版本:802.18.11.01

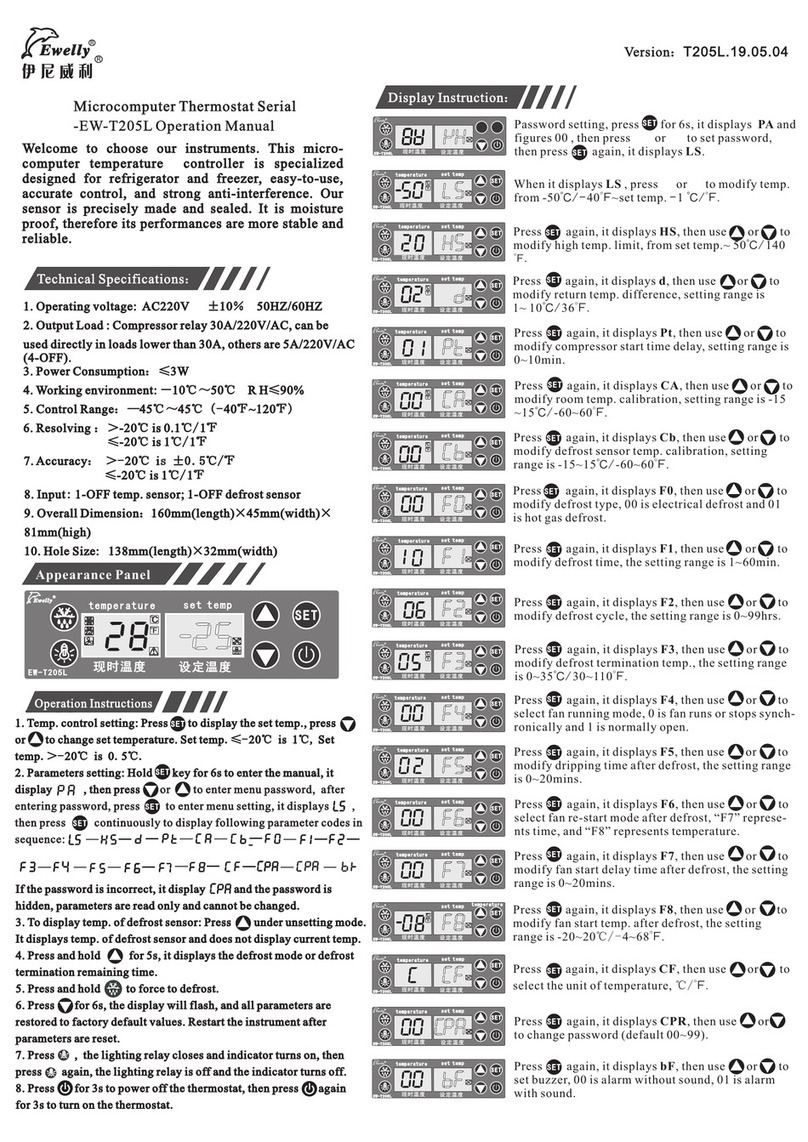

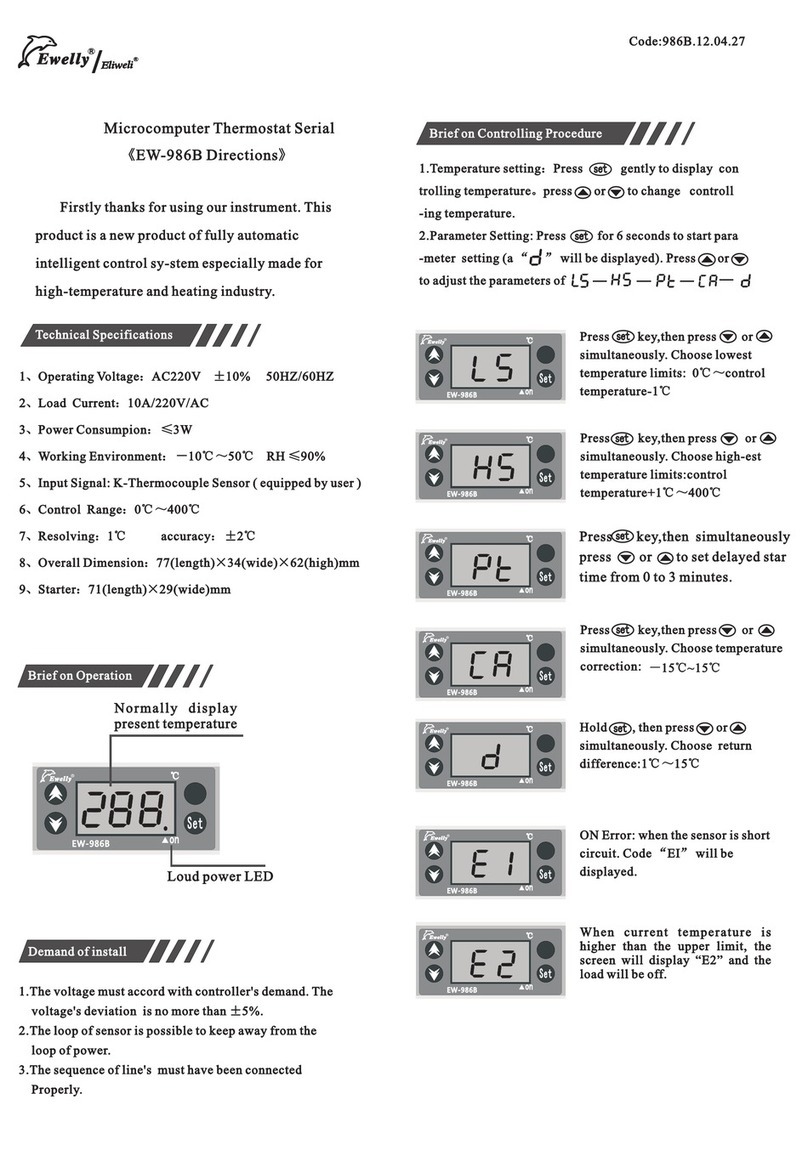

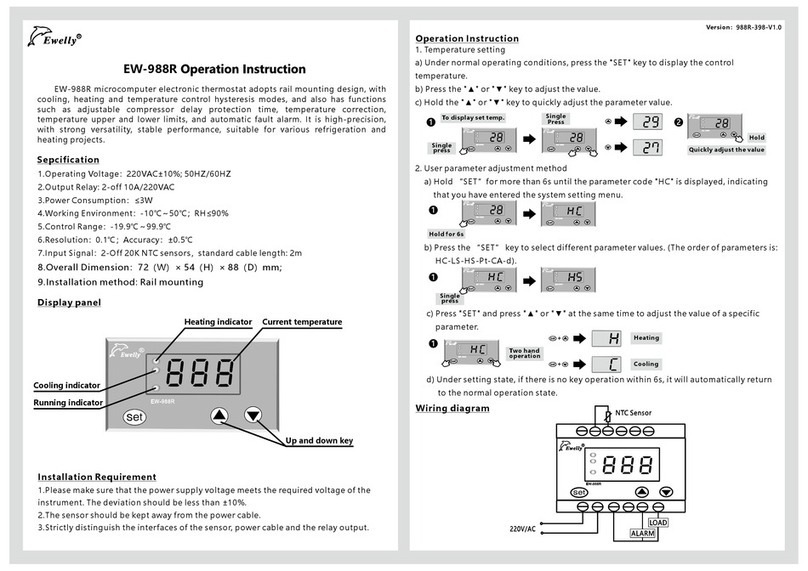

Microcomputer Thermostat Serial

《 》EW-802 Directions

