Evoqua DEPOLOX Pool E User manual

WALLACE & TIERNAN®FLOW CELL MODULE

DEPOLOX POOL E

INSTRUCTION MANUAL

2WT.050.810.020.DE.IM.0115

Flow cell module DEPOLOX Pool E

Please note

Original instruction manual!

Simone

Flow cell module DEPOLOX Pool E Contents

3

Contents

1. Introduction 5

1.1 Documentation 5

1.2 Disclaimer 6

1.3 Conventions 7

2. Safety 9

2.1 Intended use 9

2.2 General safety instructions 10

2.3 Specific operating phases 11

2.4 Notes on Special Dangers 12

2.5 Warranty conditions 12

3. Description 13

3.1 General 13

3.2 Versions 15

3.3 Design 17

3.4 Function 18

3.5 Technical data 22

4. Installation 29

4.1 Scope of delivery 29

4.2 Transport and storage 30

4.3 Mechanical installation 31

4.4 First commissioning 46

4.5 Shut-down 47

4.6 Renewed start up 48

4WT.050.810.020.DE.IM.0115

Contents Flow cell module DEPOLOX Pool E

5. Maintenance 49

5.1 Maintenance intervals 49

5.2 Maintenance parts kit 50

5.3 Checking for leakages 51

5.4 Checking the electrode cleaning sand 51

5.5 Replacing the electrode cleaning sand 51

5.6 Cleaning the fine filer 52

5.7 Cleaning the flow rate monitor and non-return

ball valve 53

5.8 Cleaning 53

6. Retrofit kits and spare parts 55

6.1 Retrofit kits 55

6.2 Retrofitting sensor measuring modules 56

6.1 Spare parts 58

7. Drawings 63

7.1 Flow cell module DEPOLOX Pool E

non-pressurized version 63

7.2 Flow cell module DEPOLOX Pool E

pressurized version 65

7.3 Electronic box DFMe 67

8. Certificates 69

9. Index 71

Flow cell module DEPOLOX Pool E Introduction

1.

5

1. Introduction

1.1 Documentation

1.1.1 Target groups

This instruction manual provides the information for installation,

operating and maintenance personnel. It is required for operation

and maintenance of the flow cell module DEPOLOX Pool E.

This instruction manual is intended for operators of the flow cell

module DEPOLOX Pool E. It contains important information for

safe, trouble-free and efficient operation of the flow cell module

DEPOLOX Pool E. Observing these instructions will help prevent

risks, reduce repair costs and downtimes, and increases the

reliability and service life of the flow cell module DEPOLOX Pool E.

Sections installation and maintenance are intended only for

trained service personnel. These sections contain important

information on assembling, configuring, and commissioning the

flowcellmoduleDEPOLOXPoolEandonmaintenanceandrepair

work.

Allthose workingwith the flowcell moduleDEPOLOX Pool Emust

have read and understood the instruction manual and, in

particular, the safety instructions.

Please consult the table of contents and the index to quickly find

the information you require.

6WT.050.810.020.DE.IM.0115

Introduction Flow cell module DEPOLOX Pool E

1.

1.2 Disclaimer

We are not liable for any damages incurred during installation or

use of these hardware and software components. This applies

specifically to trouble-free interaction with the software and

hardware components you choose.

We are not liable forbuyer damages (in particular, lost profits, lost

information and service interruptions), which arise when using the

flow cell module DEPOLOX Pool E, nor for other damages. You

are solely responsible for the installation!

The contents of the instruction manual has been checked to make

sure that it matches the detailed hardware and software.

Deviations can nevertheless not be ruled out and we therefore

assume no liability for full conformity. The details in this instruction

manual are checked regularly and any necessary corrections are

included in subsequent issues.

Flow cell module DEPOLOX Pool E Introduction

1.

7

1.3 Conventions

Please note

This instruction manual contains a number of notes with different

priorities that are marked with symbols.

