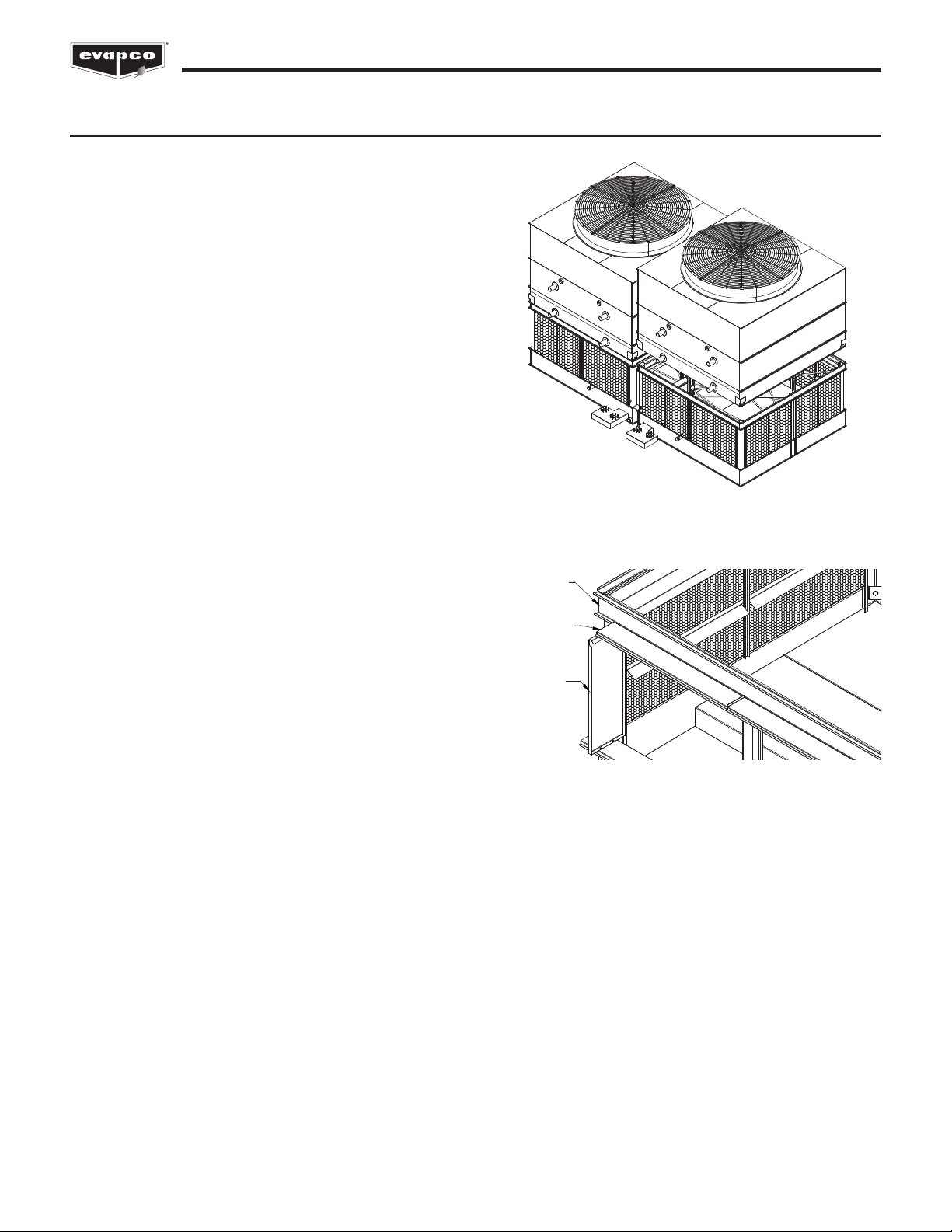

Structural Steel Support

Two structural “I” beams running the length of the unit are required for support of each cell of the units. These beams should be

located underneath the outer flanges of the unit (See Table 1). Mounting holes 3/4” (1.9mm) in diameter are located in the bottom

flanges of the unit for bolting to the structural steel (See steel support print in unit submittal for exact bolt hole location). Bolt the

bottom section to the steel support before rigging the top section.

Beams should be sized in accordance with accepted structural practices. Maximum deflection of the beam under the unit to be

1/360th of the unit length, not to exceed 1/2” (13mm). Deflection may be calculated by using 55% of the operating weight of the

unit as a uniform load on each beam (See certified print in unit submittal for operating weight).

The supporting “I” beams should be level before setting the unit. Do not level the unit by shimming between the bottom flanges

and the beams as this will not provide proper and continuous longitudinal support. Support beams and anchor bolts are to be

furnished by others. Always refer to the certified print in the unit submittal for unit weights, dimensions and technical data.

Please refer to the unit submittal for detailed, project specific steel support arrangement.

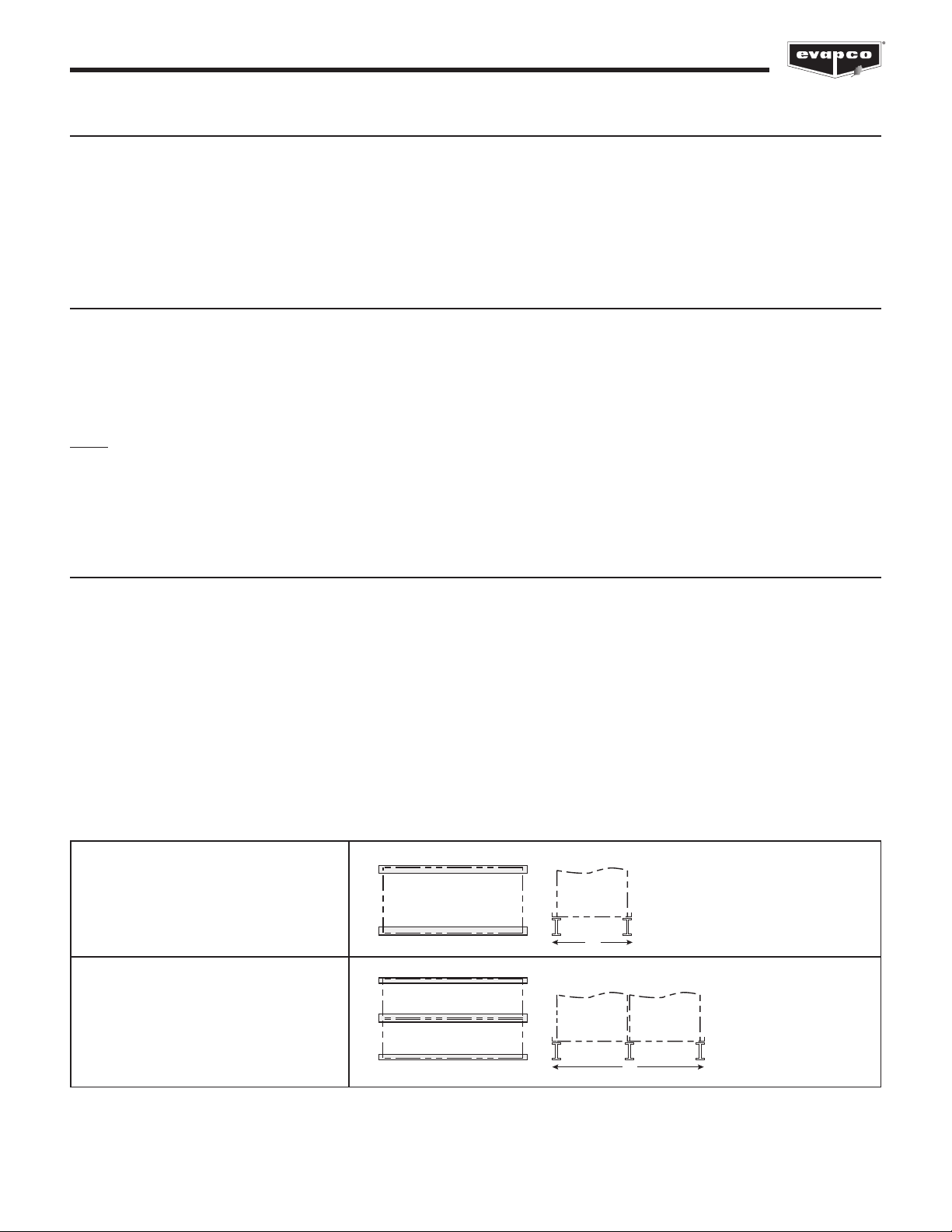

W

W

3' (0.914m), 4’ (1.2m), 7’ (2.2m), 8.5’

(2.6m), 10’ (3m), and 12' (3.6m) wide

single & multi-cell units

14’ (4.3m), 16' (4.8m), 17’ (5.2m), 20’

