Excell EX2005 User manual

User Manual

EX2005

© Excell Precision Limited 2015. All rights reserved Worldwide.

The information contained herein is the property of Excell Precision Limited and is supplied

without liability for errors or omissions. No part may be reproduced or used except as

authorised by contract or other written permission. The copyright and the foregoing

restriction on reproduction and use extend to all media in which the information may be

embodied.

1

040

1

1210

ZSME

4

00000

00

3

EXCELL PRECISION CO., LTD

CONTENT

Safety...................................................................................................................................3

Features...............................................................................................................................3

Chapter 1 Front and Rear Panel Specifications..........................................................................4

1-1 Front panel .............................................................................................................4

1-2 Rear panel..............................................................................................................4

1-3 Keypad Description ................................................................................................5

1-4 A/D Conversion.......................................................................................................5

1-5 Power supply..........................................................................................................5

1-6 Dimensions.............................................................................................................6

Chapter 2 General Function Guide......................................................................................7

2-1 Function Setup and Operation Procedures ............................................................7

2-2 Error Messages (Display in General Function setting) ...........................................8

2-3 Function Setting .........................................................................10

Chapter 3 Calibration.........................................................................................................13

3-1 Load Cell Connection...........................................................................................13

3-2 Parameter Setting and Calibration Flow Chart .....................................................14

3-3 MODBUS Calibration............................................................................................16

3-4 Specification calibration .............................................................17

3-5 General Calibration ....................................................................19

3-6 Linearity calibration ....................................................................20

3-7 Digital calibration ....................................................................22

Chapter 4 Weight Comparison Procedures .......................................................................23

4-1 Function Configuration Menu ...............................................................................23

4-2 Check Weighing Configuration.............................................................................26

4-3 Batching Signal Outputs.......................................................................................29

4-4 Normal batching flow chart (SQ-01=1) .................................................................30

4-5 Loss-in Weight flow chart (SQ1=2).......................................................................31

4-6 Hi, OK, Lo output flowchart...................................................................................32

4-7 Normal batching (built-in program) flowchart (SQ-01=4)......................................33

4-8 Loss-in Weight (built in program) (SQ-01=5)........................................................34

4-9 Hold mode (SQ-01 = 6) ........................................................................................35

4-9-1 Hold mode flow chart .................................................................................36

4-9-2 Hi, OK, Lo comparison...............................................................................37

4-10 Totalizing (ACCU.) Auto / Transmit .....................................................................37

2

04011210

ZSME

4

00000

003

EXCELL PRECISION CO., LTD

Chapter 5 Interface............................................................................................................38

5-1 Serial Input / Output Interface (default OP-01).....................................................38

5-2 BCD parallel output interface (OP-02) ......................................46

5-3 Analogue Current / Voltage Output Interface (OP-03) ..........................................48

5-4 External Parallel Input / Output Interface..............................................................50

Chapter 6 Maintenance......................................................................................................55

6-1 Restore All Parameters to Their Default Factory Values.......................................55

6-2 Maintenance Function Parameters.......................................................................55

6-2-1 Restore the function parameter back to its default value............................56

6-2-2 Clear zero compensation and TARE values...............................................56

6-2-3 Clear batch setting.....................................................................................56

6-2-4 Display zero voltage (mV/V).......................................................................56

6-2-5 Clear batch setting.....................................................................................56