Pictogram Note Meaning

Danger! Immediate danger to life and limb! If

the situation is not corrected, death

or serious injury will result.

Warning! Danger to life and limb! If the

situation is not corrected, death or

serious injury can result.

Attention! If this note is not observed,

moderate or minor injury or damage

to equipment can result.

Warning! Electrocution hazard.

Please

note These notes indicate a material risk

or provide useful information to

make working with the device

easier.

Attention! Environmental hazard!

Do not throw away or burn the

batteries!

Batteries must be disposed of at a

collection point.

8WT.050.810.020.DE.IM.0115

Introduction Flow cell module DEPOLOX Pool E

1.

Flow cell module DEPOLOX Pool E Safety

2.

9

2. Safety

2.1 Intended use

The flow cell module DEPOLOX Pool E is intended exclusively for

the measurement and control of the treatment of water in

swimming pools and baths.

The operational safety of the flow cell module DEPOLOX Pool E is

only guaranteed if it is used in accordance with its intended

application. It may only be used for the purpose defined in the

order and under the installation, operating and ambient conditions

specified in this instruction manual.

All inspection and maintenance work must be carried out in

accordance at the specified intervals.

Compliance with the intended use also includes reading this

instruction manual and observing all the instructions it contains.

The owner/operator of the installation has sole responsibility for

consequences of any use that does not conform with the

installation’s intended use.

10 WT.050.810.020.DE.IM.0115

Safety Flow cell module DEPOLOX Pool E

2.

2.2 General safety instructions

Evoqua Water Technologies GmbH attaches great importance to

ensuring that work on its device is always perfectly safe. This was

already taken into account in the design of the installation by the

integration of safety features.

Safety regulations The safety instructions in this documentation must be observed at

all times. Additional industry-wide or in-house safety regulations

also continue to apply.

Safety instructions on the

unit All safety instructions attached to the unit itself must be observed.

These instructions must always be clearly legible and complete.

State-of-the-art technology The unit has been constructed in accordance with state-of-the-art

technology and the accepted safety regulations. However, if the

unit is used by persons who have not been adequately instructed,

risks to life and limb of such persons or third parties and damage

to the unit itself or to other property cannot be ruled out. Work not

described in this instruction manual must be performed only by

authorized personnel.

Personnel The operator of the overall system must ensure that only

authorized and qualified specialized personnel are permitted to

work with and on the unit within their defined scope of authority.

“Authorized specialists” refers to skilled personnel employed by

the owner/operator or by Evoqua Water Technologies GmbH or, if

applicable, the service partner. Only qualified electricians must

perform work on electrical components.

Spare parts / components Trouble-free operation of the unit is only guaranteed if original

spareparts and componentsareusedinpreciselythecombination

described in this instruction manual. Failure to observe this

instruction may incur the risk of malfunction or damage to the unit.

Extensions and conversions Never attempt to perform any modifications, extensions or

conversionson the unitthatcouldhaveanadverse affect onsafety

without the written approval of the manufacturer.

Electrical power During normal operation, the controller must remain closed.

Connect the power cables in accordance with the wiring diagram.

Flow cell module DEPOLOX Pool E Safety

2.

11

IT security Evoqua WaterTechnologiesGmbH offersITsecurity mechanisms

for its products to support secure system operation. We

recommend checking on a regular basis to see what information is

available regarding IT security developments for your products.

Information on this can be found on the Internet.

Forthesafeoperationofaninstallation,itisfurthermorenecessary

to integrate the automation components into a holistic IT security

concept which comprises the entire system and is in accordance

with latest state of the art technology. In the process, implemented

products deriving from other manufacturers should be taken into

account.

Upon start-up of the electronic module, it should be ensured that

the factory-configured passwords and user names are replaced

with individual ones.

Disposal Ensure safe and environment-friendly disposal of agents and

replacement parts.

2.3 Specific operating phases

Normal operation Never employ any working methods which could affect safety!

Only run the flow cell module when the housing is closed!