(6m) and 24’ (7.3) wide multi-cell units

Table 1 - Standard Longitudinal Steel Support Arrangement

4

ATC-E, ATC-ES, ATWB, eco-ATWB and eco-ATWB-E Evaporative Condensers and Closed Circuit Coolers

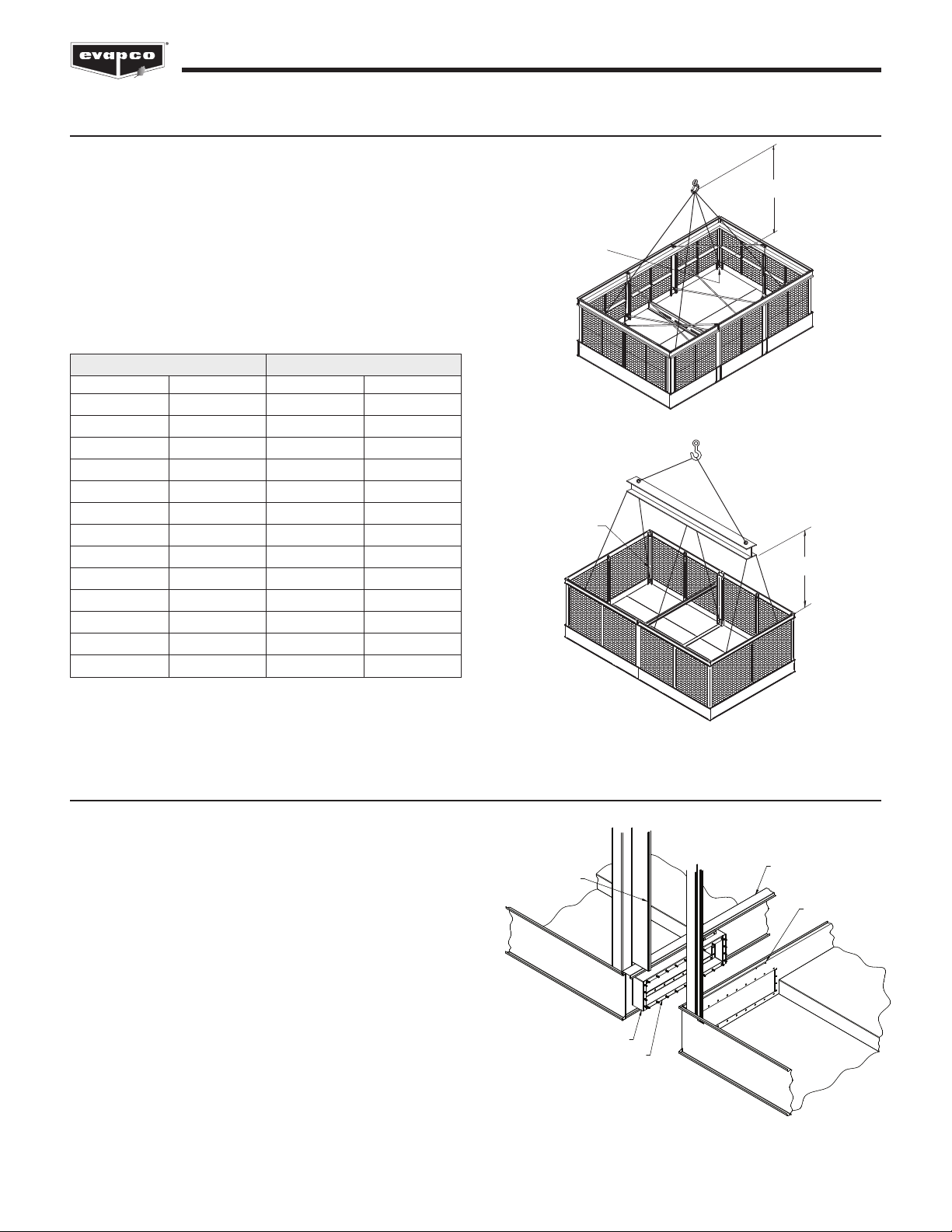

R gg ng Bas n Sect on

Lifting devices are located in the upper corners of the basin

section for lifting and final positioning purposes as shown in

igures 1a and 1b. The hook of the crane must be a minimum

dimension of “H” above the top of the section being lifted to

prevent undue strain on the lifting devices. See Table 2 for the

minimum “H” dimension. These lifting devices should not be

used for extended lifts or where any hazard exists unless

safety slings are employed under the section. (See “Extended

Lifts” section for proper arrangement.) Bolt the basin section to

the steel support before rigging the coil/fan section.

Figure 1b - Basin Section 24' (7.3m) to 40' (12.2m) long

LIFTING

EARS

H

LIFTING

EARS

H

Basin Section Length Min. “H” Dim.

eet Meters eet Meters

3 - 6 0.9-1.8 8 2.4

8.5 2.6 10 3

9 2.7 10 3

10.5 3.2 11 3.4

12 3.6 15 4.6

14 4.3 17 5.2

18 5.5 19 5.8

20 6 21 6.4

21 6.4 22 6.7

24 7.3 15 4.6

28 8.5 16 4.9

36 11 19 5.8

40 12.2 21 6.4

Table 2 - Minimum “H” Dimension for Basin Sections

Figure 1a - Basin Section up to 21' (6.4m) long

Jo n ng Mult -Cell Un ts

On all 2-cell models, the two bottom sections are shipped

separately and are typically furnished with a connecting equalizer

flume box between them.

In addition to the equalizer flumes, these units are provided with

horizontal drip channels and vertical splash guards to keep water

from splashing out from between the cells. All units have one or

more horizontal drip channel and two vertical splash guards per

flume box. lume boxes are a standard offering on multi-cell units.

The equalizer flume box is factory installed on one section for field

connection to the other. It is important to connect the equalizer

flume to balance the water level in the pans for proper pump

suction operation. The procedures that follow should be

performed in sequence.

HORIZONTAL

DRIP

CHANNEL

VERTICAL

SPLASH

GUARD

FLUME BOX

SEALER

TAPE

RETAINING

CLIP

Figure 2 - Equalizer lume Connection, 12' (3.6m) Wide Models

5

ATC-E, ATC-ES, ATWB, eco-ATWB and eco-ATWB-E Evaporative Condensers and Closed Circuit Coolers

For units on which the flume box ships loose:

1. Rig one of the bottom sections of the multi-cell unit. Bolt to steel support.

2. One face of the flume box is provided with 3/8” (10mm) welded bolts. Clean the mating flume opening on the rigged bottom

section and apply a layer of sealer tape on this surface, centered between the hole centers and the outside edge. Remove

paper backing strip from sealer tape.

3. Align the bolt holes in the rigged bottom section with the welded 3/8” (10mm) bolts on the flume box.

4. Install 3/8” (10mm) nuts and washers on every bolt around the flume opening and tighten.

5. ollow steps 4 through 10 as shown below.

For units on which the flume box ships mounted to one cell:

1. Install the bottom section with the factory installed flume box on it as described above.

2. Clean the flanges on the flume box on the end to be field connected. Apply a layer of sealer tape on the flange, centered

between the hole centers and the outside edge. Remove paper backing strip from the sealer tape.

3. Clean the mating surface of the flume opening of any dirt, grease or moisture.

4. Rig the second bottom section adjacent to the equalizer flume on the steel support as shown in the sequential figures that

follow.

5. Align the bolt holes in the flume box and flume opening with drift pins (by others) while drawing the second bottom section

against the flanged connection.

6. Install 3/8” (10mm) bolts, nuts, and washers in every hole around the flume opening and tighten.

7. Bolt the second bottom section to the steel support.

8. Remove the 1/4” (6mm) bolts which hold the drip channel retaining clips to the end panel. Place the drip channel over the

adjoining pan section flanges. Turn around the retaining clips and install them using the same hardware.

9. If there are multiple drip channels, fasten them together end-to-end by driving a self-tapping 5/16” (8mm) screw through the

section end with the larger hole into the mating end with the smaller hole. Stainless steel units will use 5/16” (8mm) stainless

steel nuts and bolts.

10. Place the vertical splash guard in the bend of the vertical supports. On galvanized units, attach the vertical splash guard using

5/16” (8mm) self-tapping screws. On stainless steel units, attach the vertical splash guards using 5/16” (8mm) stainless steel

nuts and bolts. (See figure 3a)

11. Once the bottom of the vertical splash guard has been attached to the drip channel, place the filler cap channel in the upper

flanges of the bottom section as shown in igure 3a. Attach to vertical splash guards using 5/16" (8mm) tappers (for galvanized

units) or stainless steel nuts and bolts (for stainless steel units).

