Everwin PN51B User manual

Before operating this tool, all operators should read and study this

manual to understand and follow the safety warnings and instructions.

Keep these instructions with the tool for future reference. REV Apr./26/2022

TOUGHER FASTER SMARTER

PN51 / PN51B / SCN51

Pneumatic Coil NailerPneumatic Coil Nailer

Operations and Maintenance ManualOperations and Maintenance Manual

1-Year Limited Warranty

CE Declaration of Conformity

Safety Instructions

Specifications and Technical Data

Operating Pressure, Setting Correct Pressure

Operation

Air Supply and Connections: Fittings, Hoses, Filters,

Air Consumption, Regulators, Supply Source

Lubrication

Fastener Loading

Tool Operation

Tool Operation Check

Maintaining the Pneumatic Tool

Driver Maintenance Instructions

Trouble Shooting / Repairs

INDEX

NOTE

The tool is designed for high speed, high volume stapling. These tools will deliver efficient, dependable

service when used correctly and with care. As with any fine power tool, the manufacturer’s instructions

must be followed for best performance.

Please study this manual before operating the tool and understand the safety warnings and cautions. The

instructions on installation, operation and maintenance should be read carefully, and the manuals kept for

reference.

Additional safety measures may be required because of your particular

application of the tool. Contact your EVERWIN representative or distributor with any questions concerning

the tool and its use.

Everwin Pneumatic Corp.,

No.7, Wugong 7th Road, Wufeng District, Taichung City, 413, Taiwan

Introduction

3

4

5

7

7

8

10

11

12

13

16

17

17

18

(U.S. and Canada Only)

EVERWIN products are designed and manufactured to the highest standards of both material and workman-

ship. EVERWIN warrants to the original retail purchaser that the product purchased is free from defect in

material and workmanship and agrees to repair or replace at EVERWIN ‘s option any defective EVERWIN

pneumatic stapler or er for a period of one year, subject to the exclusions and limitations described

hereunder.

To honor a warranty claim, EVERWIN and its authorized distributor need proof of purchase, may request the

damaged tool, serial number of the damaged tool, photos/videos of the defect for test and evaluation to

determine whether the damaged tool is within warranty conditions; your cooperation in this regard will be

appreciated to expedite the claim process and to help with EVERWIN’s continuous efforts in quality

improvement.

Warranty Exclusions

The following warranty exclusions apply :

.Normal wear parts are not covered by this warranty. Examples of such parts include, o-rings and seals,

driver blades, bumpers, pistons and piston rings.

.Failure due to normal wear, neglect, abuse, misuse, misapplication, accidents, over-pressure usage,

improper storage, shipping damages, improper maintenance, operation not within the operation manual’s

specification etc. are not covered by this warranty.

.Labor charges, loss, repairs from improper maintenance and/or usage of non-EVERWIN parts are not

covered by this warranty.

.This warranty does not apply to production or industrial tools as defined by EVERWIN; industrial or

production tools are covered on the following grounds.

Grounds For Industrial / Production Tool Coverage

For high production industrial tools, coverage is limited to 90 days due to high volume usage; warranty on

production tools cannot be guaranteed due to unpredictable circumstances.

Tools are subjected to abuse such as hammering or usage of adjustment tools, especially true in loan tool

programs. Upon receiving a report, EVERWIN and its authorized distributor may request the damaged tool,

serial number of the damaged tool (as a gauge for the tool’s age) and photos/videos of the defect for test and

evaluation to find root causes.

EVERWIN’s analyst will judge the issuance of defective parts and will replace at no charge if evaluation

results show that the root cause is defect in material and / or

workmanship.

All warranty services will be carried out by EVERWIN authorized repair centers, please contact

NOTE

1-Year Limited Warranty

3

CE Declaration of conformity

EVERWIN PNEUMATIC CORP. declares that the product as described in attached documentation

is in conformity with the Machinery Directive 2006/42/EC and the European standard EN 792-13.

CE Dichiarazione di conformità

EVERWIN PNEUMATIC CORP. dichiara, assumendo la piena responsabilità, che questa fissatrice

e conforme alla Direttive Europee 2006/42/EC e alla norma

armonizzata EN 792-13.