Inspecttheflow cellmoduleatleastonce daily for externally visible

damage and faults! Inform the responsible person/authority

immediately of any detected changes (including any changes in

the operating performance)!

In the event of malfunctions, alwaysswitch the flow cell module off

immediately! Have malfunctions remedied immediately!

Installation and

maintenance work Always perform installation or maintenance work in accordance

with this instruction manual or the technical documentation for

installed system components!

Secure the flow cell module against activation during installation

and maintenance work!

Always retighten released screw connections!

Never use corrosive cleaning agents (e.g. spirit)!

Use only a damp cloth to clean the device.

Ensure safe disposal of agents and replaced parts in accordance

with environmental regulations!

12 WT.050.810.020.DE.IM.0115

Safety Flow cell module DEPOLOX Pool E

2.

2.4 Notes on Special Dangers

Electrical power Only qualified electricians or trained personnel supervised by a

qualifiedelectrician are permittedto perform any work on electrical

components in accordance withvalid electro-technicalregulations.

If stipulated, disconnect all parts of the flow cell module from the

power supply before performing any inspection, maintenance or

repair work. Then first test the disconnected components to

ensure they do not carry any voltage.

The system may still be live even if the operating voltage is

switched off.

In the event of a fault in the electrical power supply, switch the flow

cell module off immediately!

Inspect/check the flow cell module of the system regularly.

Remedy any faults immediately.

Connect disconnected cables in accordance with the wiring

diagram.

2.5 Warranty conditions

The following must be observed for compliance with warranty

conditions:

• Installation and commissioning by Evoqua Water Technologies

GmbH personnel or trained and authorized specialized

personnel, e.g. of contracted companies

• Intended use

• Observation of the operational parameters and settings.

• The unit may only be operated by trained personnel.

• An operating log book must be kept (only in the public sector).

• Only approved calibration chemicals may be used

• The unit must not be exposed to frost.

• Maintenance work must be executed

• Use of genuine spare parts

If any of the above conditions are not met, the warranty is void.

Flow cell module DEPOLOX Pool E Description

3.

13

3. Description

3.1 General

The flow cell module DEPOLOX Pool E is part of the pool

management system DEPOLOX Pool E 700 P.

Theflowcell moduleDEPOLOX Pool E andsensors, together with

the electronic module 700 P is used to measure and control the

hygiene assistance parameters free chlorine, pH value and Redox

voltage, as well as combined chlorine, total chlorine, conductivity

and temperature.