6

ATC-E, ATC-ES, ATWB, eco-ATWB and eco-ATWB-E Evaporative Condensers and Closed Circuit Coolers

FACTORY INSTALLED

EQUALIZER FLUME BOX

VERTICAL

SPLASH

GUARD

FLUME

BOX

DRIP CHANNEL

FILLER CAP

CHANNEL

SIDE PANEL

VERTICAL

SPLASH GUARD

VERTICAL

SPLASH

GUARD

EQUALIZER FLUME BOX

SEALER TAPE

DRIP CHANNEL

RETAINING CLIP

Figure 3a - Drip Channel and Vertical Splash Guard Installation

D IP CHANNEL

SECTION

SEALE TAPE

5/16” (8mm)

TAPPE

DRILLING IS

REQUIRED

IN THE FIELD

FOR THESE

HOLES

DRIP

CHANNEL

RETAINING

CLIP

END PANEL

TAPPERS (GALVANIZED)

OR STAINLESS STEEL

BOLTS (STAINLESS)

Figure 3 - Joining Bottom Sections – Multi Cell Units

7

ATC-E, ATC-ES, ATWB, eco-ATWB and eco-ATWB-E Evaporative Condensers and Closed Circuit Coolers

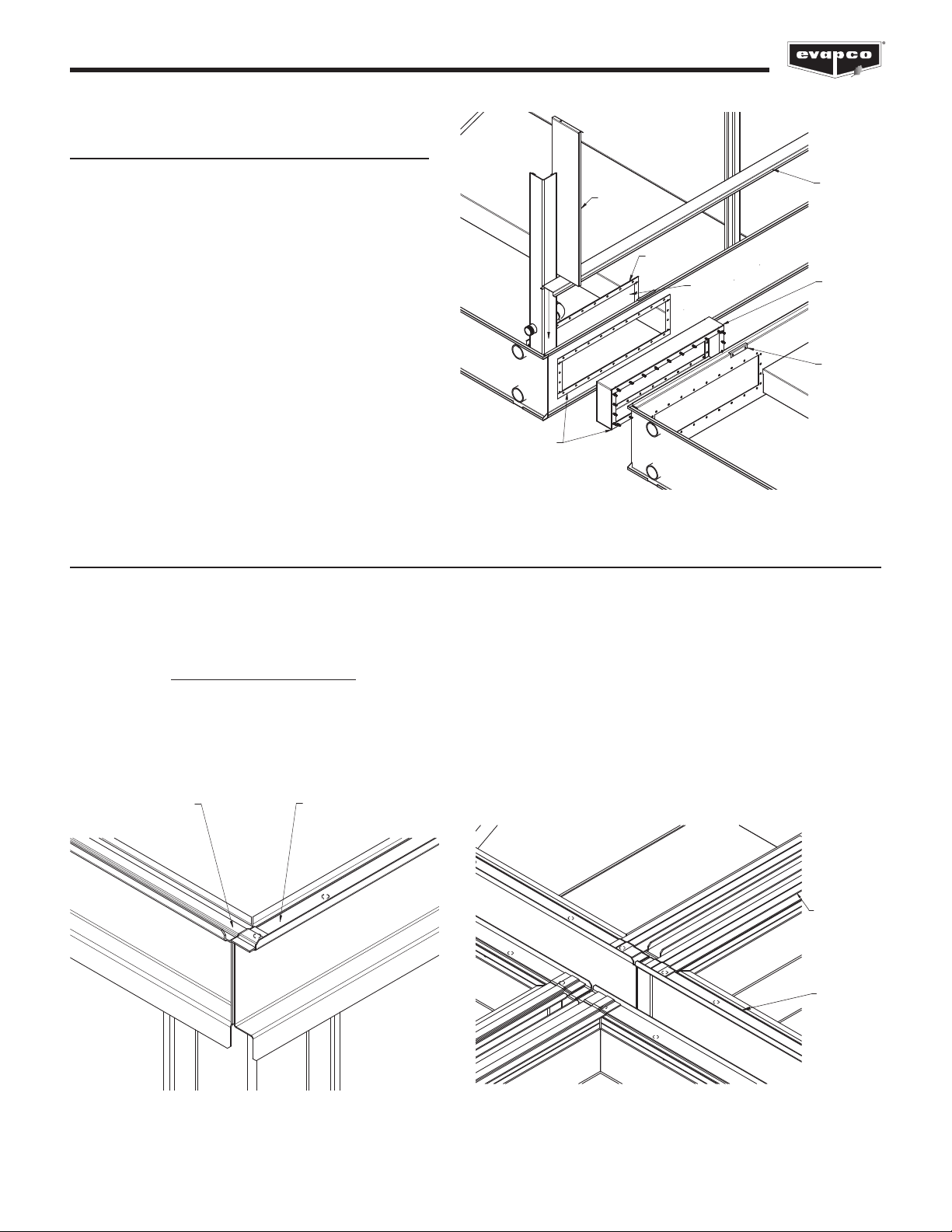

Equal zer Blank-Off Plate:

Mult Cell Un ts

Equalizer blank-off plate(s) are available to isolate the

bottom sections for individual cell operation, periodic

cleaning, or maintenance.The optional equalizer blank-off

plate is factory installed on the equalizer flume and

secured by wing nuts. This plate is also known as a

“flume plate” or “positive closure plate.”

or units not requiring the blank-off plate under normal

operating conditions, remove the wing nuts, washers,

plate and gasket. Reinstall washers and wing nuts for

proper leak free operation of the equalizer flume box.

Appl cat on of Sealer Tape

Once the bottom section has been set on the supporting steel and bolted in place, the top flanges should be wiped down to remove

any dirt or moisture. Sealer tape should be placed over the mounting hole centerline on the side flanges along the entire length of

all sides. Apply two strips of sealer tape, one partially overlapping the other, on the entire length of the end flanges (flanges with no

bolt holes).

The sealer tape should overlap on the corners as shown in igure 5a. Do not splice the sealer tape along the end flanges and

preferably not on the side flanges if it can be avoided.

Always remove the paper backing from the sealer tape.

All models with two or more top sections must have sealer tape applied along the entire length of all internal flanges, as shown in

igure 5b.

DRIP

CHANNEL

SEALER TAPE

GASKET

RETAINER

CLIP

FLUME

BOX

BLANK

OFF PLATE

VERTICAL

SPLASH

GUARD

Figure 4 - Equalizer Blank-Off Plate Installation

2 OVERLAPPING LAYERS

OF SEALER TAPE

ON THE ENDS

1 LAYER OF SEALER TAPE

CENTERED OVER THE

MOUNTING HOLES

END SIDE

2 OVERLAPPING

LAYERS

OF SEALER

TAPE ON

THE ENDS

1 LAYER OF

SEALER TAPE

CENTERED

OVER THE

MOUNTING

HOLES

Figure 5b - Sealer Tape Detail for Center Joint of Units with

our Top Sections

Figure 5a - Sealer Tape on lange of Bottom Section

8

ATC-E, ATC-ES, ATWB, eco-ATWB and eco-ATWB-E Evaporative Condensers and Closed Circuit Coolers