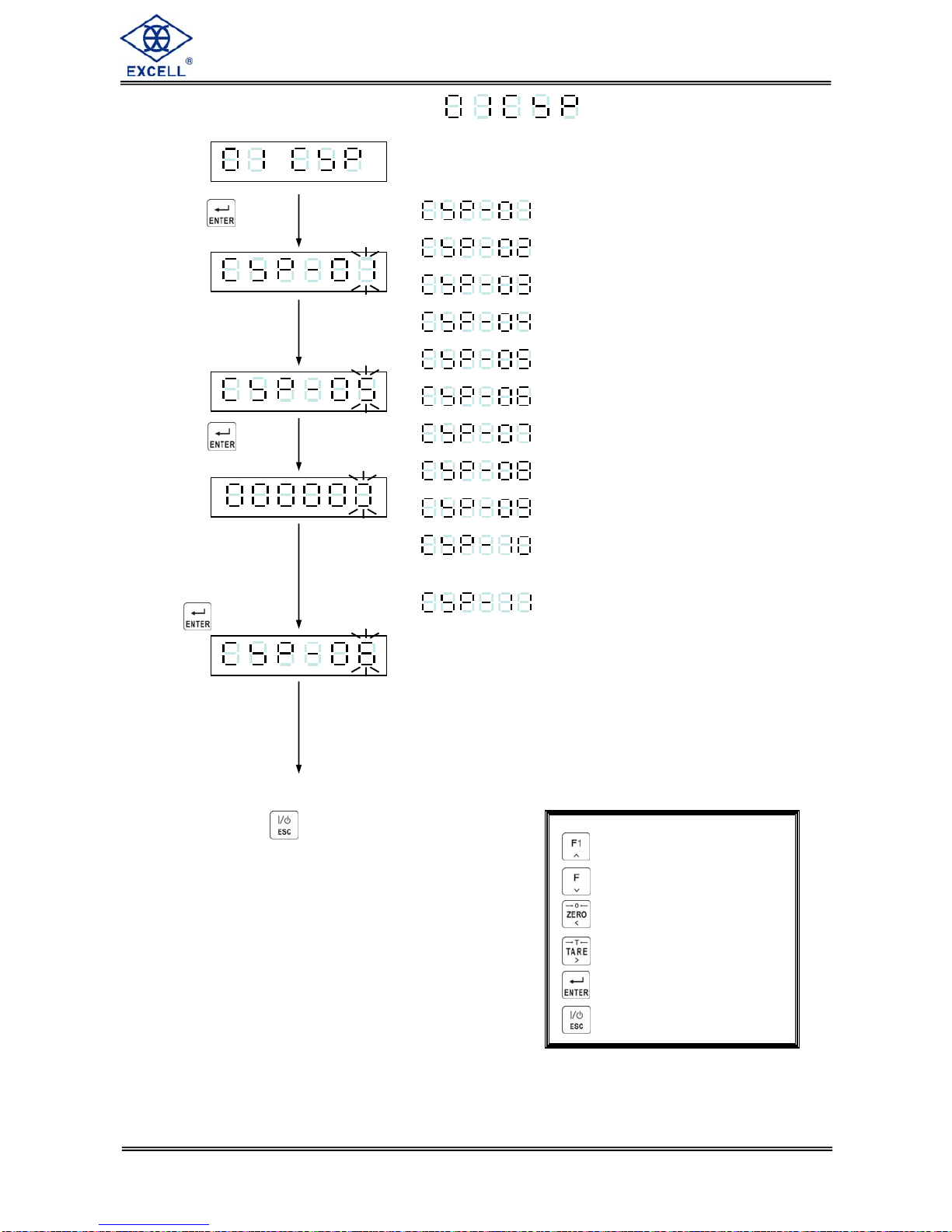

6-3 Test mode.............................................................................................................57

6-3-1 7-Segment display testing..........................................................................58

6-3-2 Keypad and calibration SW testing ............................................................58

6-3-3 Display A/D internal value display ..............................................................58

6-3-4 RS-232 serial loop back testing..................................................................58