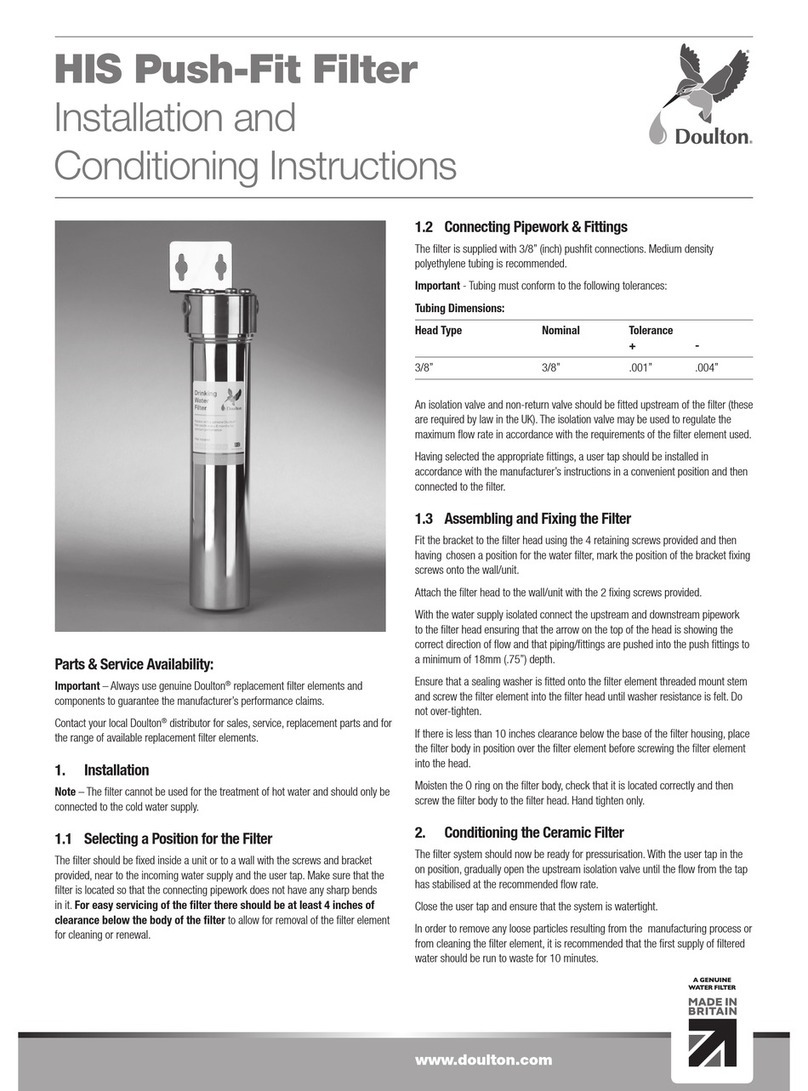

A Flow cell module DEPOLOX Pool E with sensors

B Electronic module 700 P

AB

14 WT.050.810.020.DE.IM.0115

Description Flow cell module DEPOLOX Pool E

3.

Flow cell module

DEPOLOX Pool E The flow cell module DEPOLOX Pool E is a special flow cell

adapter for sample water from various pool applications.

The flow cell module DEPOLOX Pool E is available as a non-

pressurized or pressurized version.

The non-pressurized and pressurized version of the flow cell

module differ in the number of sensors that can be installed and in

the design of the sample water outlet.

The non-pressurized version is characterized by a free sample

water outlet.

With the pressurized version, the sample water can be returned to

the system circuit.

All sensors that are required for the measurement tasks in

swimming pools, are attached orscrewed into the cover of the cell

body of the flow cell module DEPOLOX Pool E.

The maintenance-free flow control valve is the main hydraulic part

of the flow cell module DEPOLOX Pool E. The task of the flow

control valve is to keep the sample water flow constant,

irrespective of fluctuations in operating pressures.

The multi-sensor monitors the correct flow and records the

temperature of the sample water. The metallic sensor housing

guarantees good sample water earthing. The continuous

hydromechanical cleaning of the electrode of the chlorine sensor

prevents the effective natural contamination of the electrode

surfaces and guarantees long-term chlorine measurements.

The transformation of the analog sensor signal for the digital

transfer to the electronic module 700 P is realized via the

electronic box DFMe. If optional sensors are used, this occurs via

the module SiDiSens LF (conductivity).

Flow cell module DEPOLOX Pool E Description

3.

15

3.2 Versions

The flow cell module DEPOLOX Pool E is configured in the factory

according to the customer's specific requirements, with the

electronic module 700 P according to the variant code. The scope

of delivery differs in the version of the flow cell module DEPOLOX

Pool E, the sensors, electronic components and accessories.

The variant code consists of 12 digits and is printed on both the

type plate and packaging sticker.

