Belimo F6 Series User manual

Other manuals for F6 Series

2

This manual suits for next models

15

Other Belimo Control Unit manuals

Belimo

Belimo EFB Series Reference guide

Belimo

Belimo Z2075QS-K User manual

Belimo

Belimo Z2050Q-J User manual

Belimo

Belimo F6 HS Series User manual

Belimo

Belimo Z2050QS-J User manual

Belimo

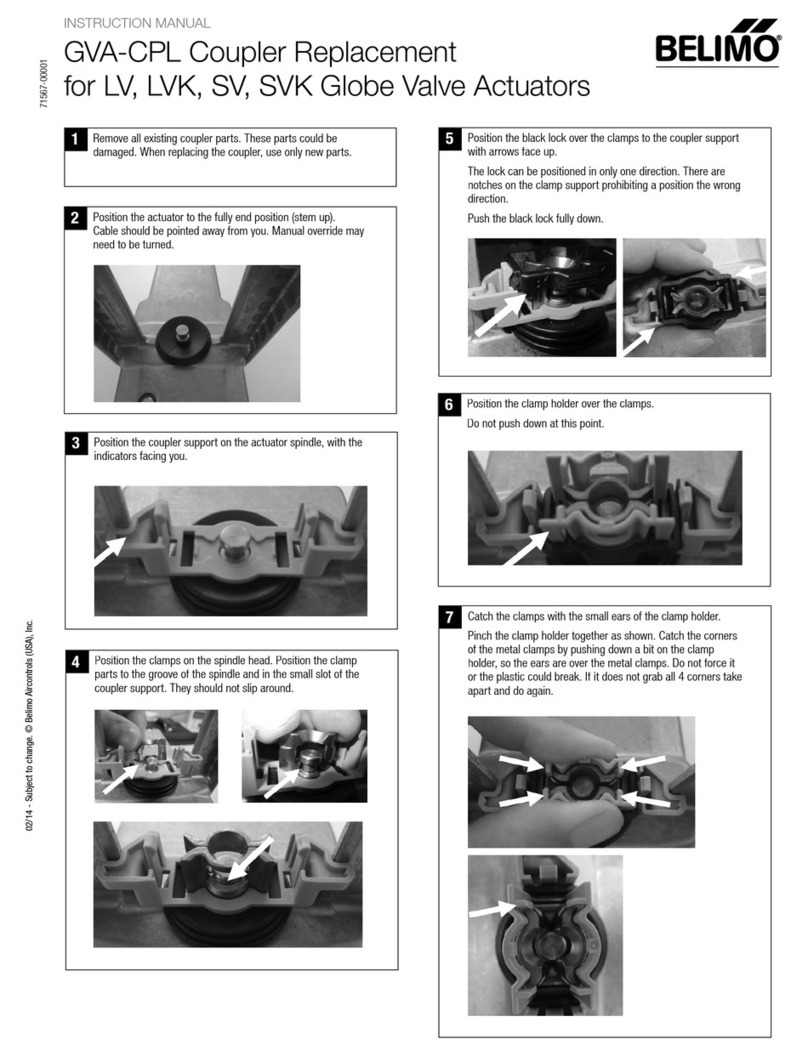

Belimo GVA-CPL User manual

Belimo

Belimo 6-Way ePIV User manual

Belimo

Belimo F6 Series User manual

Belimo