CE Konformitätserklärung

EVERWIN PNEUMATIC CORP. erklärt hiermit in alleiniger Verantwortung das dieses Gerät

ubereinstimmt mit den Europäischen Richtlinien 2006/42/EC undden Europäischen Norm EN 792-13.

CE Déclaration de conformité

EVERWIN PNEUMATIC CORP. déclare et prend sur soi toute la responsabilité de cette déclaration,

que le produit esten conformité avec les Directives Européennes 2006/42/EC et avec la norme

harmonisée EN 792-13.

CE konformiteitsverklaring

EVERWIN PNEUMATIC CORP. verklaart hierbij onder eigen verant woordelijkheid dat deze machine

in overeenstemming is met de Europese Richtlijnen 2006/42/EC en de Europese norm EN 792-13.

CE Declaracion de conformidad

EVERWIN PNEUMATIC CORP. declaramos bajo nuestra sola responsabilidad que este producto

esta enconformidad con las Directivas Europeas 2006/42/EC y con la normativa EN 792-13.

Overensstemmelseserklæring / CE Deklaration

EVERWIN PNEUMATIC CORP. erklærer herved, at produktet er i overenstemmelse med nedenstående

normer eller normative dokumenter 2006/42/EC i henhold til bestemmelserne i EU’s direktiv EN 792-13.

Överstämmelseförklaring / CE Deklaration

EVERWIN PNEUMATIC CORP. förklarar härmed att produkten överensstämmer med följande

normer och direktiv 2006/42/EC och SS-EN 792-13.

SAMSVARSERKLÆRING / CE Deklaration

EVERWIN PNEUMATIC CORP. erklærer herved att produktet er i samsvar med følgende normer

og direktiv 2006/42 EC og NS-EN 792-13.

Todistus CE standardinmukaisuudesta

EVERWIN PNEUMATIC CORP. vakuuttaa täten tuotteen vastaavan seuraavla standardeja ja

direktiivejä: 2006/42/EC ja EN 792-13.

Deklaracja zgodności CE

EVERWIN PNEUMATIC CORP. oświadcza, że produkty opisane w załączonej dokumentacji

spełniają wymogi Dyrektywy Maszynowej 2006/42/EC oraz Europejskiej normy EN 792-13.

ENGLISH

ITALIANO

DEUTSCH

FRANCAIS

NEDERLANDS

ESPAGNOL

DANSK

SVENSK

NORSK

FINSK

POLSKIE

Machine Type : PN51 / PN51B / SCN51

Machine Name : Pneumatic Fastener Driving Tool

Place of Issue : No. 7, Wugong 7th Rd., Wufeng Dist., Taichung City 41353, Taiwan.

Date of Issue : Apr. 26, 2022

Signature of Issuer : 1

Hung-Ming Chuang

General Manager

CE Declaration of Conformity

4

NOTE

To Avoid Severe Personal Injury Or Property Damage

Before operating this tool, all operators should read and study this manual to understand

and follow the safety warnings and instructions. Failure to follow warnings could result in

death or serious injury. Keep these instructions with the tool for future reference.

Eye Protection

Which conforms to ANSI/ CE specifications and provides protection against flying particles

both from the FRONT and SIDE should ALWAYS be worn by the operator and others in

the work area when connecting to air supply, loading, operating or servicing this tool.

Eye protection is required to guard against flying fasteners and debris, which could cause

severe eye injury. The employer and/or user must ensure that proper eye protection is

worn. Eye protection equipment must conform to the requirements of the ANSI Z87.1

and 89/686/EEC, and provide both frontal and side protection.

Non-side shielded spectacles and face shields alone do not provide adequate

protection.

Caution

Additional Safety Protection will be required in some environments. For example, the

working area may include exposure to noise level which can lead to hearing damage. The

employer and user must ensure that any necessary hearing protection is provided and

used by the operator and others in the work area. Some environments will require the use

of head protection equipment. When required, the employer and user must ensure that

head protection conforming to ANSI Z89.1/ CE is used.

Air Supply and Connections

Do not use oxygen, combustible gases, or bottled gases as a power source for this tool as

tool may explode possibly causing injury.

Do not use supply sources which can potentially exceed 200 PSI (14 kg/cm2) as tool may

burst, possibly causing injury.