Example CPMNL4RLBDEOO

Selection of sensor measuring module for free chlorine

C Sensor measuring module DEPOLOX Pool E

5 Sensor measuring module DEPOLOX 5 E

Selection of sensor measuring module for pH value

P Sensor measuring module pH value

O No sensor measuring module pH value

Selection of sensor measuring module for Redox voltage

M Sensor measuring module Redox voltage

O No sensor measuring module Redox voltage

Selection of sensor measuring module for total chlorine

N Sensor measuring module total chlorine TC2

S Sensor measuring module total chlorine TC2-S

O No sensor measuring module total chlorine

Selection of sensor measuring module for conductivity

L Sensor measuring module conductivity

O No sensor measuring module conductivity

Selection of analog output

4 4-way mA analog output

O No mA analog output

Selection of relay board

R Additional relay board 4-way

O No additional relay board

Selection of flow cell module DEPOLOX POOL E

LFlow cell module DEPOLOX POOL E unpressurized

FFlow cell module DEPOLOX POOL E pressurized

Selection of LED lighting

B LED glow stick for flow cell module

Selection of language for instruction manual

DE Instruction manual in German

EN Instruction manual in English

FR Instruction manual in French

Not used

Not used

16 WT.050.810.020.DE.IM.0115

Description Flow cell module DEPOLOX Pool E

3.

