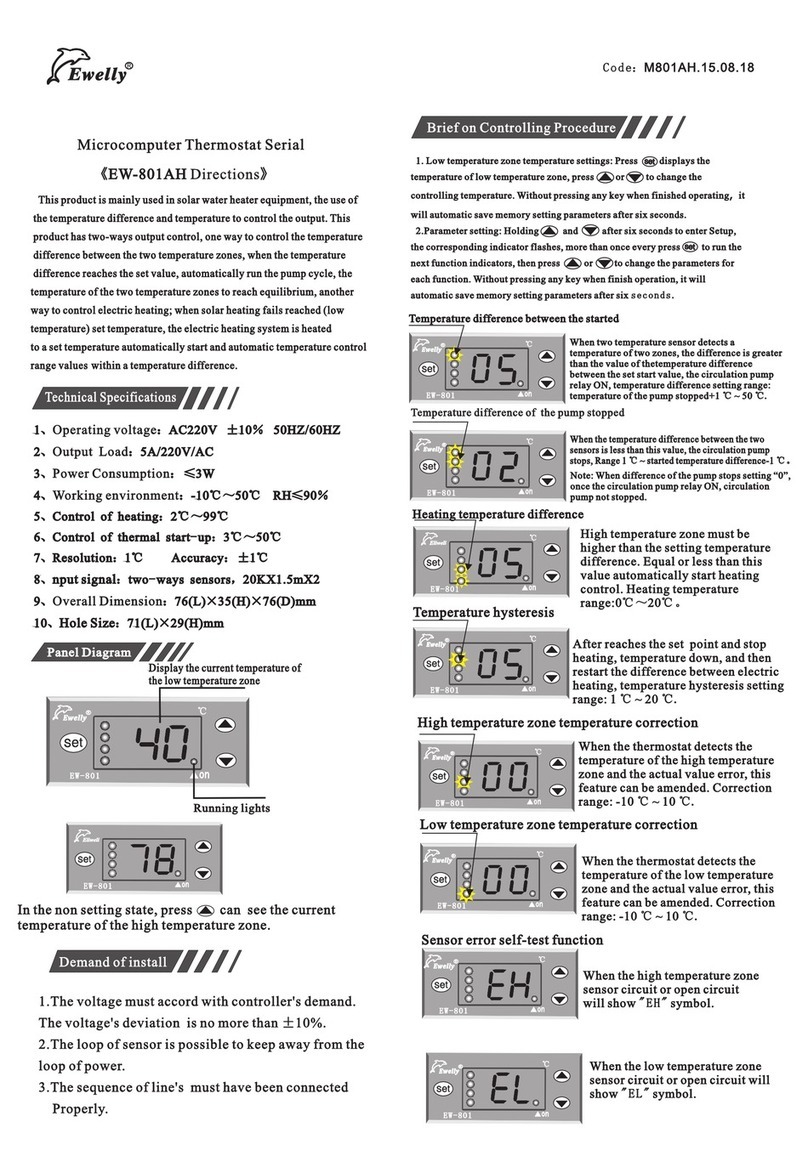

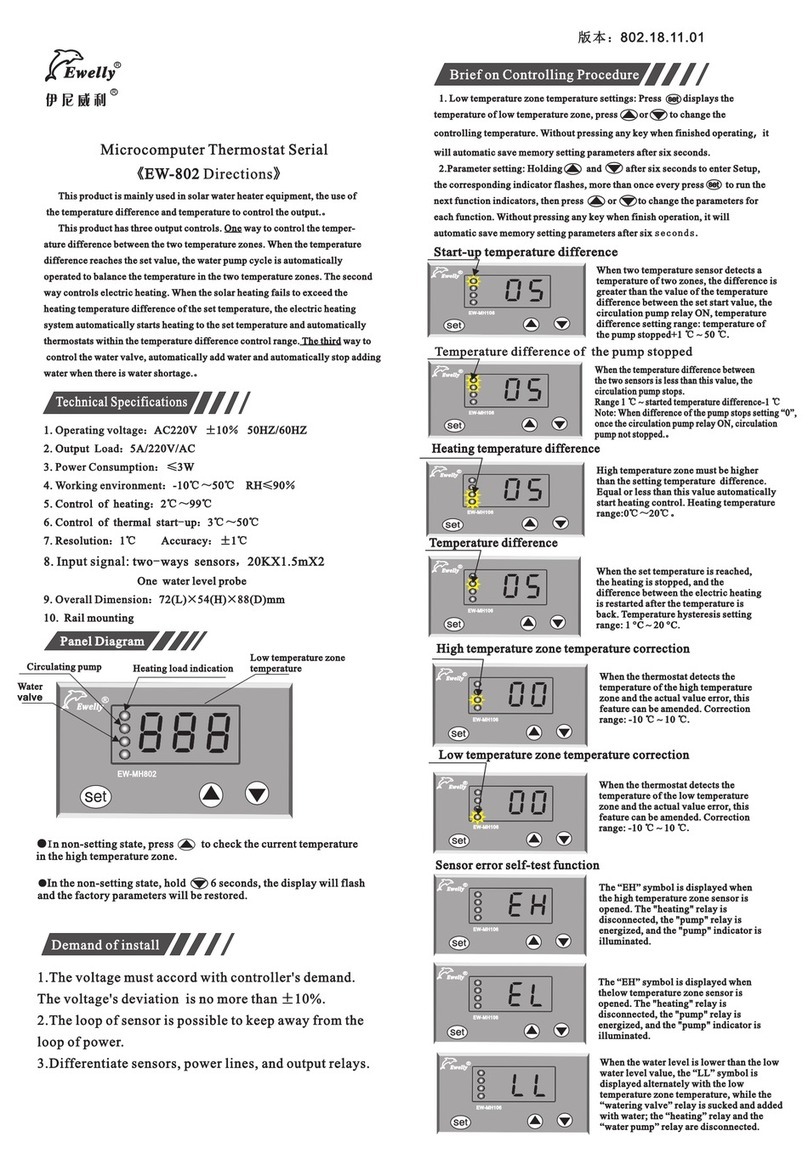

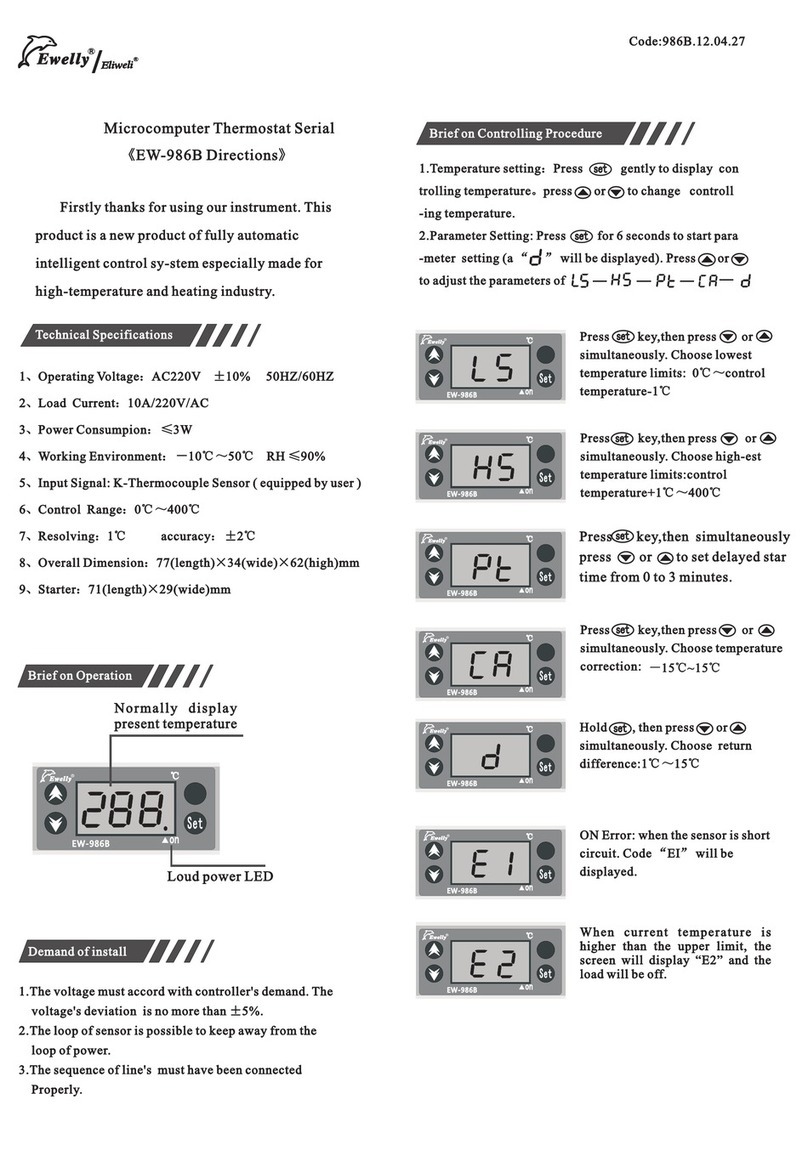

Room Tmep.

calibration 00

℃/°

F

Wiring Diagram

Program Parameter Table

Code Function Setting range

Factory Settings

Unit

-45℃

45℃

-15~15℃/-60~60

0~10

-30℃/5°

20℃/60°

00

1

2℃/5°

℃/°

min

01~60 10

00~99 Hr

6

00~35

05/40

00

00=synchronous operation

01=operation all the time

02

00~99 00

-

/-40°

FF

F

120°

F

F

℃/°

F

℃/°

F

℃/°

F

to control temperature -1℃

control temperature+1 ℃ to

35~110

0

00= electic heating defrosting

01= hot-gas defrosting

-

-

1-10℃

1-36°

F

℃/°

F

Password input

Temp. set

lower limit

Temperature return

difference

Time delay

Defrosting type

Defrosting time

Defrosting cycle

Defrost termination

temperature

Fan start mode

Dripping time after

defrost

F

Temp. set

upper limit

-15~15/- 60~60

Defrost calibration

min

00~10 min

00

Fan running mode

after defrost

00= run as per F7 setting

01= run as per F8 setting

-

02

Fan start delay time

after defrost 00~20 min

Fan start temp. after defrost

(defrost temp. ≤ set temp.)

-20~20℃

-04~68℉

-08℃/18℉

℃/°

