E2648 series heavy duty detectors-transmitters belong to the PluraSens® family of

multifunctional measurement instruments. The instruments utilise gas sensors of

various types with excellent repeatability, stability and long lifetime. Due to its IP66

enclosure of die cast aluminium, the device may be used under harsh conditions.

E2648 series provides two independent analog outputs OUT1 and OUT2, user-

selectable to 4-20 mA or 0-10 V, proportional either to gas concentration or temperature.

RS485 Modbus RTU digital communication interface allows easy instrument

configuration and integration into various automation systems.

The following features are available as option:

Two relays RE1 and RE2 with closing contacts. Relay outputs can be used to

switch alarm sirens, ventilation fans, shut-off valves or other actuators

Integrated 230 V mains power supply module

Remote probe.

The version of your device is marked on the package.

If symbol is marked on the equipment, consult the documentation for further

information.

Safety requirements

Misuse will impair the protection of the equipment.

Always adhere to the safety provisions applicable in the country of use.

Do not perform any maintenance operation with the power on. Do not let water or

foreign objects inside the device.

External circuits connected to the equipment should have sufficient insulation rating

according to the environmental conditions and equipment power

A disconnecting device that is marked as such and easily accessible should be

included in the installation of this product.

Operating conditions

The device should be used in explosion-safe areas. Avoid strong mechanical shock,

vibrations or EMI. Avoid corrosive atmosphere and areas highly contaminated with dust,

oil mist etc. Keep the device away from direct sunlight.

See Specification table for more details.

Mounting dimensions

Installation

Before proceeding with the installation it is mandatory to read carefully the Safety

requirements section and make sure to comply with all listed instructions. During the

installation of the device the following points must be considered:

application (air quality control or leakage detection),

properties of the space under investigation (room geometry, direction and velocity of

air flows etc),

detected gas (relative density to air, temperture, whether the gas is flammable, or

toxiс, or oxygen displacing),

safety: strong vibrations, mechanical shock, and the sources of strong

electromagnetic interference should be avoided,

the device should be accessible for maintenance and repair.

For early leakage detection install the sensor as close as possible to the potential

leakage sources (flanges, valves, pressure reducers, pumps, etc), taking into

consideration other points listed above. Do not locate the detector close to ventilation

openings and strong air currents. Avoid the areas without air circulation (corners,

niches) as well. For general area monitoring without definite leakage sources, the

detectors should be distributed evenly in the room. For personal safety control the

detectors are installed in the breathing zone (at the height of the head of people or

animals). Recommended sensor position is vertical, pointing downwards. See

Installation guidelines section for more information.

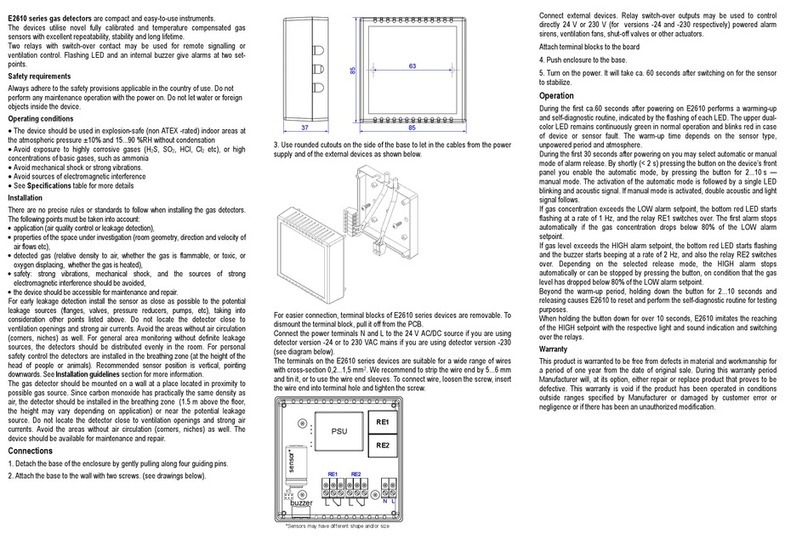

The device is fixed on the wall using two holes located outside the sealed area of the

device (NOTE Dimensional drawings and connection diagrams are presented on a

separate sheet.).

Connections

NOTE Dimensional drawings and connection diagrams are presented on a separate

sheet.

1. Unscrew four lid screws and detach the lid from the device.

2. Attach the device to the wall. (This step may be done after the step 3, consider

your convenience).

3. Use two M16 cable glands to let in the cables of the power supply and of the external

devices. Without turning on the power, plug the power cable and connect the

analog/relay outputs and/or digital interface terminals to the necessary devices

according to the relevant connection diagram.