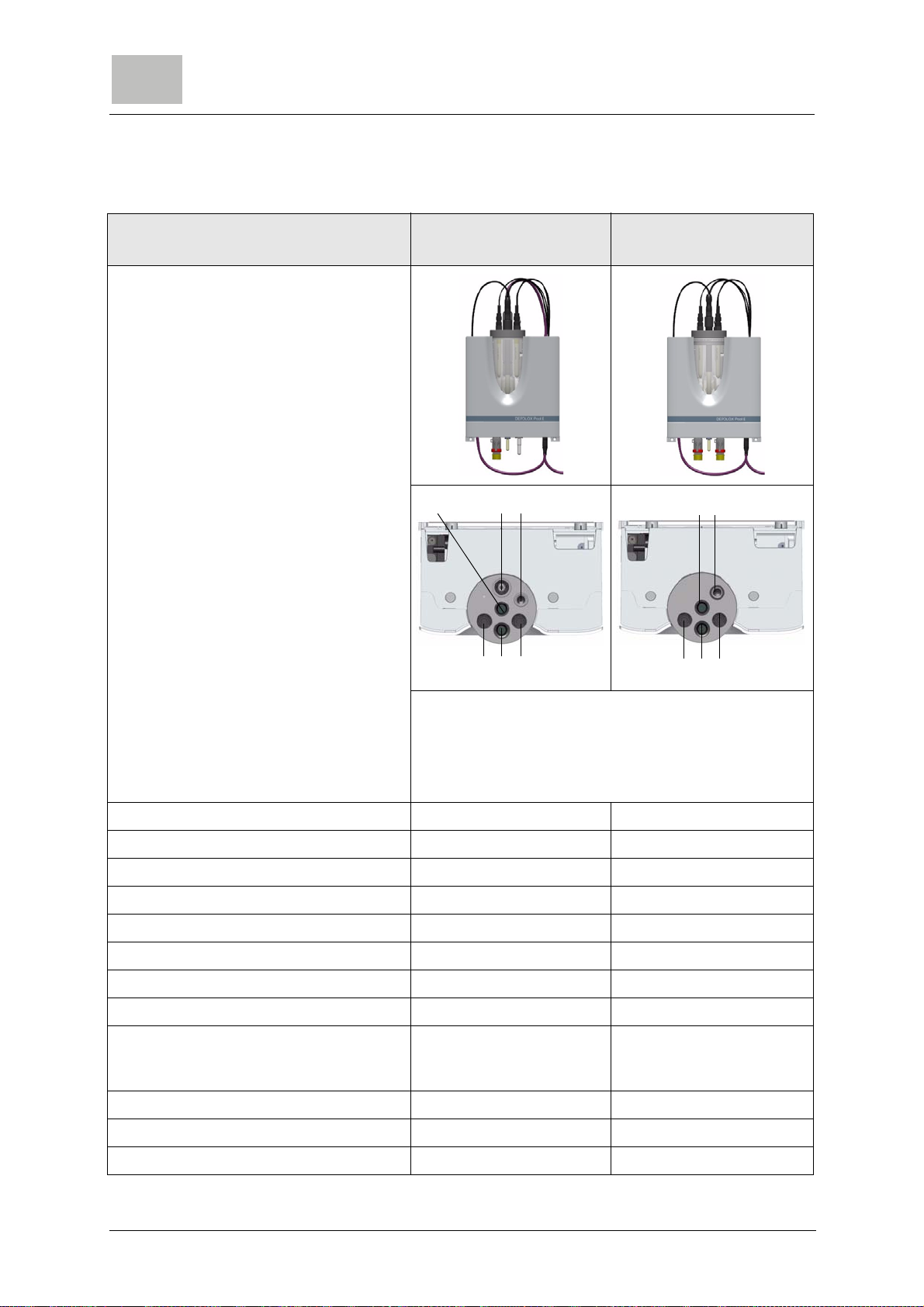

Configuration options

Description DEPOLOX POOL E

Non-pressurized version DEPOLOX POOL E

pressurized version

A Chlorine sensor (free chlorine)

B Total chlorine membrane sensor

C LED glow stick

D Redox single-rod measuring chain

E Conductivity sensor

F pH single-rod measuring chain

Chlorine sensor (free chlorine) X X

Total chlorine membrane sensor X -

pH single-rod measuring chain X X

Redox single-rod measuring chain X X

Conductivity sensor X X

Sample water temperature (multi-sensor) X X

Flow rate monitor (multi-sensor) X X

Sample water earthing (multi-sensor) X X

Sample water fine filter (X)

only when using the total

chlorine membrane sensor

-

LED glow stick X X

Ball valve (sample water inlet) X X

Ball valve (sample water outlet) - X

AB

DEF

C

AC

FED

Flow cell module DEPOLOX Pool E Description

3.

17

3.3 Design

The flow cell module DEPOLOX Pool E essentially consists of

(from the sample water inlet to the sample water outlet):

• Sample water inlet (H) with ball valve (I)

• Fine filter (J)

• Multi-sensor (L) for monitoring the flow rate, measuring the

temperature and for sample water earthing

• Flow control valve (K) for constant flow of sample water

• Cell body (B) with cover (A) to hold sensors

• Sample water outlet(F), in pressurized version also with ball

valve

• Drain/extract specimen (G)

• Electronic box DFMe (D)

• Module SiDiSens LF (M) (optional)

• Plastic housing (C) with removable housing cover

• Calibration holding clip (E) in housing cover

A

C

D

FG

I

J

E

K

M

H

E

L

B

18 WT.050.810.020.DE.IM.0115

Description Flow cell module DEPOLOX Pool E

3.

3.4 Function

3.4.1 General

The sample water is connected on the input side via the G1/2”

connection to the ball valve. The input pressure must be around

0.25 to 4.0 bar. To guarantee a constant flow, the minimum input

pressure must not be less than 0.25 bar.

In the flow direction, the connected filter unit gives the option to

install a stainless steel fine filter with a mesh size w=500 µm. The

fine filter is only used in conjunction with membrane sensors.

The return ball valve housing that is connected after the filter unit,

offers a kickback function and guides the ball for monitoring the

flow rate.

The multi-sensor combines the function of temperature

measurement of the sample water with a Pt1000, flow rate

monitoring following the float principle with reed switch and wide

area sample water earthing with stainless steel sensor housing.

A flow of the sample water that is not dependent on the operating

pressure is assured by the flow control valve. The correct sample

water flow of 33 l/h is preset at the factory, checked and logged.

The flow control valve is maintenance-free. If the admission

pressure rises, the valve ball moves towards the closing direction,

if the admission pressure drops, the ball moves towards the

opening direction.

The clear cell body holds thesensors and due to its design, is able

to provide good cleaning and service options. The sensors are

installed in the cover of the cell body with standardized threaded

connections or in special sensor holders.