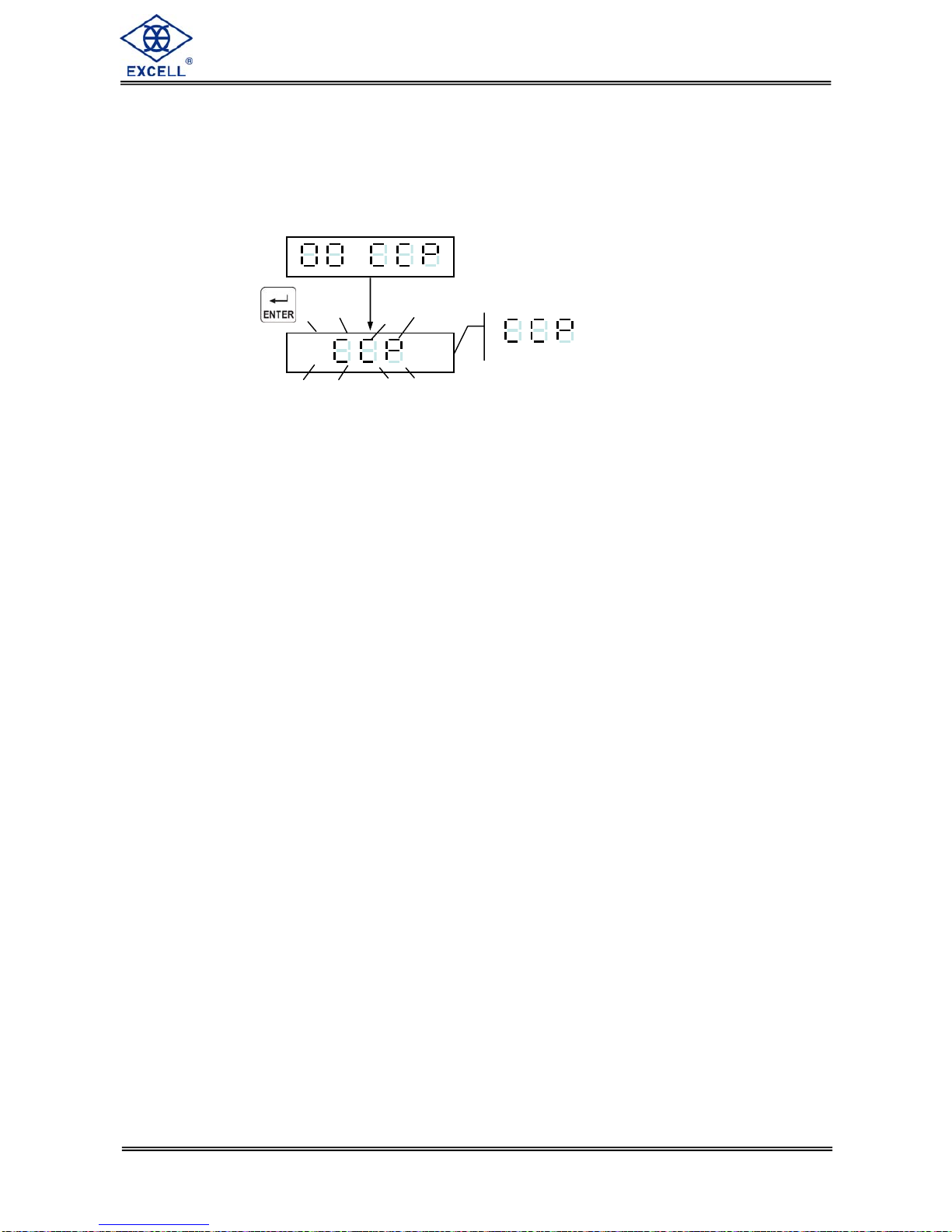

6-3-5 EEPROM memory testing..........................................................................58

6-3-6 Option interface card testing ......................................................................58

Appendix 1 Description of 7-Segment Characters.............................................................60

Appendix 2 Function Table.................................................................................................61

Appendix 3 MODBUS DataAddress Table I ......................................................................70

Appendix 4 MODBUS DataAddress Table II .....................................................................71

Appendix 5 Examples for Input and Output of Modbus......................................................72

3

040

1

1210

ZSME

4

00000

00

3

EXCELL PRECISION CO., LTD

Safety

zWhen the instrument is installed, connect an earth bonding conductor from FG to the

earth connection marked “ ”.

zDisconnect the mains power supply before opening the instrument housing.

zTo install the optional interface cards, it is necessary to disconnect the mains power

supply and fit a yellow/green earth bonding cable to the rear panel.

zBefore turning the power on ensure the supply voltage is within the acceptable range,

DC24 V.

zThe operating ambient temperature range is 0 oC ~ 40 oC (32 °F ~ 104 °F).

Features

EX2005 has a wide range of applications from batching to simple weighing.

Features:

Stand alone batching mode or connect to PLC for external system control

Built in batching / dosing functions

Manual / automatic discharge operation

Set cycle times in a batch

Totalise weight and number of cycles

Key in the signal voltage value (mV / V) directly via the keypad, no need to apply

any weight to the bottom work to calibrate the weigher

Display load cell output voltage (mV / V) for future maintenance

Adjustable filter

RS232C bi-directional and RS485 communication

Built-in MODBUS (RTU) format

Interface options:

OP-01 RS-422 / RS-485 / RS-232 serial interface

OP-02-1 BCD parallel output interface (Open collector output)

OP-02-2 BCD parallel output interface (TTL output)

OP-03 16 Bit Analogue current/voltage output interface

(4~20mA/0~10V)

OP-04 Control I/O (4 In / 4 Out) + Setpoint In (BCD code)

OP-05 Control I/O (8 In / 8 Out)

4

040

1

1210

ZSME

4

00000

00

3

EXCELL PRECISION CO., LTD

Chapter 1 Front and Rear Panel Specifications

1-1 Front panel

Display

•6 digits, bright red, 7 segment LED display, character height 16mm (0.63”).