The connector on the tool must not hold pressure when air supply is disconnected. If a

wrong fitting is used, the tool can remain charged with air after disconnecting and thus will

be able to drive a fastener even after the air line is disconnected, possibly causing injury.

Do not pull trigger or depress contact arm while connected to the air supply as the tool may

cycle, possibly causing injury.

Always disconnect air supply: 1.) Before making adjustments; 2.) When servicing the tool;

3.) When clearing a jam; 4.) When tool is not in use; 5.) When moving to a different work

area, asaccidental actuation may occur, possibly causing injury.

C2H2

O2

Safety Instructions

5

Maintaining the Tool

When working on air tools, note the warnings in this manual and use extra care when

evaluating problem tools.

staple Loading

When loading tool: 1.) Never place a hand or any part of body in fastener discharge area of

tool; 2.) Never point tool at anyone; 3.) Do not pull the trigger or depress the trip as

accidental actuation may occur, possibly causing injury.

Operation

Always handle the tool with care: 1.) Never engage in horseplay; 2.) Never pull the trigger

unlessnose is directed toward the work; 3.) Keep others a safe distance from the tool while

tool is inoperation as accidental actuation may occur, possibly causing injury.

The operator must not hold the trigger pulled on contact arm tools except during fastening

operation as serious injury could result if the trip accidentally contacts someone or

something,causing the tool to cycle.

Keep hands and body away from the discharge area of the tool. A contact arm tool may

bouncefrom the recoil of driving a fastener and an unwanted second fastener may be

driven, possibly causing injury.

Check operation of the contact-arm mechanism frequently. Do not use the tool if the arm is

not working correctly as accidental driving of a fastener may result. Do not interfere with

the proper operation of the contact-arm mechanism.

Do not drive fasteners on top of other fasteners or with the tool at an overly steep angle as

this may cause deflection of fasteners which could cause injury.

Do not drive fasteners close to the edge of the work piece as the wood may split, allowing

the fastener to be deflected possibly causing injury.

This tool has either selective actuation for contact actuation or continuous contact

actuation by actuation mode selectors or is a contact actuation or continuous actuation

contact tool and has been marked with the symbol above. Its intended uses are for

production applications such as pallets, furniture, manufactured housing, upholstery and

sheathing.

If using this tool in selective actuation mode, always ensure it is in the correct actuation

setting.

Do not use this tool in contact actuation for applications such as closing boxes or crates

and fitting transportation safety systems on trailers and lorries.

Be careful when changing from one driving location to another.

Safety Instructions

6

Air Consumption

Tool air consumption: PN51-2.27 cfm (1.07 liter/cycle), PN51B-2.27 cfm (1.07 liter/cycle),SCN51-2.27 cfm

(1.07 liter/cycle) of free air to operate at the rate of 100 nails per minute, at 90 psi (6.0 kg/cm2). Take the

actual rate at which the tool will be run to determine the amount of air required. For instance, if your

fastener usage averages 50 nails per minute, you need 50% of the tool air consumption in running at 100

nails per minute.

Operating Pressure

70 to 120 psi (5 to 8 kg/cm2). Select the operating pressure within this range for best fastener performance.

Do not exceed this recommended operating pressure.

Tool Air Fitting

This tool uses a 1/4"-18 N.P.T or 1/4"-19 P.T male plug. The inside diameter should be .280" (7 mm) or

larger. The fitting must be capable of discharging tool air pressure when disconnected from the air supply.

Specifications

Model PN51 PN51B SCN51

Height 271mm (10.6") 271mm (10.6") 364mm (14.3")

Width 126mm (4.9") 126mm (4.9") 130mm (5.1")

Length 246mm (9.6") 246mm (9.6") 311mm (12.2")

Weight 2.0 kgs (4.4 lbs) 2.0 kgs (4.4 lbs) 3.05 kg (6.7 lbs)

Loading Capacity 200~400 200~400 150~300

Air Consumption

at 90PSI (6bar) pres.