F

00

-

00

-

C-℃;F-℉

Temperature unit

transfer C

℃/°

F

Password setting

Buzzer setting

00~99

00~01

Notes: If a password is set, the locking indicator turns on, and only

the right (PA) can change other parameters, otherwise the set para-

meters can only be read and cannot be modified, in addition, the p-

assword menu is hidden, but the control temp. still can be modified.

- When F7 is set to “00”, F7 is enable, and F8 is disable;

When F7 is set to “01”, F8 is enable, and F7 is disable.

- When transfer the temp. unit, temp. units (℃/℉) are restored

to the factory set parameters.

- When defrost cycle is set to “0”, defrost function turns off.

Feature Descriptions

Cooling:

When the current temperature ≥ set temperature + temp. return difference and reach

set“time delay”, the load relay is closed.

Stop cooling:

When the current temperature ≤ setting temperature, the load relay is off.

Enter defrost mode:

1. When the instrument finishes running a set “running cycle” after defrost or just

after boot, it enters defrost mode (the load relay is off , defrost relay on , defrost in-

dicator is on), and the set temp. displays the defrost temp. (Need to press after

existing defrost mode to check).

Note: Under defrost mode, room temp. sensor is displayed on left hand side, defrost

sensor temp. is displayed on right hand side.

Exit defrost mode:

1. Under the defrost mode, when the system runs over the set defrost time, defrost relay

off, defrost indicator off, system exits defrost mode and returns to the normal control.

2. The defrost sensor reaches defrost status, the system returns to the normal control.

Note: When pressing, if defrost sensor temp. ≥ defrost termination temp., the system

will not enter defrost status, and will remain current operation mode.

Failure mode management:

1. Note: the super temperature processing mode is as follows

1. No warning while defrosting;

2.When temperature exceeds set value +10 ℃/30℉, there will be a HH alarm output, it

enters the fault runningg mode, the compressor runs for 45 minutes and stops for 15

minutes;

3. When the temperature is lower than set value -5℃ /15℉, there will be a LL output

alarm, all operations will be stopped;

4. When sensor is open or short circuit, there will be an E1 alarm output, and it enters

the fault running mode.

