SKU 98656 For technical questions, please call 1-800-444-3353. Page 3

SPECIFICATIONS

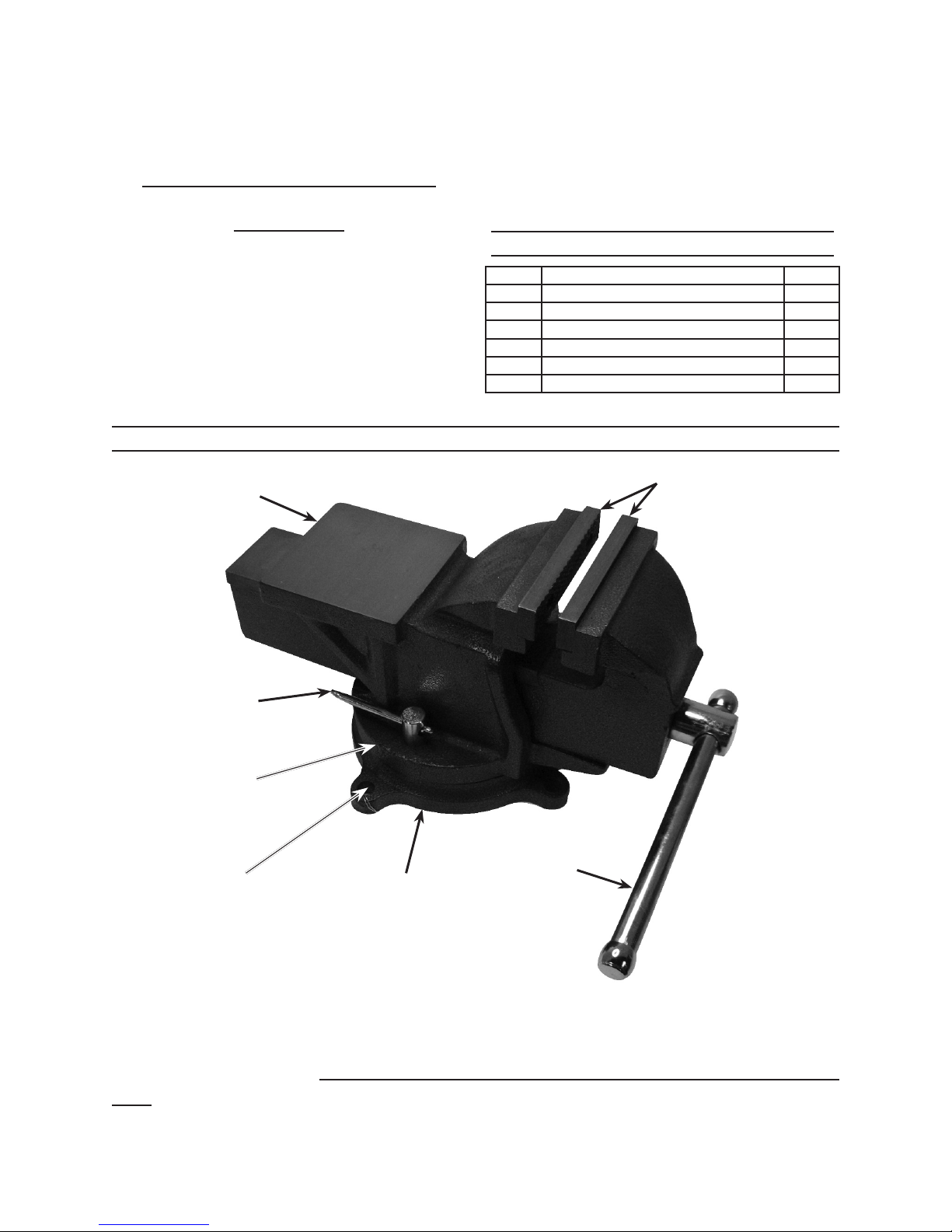

Item Description

Construction Material 360° Swiveling Cast Iron Base

Jaw Material Machined High-Carbon Steel

Jaw Opening 5-5/16"

Throat Depth 2-1/2"

Leadscrew Steel, 5/8" Dia.

Sliding “T” Locking Handles Chrome (2)

Mounting Hole Size 7/16" Dia.

Weight 25.2 lbs.

UNPACKING

When unpacking, check to make sure that

the item is intact and undamaged. If any parts are

missing or broken, please call Harbor Freight Tools

at the number shown on the cover of this document

as soon as possible.

You will need the manual for the safety warn-

ings and precautions, operating and maintenance

procedures, parts list and diagram. Keep your

invoice with this manual. Write the invoice number

on the inside of the front cover. Keep the manual

and invoice in a safe and dry place for future refer-

ence.Assembly Instructions

Read the ENTIRE IMPORTANT

SAFETY INFORMATION section at the

beginning of this document including

all text under subheadings therein

before set up or use of this product.

OPERATING INSTRUCTIONS

Set-Up:

Use the mounting holes on the vise’s Fixed1.