2.75 cfm

(1.3 liter/second)

2.75 cfm

(1.3 liter/second)

3.4 cfm

(1.6 liter/second)

Fastener Specifications

Model PN51 PN51B SCN51

Nail Length 25 ~ 50mm

(1" ~ 2") 25 ~ 50mm

(1" ~ 2") Wire:32~50mm(1-1/4"~2")

Plastic:25~50mm(1"~2")

Shank Dia. 2.1 ~ 2.3mm

(0.083" ~ 0.090") 2.1 ~ 2.3mm

(0.083" ~ 0.090") 4.2~5.3mm

(0.165" ~ 0.209")

Head Dia. 4.2~5.3mm

(0.165" ~ 0.209") 4.2~5.3mm

(0.165" ~ 0.209") 2.1 ~ 2.3mm

(0.083" ~ 0.090")

Shank Type Smooth, Ring, Screw Smooth, Ring, Screw Smooth, Ring, Screw

Collation 15° Wire / Plastic 15° Wire / Plastic15° Wire

Specifications and Technical Data

7

Noise

A-weighted single-event sound power level LWA, 1s: PN51-102.5, PN51B-102.5, SCN51-102.5 dBA.

A-weighted single-event emission sound pressure level at work station LpA 1s,d: PN51-104.5,

PN51B-104.5, CN51-104.5 dBA.

These values are determined and documented in accordance to EN12549.

Vibration

Vibration characteristic value: PN51-3.76 m/s2, PN51B-3.76 m/s2, SCN51-3.76 m/s2

These values are determined and documented in accordance to ISO 8662-11.

This value is a tool-related characteristic value and does not represent the influence to the hand-arm-sys-

tem when using the tool. An influence to the hand-arm-system when using the tool will, for example,

depend on the gripping force, the contact pressure force, the working direction, the adjustment of mains

supply and the workpiece support.

Refer to Operation Instructions and warnings on pages before proceeding to use this tool.

1. Contact Trip

Identified by Grey TriggerIdentified by Black Trigger Identified by Trigger Switch Dial

2. Sequential Trip 3. Switchable Trigger (SCN51 only)

1. Contact Trip

The common operating procedure on “Contact Trip” tools is for the operator to contact the work to actuate

the trip mechanism while keeping the trigger pulled, thus driving a fastener each time the work is contacted.

This will allow rapid fastener placement on many jobs, such as sheathing, decking and pallet assembly. All

pneumatic tools are subject to recoil when driving fasteners. The tool may bounce, releasing the trip, and if

unintentionally allowed to recontact the work surface with the trigger still actuated (finger still holding trigger

pulled) an unwanted second fastener will be driven.

Operation

Specifications and Technical Data

Identified by Control Valve Air Inlet

4. Remote Fire

8

If trigger system is not operating as described, do not use the tool and contact your

nearest service center.

2. Squential Trip

The Sequential Trip requires the operator to hold the tool against the work before pulling the trigger. This

makes accurate fastener placement easier, for instance on framing, toe stapling and crating applications.

The Sequential Trip allows exact fastener location without the possibility of driving a second fastener on

recoil, as described under “Contact Trip”. The Sequential Trip Tool has a positive safety advantage because

it will not accidentally drive a fastener if the tool is contacted against the work – or anything else – while the

operator is holding the trigger pulled.

Single Sequential Fire Operation With Switchable Trigger

The single sequential fire operation requires the operator to hold the tool against the work with the safety

yoke depressed before pulling the trigger. In order to drive additional fasteners, the trigger must be

released and the tool lifted away from the work, before repeating the above-mentioned steps. This makes

accurate fastener placement easier, for instance on framing, toe nailing and crating applications. The single

sequential fire operation allows exact fastener location without the possibility of driving a second fastener

on recoil, as described under Continuous Bump Fire Operation (below). The single sequential fire operation

has a positive safety advantage because it will not accidentally drive a fastener if the tool is contacted

against the work - or anything else - while the operator is holding the trigger pulled.

Continuous Bump Fire Operation with Switchable Trigger

The common operating procedure on “Contact Trip” tools is for the operator to actuate the safety yoke while

keeping the trigger pulled, thus driving a fastener each time the work is contacted. This will allow rapid

fastener placement on many jobs, such as sheathing, decking and pallet assembly. All pneumatic tools are

subject to recoil when driving fasteners. The tool may bounce, releasing the safety yoke and if

unintentionally allowed to re-contact the work surface with the trigger still actuated (finger still holding the

trigger pulled) an unwanted second fastener will be driven.

