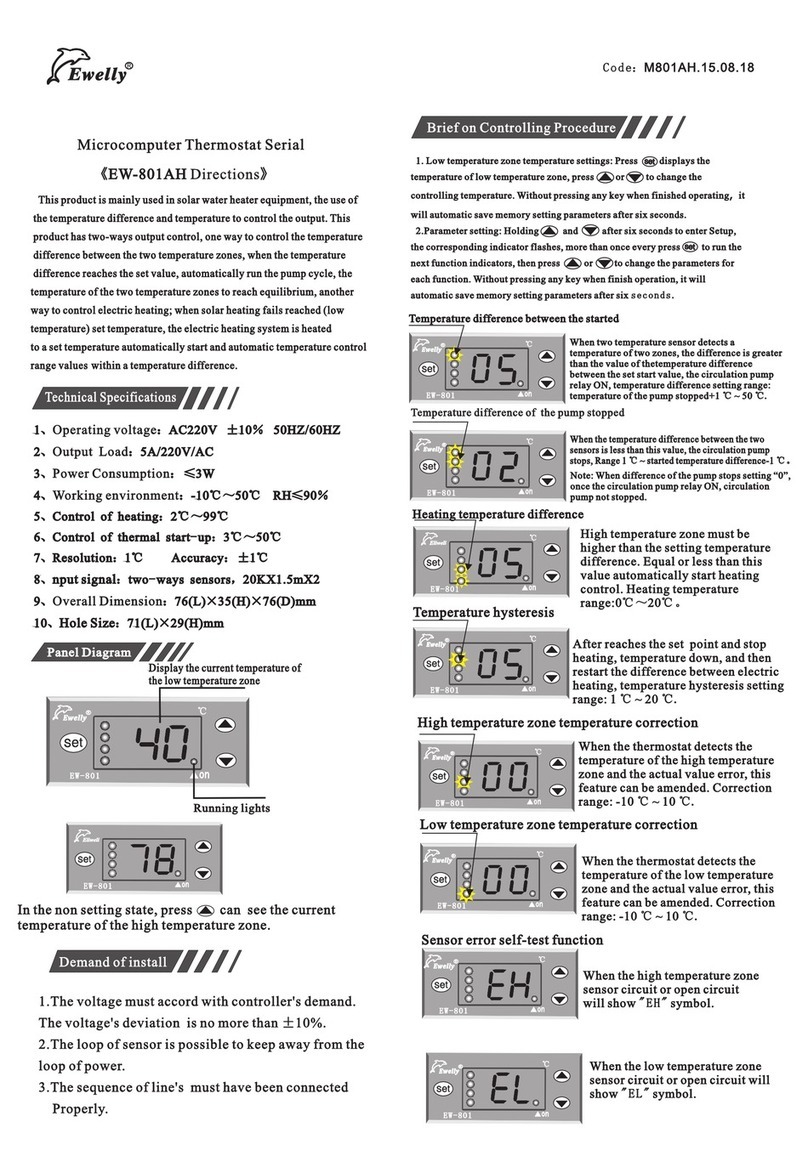

℃/℉

℃/℉

℃/℉

℃/℉

℃/℉

Setting range

Delayed Time

Temperature

Correction

Temperature

Difference

5~400/5~800

120/250

415/800

-75

Heating 0

2/5

00

Heating0~5

Cooling1~5

1~15/1~60

-25~25/-60~60

Mins

Model:EW-986GP

220V/AC

2345678910

1

-75℃~temp.control-d-1℃

control temp.+d to 415/800

Low temperature

limit.