•Display can be switched between Gross Weight / Net Weight / Totalised Weight /

Number of transactions in the total.

Indication icons “◄”

ZERO ◄:Zero Indication

MD ◄:Unstable weight Indication

GROSS ◄: Gross weight Indication

NET ◄: Net weight Indication

♦The indicator is supplied with suitable labels to customise the icon displays.

♦Refer to FNC-06 ~ FNC-09 for the various options available.

Weighing Units

zWeighing Units kg / g / t / lb.

1-2 Rear panel

zCalibration Switch set to the left is “OFF” and to the right is “ON”

Terminal Block Calibration Switch

z13 Way Terminal Block

1st FG

2nd DC+

3rd DC-

4th NC

5th TX

6th RX

7th SG

8th E+

9th SEN+

10th E-

11th SEN-

12th SIG +

13th SIG -

Display Area

Weight Unit

Indication

5

040

1

1210

ZSME

4

00000

00

3

EXCELL PRECISION CO., LTD

1-3 Keypad Description

:

When entering data or reference setting, it means “ESC”.

In the normal operation, it puts the indicator in standby mode or escape.

Entering standby mode: All of the display (except ZERO “3” symbol)

and serial data output are disabled.

Escape from standby mode: Re-power on mains for normal operation.

Function FNC-03 can be used to selectively disable individual keys.

Zero operation, will be limited by functions CSP-05 and CSP-10.

Zero operation, will be limited by functions CSP-10 and CSP-11.

1-4 A/D Conversion

* Input Sensitivity

* Internal Resolution

* Max. Sampling Speed

* Application Range

* Load Cell Excitation Voltage

: Over 0.12μV/d

: 1 / 1 000 000

: 120 times/s.

: - 0.1 ~ 4.0 mV / V

: 5 V DC ±5%, 120 mA

(Up to eight (8) 350 Ωload cells can be connected)

1-5 Power supply

♦DC24 V

♦Power consumption is about 10 VA

:When parameter setting, it moves the flashing digit left.

In the normal mode, it performs a Zero operation.

:When parameter setting, it moves the flashing digit right.

In the normal mode, it performs a semi-auto Tare operation.

:When parameter setting, it increments the flashing digit or steps up the

select item.

In the normal mode, it accesses the FNC-05 setting.

:When parameter setting, it decrements the flashing digit or steps down

the select item.

In the normal mode, it accesses the FNC-04 setting.

:

Confirm / enter key.