。

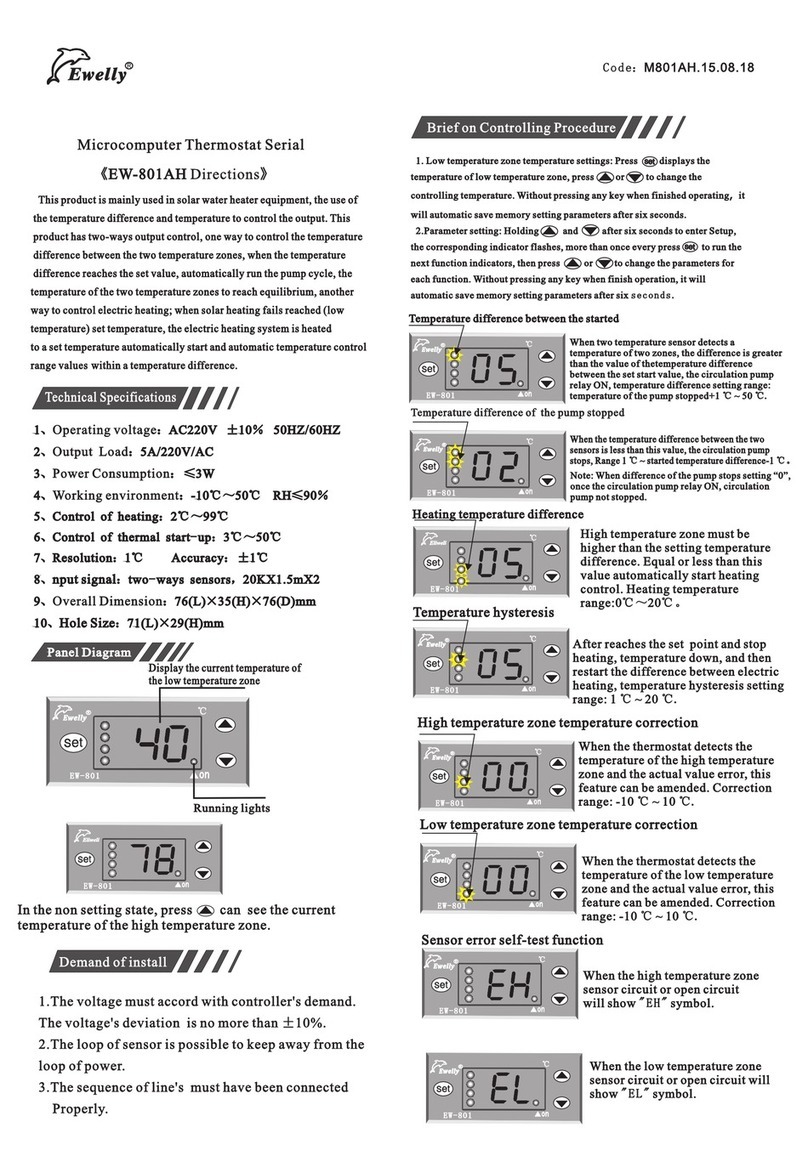

This product is mainly used in solar water heater equipment, the use of

the temperature difference and temperature to control the output.

