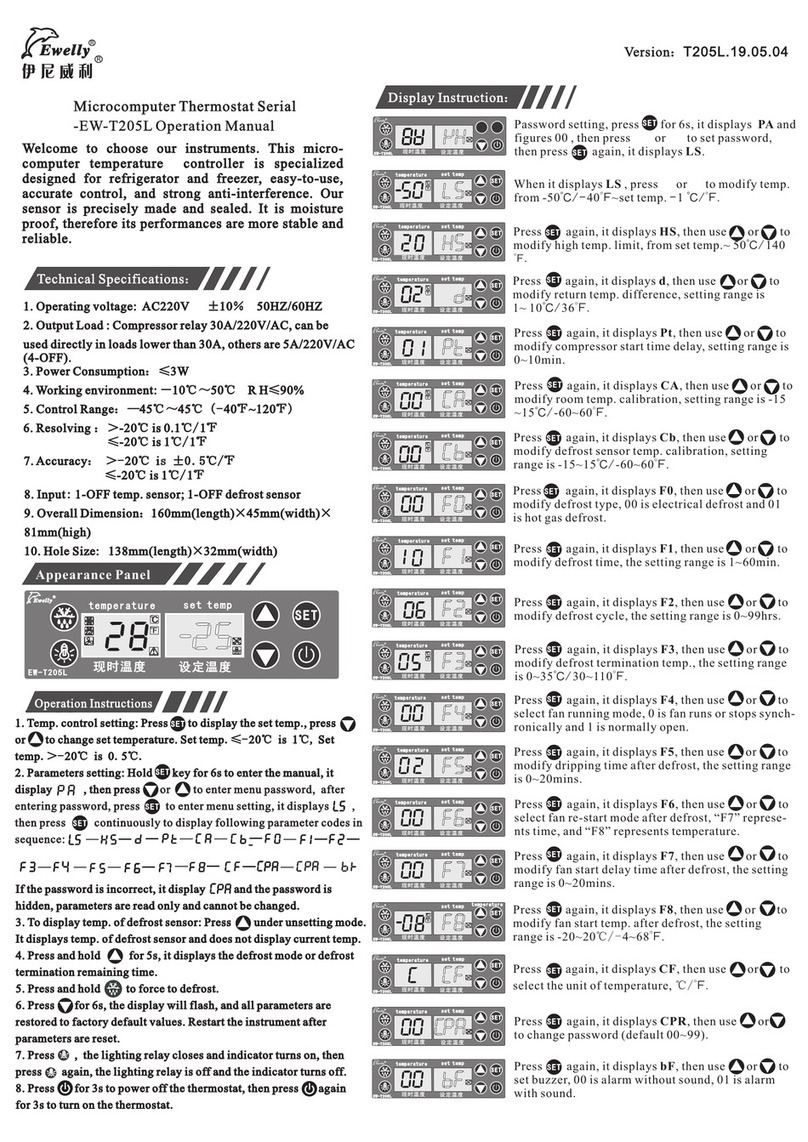

Operating Guide

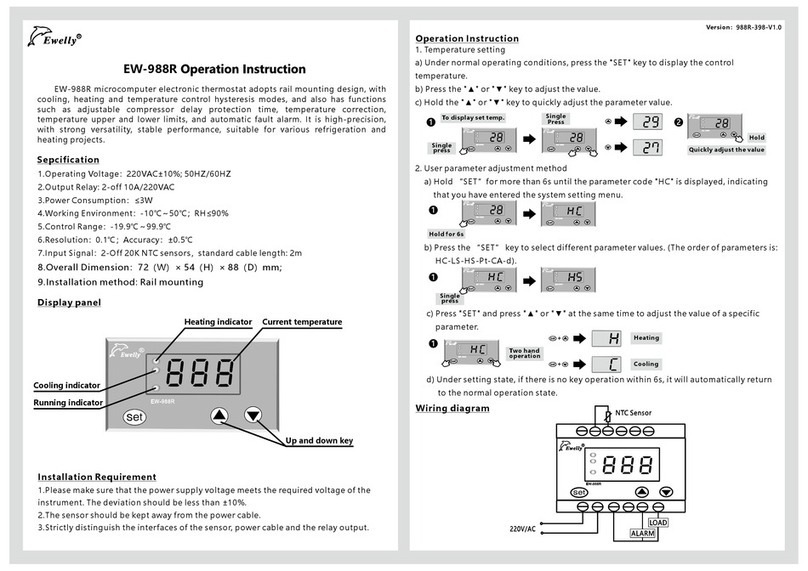

Parameter settings: press “set” to the “set temp” lighting, each

press “set” key, it will enter to next menu settings (circulating

operation). Enter the menu, press or can change the

program parameters.

Menu settings includes temp setting--

Lower limit ( )--

unction can be

cycled operations. Enter the menu, press or to modify the

corresponding parameters.

Set temperature:

Press ”set” until “set temp” lighting, press or to re-set the

new temperature control (this feature is when the temperature

reaches the set value then machine OFF).