The screwless quick connect spring terminals on the E2648 series devices are

suitable for a wide range of wires with cross-section 0,2...1,5 mm2. We recommend

to strip the wire end by 8...9 mm and use the wire end sleeves.

To connect the wire, insert the wire end into terminal hole. To disconnect, push the

spring loaded terminal lever, pull the wire out, and release the lever.

Use twisted pair cable, e.g. LiYY TP 2×2×0,5 mm2or CAT 5, to connect the device

to RS485 network. Use one pair for A and B wires to connect the transmitter to

Fieldbus network. Respect polarity.

The type of each analog output can be independently changed between 4-20 mA

and 0-10 V with jumpers J1 (OUT1) and J2 (OUT2). With closed jumper the output

is 0-10 V, with open jumper the output is 4-20 mA. Power restart is required after

changing the position of the jumpers.

By default both outputs OUT1 and OUT2 are assigned to gas concentration. The

device has built-in temperature sensor which may be tied to any of the outputs. The

built-in temperature sensor is intended for temperature compensation. E2648 series

devices are not meant for ambient air temperature measurement.

We recommend to set the difference between the upper and bottom limits of the

output scale not narrower than 20% of detection range (for CO detectors the scales

down to 5% of range are allowed). In any case, do not set the output scale below

the tenfold resolution of the device.

NOTE The outputs are not galvanically isolated from 24 V power supply and share

common 0V. Allowed load resistance limits are stated in Specifications table. To power

the instrument from an external 24 VDC source, connect terminals 0V and +U to the

source. If the integrated mains power supply module is used, connect terminals Land N

to the mains.

NOTE Actuator short-circuits should be avoided, to protect the instrument relays

use external fuses or safety switches.

4. Turn on the power. The sensor heating up takes ca. 60 seconds after switching on.

The operating status is indicated by the LED on the PCB of the device. The LED

response to different processes is presented in the table below.

Sensor absence or malfunction

Blinking 0.5 Hz (90% off, 10% on)

Blinking 1 Hz (50% on, 50% off)

Blinking 2 Hz (50% on, 50% off)

The signal is modulated with short on-off pulses,

even single Modbus cycle is traceable*

5. Make sure that the device is properly installed, the external devices connected,

power on and control LED is constantly lit. Make certain that the cable glands are

properly tightened to ensure the conformity to IP66 protection class. Place the lid

back and fix it with the screws. The device is ready to use.

Remote sensor probe handling

The E2648 series devices are available with remote probe (dimensional drawing is

presented on a separate sheet). The remote probe is connected to the main unit with

shielded cable. Default connection cable length is 3 m. The sensor probes of all types

are equipped with a hydrophobic microporous PTFE filter to protect the sensor from

dust, dirt and water drops. The filter may be replaced if it gets strongly contaminated. To

replace the PTFE filter, unscrew the M25 nut and remove the old filter. Place a new

filter into the nut and tighten it again.

NOTE Never stab or press the filter near its centre where the sensor is located since

this may damage the sensor. The recommended orientation of sensor probe is vertical

with the sensor tip pointing downwards. This prevents possible accumulation of

condensed water on the sensor protection filter.

Return to default settings

To reset the device’s Slave ID, baudrate and sbit number to factory settings: proceed as

follows

1. De-energize the device

2. Connect the J3 jumper

3. Turn on the device

4. De-energize the device

5. Disconnect the J3 jumper

6. Turn on the device

Configuring

Detectors- transmitters E2648 share all functionalities of the PluraSens®multifunctional

platform. The features and options include:

- digital output change rate limiting filter

- digital integrating (averaging) filter

- temperature measurement channel with internal sensor

- free assignment of each analog output to chosen parameter

- flexible setting of analog output scales for each output

- output shift and slope adjustment for calibration

- free assignment of each of two relays to chosen parameter

- several relay control logic modes

- switch delays and minimum on/off state durations for each relay

A standard configuration kit includes a USB-RS485 converter and a software pack.

Please contact your Seller for more information.

RS485 communication interface

See Annex 1

Maintenance

Do not perform any maintenance operation with the power on.

Clean the device with soft damp cloth. Do not use any abrasive cleaning agents. Do

not immerse the device into water or any cleaning media.

Delivery set

–Detector-transmitter E2648

–Mounting accessories:

2 screws with plastic dowels

fixing clamp for remote probe version

Warranty

This product is warranted to be free from defects in material and workmanship for a

period of one year from the date of original sale. During this warranty period

Manufacturer will, at its option, either repair or replace product that proves to be

defective. This warranty is void if the product has been operated in conditions outside

ranges specified by Manufacturer or damaged by customer error or negligence or if

there has been an unauthorised modification.