Belimo UGVL Series User manual

Belimo

Belimo Z2075Q-K User manual

Belimo

Belimo Clear Edge EAP005 User manual

Belimo

Belimo EPIV Series Product guide

Belimo

Belimo SHP Series Operating instructions

Belimo

Belimo NMV-D2M User manual

Belimo

Belimo FS Series User manual

Belimo

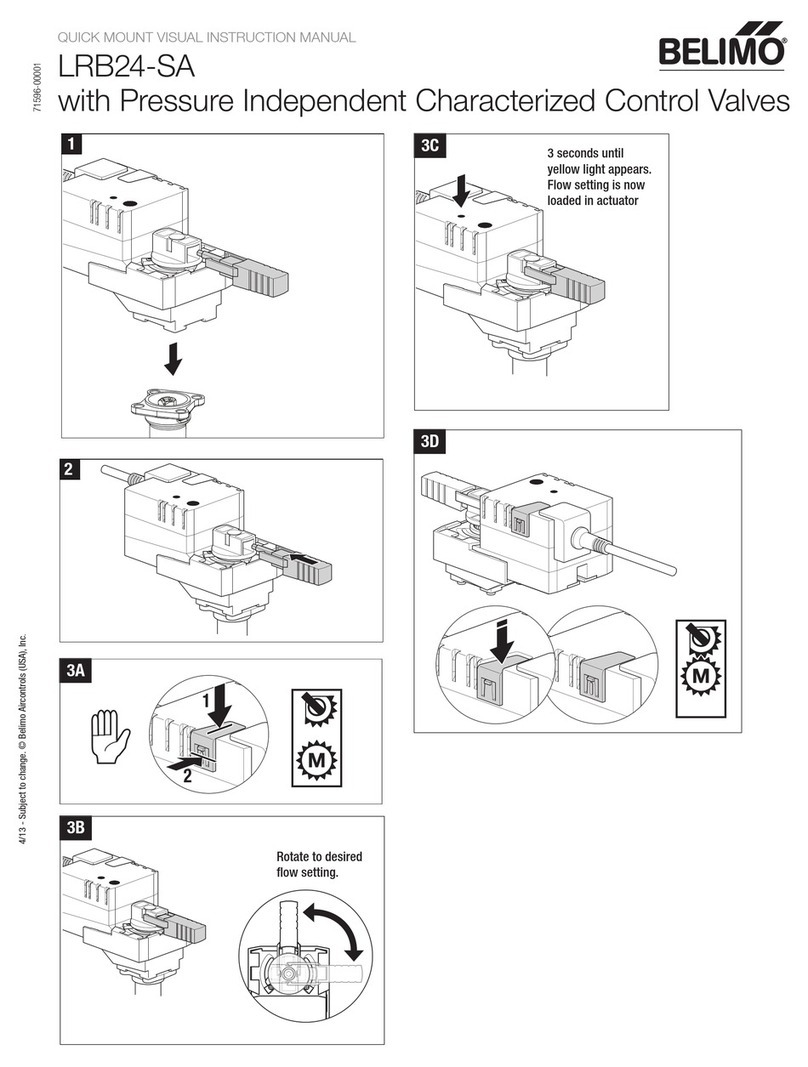

Belimo LRB24-SA User manual

Belimo

Belimo Z2050QPT-D User manual

Belimo

Belimo H650SP Instruction Manual

Belimo

Belimo EPF+MP Series Instruction Manual

Belimo

Belimo B2100VB-024 Guide