WARNING

Operation

9

Fittings

Install a male plug on the tool which is free flowing and which will release air pressure from the tool when

disconnected from the supply source.

Do not use oxygen, combustible gases, or bottled gases as a power source for this tool as

tool may explode possibly causing injury.

C2H2

O2

Hoses

Air hoses should have a minimum of 150 PSI (10.6 kg/cm2) working pressure rating or 150 percent of the

maximum pressure that could be produced in the air system. The supply hose should contain a fitting that

will provide “quick disconnecting” from the male plug on the tool.

Supply Source

Use only clean, regulated compressed air as a power source for this Tool. Never use oxygen, combustible

gases, or botted gases as a power saource for this tool as tool may explode.

Regulator

Apressure regulator with an operating pressure of 0 - 125 PSI (0 - 8.79 kg/cm2) is required to control the

operating pressure for safe operation of this tool. Do not connect this tool to air pressure which can

potentially exceed 200 PSI (14kg/cm2) as tool may fracture or burst, possibly causing injury.

Operating Pressure

Do not exceed recommended maximum operating pressure as tool wear will be greatly increased. The air

supply must be capable of maintaining the operating pressure at the tool. Pressure drops in the air supply

can reduce the tool’s driving power. Refer to “Tool Specifications” for setting the correct operating pressure

for the tool.

Filter

Dirt and water in the air supply are major causes of wear in pneumatic tools. A filter will help to get the best

performance and minimum wear from the tool. The filter must have adequate flow capacity for the specific

installation. The filter has to be kept clean to be effective in providing clean compressed air to the tool.

Consult the manufacturer’s instructions on proper maintenance of your filter. A dirty and/or clogged filter

will cause a pressure drop which will reduce the tool’s performance.

Air Supply and Connections

10

Frequent, but not excessive, lubrication is required for best performance. Air - tool oil added through the air

line connection will lubricate the internal parts. Do not use detergent oil or additives as these lubricants will

cause accelerated wear to the seals and bumpers in the tool, resulting in poor tool performance

and frequent tool maintenance.

If no air line lubricator is used, add oil during use into the air fitting on the tool once or twice a day.

Only a few drops of oil at a time is necessary. Too much oil will only collect inside the tool and will be

noticeable in the exhaust cycle.

Cold Weather Operation

For cold weather operation, near and below freezing, the moisture in the air line may freeze and prevent

tool operation. We recommend the use of permanent antifreeze (ethylene glycol) as a cold weather

lubricant.

Caution

Do not store tools in a cold-weather environment to prevent frost or ice formation on the tools operating

valves and mechanisms, which could cause tool failure. Test tool without fasteners prior to operations to

ensure no malfunction on the tool due to ice formation.

Note

Some commercial air line drying liquids are harmful to O-Rings and seals – do not use these low

temperature air dryers without checking compatibility.

Lubrication

11

Eye Protection

Which conforms to ANSI/ CE specifications and provides protection against flying particles

both from the FRONT and SIDE should ALWAYS be worn by the operator and others in the

work area when connecting to air supply, loading, operating or servicing this tool.

Eye protection is required to guard against flying fasteners and debris, which could cause

severe eye injury.

To Prevent Accidental Injuries

.Never place a hand or any other part of the body in staple discharge area of tool while

the air supply is connected.

.Never point the tool at anyone else.

.Never engage in horseplay.

.Never pull the trigger unless nose is directed at the work.

.Always handle the tool with care.

.Pull the trigger or depress the trip mechanism while loading the tool.

Open the Magazine Nail Length Adjustment Nail Loading Swing Cover Closed

Close the door

Loading the Tool

Pull down door latch and swing

door open. Open the magazine.

The nail support can be moved

up and down to four settings. To

change setting pull up on the

post and twist to the correct step.

The nail support should be

adjusted correctly to the position

indicated in inches and

millimeters inside magazine.

Place a coil of nails over the post

in the magazine. Uncoil enough

nails to reach the feed pawl, and

place the second nail between

the teeth on the feed pawl. The

nail heads fit in slot

on nose.