6

040

1

1210

ZSME

4

00000

00

3

EXCELL PRECISION CO., LTD

1-6 Dimensions

7

040

1

1210

ZSME

4

00000

00

3

EXCELL PRECISION CO., LTD

Chapter 2 General Function Guide

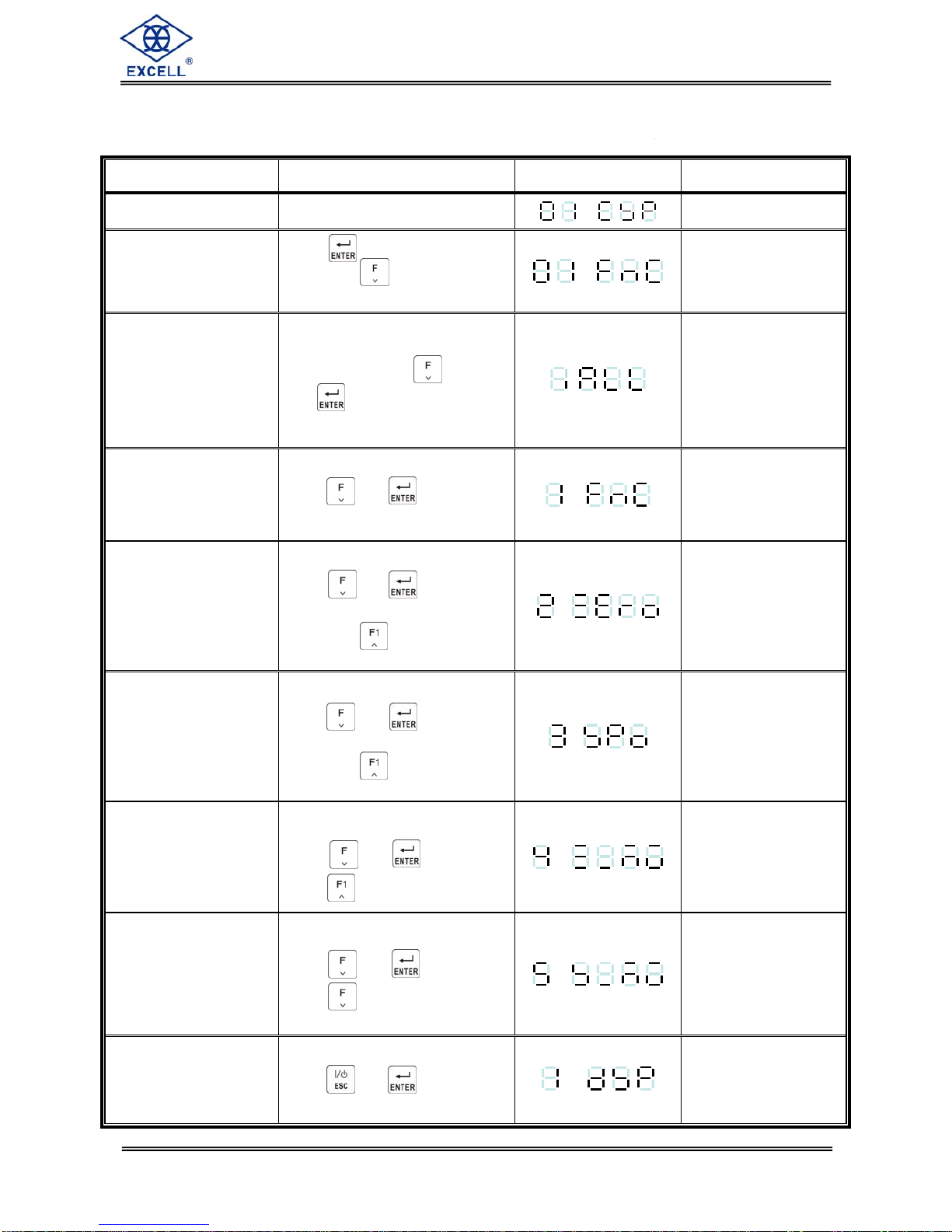

2-1 Function Setup and Operation Procedures

Function Operation Display Description

Enter calibration mode Turn the calibration switch to “ON” See 3-2 for details

Enter function setting

Press not release,

then press key

after the power is turned on

See 2-2 for details

Reset all parameters

back to default

Turn the power on then turn the

calibration switch to “ON” then

press and hold the

and keys during the

self-testing sequence

. See 6-1 for details

Reset general function

parameters back to

default

Turn the power on and

press and keys

during self-testing sequence

See 6-2-1 for details

Clear zero point

compensation and tare

value

Turn the power on and

press and keys

during self-testing sequence, and

then press key

See 6-2-2 for details

Clear setpoint parameter

setting

Turn the power on and

press and keys

during self-testing sequence, and

then press two times

See 6-2-3 for details

Value of zero point

voltage(mV / V)

Turn the power on and

Press and ,then

press key three times

See 6-2-4 for details

Value of Span voltage

(mV / V)

Turn the power on and

Press and , then

Press key

See 6-2-5 for details

Entering to test mode

Turn the power on and

press and keys

during self-testing sequence

. See 6-3 for details

8

040

1

1210

ZSME

4

00000

00

3

EXCELL PRECISION CO., LTD

Function Operation Display Description

Check weighing setpoint

parameter setting

Press the key to set

the parameter of FUNC.4 to 1 in

the normal mode

.

or

.