Troubleshooting

Failure

No display when power is on

With display but no operation

Displayed temperature unstable

or malfunction

Real temp. is much different to

thermostat display.

Not shut down after temperature

reached

LL shown

HH shown

Causes Solutions

Whether the power source is off;

Whether the temperature controller is

defective.

Set temperature higher than the current

temperature; pressure overrun and overloaded,

thermal protection opens; internal thermal

protection of compressor opens.

Sensor circuit interfered; connection poor;

binding with other power cords; circuit

damage.

Installation position of sensors incorrect;

connecting wire too long; line resistance too

large; contact of connecting wire is poor;

sensor damaged.

Sensor installed incorrectly, unable

to measure value correctly;

Contactor of compressor defective.

Ultralow temperature alarm or sensor line off.

Ultralow temperature alarm or sensor line shorted.

Check the power supply line, and replace the fuse;

Check whether the power end is imputed, or inform

the distributor to replace the temperature controller.

Reset the required temperature control value;

Check overrun and overload, check overheat

causes, and eliminate the troubles before reset to

work.

Separate sensor with power cord or replace

shielded wire, check whether connecting

terminal is tightened.

Must install sensors correctly; increase cross

section of extension wire; ensure sealing

property of connecting wires, water and

moisture proofing; replace sensor.

Check whether sensor measures temperature

correctly; replace contactor of compressor.

Check set data or check whether sensor line

connected well with joint.

Note: When LL or HH is shown, the machine will run automatically in the running mode before failure occurred to guarantee the

temperature being not affected too much.

“E1”、“E2” is displayed The sensor circuit is opened or shorted. Check connection between the sensor wiring

and coupling end.

Warnings

1. Please read this product instruction carefully and connect input/output plugs of power &

sensor to the corresponding sockets strictly by following connection diagram strictly. Check

again to make sure there is no mistake, tighten all the screw of connection plugs again, and

then connect the power afterwards. Otherwi-

se wrong connection will affect the usage and control, and even result in parts burning.

2. Keep this product from away moisture, corrosive air and high magnetic field. Otherwise

the normal operation of this product will be affected.

3. All our products have passed strict quality inspections before leaving factory. We provide

one-year quality guarantee (which is limited to product itself ,and is not responsible for any

other joint and several liability) period for this product.

If you have any doubt or problem regarding to our products,

please contact our distributors and we will provide you

high-quality after-sale services.

Thanks you.

Guangzhou Ewelly Automatic Control Co., Ltd.

http://www.eliweli.com

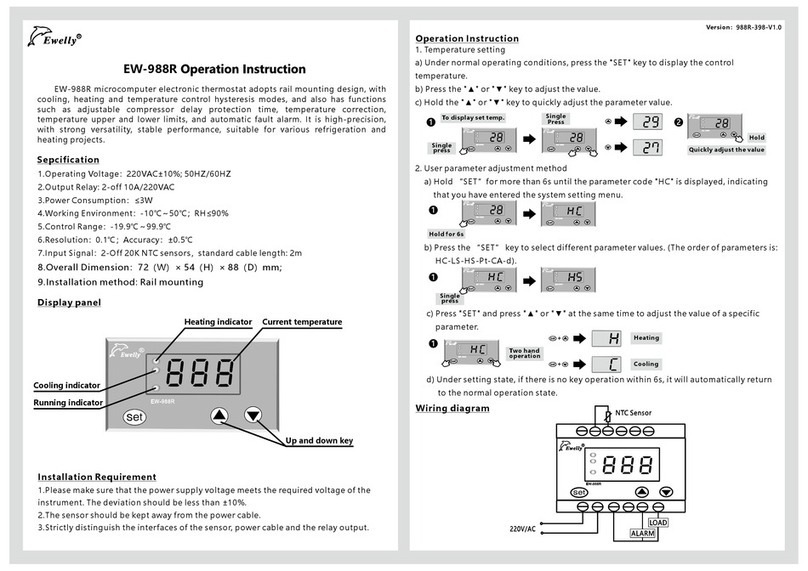

Model:EW-T205L

56 7 8 9 1

0

1234

220V/AC

220V/AC

30A

5A

11

1

2

5A 5A

1

3

14

1

5

5A

NTC

Sensor

Compr essor

Defrost Lighting Alarm

Room

temp.

Fan

Defrost

temp.