8

8.0 MAINTENANCE

8.1 It is recommended that a pool water sample is taken to a pool shop and tested once per

month for analysis. Please refer to Section 2.0, 6.0 and 7.0 for additional information.

8.2 The Low Salt Oxidiser cell operates most efficiently when it is clean. As a natural result

of the electrolytic process, calcium is attracted to the titanium plates in the cell. The

self-cleaning feature helps to inhibit such build-up and scaling. However, the attraction

of calcium and other minerals is inevitable, and eventually, it must be removed by

manual cleaning.

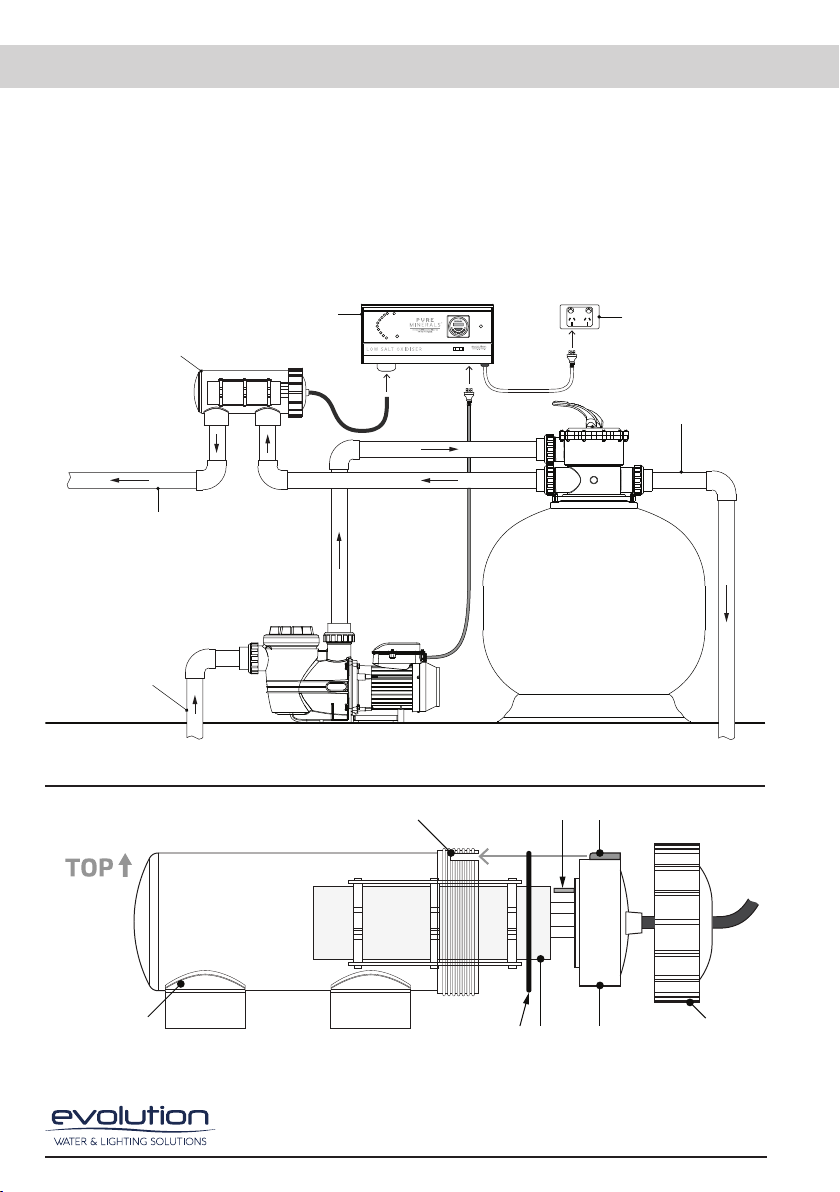

8.3 The transparent housing of the cell allows easy visual inspections, and with correct

water chemistry, the cell will only need cleaning approximately every 3-6 months. In

regions with hard water (high calcium levels), more frequent cleaning may be required.

8.4 To clean the cell follow these instructions:

1. Turn off power to the Oxidiser and pump.

2. Remove the cell from the cell housing by loosening the cell collar and pulling the

cell out of the housing. If required, disconnect the cell cable wires at the junction box

underneath the power pack (these must be reconnected firmly and tightly).

3. With the cell removed, use a high-pressure hose nozzle to spray off as much loose

scale as possible. Do not use any sharp or metallic objects to remove scale, as this will

damage the cell.

4. If further cleaning is required, the cell needs to be cleaned in a mixture of 1 part

Hydrochloric Acid to 10 parts water. Mix the acid solution in a bucket or tube that will

fit the cell.

5. iWARNING: Chemical Hazard - When mixing acid with water, always add the

acid to the water, never add water to the acid. When using the acid, ensure to use

rubber gloves and appropriate eye protection and follow safety directions on the

Hydrochloric Acid label.

6. Place the cell into the cleaning solution submerging the plates and ensuring that

the cell head (Section 3.0 Fig. 2) does not contact the acid solution. Once the cell is

clean, remove it from the cleaning solution and rinse. Replace the cell into the housing

in the reverse manner to the steps above.

8.5 Only qualified electrical technicians should service the power pack. For the nearest

Evolution recommended service technician, please contact Evolution Water & Lighting

Solutions on 07 5565 0000 or email us at service@evolutionwls.com.au.