See 4-2 for details

Key actions in function set up mode

⇒Increases the number of the flashing digit

⇒Decreases the number of the flashing digit

⇒Moves the flashing digit one space to the left

⇒Moves the flashing digit one space to the right

⇒Saves the configuration

⇒Quits set up mode / Escape

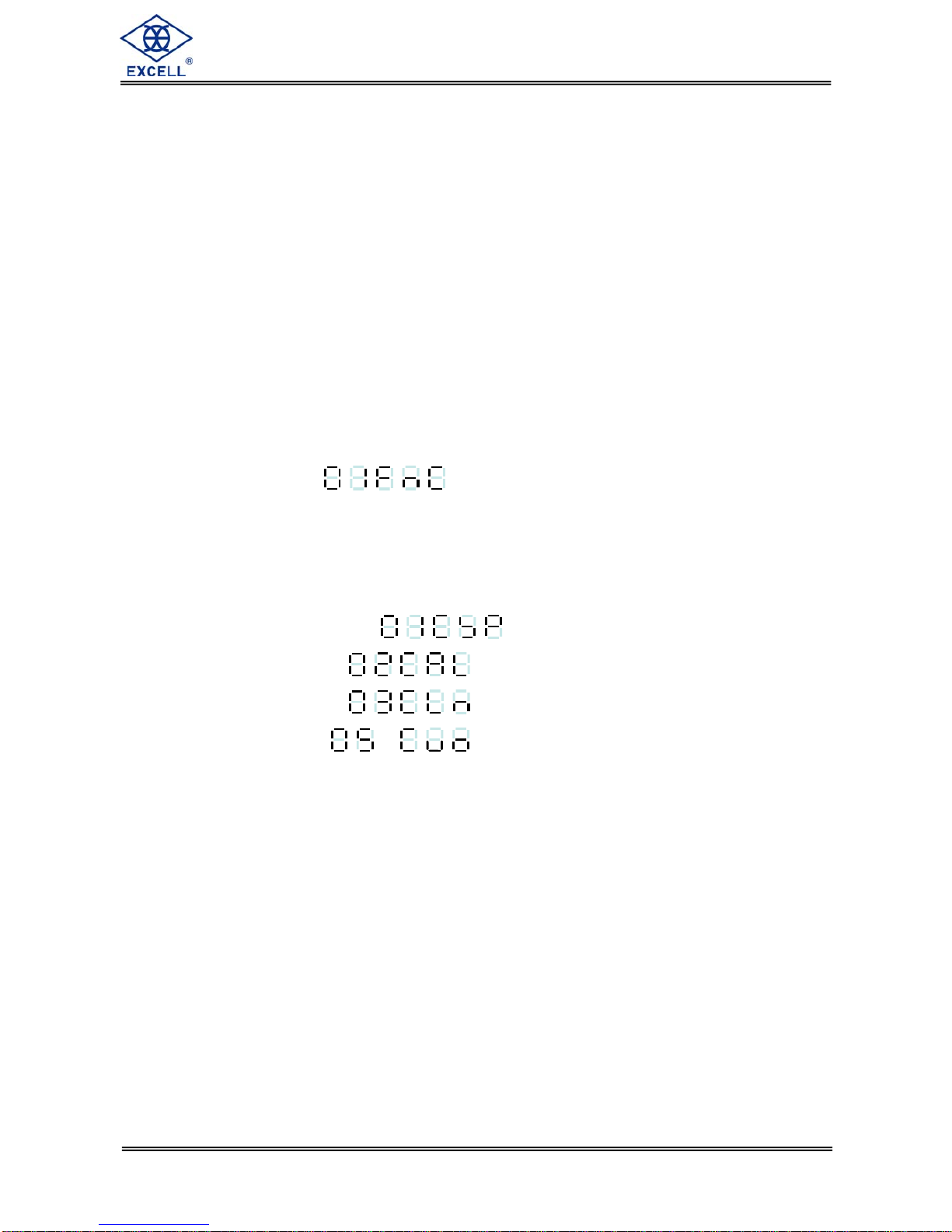

2-2 Error Messages (Display in General Function setting)

. ⇒Load Cell output voltage <- 0.1m V / V or >4mV / V

. ⇒Weight value ≤previous weight value

. ⇒Actual measured weight value ≤previous weight value

. ⇒Setting value 0

. ⇒mV / V value entered >measuring range

. ⇒mV / V value entered is too small (SPAN – Zero <0 mV / V)