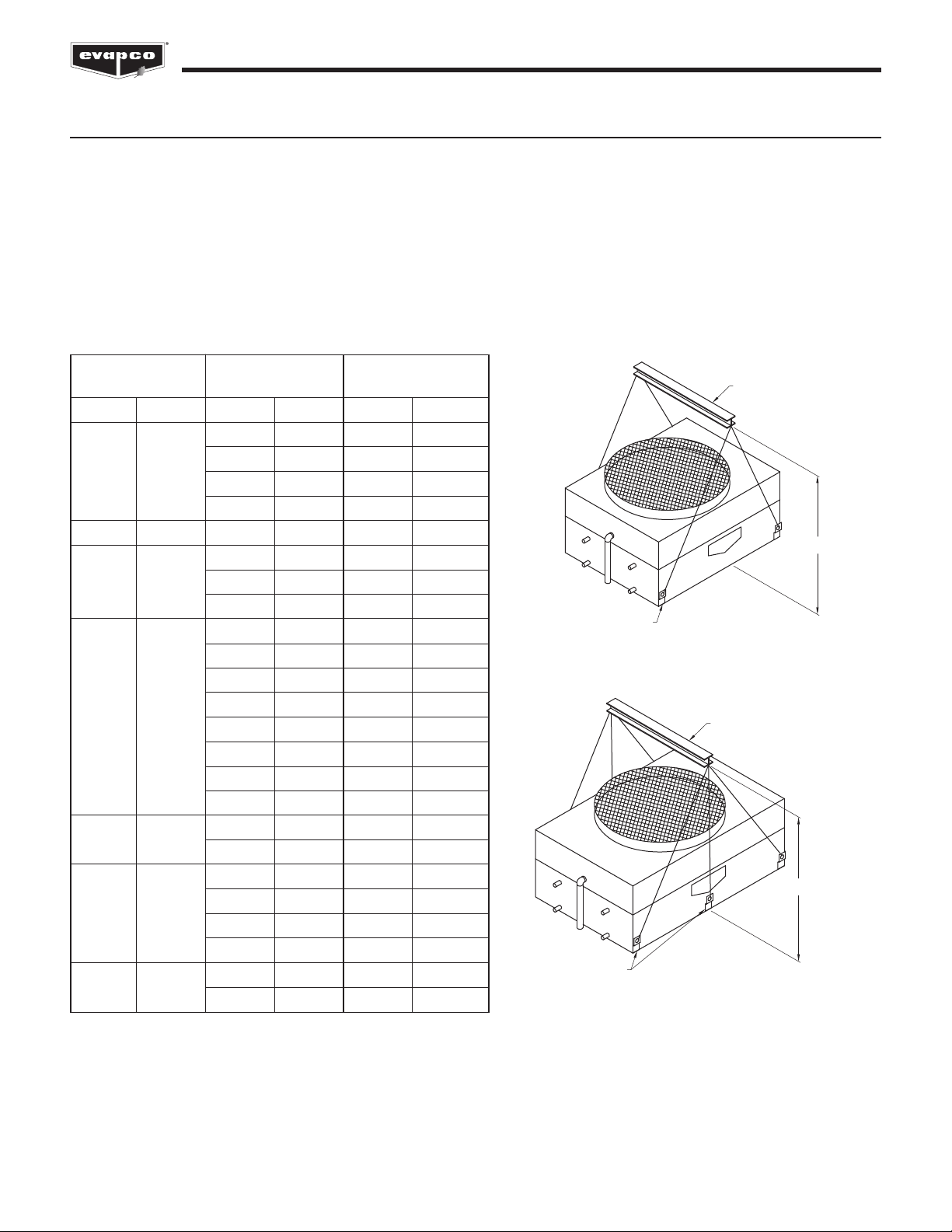

R gg ng Co l/Fan Sect on

our lifting ears are provided in the lower corners of most coil/fan sections for lifting into final position. Some 18' (5.5m) long

sections and longer will have two additional lifting ears in the middle of the section. (See igures 6a and 6b.)

Use all lifting ears. A spreader beam must be used for lifting the top section(s) as shown in igures 6a and 6b.

The hook of the crane must be a minimum dimension “H” above the lifting ear to prevent undue strain on the lifting ears. See Table

3 for the minimum “H” dimension. These lifting devices should not be used for extended lifts or where any hazard exists unless

safety slings are employed under the section. (See “Extended Lifts” for proper arrangement.)

Note: or 7' (2.24m) and 8.5' (2.6m) wide models, mount the external motor prior to rigging as detailed in the “External Motor

Installation” section.

Section Section Minimum "H"

Width Length Dimension

eet Meters eet Meters eet Meters

4 1.2 5 1.5

4 1.2 6 1.8 6 1.8

9 2.7 8 2.4

12 3.6 11 3.4

6 1.8 8.5 2.6 9 2.7

9 2.7 9 2.7

7 2.2 12 3.6 10 3

18 5.5 14 4.3

6 1.8 7 2.1

7.5 2.4 8 2.4

9 2.7 9 2.7

8/8.5 2.4/2.6 10.5 3.2 10 3

12 3.6 10 3

14 4.3 12 3.6

18 5.5 14 4.3

21 6.4 17 5.2

10 3 12 3.6 12 3.6

18 5.5 14 4.3

12 3.6 12 3.6

12 3.6 14 4.3 13 4

18 5.5 14 4.3

20 6 15 4.6

14 4.4 24 7.3 17 5.2

26 7.8 22 6.7

Table 3 - Minimum "H" Dimension for Coil/ an Sections

Figure 6a - our Point Lift

SPREADER BEAM

H

LIFTING EARS

SPREADER BEAM

LIFTING EARS

H

Figure 6b - Six Point Lift

9

ATC-E, ATC-ES, ATWB, eco-ATWB and eco-ATWB-E Evaporative Condensers and Closed Circuit Coolers

H

LIFTING

EAR

LIFTING

EAR

SPREADER

BARS

SAFETY SLINGS

Figure 7 - Extended Lifts

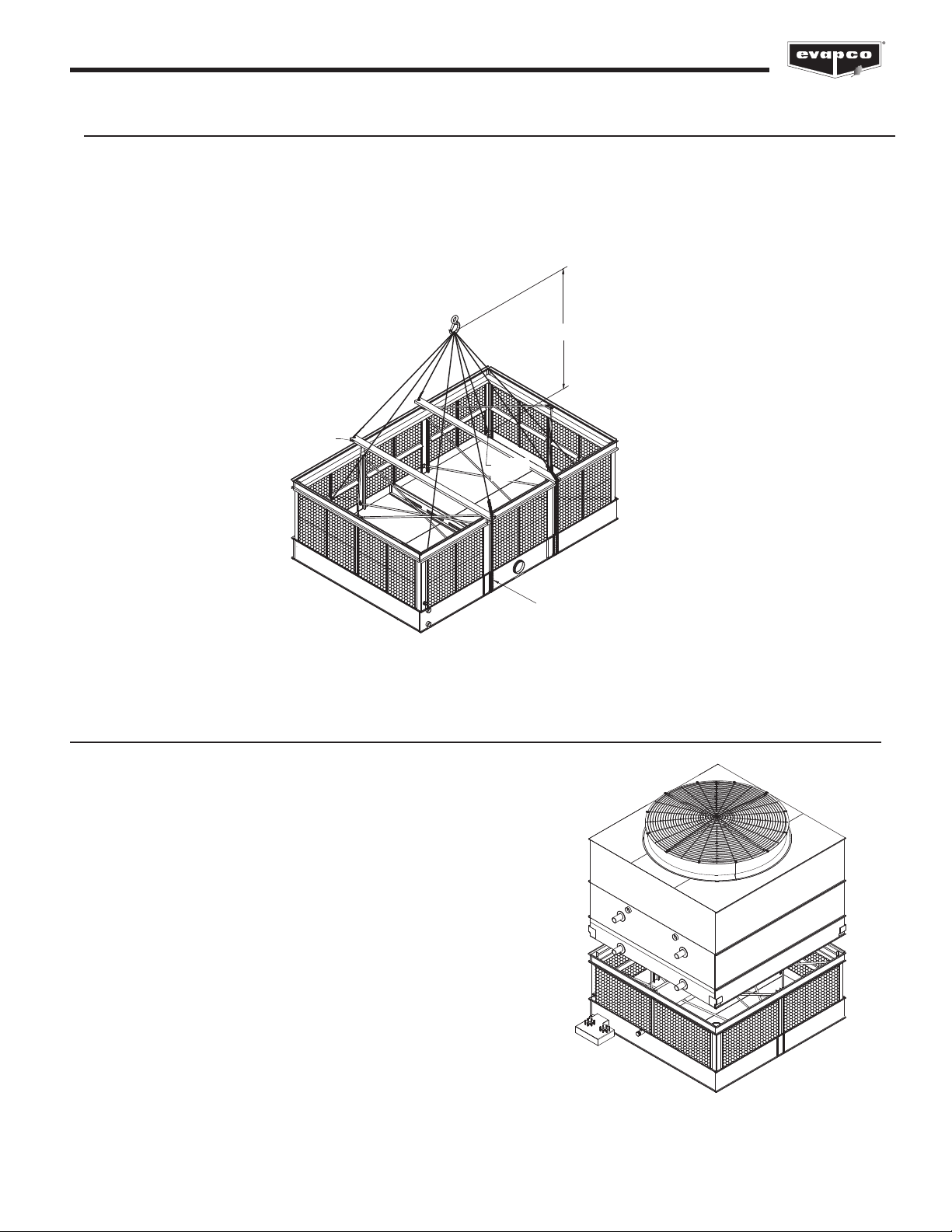

Extended L fts

mportant: The lifting devices and “U” bolts should be used for final positioning only and for lifting where no danger

exists. f they are used for extended lifts, safety slings should be provided under the sections.

Safety slings and skids must be removed before final positioning of the unit.

The preferred method for extended lifts is to use slings under the unit, as shown in igure 7 below. Spreader bars should always be

used between the cables at the top of the section to prevent damage to the upper flanges or fan cylinders.

Assembly of the Co l/Fan Sect on to the Bas n

Before securing the upper section to the bottom section, remove any loose

parts shipped in the basin.

Wipe the flanges on the bottom of the upper section. Check to see that the

water distribution connection on the top section is in the correct position

relative to the bottom section (see unit certified drawing). Units are also

provided with match markings on each section (i.e. A1 of bottom section

should match up with A1 of top section).