Check that latch engages. (If it

does not engage, check that the

nail heads are in the slot on the

nose.)

door latch door latch

door

nail support feed pawl

magazine

cover

magazine

door

magazine

cover

Fastener Loading

12

Eye Protection

Which conforms to ANSI/ CE specifications and provides protection against flying particles

both from the FRONT and SIDE should ALWAYS be worn by the operator and others in the

work area when connecting to air supply, loading, operating or servicing this tool. Eye

protection is required to guard against flying fasteners and debris, which could cause

severe eye injury. The employer and/or user must ensure that proper eye protection is

worn. Eye protection equipment must conform to the requirements of the ANSI Z87.1 and

89/686/EEC, and provide both frontal and side protection.

Before Handling or Operating This Tool

Read and understand the warnings contained in this manual.

Refer to “tool specifications” in this manual to identify the operating system on your tool.

The operator must not hold the trigger on contact trip tools except during fastening

operation, as serious injury could result if the trip accidentally contacts someone or something, causing the

tool to cycle.

2. Sequential Trip Operation :

To operate the tool in this manner, first position the contact trip on the work surface, WITHOUT

PULLING THE TRIGGER. Depress the contact trip until the nose touches the work surface and then

pull the trigger to drive a fastener. Do not press the tool against the work with extra force. Instead, allow

the tool to recoil off the work surface to avoid a second unwanted fastener. Remove your finger from

the trigger after each operation

1. Contact Trip Operation (Rapid Fire) :

To operate the tool in this manner, hold the tool with the contact trip pointing towards but not touching

the work surface. Pull the trigger and then tap the contact trip against the work surface using a

bouncing motion. Each depression of the contact trip will cause a fastener to be driven.

Keep hands and body away from the discharge area of the tool. A contact trip tool

may bounce from the recoil of driving a fastener and an unwanted second fastener may be driven, possibly

causing injury.

WARNING

WARNING

There are three available systems on the PN51, PN51B:

Tool Operation

13

3. Remote Fire :

The Remote fire model is cycle by actuation of remote valve (RCVA1) for mounted machine.

Tools must NOT be used in Continuous Bump Fire Operation where changing from

one working position to another involves the use of ladders, stairs or similar structures such as roofs.

WARNING

1. Switchable Trigger Operation :

SINGLE SEQUENTIAL FIRE OPERATION WITH SWITCHABLE TRIGGER

The single sequential fire operation requires the operator to hold the tool against the work with the

safety yoke depressed before pulling the trigger. In order to drive additional fasteners, the trigger must

be released and the tool lifted away from the work, before repeating the above-mentioned steps. This

makes accurate fastener placement easier, for instance on framing, toe nailing and crating applications.

The single sequential fire operation allows exact fastener location without the possibility of driving a

second fastener on recoil, as described under Continuous Bump Fire Operation (below). The single

sequential fire operation has a positive safety advantage because it will not accidentally drive a

fastener if the tool is contacted against the work - or anything else - while the operator is holding the

trigger pulled.

CONTINUOUS BUMP FIRE OPERATION WITH SWITCHABLE TRIGGER

The common operating procedure on “Contact Trip” tools is for the operator to actuate the safety yoke

while keeping the trigger pulled, thus driving a fastener each time the work is contacted. This will allow

rapid fastener placement on many jobs, such as sheathing, decking and pallet assembly. All pneumatic

tools are subject to recoil when driving fasteners. The tool may bounce, releasing the safety yoke and if

unintentionally allowed to re-contact the work surface with the trigger still actuated (finger still holding

the trigger pulled) an unwanted second fastener will be driven.

SELECTING THE OPERATION MODE (As shown below)

To change the operation mode, rotate the switch in the counterclockwise

direction. The switch will lock automatically when the indicating arrow is

pointing to the left (Single Sequential Fire Operation) or the right

(Continuous Bump Fire Operation).

There are three available systems on the SCN51:

Tool Operation

14

Driving Depth Adjustment Dial (SCN51)

1. With air pressure set, drive nails into a representative

material sample to determine if adjustment is necessary.

2. If adjustment is required, disconnect air supply.

3. Refer to the label on the Contact Arm area for direction

to turn the Adjustment dial

4. Reconnect air supply.

ALWAYS discount air supply before Adjustment dial.