Popular Control Unit manuals by other brands

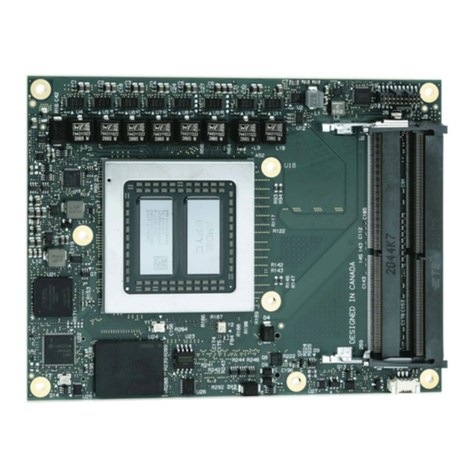

Kontron

Kontron COMe-bEP7 user guide

Balcrank

Balcrank Synergy 3110-019 Service bulletin

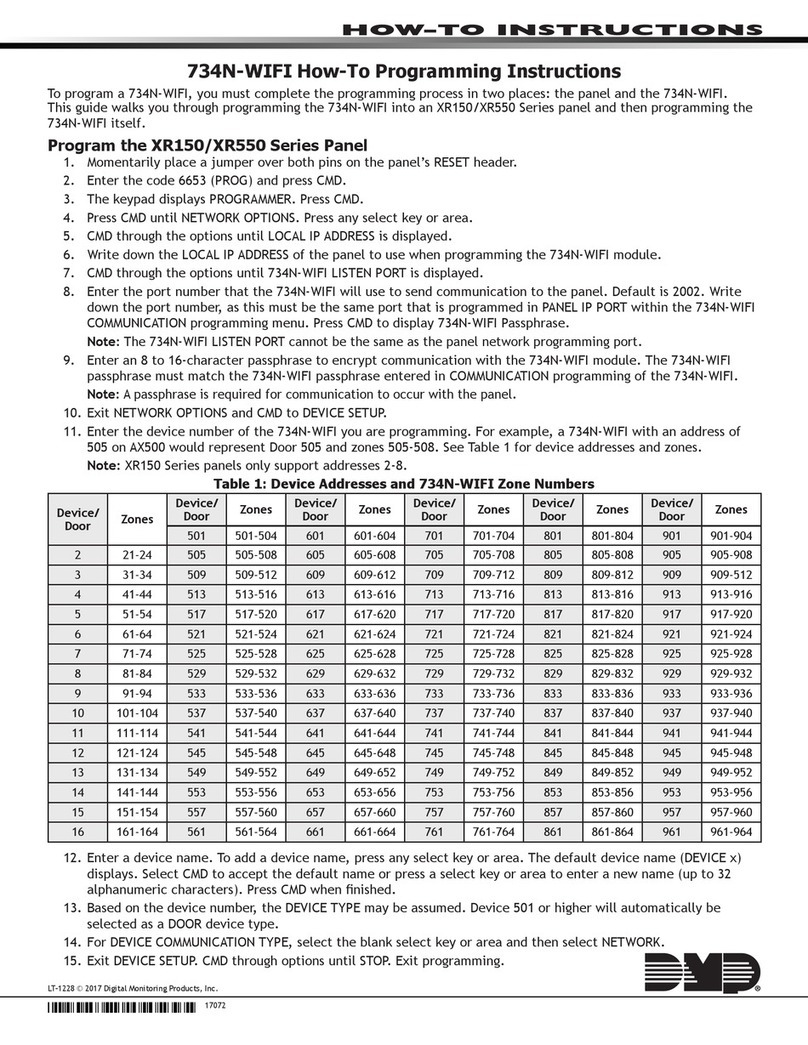

DMP Electronics

DMP Electronics 734N-WIFI How-to guide

Tews Technologies

Tews Technologies TAMC532 user manual

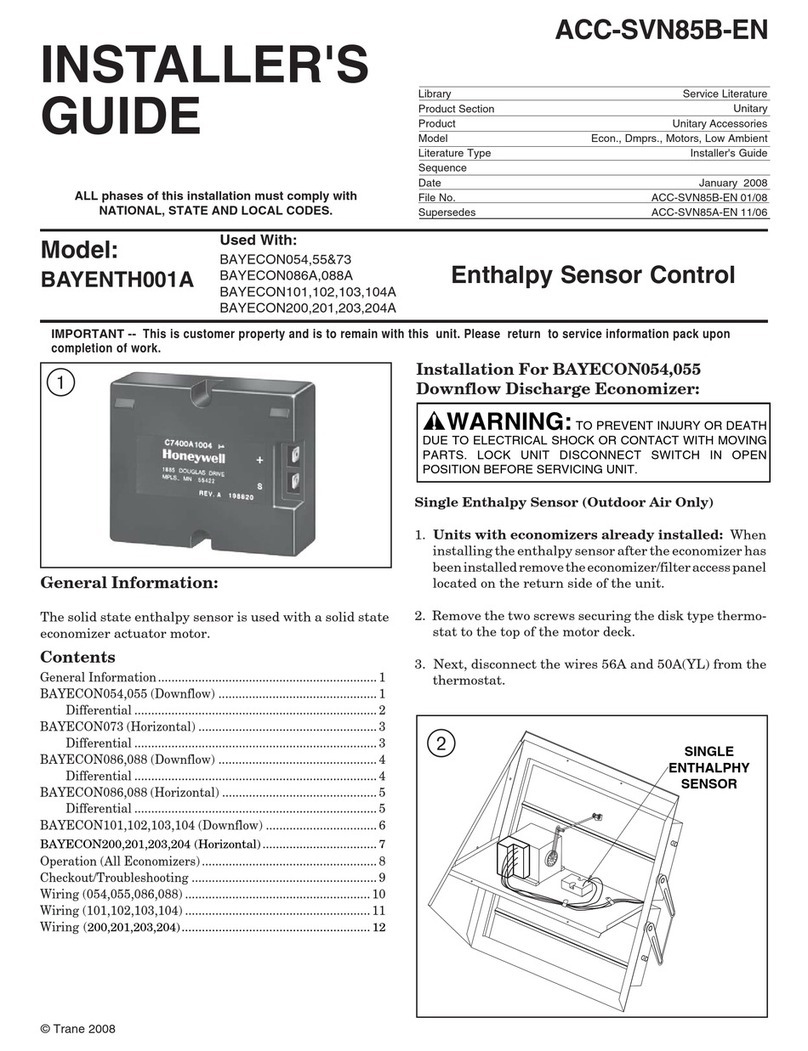

Trane

Trane BAYENTH001A Installer's guide

Johnson Controls

Johnson Controls METASYS NU-XBN101-0 Technical manual