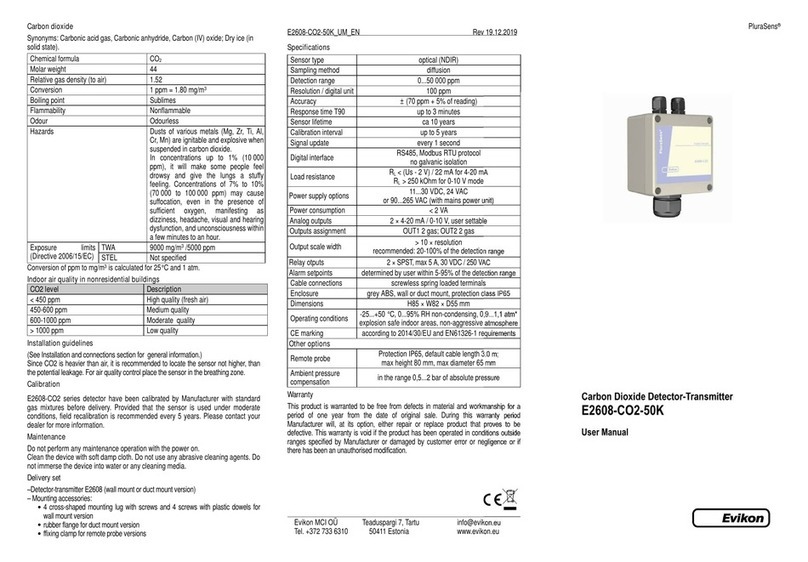

Carbon dioxide transmitter E2618-CO2 is a member of new PluraSens® family of

multifunctional measurement instruments. Applications include HVAC and air

quality control in public, office and industrial buildings, greenhouses, underground

parkings, and other confined spaces, where potentially toxic concentration of

carbon dioxide can accumulate.

The instrument utilises digital fully calibrated and temperature compensated optical

(NDIR technology) gas sensor with excellent repeatability, stability and long

lifetime. The transmitteris supplied either in duct-mount or wall-mount version. The

wall mount version of the transmitter is available with remote probe. The remote

probe is connected to the main unit with shielded cable. The connection cable

length options are 2.5 m or 5 m.

Two freely configurable 4-20 mA or 0-10 V analog outputs can be used to connect

the transmitter to secondary instruments. RS485 interface with industry-standard

Modbus RTU protocol allows direct Fieldbusnetworking of the transmitter.

Safety requirements

Always adhere to the safety provisions applicable in the country of use.

Do not perform any maintenance operation with the power on. Do not let water or

foreign objects inside the device.

Operating conditions

The device should be used in explosion-safe (non ATEX -rated) indoor areas,

without aggressive gases in the atmosphere. Avoid electrostatic charging of the

transmitter. See Specifications table for moreinformation.

Installation and connection

1. Duct mount version: Connect the sensor probe to the device main unit. Make

sure that the connections are tightened properly.

Cut a 30 mm diameter hole in the air duct at the chosen mounting place. Place the

rubber flange in the hole and fix it with three self-tapping screws. Pass the sensor

probe through the flange and adjust it to the appropriate depth. Unscrew four lid

screws and detach the lid from the instrument.

Wall mount version: Unscrew four lid screws and detach the lid from the

instrument. Fix the transmitter through mounting holes by screws.

The transmitter should be located 60...80 cm from the floor to control leakages or

in the breathing zone (1,2...1.5 m from the floor) for air quality control. Locate your

device away from ventilation holes or dead-air spaces such as corners. The

recommended orientation of sensor probe is vertical with the sensor tip pointing

downwards. Coverage area for each transmitter is 500...1000 m2(12...18 m

radius).

2. Plug the power cable and connectthe analog outputs and/or digital interface

terminals to the relevant devices according to the connection diagram.

Make certain that the cable gland is properly tightened to ensure the conformity to

IP65 protection class.

The screwless quick connect spring terminals on the E2618 series devices are

suitable for a wide range of wires with cross-section 0,2...1,5 mm2. The

recommended wire stripping length is 8...9 mm. Push the spring loaded terminal

lever, insert the wireend into terminal hole and releasethe lever.