WARNING

Shallower

Deeper

Direction of the exhaust air is changed by rotating exhaust cover by hand.

ALWAYS disconnect air supply before rotating the exhaust cover by hand.

WARNING

Directional Exhaust Cover

Tool Operation

15

16

In addition to the other warnings contained in this manual observe the

following for safe operation :

.Use this pneumatic tool only for the purpose for which it was designed.

.Never use this tool in a manner that could cause a fastener to be directed toward the user or others in the

work area.

.Do not use the tool as a hammer.

.Always carry the tool by the handle. Never carry the tool by the air hose.

.Do not carry this tool with the trigger depressed when not in use.

.Do not alter or modify this tool from the original design or function.

.Always be aware that misuse and improper handling of this tool can cause injury to yourself and others.

.Never clamp or tape the trigger or contact trip in an actuated position.

.Never leave a tool unattended with the air hose attached.

.Do not operate this tool if it does not contain a legible WARNING LABEL.

.Do not continue to use a tool that leaks air or does not function properly. Notify your distributor or

representative if your tool continues to experience functional problems.

Remove all fasteners from tool before performing tool operation check.

CAUTION

1. Contact Trip Operation : 2. Sequential Trip Operation :

a. With finger off the trigger, press the contact trip

against the work surface

The tool must not cycle.

b. Hold the tool off the work surface,

and pull the trigger.T NOT CYCLE

The tool must not cycle.

c. With the tool off the work surface, pull the trigger.

Press the contact trip against the work surface.

The tool must cycle.

d. Without touching the trigger, press the contact

trip against the work surface, then pull the trigger.

The tool must cycle.

a. Press the contact trip against the work surface,

without touching the trigger.

The tool must not cycle.

b. Hold the tool off the work surface,

and pull the trigger.CLE

The tool must not cycle.

Release the trigger. The trigger must return to

the trigger stop on the frame.

c. Pull the trigger and press the contact trip

against the work surface.

The tool must cycle.

d. With finger off the trigger, press the contact trip

against the work surface. Pull the trigger

The tool must cycle.