The flow distributor cap screwed into the cell body from the bottom

enablesthecontinuoushydromechanicalcleaning oftheelectrode

of the chlorine sensor using special cleaning sand and thereby

effectively prevents the natural contamination of the electrode

surfaces. Clean electrode surfaces and a constant flow of sample

water are decisive criteria for a qualitative good chlorine

measurement and quick responsiveness.

The sample water runs across the top cell body outlet and directly

via a discharge nozzle for hoses with ID 6 mm or, in the case of the

pressurizedversion,via a ballvalve with G1/2” thread connection.

Withthe pressurizedversion, a maximumback pressureof1.5 bar

is permitted here.

For calibration purposes, there is also a specimen extraction

device. It is used to extract sample water from the low-pressure

side of the flow control valve in the cell body or to drain the cell

body for servicing purposes.

Flow cell module DEPOLOX Pool E Description

3.

19

Two calibration holding clips are attached in the cover of the flow

cell module. The calibration holding clips are pushed through the

side of the basic housing of the flow cell module, thereby enabling

the “hand-free” calibration of the sensors with a buffer solution

from bags or in the calibration beaker.

The electronic box DFMe is used to convert the analog sensor

signals for the digital transfer to the electronic module 700 P. The

electronic box DFMe is integrated directly in the basic housing.

The sensors and sensor cables are built in and preconfigured in

the DFMe housing and are splash-proof in accordance with IP66.

If optional sensors are used, this occurs via the module SiDiSens

LF (conductivity). This measurement module is also built into the

plastic housing of the flow cell module.

An LED glow stick is screwed into the cover of the cell body as an

optical warning indicator.

Please note

When disinfecting the inline electrolysis systems, the chlorine

sensor and Redox single-rod measuring chain must be used, gold

version (gold electrode).

For applications in brine water with conductivity levels of 2.5 to

60 mS/cm(approx.4% NaCl),thetotal chlorinemembranesensor

TC2-S must be used.

20 WT.050.810.020.DE.IM.0115

Description Flow cell module DEPOLOX Pool E

3.