Temperature difference:

Press “set” to enter the menu, scroll to the “D-temp” lights, press

or to re-set the new operating parameters (this function is when

the temperature rises to the set value + return difference, machine

ON).

Operating cycle:

Press “set” to enter the menu, scroll to the “DEF cycle ” lights,

press or to re-set the time interval between two defrost (This

feature is time setting of each operating cycle)

.Defrost time:

Press “set” to enter the menu, scroll to “DEF time” lights, press

or to re-set the new defrost time (this function is working time

of each defrosting)。

Delay time:

Press “set” to enter the menu, scroll to the “Delay time” lights,

press or to re-set the new delay time (this feature is a time

delay before the compressor running, to avoid frequent compressor

start and stop).

Exit temperature:

Press “set” to enter the menu, scroll to “DEF exit temp” lights,

press or key to re-set the new defrost exit temperature.

Temperature correction:

Press and till six lights all lighting, press or to

correct the display temperature value (This feature is when the

temperature error, it can be used for temperature correction by plus

or minus).

High temperature alarm:

Press “set” to enter the menu, scroll to displayed, press or

to re-set the new limit parameters (this function is when the

temperature exceeds set value displayed and alarm output).

Low temperature alarm:

Press “set” to enter the menu, scroll to displayed, press or

to re-set the new limit parameters (this function is when the

temperature exceeds the set value of the lower limit, it will

displayed and alarm output).

Evaporator fan mode:

Press “set” to enter the menu, scroll to displayed, press or

to set the fan normally open (parameter to -1), with the same

start/stop (parameter to 00), delay started (parameter can be set

from 1 to 5 minutes).

Dripping time:

Press “set” to enter the menu, scroll to the displayed, press

or to re-set the time of dripping after defrosting.

Defrost mode:

Press “set” to enter the menu, scroll to the displayed

, press or can set electric defrost or steam defrost (Ex-

factory setting for electric defrost).

temp difference--

Operating cycle--Defrost time--Delay time--Exit temperature

Upper limit ( )-- Evaporator Fan Mode( )-

-Dripping time ( )--Defrost mode ( ) . The f

Code Remark

Storage temperature sensors are not installed well or burned,

shorted or opened, the system enters the automatic intermittent

operation mode, the output alarm

Defrost temperature sensors are not installed well or burned,

shorted or opened, the system enters the automatic intermittent

operation mode, the output alarm

Storage temperature exceeds the upper limit and output alarm

Storage temperature exceeds the lower limit, compressor,

evaporator fan stops, output alarm

E1

E2

E5

E6

●Cooling: When the current temperature ≥ setting temperature +

temperature hysteresis and delay the setting of the "delay time",

the load relay On.

Cooling stop: When the real temperature ≤ the set temperature,

the load relay is Off.

●

。

●

Into defrost:

1. when the instrument after defrost (or boot) to run a set running

period of time and then into defrost ( load relay Off,defrost relay

On, defrost indicator On).

2.

relay On, defrost indicating On).

Exit the defrost:

1.Entering defrost and delay the setting defrosting time, defrost relay Off,

defrost indicator Off, exit the defrost status, finally,

2. Sensor up defrost exit temperature of defrosting, exit defrosting, returns

to normal control .

Hold Defrost key 6 seconds into the defrost (load relay Off, defrost

Note: After entering the defrost will disconnect all relays first, the defrost

relay ON one minute later, the compressor relay ON five seconds later,

disconnect the compressor relay when exit, one minute after and then

disconnect the defrost relay.

Trouble shooting

Feature descriptions

Warnings

1. Please read this product instruction carefully and connect input/output

plugs of power & sensor to the corresponding sockets strictly by

following connection diagram, otherwise the usage & operations will

be affected. Check again to make sure there is no mistake. Tighten all the

screw of connection plugs again, and then connect it to the power for

running.

2. Keep away this product from moist or corrosive air and high magnetic

field. Otherwise the normal operation of this product will be affected.

.3. All our products have passed strict quality inspections before leaving

factory. We provide one-year quality guarantee (which is limited to

product itself ,and is not responsible for any other joint and several

liability) period for this product.

If you have any doubt or problem concerning the electronic

temperature or humidity controller made by us, please contact our

distributors and we will provide you high-quality after-sale services.

Thanks!

Guangzhou Eliweli Autocontrol Tech. Co., Ltd.

If the products including but not limited to, the following is not

the product itself quality problem caused by the damage, Install and use

under the do not conform to the safe environment; That the load

capacity is beyond the scope of product is allowed; Products by users to

disassemble and change, change the internal components, etc.,We will

not be so and damaged products provide a replacement and maintenance

services, regardless of whether its in the quality assurance period;

Meanwhile, we will not assume so direct or indirect losses caused by

the liability to pay compensation.

Product warranty date on the case is important basis of product

quality assurance. Appeared including but not limited to full filling

without permission, to change, to replace lost, damaged, scratched,

dirty, and so on, we will not provide a replacement and maintenance

services for these products.

http://www.eliweli.com