Lower the upper section to within several inches of the bottom section making

sure the two sections do not touch and the sealer tape is not disturbed.

asten all four corners. Make use of drift pins to simplify the fastening

process, for further instructions on the use of drift pins, see page 10.

Install the remaining fasteners, working from the corners towards the center.

asteners must be installed in every hole in the side flanges. No fasteners

are required on the end flanges.

Figure 8 - Mating Upper Section to Basin Section

10

ATC-E, ATC-ES, ATWB, eco-ATWB and eco-ATWB-E Evaporative Condensers and Closed Circuit Coolers

Assembly of the Co l/Fan Sect on to the Bas n (Cont.)

Use of Drift Pins for Final Positioning

Drift pins are tools used to align holes in the flanges of the

upper and lower sections of the unit prior to final fastening. By

the time drift pins are needed, the lower section of the unit has

already been anchored to its support structure. The sealer tape

has been laid down on the lower section’s flanges, and the

upper section is now hovering over the lower section.

A drift pin should be driven in to each of the corner bolt holes

such that the upper and lower flanges are aligned as best as

possible with sideways motion restricted.

On units which are longer than 12’ (“L” > 12' [3.7m]), a drift pin

should be used at an intermediate pair of bolt holes in the

rigging seam to allow for proper alignment.

VERTICAL

SPLASH

GUARD

PAN SECTION

SIDE PANEL

FILLER CAP

CHANNEL

Figure 9 - Mating Upper Section to Basin Section

Figure 10 - iller Cap Channel Assembly

Notes:

For multi-cell units, the side flanges located in between cells

can be accessed from inside the unit.

Bolts can be driven upward through the mating flanges if

access is restricted.

All rigging hardware is provided by EVAPCO. Drift pins are

by others.

11

ATC-E, ATC-ES, ATWB, eco-ATWB and eco-ATWB-E Evaporative Condensers and Closed Circuit Coolers

Conta ner zed Un t Assembly

7' and 14' (2.2m and 4.4m) wide ATWB units are optimized to be transported in export containers for overseas shipment. When these

units are required to be shipped in containers, the fan section is loosely bolted to the basin section prior to placing in the container.

Depending on the size of the unit and accessory options, there a few different shipping configurations as outlined below.

Notes:

*HC indicates “High Cube.” High cube containers provide an additional foot of container height which allows for

standard fan cylinders to ship mounted to the fan sections (See Figure 11 for an example of a high cube container).

igure 11 below shows an example of a 7’ x 18’ unit shipping in a 40’ high cube container. A high cube container is used

so that the fan cylinders can ship mounted to the fan section. In such a case, the fan section is loosely bolted to the basin

section.

Figure 11 - 40’ High Cube Container Shipment

LIFTING EARS

CASING SECTION

FAN SECTION

BASIN SECTION

# of Containers Required

Box Size Standard Fan SLSF

7 x 9 (1) 20' (1) 40'

7 x 12 (1) 40' HC* (1) 40'

7 x 18 (1) 40' HC* (1) 40' + (1) 20'

14 x 9 (1) 40' HC* (2) 40'

14 x 12 (1) 40' HC + (1) 20' (2) 40'

14 x 18 (2) 40' HC* (3) 40'

7 x 24 (1) 40' HC + (1) 20' (2) 40'

7 x 36 (2) 40' HC* (3) 40'

Single Cell

Unit Type

Multi-Cell

Multi-Cell

Table 4 - Number of Containers Required

12

ATC-E, ATC-ES, ATWB, eco-ATWB and eco-ATWB-E Evaporative Condensers and Closed Circuit Coolers

igure 12 shows a 7’ x 9’ unit shipping in a 20’ standard height container. 20’ containers are not available in high cube

configuration, therefore requiring the fan cylinders to ship loose in the basin for assembly in the field.

Figure 12 - 20’ Standard Height Container Shipment

Figure 13 - Split an Cylinder for Standard Height Container Shipment

CYLINDER ASSEMBLY

(CUT IN HALF)

ATTACH TOGETHER USING

5/16Ø HARDWARE

nstructions to put together fan cylinder:

1. Line up match-markings on the fan deck to ensure proper alignment.

2. Make sure fan assembly is centered within cylinder before attaching to fan section.

LIFTING EARS CASING SECTION

FAN SECTION

BASIN SECTION

13

ATC-E, ATC-ES, ATWB, eco-ATWB and eco-ATWB-E Evaporative Condensers and Closed Circuit Coolers

Figure 14 - 40’ Standard Height Container, Unit with Super Low Sound an

igure 14 shows a 7’ x 12’ unit with super low sound fan shipping in a 40’ standard height shipping container. Any containerized

unit selected with Super Low Sound ans will ship in 3 pieces as shown below.

While the image below is not representative of all possible accessory options, but it provides an example of how containerized

unit’s basins are set up for shipment. Platforms and ladders are strapped to the top of the casing

PUMP MOTO * FAN MOTO

MOTO DAVIT

WATE SILENCE S

* On Coolers & Condensers only. Not applicable to towers.

ISE PIPING*

IGGING BOX

BASIN SECTION LIFTING EARS CASING SECTION

FAN SECTION

Once the sections have been unloaded from the shipping container, follow the below steps to complete assembly. Please check

table of contents for associated page numbers to get to the instructions referenced below.

1. Unbolt fan section from basin section.

2. Lift fan section and rig to casing section using instructions from "Assembly of the fan section to the coil section (Containerized)".

3. Rig basin section using instructions from “Rigging Basin Section”.

4. Lift upper section (fan + casing) and rig to basin using instructions from "Assembly of the Coil Section to the Basin

(Containerized)".

14

ATC-E, ATC-ES, ATWB, eco-ATWB and eco-ATWB-E Evaporative Condensers and Closed Circuit Coolers

Assembly of the Fan Sect on to the Co l Sect on (Conta ner zed)

7' and 14' (2.2m and 4.4m) Wide Models – an Section Will Need To Be

Mounted to the Coil Section irst

our lifting U-Bolts are provided in the top corners of most fan sections for

lifting into final position. 18' (5.5m), long sections will have two additional

U-Bolts in the middle of the fan section. Use all U-Bolts. The hook of the

crane must be a minimum dimension “H” above the top section being lifted

to prevent undue strain on the section being lifted. See Table 3 for the

minimum “H” dimension. These lifting devices should not be used for

extended lifts or where any hazard exists unless safety slings are

employed under the section. (See Extended Lifts’ for proper arrangement.)

Before assembling the fan section to the coil section, wipe the flanges on

the bottom of the fan section and apply sealer tape. Check to see that the

motor access doors are in the correct position relative to the coil section

(see certified print). Units are also provided with match markings on each

section (i.e. A1 of the coil section should match up with the A1 of the fan

section). Place nuts and bolts in all four corner bolt holes. Then continue to

install the rest of the nuts and bolts working from the corners towards the

center. Nuts and bolts are required on the end flanges. Drift pins are

provided in rigging box to assist with alignment.

Figure 15 - Mating an Section to Coil Section

Assembly of the Co l Sect on to the Bas n (Conta ner zed)

7' and 14' (2.2m and 4.4m) Wide Models – an Section Will Need To

Be Mounted to the Coil Section irst

Before assembling the coil section to the basin section, remove any loose

parts shipped in the pan. our lifting ears are provided in the corners of

coil sections for lifting into final position. 18' (5.5m), long sections will

have two additional lifting ears in the middle of the section. Use all lifting

ears. When lifting assembled fan/coil sections, use the lifting ears at the

bottom of the coil section and not the U-Bolts of the fan section. The hook

of the crane must be a minimum dimension “H” above the lifting ear to

prevent undue strain on the lifting ears. See Table 3 for the minimum “H”

dimension. These lifting devices should not be used for extended lifts or

where any hazard exists unless safety slings are employed under the

section. (See Extended Lifts for proper arrangement.)

Before assembling the fan/coil section to the basin section, wipe the

flanges on the bottom of the coil section and apply sealer tape to the

basin section. Check to see that the access doors are in the correct

position relative to the basin section (see certified print). Units are also

provided with match markings on each section (i.e. A1 of the coil section

should match up with the A1 of the fan section). Place nuts and bolts in all

four corner bolt holes. Then continue to install the rest of the nuts and

bolts working from the corners towards the center. Nuts and bolts are

required on the end flanges. Drift pins are provided in rigging box to

assist with alignment

Figure 16 - Mating an/Coil Section to Basin Section

15

ATC-E, ATC-ES, ATWB, eco-ATWB and eco-ATWB-E Evaporative Condensers and Closed Circuit Coolers

WING BOLTS

UPPER

PANEL

LOWER

PANEL

TAPPERS

Figure 17 - Upper Partition/ irewall Installation in ield

Install ng Watert ght Part t ons & F rewalls

In some cases, a multi-cell unit is ordered with watertight partitions to allow for independent cell operation. To correctly assemble the

upper sections to the bottom sections, access to the rigging seams in between cells is necessary. To facilitate with this access, the

upper watertight partition is shipped loose for installation in the field. igure 17 below provides instruction to install these in the field.