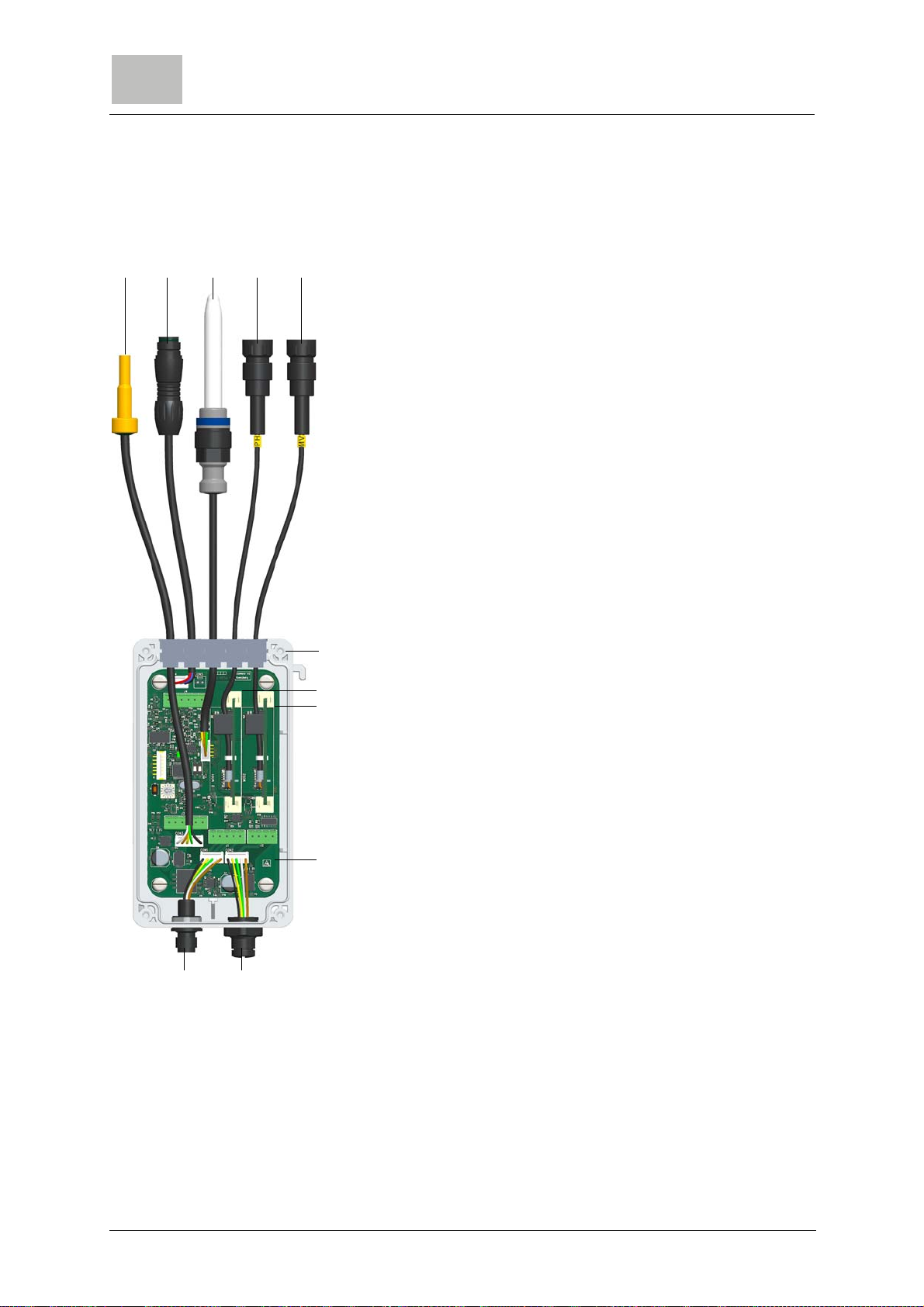

3.4.2 Electronic box DFMe

The electronic box DFMe consists of a spray-proof housing with

built-in sensor electronics.

The base plate of the electronic box DFMe includes the sensor

input for the chlorine sensor and the evaluation electronics for the

multi-sensor for the temperature measurement and flow rate

monitoring.

Two additional slots are integrated on the base plate for the pH

and Redox single-rod measuring chain.

Via the integrated CAN connection socket, the electronic box is

connected to the electronic module 700 P using the CAN

connection cable.

If additional sensors, such as total chlorine and/or conductivity are

installed, the electronic box DFMe is equipped with a second CAN

connection socket. Sensors can be retrofitted at any time (see

„retrofit kits” on page 55).

A Multi-sensor

B Sensor cable Cl2free

C LED glow stick

D pH sensor cable

E Redox sensor cable (mV)

F Housing DFMe

G pH sensor module

H Redox sensor module

I Base plate DFMe with measurement input Cl2

J CAN extension socket

K CAN connection socket for electronic module 700 P

ABCDE

H

I

F

G

JK

Table of contents

Other Evoqua Water Filtration System manuals

Popular Water Filtration System manuals by other brands

Cuckoo

Cuckoo CP-QN1401SW/WHCBMYCI user manual

Pool Technologie

Pool Technologie UNO LTE user manual

Danfoss

Danfoss AHF 005 operating instructions

Ebbco

Ebbco CLS-141-24K H.E.-SWS Operation and maintenance manual

FCI Watermakers

FCI Watermakers MAX-Q+ User manual & installation guide

3B Filters

3B Filters 8600 Series Service instructions

Dean

Dean Portable Filters MF90 Series parts manual

Eureka Forbes

Eureka Forbes Dr. Aquaguard MAGNA UV user manual

Pentair

Pentair Fleck 5800 XTR Installer manual

Aqua PRO

Aqua PRO AP-600W-A5-GST2 manual

Dräger

Dräger PAS Filter Series Instructions for use

Mayfran

Mayfran ConSep 2000-125HP Technical documentation