Alarm on high limit

Temperature

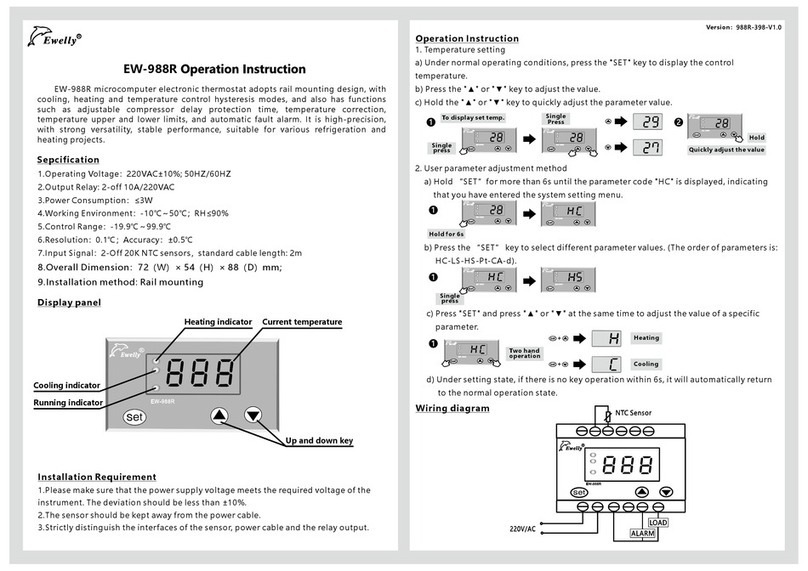

●Heating(H mode): When the current temperature ≤ set temperature - hysteresis temperature and the set "delay time" is delayed, the load relay pulls in.

Heating stop: When the current temperature ≥ set temperature, the load relay is disconnected.

11 12

220V/AC

Lo a d:

10A/220V/AC

Temperature Switch C/F C

Pt100

Heating/ cooling

mode

Heat H/C Cold

H

●Cooling(C mode): When the current temperature ≥ set temperature - hysteresis temperature and the set "delay time" is delayed, the load relay pulls in.

Cooling stop: When the current temperature ≤ set temperature, the load relay is disconnected.

Note: 1 When the parameter is reset, the setting parameters are reset to the Celsius temperature

2 Reset to the default parameters when the temperature unit is converted.

Load

Function

Setting Range Ex-factory

Value Unit

Failure Causes Precautions

No display when power

is on.

Check to see if the power is short circuit.

The thermostat fails.

Check power supply and change fuse.

Check if there is 220V power input or change

thermostat with our distributor.

Machine does not work

but display exits

The set temperature is lower than the real time

temperature.

The heat protector is open circuit because the

pressure is over loads.

Reset the necessary controlling temperature.

Check the reasons for overload and overheating.

After the trouble is solved, restart to work.

Displayed temperature is

unstable or there exists

misplay..

The sensor wiring is interfered, poorly contacted or

is tied with other cables. The current is light because

of damage in the wiring.

Separate sensor wiring with power cables or change

shielded lines or check if the contact is tight or not.

The actual temperature value is in error with

the measured value of the thermostat

The locations for the sensors are not correct or

sensor wiring is too long and its resistance is too

big. The wiring contact is poor and the sensor`s

damag.

All sensors should be corrected at their locations.

Enlarge the cross section of the expanded wires.

Make sure the wiring sealing, is good.

Change sensor.

Machine does not stop

when the temperature

reaches.

The sensor is not correctly installed and cannot

measure the correct temperature. Compressor

contactor fails.

Check if the sensor has accurately measured the

temperature or not. Change compressor contactor.

Relay over frequency work The hysteresis temperature value is too small. Re-adjust the increase in the temperature value

of the return。

Temperature value does not change or

display HH, LL

The thermocouple line is shorted open or

damaged.

Check if the thermocouple line and the connection

are connected.

1. Please read this product instruction carefully and connect

input/output plugs of power & sensor to the corresponding sockets

strictly by following connection diagram, otherwise the usage &

operations will be affected. Check again to make sure there is no

mistake. Tighten all the screw of connection plugs again, and then

connect it to the power for running.

2. Keep away this product from moist or corrosive air and high

magnetic field. Otherwise the normal operation of this product will

be affected.

.

3. All our products have passed strict quality inspections before

leaving factory. We provide one-year quality guarantee (which is

limited to product itself ,and is not responsible for any other joint and

several liability) period for this product.

If you have any doubt or problem concerning the electronic

temperature or humidity controller made by us, please contact our

distributors and we will provide you high-quality after-sale

services. Thanks!

If the products including but not limited to, the following is not the

product itself quality problem caused by the damage, Install and use under the

do not conform to the safe environment; That the load capacity is beyond the

scope of product is allowed; Products by users to disassemble and change,

change the internal components, etc.,We will not be so and damaged products

provide a replacement and maintenance services, regardless of whether its in

the quality assurance period; Meanwhile, we will not assume so direct or

indirect losses caused by the liability to pay compensation.

Product warranty date on the case is important basis of product quality

assurance. Appeared including but not limited to full filling without

permission, to change, to replace lost, damaged, scratched, dirty, and so on, we

will not provide a replacement and maintenance services for these products.

About Failure

Warnings

Guangzhou Ewelly Autocontrol Tech. Co., Ltd.

http://www.eliweli.com

Wiring diagram 程序参 数表

Parameters for Procedure

功能说 明

Feature descriptions