Note: The below instruction and arrangement also applies for Factory Mutual (FM) Approved multi-cell units, in which

case these partitions will be referred to as firewalls.

UPPE PA TITION WALL TO

SHIP LOOSE FO FIELD

INSTALLATION AFTE UNIT IS

IGGED, IF NECESSA Y.

LOWE PA TITION WALL

INSTALLED BY SHOP

P IO TO SHIPPING. MAY

BE ONE PIECE FO END

TO END UNITS.

(2) MOUNTING CHANNELS

INSTALLED BY SHOP P IO

TO SHIPPING.

1/4Ø (8) 20 X 1” LG

FULLY TH EADED HHCS

1/4Ø (8) B ASS IVNUT

APPLY SEALE TAPE

TO BOTH SIDES FO

COMP ESSION

1/4” (8) WIDE

FLAT WASHE

SEALE TAPE

AND CAULK AS

NECESSA Y

16

ATC-E, ATC-ES, ATWB, eco-ATWB and eco-ATWB-E Evaporative Condensers and Closed Circuit Coolers

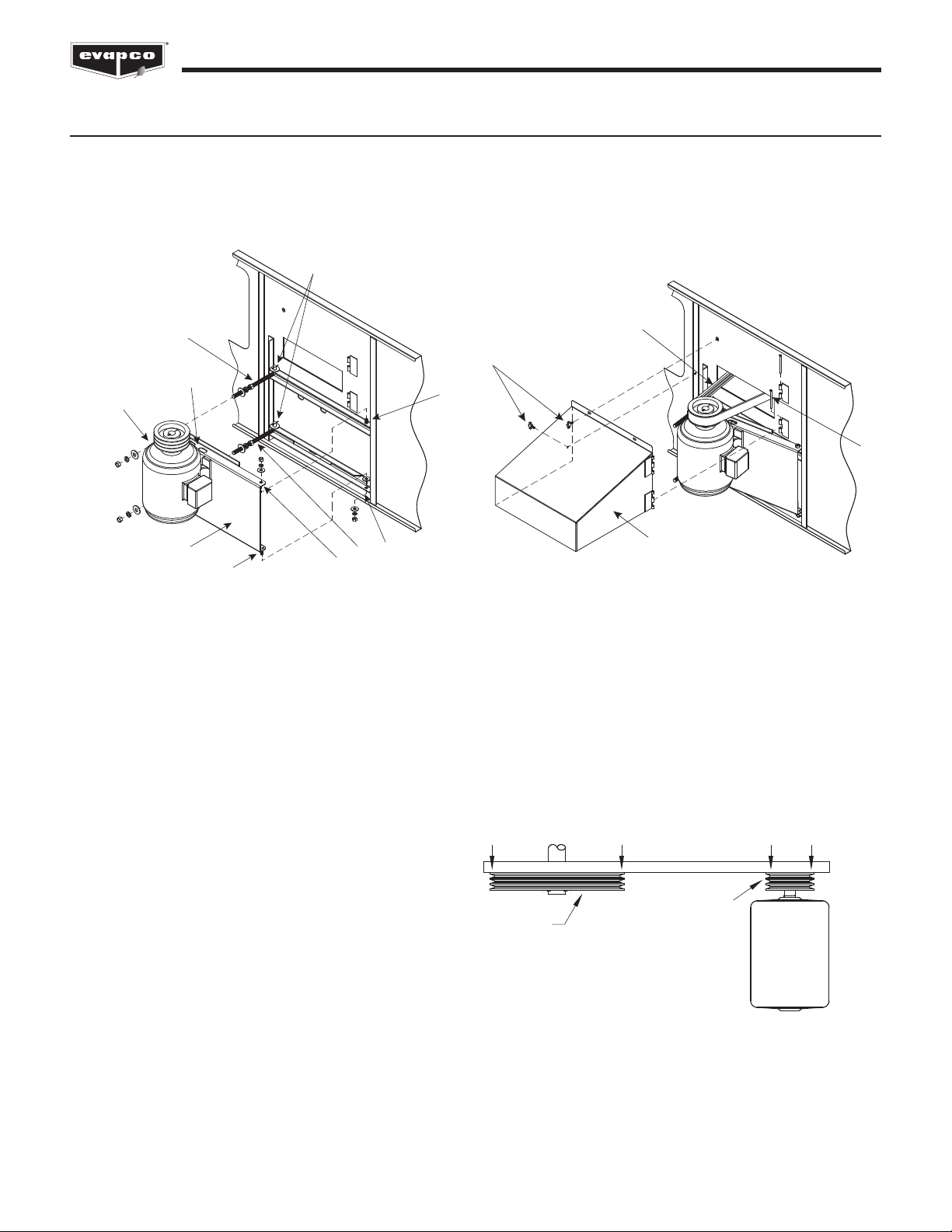

1. Study igure 18a above before installing the motor base on the unit.

2. Insert the lifting device into the slots Alocated on the top of the motor base.

3. Lift the motor base Band insert the pivot pin Cdown into hole Eand pivot pin Finto hole D.

4. Install washer and nut (do not overtighten) on pivot pins. Install jam nut on pivot pin C.

5. Insert “J” bolts Ginto holes H. Install flat washers and cotter pins. Place nuts and washers on threaded portion of “J” bolts.

These will be behind the motor base installed in the next step.

6. Install “J” bolts Ginto holes Jin the motor base. Install flat washers, lock washer and nuts. Remove lifting device from the

motor base. Position motor base towards top section of unit for belt installation.

7. Install Power-Band belt K( igure 18b) around fan

sheave and motor sheave. Tighten belt by adjusting

nuts on “J” bolts. Do not overtighten the belts. The

center of the belt should deflect approximately 3/4”

(19mm) in the horizontal plane with moderate hand

pressure.

8. Measure to see that the top and bottom of the

motor base are the same distance out from the

casing of the unit. This will ensure that the sheaves

are properly aligned since the driven sheave on the

fan shaft comes pre-set from the factory.

9. As a final check, lay a straight edge from sheave to

sheave as shown below in igure 19. There should

be four-point contact. Adjust the position of the

motor sheave as necessary until four-point contact

is achieved.

FAN SHEAVE

ADJUST POSITION

OF MOTOR SHEAVE

(only if necessary)

12 3 4

Figure 19 - Sheave Alignment Check

10. To install motor guard L, match up hinges and install hinge pins Mas shown in igure 18b.

11. Close motor guard Land install wing bolts M.

Note: For European market, additional belt cover plate needs to be installed.

G

H

F

GE

D

C

B

A

J

N

K

M

L

External Motor Installat on – Belt Dr ve

All units narrower than 10’ (3m) wide have their motors installed outside the unit in a shaft up configuration as shown in figures 18a

and 18b below. Due to shipping width restrictions, these motors cannot ship mounted on the units since they would extend past the

width of the truck. or this reason, the motor(s), motor base(s), motor guard(s), “J” bolts, pivot pins and belt(s) are shipped in the

cold-water basin of the cooling tower. Please follow the step-by-step instructions below to properly install these components.

Figure 18a - External Motor Installation Figure 18b - Motor Guard and Power-Band

Belt Installation

17

ATC-E, ATC-ES, ATWB, eco-ATWB and eco-ATWB-E Evaporative Condensers and Closed Circuit Coolers

M

MOUNTING

BRACKET

MOUNTING

BRACKET

MOUNTING

BRACKET

MOUNTING CHANNEL

(SHIPS LOOSE)