Tool Operation Check

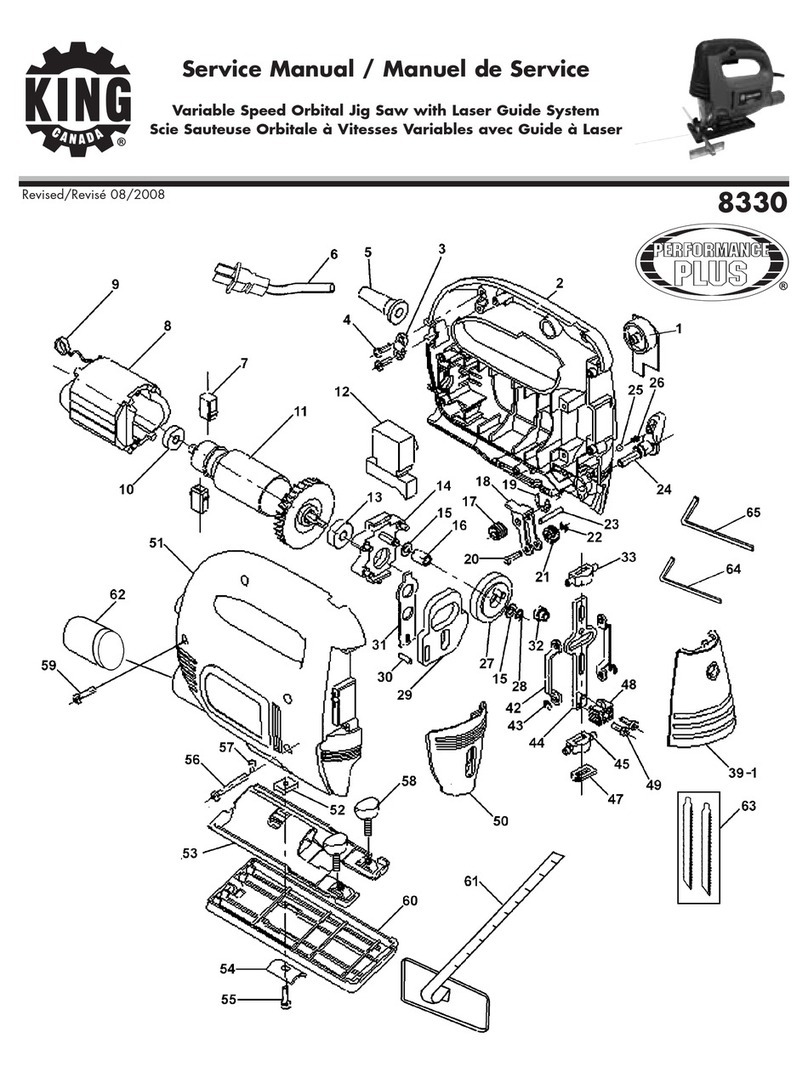

Worn driver causing poor driving quality or loss of power:

Wear or a chip on the driving tip will affect the nail drive, giving symptoms of bent and incompletely driven

nails, and damaged nail heads.

The driver length may be adjusted to allow the driving tip to be redressed to compensate for wear. Heat and

precise measurement are required. Contact a qualified service technician for this adjustment.

The length setting for a new driver is shown below. Measurement is from the bottom face of the main

piston.

Air Pressure and Volume

Air volume is as important as air pressure. The air volume supplied to the tool may be inadequate because

of undersize fittings and hoses, or from the effects of dirt and water in the system. Restricted air flow will

prevent the tool from receiving an adequate volume of air, even though the pressure reading is high. The

results will be slow operation, misfeeds or reduced driving power. Before evaluating tool problems for these

symptoms, trace the air supply from the tool to the supply source for restrictive connectors, swivel fittings,

low points containing water and anything else that would prevent full volume flow of air to the tool.

Driver Maintenance Instructions

WARNING

Replacement Parts

Use only genuine parts from the manufacturer or distributor. Do not use modified parts or parts which will not

give equivalent performance to the original equipment. Tighten all screws. Keep contact arm moving

smoothly.

When working on air tools, note the warnings in this manual and use extra care

evaluating problem tools. Disconnect air supply and empty the magazine when inspecting or maintaining the

tool.

Assembly Procedure for Seals

When repairing a tool, make sure the internal parts are clean and lubricated. Use O-Ring lubricant on all

O-Rings. Coat each O-Ring with O-Ring lubricant before assembling. Use a small amount of oil on all moving

surfaces and pivots. After reassembly add a few drops of Air Tool Lubricant through the air line fitting before

testing.

Maintaining The Pneumatic Tool

17

Troubleshooting / Repairs

The troubleshooting and / or repairs shall be carried out only by the authorized dealer / distributor or by other

pneumatic tool specialists.

Note that the measurement from the top of the piston gives the maximum amount the driver may be

adjusted to allow redressing. Always extend the driver the minimum required to allow redressing to restore

the driving end; several redressings will be possible before this maximum depth is reached.

When using optional flangeless driver, see adjustment below. Be sure to use proper preparation and

installation.

PN51 : 123.3mm~123.7mm (4.854"~4.870")

PN51B : 123.3mm~123.7mm (4.854"~4.870")

SCN51 : 123.3mm~123.7mm (4.854"~4.870")

Standard Length

Driver Maintenance Instructions

18

Note

TOUGHER FASTER SMARTER

Everwin Pneumatic@everwin_official@everwintaiwan

Follow Us to Get More InformationFollow Us to Get More Information

TEL. : +886-4-2333-2999No.7, Wugong 7th Road, Wufeng District,

Taichung City, 413, Taiwan FAX : +886-4-2333-0555

www.everwinpneumatic.com

This manual suits for next models

2

Table of contents

Other Everwin Power Tools manuals

Everwin

Everwin PN51 User manual

Everwin

Everwin FS9240BC User manual

Everwin

Everwin PN65 User manual

Everwin

Everwin FCN90B User manual

Everwin

Everwin FCN90B User manual

Everwin

Everwin SCN65 User manual

Everwin

Everwin SCN90L User manual

Everwin

Everwin PN51 User manual

Everwin

Everwin PN130 User manual

Everwin

Everwin PN57 Series User manual