This product has three output controls. One way to control the temper-

ature difference between the two temperature zones. When the temperature

difference reaches the set value, the water pump cycle is automatically

operated to balance the temperature in the two temperature zones. The second

way controls electric heating. When the solar heating fails to exceed the

heating temperature difference of the set temperature, the electric heating

system automatically starts heating to the set temperature and automatically

thermostats within the temperature difference control range. The third way to

control the water valve, automatically add water and automatically stop adding

water when there is water shortage.。

1. :AC220V ±10% 50HZ/60HZ

2. Output :5A/220V/AC

3. :≤3W

4. :-10℃ ~50℃ RH≤90%

5. Control of heating:2℃ ~99℃

6. Control of thermal start-up:3℃~50℃

7. Resolution:1℃ Accuracy:±1℃

8. I two-ways sensors,20KX1.5mX2

ne water level probe

9. :72(L)×(H)×(D)mm

Operating voltage

Load

Power Consumption

Working environment

Overall Dimension 54 88

O

10. Rail mounting

nput signal:

When two temperature sensor detects a

temperature of two zones, the difference is

greater than the value of the temperature

difference between the set start value, the

circulation pump relay ON, temperature

difference setting range: temperature of

the pump stopped+1 ℃ ~ 50 ℃.

Start-up temperature difference

Temperature difference

When the set temperature is reached,

the heating is stopped, and the

difference between the electric heating

is restarted after the temperature is

back. Temperature hysteresis setting

range: 1 °C ~ 20 °C.

High temperature zone temperature correction

Low temperature zone temperature correction

When the thermostat detects the

temperature of the high temperature

zone and the actual value error, this

feature can be amended. Correction

range: -10 ℃ ~ 10 ℃.

When the thermostat detects the

temperature of the low temperature

zone and the actual value error, this

feature can be amended. Correction

range: -10 ℃ ~ 10 ℃.

Sensor error self-test function

The “EH” symbol is displayed when

the high temperature zone sensor is

opened. The "heating" relay is

disconnected, the "pump" relay is

energized, and the "pump" indicator is

illuminated.

The “EH” symbol is displayed when

thelow temperature zone sensor is

opened. The "heating" relay is

disconnected, the "pump" relay is

energized, and the "pump" indicator is

illuminated.

●In non-setting state, press to check the current temperature

in the high temperature zone.

Temperature difference of the pump stopped

When the temperature difference between

the two sensors is less than this value, the

circulation pump stops.

Range 1 ℃ ~ started temperature difference-1 ℃

Note: When difference of the pump stops setting “0”,

once the circulation pump relay ON, circulation

pump not stopped.。

Heating temperature difference

High temperature zone must be higher

than the setting temperature difference.

Equal or less than this value automatically

start heating control. Heating temperature

range:0℃ ~20℃ 。

EW-MH802

Ewelly

EW-M H106

Ewelly

EW-M H10 6

Ewelly

EW-M H106

Ewelly

EW-M H10 6

Ewelly

EW-M H10 6

Ewelly

EW-M H106

Ewelly

EW-M H106

Ewelly

EW-M H10 6

Ewelly

EW-M H10 6

Ewelly

When the water level is lower than the low

water level value, the “LL” symbol is

displayed alternately with the low

temperature zone temperature, while the

“watering valve” relay is sucked and added

with water; the “heating” relay and the

“water pump” relay are disconnected.

EW-M H10 6

Ewelly

●In the non-setting state, hold 6 seconds, the display will flash

and the factory parameters will be restored.

Heating load indication

Circulating pump

Water

valve

Low temperature zone

temperature

Technical Specifications

Panel Diagram

1.The voltage must accord with controller's demand.

The voltage's deviation is no more than ±10%.

2.The loop of sensor is possible to keep away from the

loop of power.

3.Differentiate sensors, power lines, and output relays.

Demand of install

1. Low temperature zone temperature settings: Press displays the

temperature of low temperature zone, press or to change the

controlling temperature. Without pressing any key when finished operating,it

will automatic save memory setting parameters after six seconds.

2.Parameter setting: Holding and after six seconds to enter Setup,

the corresponding indicator flashes, more than once every press to run the

next function indicators, then press or to change the parameters for

each function. Without pressing any key when finish operation, it will

automatic save memory setting parameters after six seconds.

Brief on Controlling Procedure