ACCESS

DOOR

MOUNTING BRACKET

MOUNTING CHANNEL

BOLT

FLAT WASHER

FLAT WASHER

LOCK WASHER

NUT

Figure 20 - Dual-Point Davit Arrangement

Figure 21 - Mounting Channel Installation

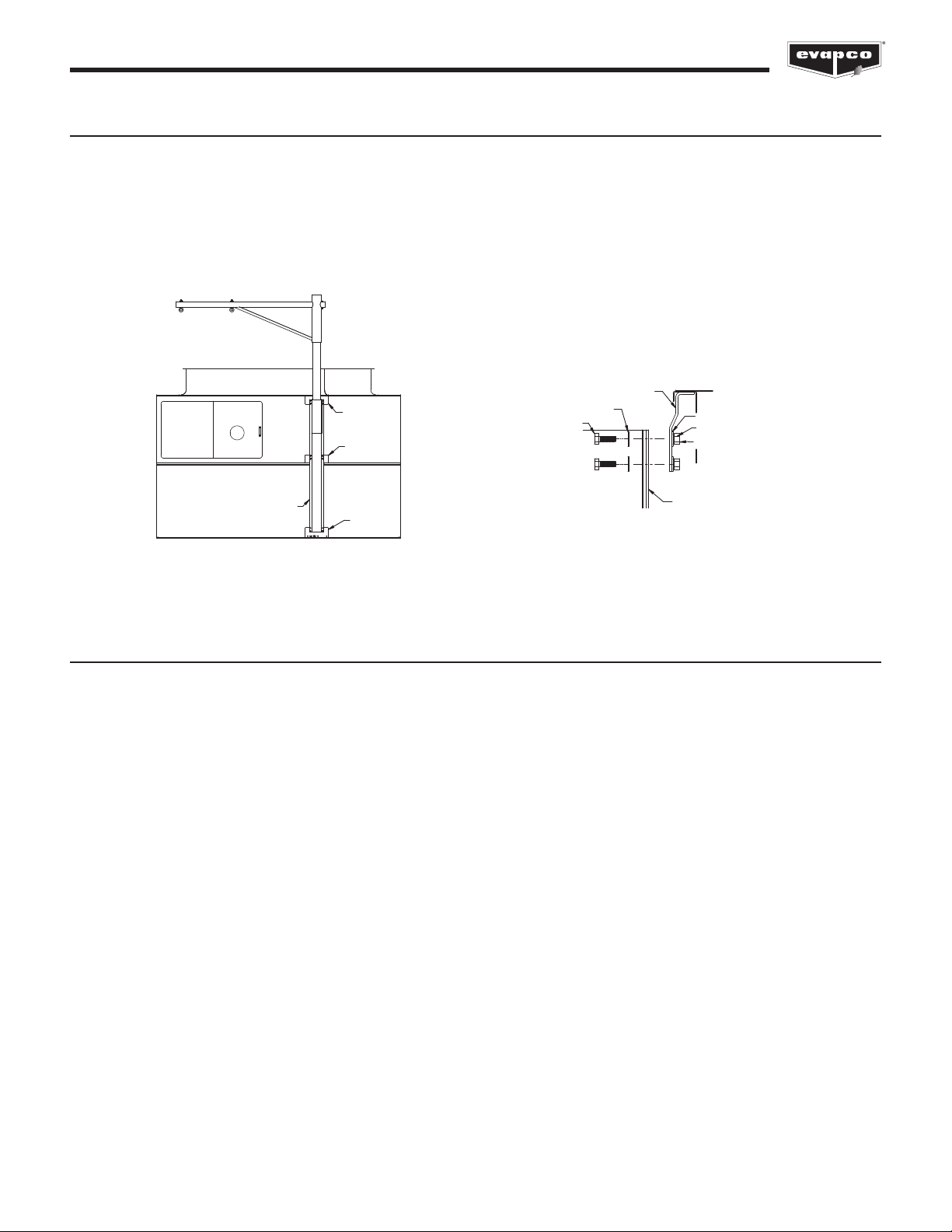

Opt onal Motor & Gear Box Dav t Installat on

Motor davits, also known as jib-booms, are offered by EVAPCO as an optional accessory to facilitate removal of the motor, fan

assembly or gear box. The assembly consists of a davit and a mounting base that is to be attached to the side of the unit next to the

access door, as shown below in igure 20. Both these items will ship loose in the unit’s basin. On multi-cell units, there will be

provisions to install a mounting channel on each cell. Use the following procedure to install the mounting channel:

1. Align the mounting channel with 3/8” (10mm) bolts and flat washers to the factory installed mounting brackets

2. Use 3/8” (10mm) flat washers, lock washers and nuts to secure the mounting channel to the bracket, as shown in igure 21.

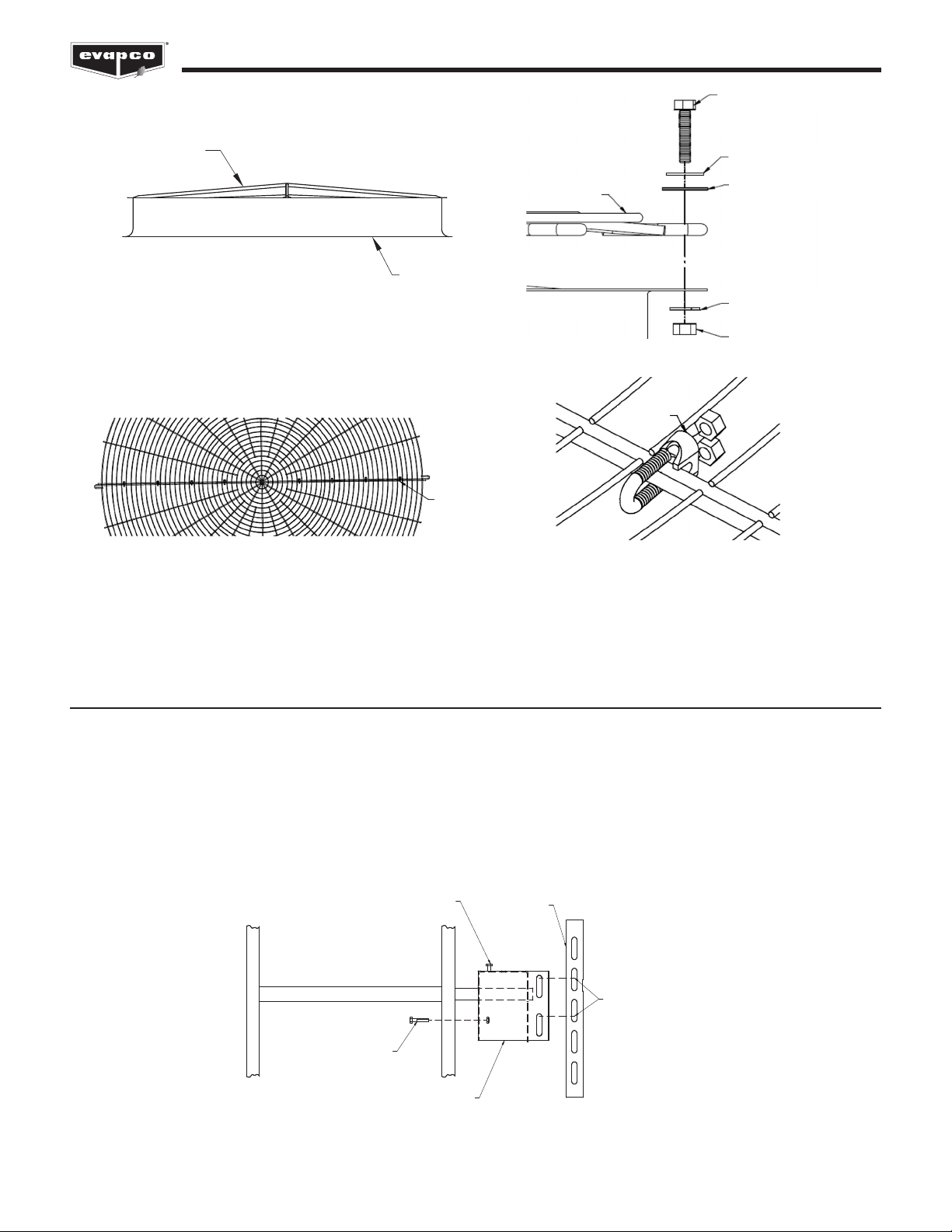

Mount ng Fan Screens

On 10’ (3m) wide units and larger, a conical fan screen support is used in order to prevent the fan screen from sinking down into

the fan cylinder. In some cases, shipping height restrictions may require the fan screen support(s) and fan screen(s) to ship loose

for installation in the field. Please follow the below instructions to install these components on the fan cylinder(s).

1. Set the fan screen support across the top of the fan cylinder as shown in igure 22.

2. Place both halves of the fan screen on top of the fan screen support. Each half will be tagged to match markings on the

cylinder. Align the eyelets of the fan screen with the holes on the cylinder perimeter.

3. Join the two screen halves with “U” bolts, as shown in igure 23.

4. At each hole, attach the fan screen to the fan cylinder as shown in igure 22. At the four points where the fan screen support

meets the cylinder, bolt the support to the cylinder together with the fan screen.

18

ATC-E, ATC-ES, ATWB, eco-ATWB and eco-ATWB-E Evaporative Condensers and Closed Circuit Coolers

Sloped Ladder Installat on

When sloped ladders are supplied with a unit, they are shipped in the unit’s basin. One sloped ladder will be provided for each cell.

Assembly is identical for each cell, unless otherwise noted in the submittal.

Sloped ladders are attached at a minimum of three points. At each point of attachment, the ladder will be fitted with a ladder

bracket assembly. The ladder bracket assembly looks like a metal box and is shown as component d in igure 24 below. The upper

two assembly brackets will be rigidly mounted to the ladder and are not adjustable. These two brackets define the slope of the

ladder. The lower bracket(s) are adjustable.