Use twisted pair cable, e.g. LiYY TP 2×2×0,5 mm2or CAT 5, to connect the device

to RS485 network. Use one pair for A and B wires and the second pair for common

0 V and power +U wires. to connect the transmitter to Fieldbus network. Respect

polarity. Overall length of all connections via RS485 interface should not exceed

1200 m.

Place the lid back and tighten itwith the four screws.

Note Avoid exposing the sensor to any mechanical stress during installation or

operation sinse this may damage the device and lead to relevant measurement

errors.

The type of each analog output can be independently changed between 4-20 mA

and 0-10 V with jumpers J1 (OUT1) and J2 (OUT2).

With closed jumper the output is 0-10V, with open jumper the output is 4-20 mA.

By default both outputs OUT1 and OUT2 are assigned to gas concentration. The

device has built-in temperature sensor wich may be connected to any of the

outputs.

The output assignments and scales can bechanged by Modbus commands.

Emergency mode

The current outputs ofthe transmitter may be programmed via Modbus commands

to signal if the connection with the sensor is lost. The signal maybe set to 3,8 mA

or 21,5 mA. See the table of Modbus registers for more information.

Return to default settings

To reset the device’s Slave ID, baudrate andsbit number to factory settings,

proceed as follows:

1. De-energize the device

2. Connect the J3 jumper

3. Turn on the device

4. De-energize the device

5. Disconnect the J3 jumper

6. Turn on the device

Calibration

Two optical sensor options are available.

Type A double-beam sensor has a built-in reference sample for autocalibration.

Manual calibration by fresh air should beperformed once in 5 years.

Type B sensor performs autocalibration by settling the minimal CO2concentration

to 400 ppm. To use this type it is required that CO2 level decreases to fresh air

level at least once a week. Transmitters with B-type sensors should not be used in

areas with constantly high CO2 level (greenhouses,hospitals etc).

Delivery set

– Carbon dioxide transmitter E2618-CO2 or E2618-CO2-DM

– Mounting accessories:

4 screws with plastic dowels for wall mount version

rubber flange with 3 self-tapping screws for duct mount version.

fixing clamp for remote probe versions

Warranty

This product is warranted to be free from defects in material and workmanship for a

period of one year from the date of original sale. During this warranty period

Manufacturer will, at its option, either repair or replace product that proves to be

defective. This warranty is void if the product has been operated in conditions

outside ranges specified by Manufacturer or damaged by customer error or

negligence or if there has been an unauthorized modification.

4-20 mA/ 0-10 V

4-20 mA/ 0-10 V

0V / GND

0V

Controller

Power Supply

Input 1

Input 2 OUT1

OUT2

0V

A

BRS485

+U

J1 J2

Fieldbus

Sensor module

+12 V

J3

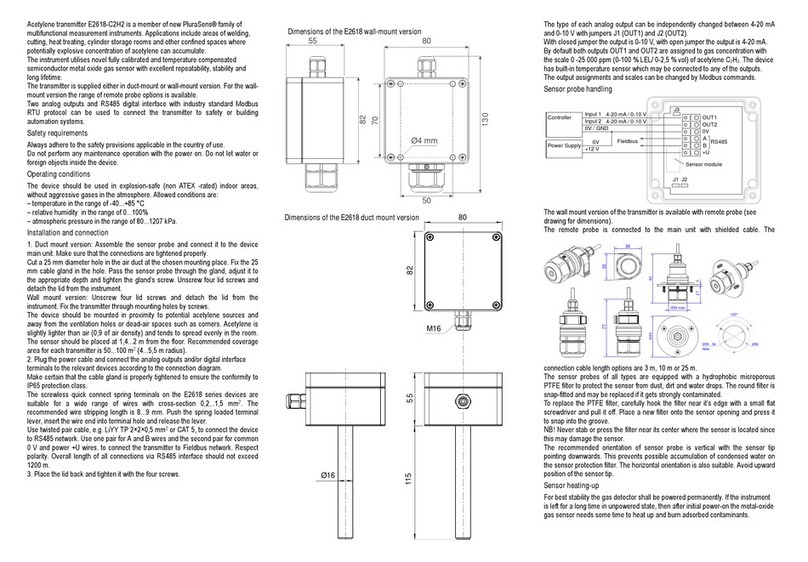

Dimensions of the E2618-CO2 wall-mount version and the remote probe

Dimensions of the E2618-CO2 duct mount version

Ø28

55

80

152

82

80

Ø28