Base (1) as a template to mark drill points.

Set the Vise at on the workbench so that the

mounting holes are positioned as desired.

With a pencil, mark the points at which to

fasten the Vise onto the workbench. Set the

Vise aside.

Drill holes of the appropriate size (where2.

previously marked with a pencil) through the

top of the workbench.

WARNING: Before drilling holes,

check for hidden electrical wires or

cords in drilling path.

Carefully set the Fixed Base (1) of the Vise3.

with the Mounting Holes corresponding to the

holes previously drilled through the top of the

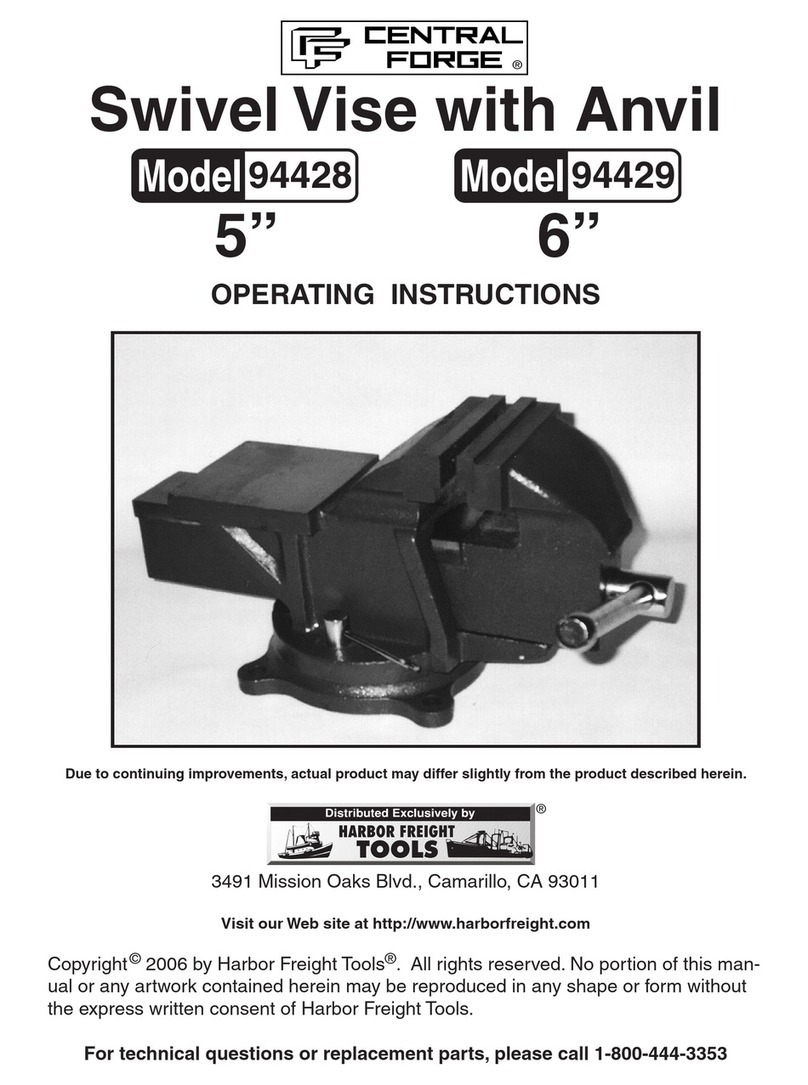

workbench. (See Fig. 1.)

Insert hardened steel bolts (not provided), of4.

the appropriate diameter (to t 1/2" diam-

eter mounting holes) and length, downward

through the Fixed Base (1) and through the

workbench. The length of the mounting bolts

will be determined by the thickness of the

workbench. Secure the mounting bolts in

place with the appropriate washers and nuts.

Turn the Handle (6) counterclockwise to5.

open the Jaws (3) of the Vise. Place the item

you are working on inside the Jaws. Tighten

Jaws (3) against the workpiece by turning the

Handle (6) clockwise until your workpiece is

held securely against the Jaws (3).

Warning: Damage could occur to your

vise and/or workpiece if you overtighten

the Handle (6). (See Fig. 1.)

To remove the object you are working on,6.

turn the Handle (6) counterclockwise two to

three times, opening the Jaws (3). Remove

your workpiece.

Swivel the Mounted Vise

By swiveling the Vise around you can access

your workpiece easier.

Turn the two Locking T-Handles (4) until they1.

release the Swivel Base (5) of the Vise.

Turn the Vise to the desired position. (Ex-2.

ample: Swivel 125°).

Tighten the Locking T-Handles (4) once you3.

have the Vise in the position best suited for

your work.

Maintenance

Keep the moving parts lubricated. Wipe off1.

any lubricant off of the Handles (4, 6) and

Jaws (3).

Keep the Jaws (3) clean.2.

The jaws can be removed for cleaning and3.

are replaceable. Each is held on by two 5mm

cap screws. Use a 5mm hex wrench (not

included) to loosen/tighten the cap screws.