To install the ladder assembly, complete the steps that follow. R efer to igure 24:

LADDER

MOUNTING

CHANNEL (b)

ADJUSTING SCREW (e)

(WHEN APPLICABLE)

LADDER BRACKET

MOUNTING BOLTS (a)

LADDER BRACKET

ASSEMBLY BOLTS (c)

LADDER BRACKET

ASSEMBLY (d)

Figure 24 - Detail of Ladder, Ladder Bracket Assembly & Mounting Channel

FAN SCREEN

SUPPORT

FAN

CYLINDER

Figure 22 - an Screen Support & an Screen installation

Figure 23 - U-Bolt Assembly Spacing & Arrangement

Note: European market utilizes alternative CE compliant fan screen with 30mm x 30mm mesh. Screen has 120mm

clearance from trailing edge of fan blades.

1/2” (13mm) BOLT

1/2” (13mm) FLATWASHE

5/8” (16mm) FLATWASHE

5/8” (13mm) LOCKWASHE

1/2” (13mm) HEX NUT

FAN

CYLINDE

FAN SC EEN

SUPPO T

U-BOLT

ASSEMBLY

U-BOLT

ASSEMBLY

FAN SC EEN

19

ATC-E, ATC-ES, ATWB, eco-ATWB and eco-ATWB-E Evaporative Condensers and Closed Circuit Coolers

Notes:

Upper section of unit must be properly oriented with respect to the lower section.

All mounting brackets must be on the same side of the unit. Refer to submittal for proper orientation.

Sloped ladders are not CE compliant & are not available for European market.

1. Remove the ladder bracket mounting bolts (a) from the ladder mounting channels (b) on basin and casing sections.

2. Loosen, but do not remove, the ladder bracket and assembly bolts (c).

3. Slide the bracket assembly (d) over the ladder mounting channels (b) located on the pan and casing sections. Do not

remove the ladder bracket assembly (d) from the ladder.

4. Align the bolts and reinstall the ladder bracket assembly mounting bolts (a) through the ladder bracket assembly and the

ladder mounting channels (b).

5. Tighten all bolts.

6. Tighten the adjusting screw (e) in the adjustable mounting bracket where applicable.

Figure 25a - End View of Ladder Assembly Figure 25b - Side View of Ladder Assembly

20

ATC-E, ATC-ES, ATWB, eco-ATWB and eco-ATWB-E Evaporative Condensers and Closed Circuit Coolers

External Platform and Vert cal Ladder Installat on

If your unit is accessorized with an external service platform assembly with a vertical ladder, this equipment is shipped in the basin

of your unit. In some cases, they are shipped separately due to other basin accessories that may interfere with storage. The

platform is partially assembled prior to shipment to minimize field assembly.

Typically, there is one working platform and ladder assembly per fan section. Refer to your factory submittal for details.

The platform and ladder assembly should be attached after the unit is fully rigged, by following the instructions in the

drawing below.

Figure 26 - Platform Mounting General Arrangement

7,7/(

&87

1&

'5$:1

*$ 5$:

3$5712 5(912

$//¡+2/(66+28/'%(¡

86(67$,1/(6667((/1&6(7836+((7

67$,1/(6667((/237,21

3$5712 5(912

5(9,6,216

3$57

1(;7

6,=(

,1)2

%<

$66( %/<

$7/

12 $7/

5$:

127(

(9$3&2,1&

'$7(

&+.'

%<

&21),'(17,$/

7KLVGRFXPHQWLVWKHSURSHUW\RI(YDSFR,QF,WVKRXOGQRW

EHFRSLHGRUGLVFORVHGZLWKRXWSULRUZULWWHQDXWKRUL]DWLRQ

6&$/(

127(6

3/$7)25 *5$7,1*1276+2:1

)25&/$5,7<

$'(7$,/$

%'(7$,/%

'

'(7$,/'

(

'(7$,/(

&

'(7$,/&

6(&85(',$*21$/

683325772'(&.

683325786,1*

*5$'(+$5':$5(

'(&.

6833257

',$*21$/

6833257

6(&85('(&.6833257

72&211(&7,213/$7(6

86,1**5$'(

+$5':$5(

'(&.

6833257

&211(&7,21

3/$7(

6(&85('(&.683325772

&211(&7,213/$7(686,1*

*5$'(+$5':$5(

',$*21$/

6833257

&211(&7,21

3/$7(

6(&85(5$,/,1*),77,1*

72)521772(3/$7(86,1*

*5$'(+$5':$5(

5$,/,1*

),77,1*

)5217

72(3/$7(

/2:(5

&+$11(/

$66<

/$''(5

&+$11(/

6(&85(/$''(5

&+$11(/672/2:(5

&+$11(/$66( %/<

2181,786,1*

*5$'(+$5':$5(

5()

)52 723

2)72(3/$7(

727232))7*

),77,1*621/$''(5 $<

1(('72%($'-867('

,1),(/'

6(1'7+,6'5$:,1*727+(6+,33,1*'(3$570(17

72%(3/$&(',17+(5,**,1*3$&.$*(

),(/'$66<3/$7)25 *(1$55

176

1/1 *$

*$

5(3/$&('6$)(7<

&+$,16:6:,1**$7(

$ *

Y

Other manuals for ATC-E

3

This manual suits for next models

4

Table of contents

Other EVAPCO Accessories manuals

Popular Accessories manuals by other brands

Fluke

Fluke 80K-15 instruction sheet

Emmaljunga

Emmaljunga NXT Curb Lifter instruction manual

CARLO GAVAZZI

CARLO GAVAZZI ROG400 instruction manual

PCB Piezotronics

PCB Piezotronics 208C03 Installation and operating manual

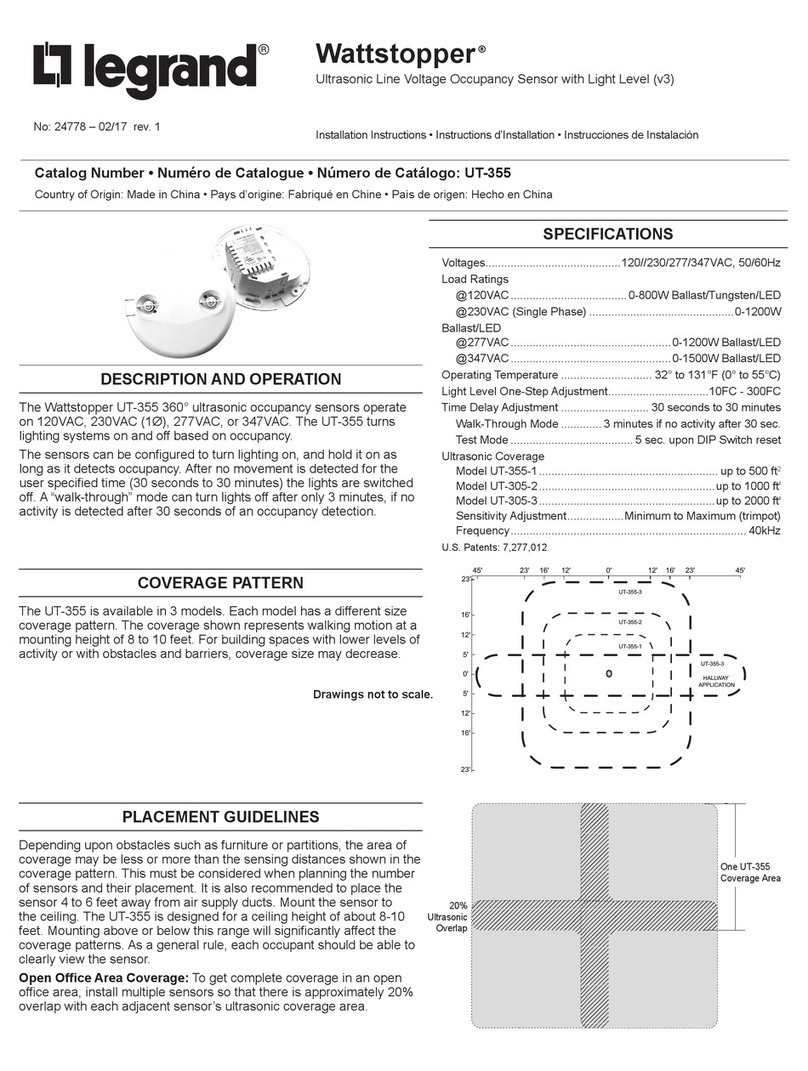

LEGRAND

LEGRAND Wattstopper UT-355 installation instructions

Rohde & Schwarz

Rohde & Schwarz NRQ6 user manual