. ⇒Displayed resolution is less than 0.12 μV / division

9

040

1

1210

ZSME

4

00000

00

3

EXCELL PRECISION CO., LTD

Function Setting

First Serial Port Interface

Second Serial Port

Interface

BCD Parallel Port output

interface

A

nalogue current / voltage

output interface

External parallel control

input interface

External parallel trip output

interface

Function Setting Procedures

With weight displayed press and hold the key. Then, press key

See 5-1 for details

See 5-2 for details

See 5-3 for details

See 5-1 for details

See Function Setting 2-2

for details

See Chapter 4 for details

See 5-4 for details

See 5-4 for details

Set Point Procedure

10

040

1

1210

ZSME

4

00000

00

3

EXCELL PRECISION CO., LTD

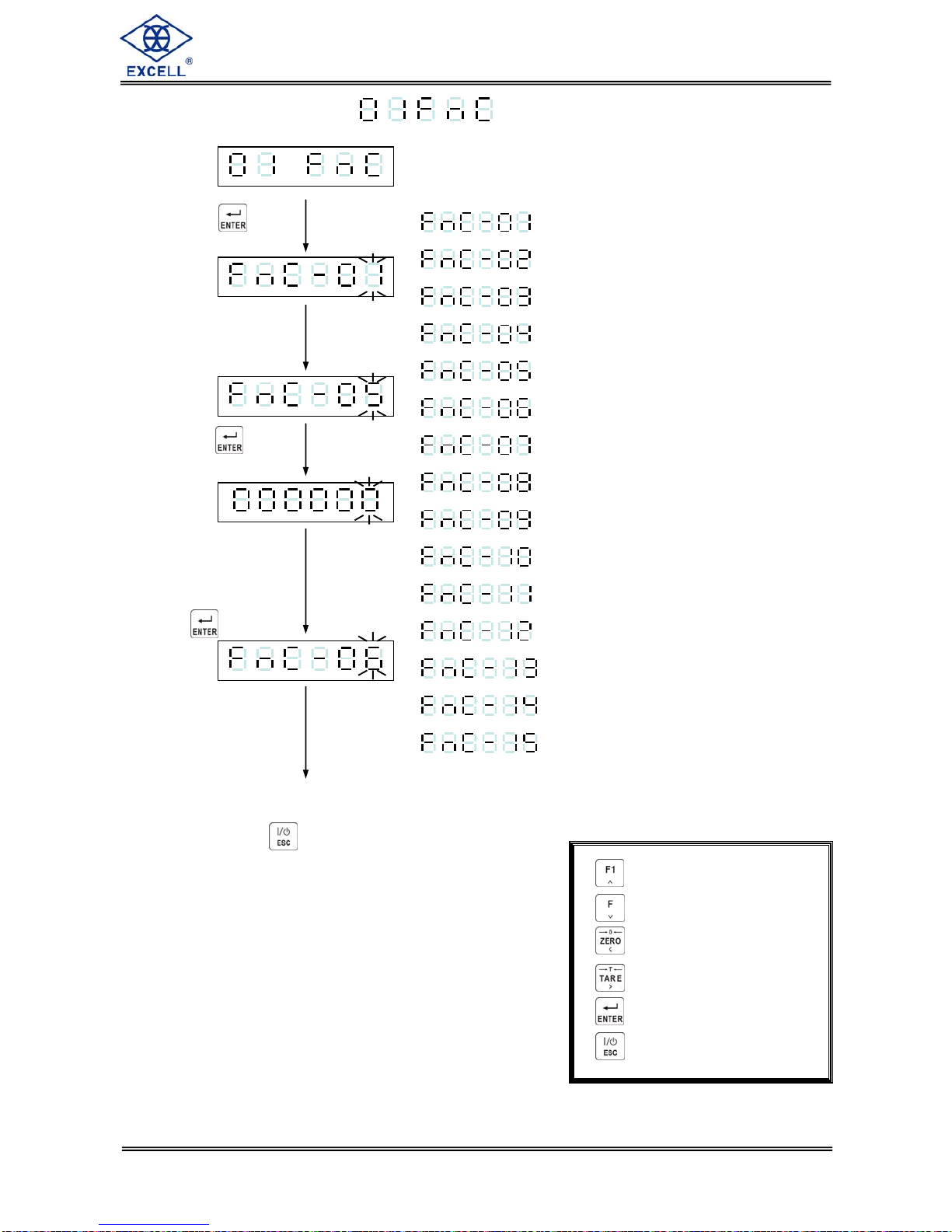

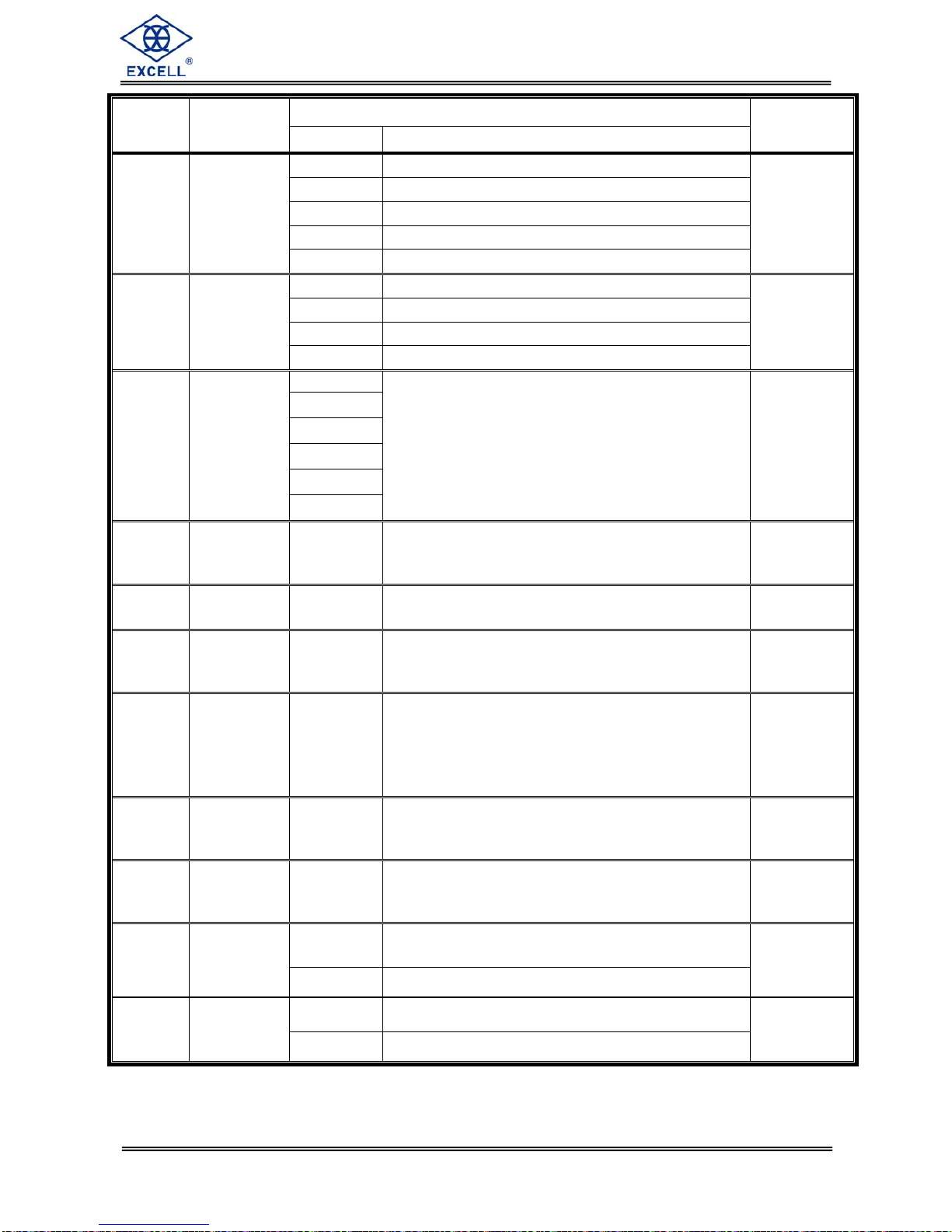

2-3 Function Setting

Press key

Input desired

Parameter code

Press key

Display shows the

previous parameter

code. Input the new

code as required

Press key

To continue the next function setting

or press key to escape

⇒Increment flashing digit

⇒Decrement flashing digit

⇒Move flashing point left

⇒Move flashing point right

⇒Store data in memory

⇒Exit / Escape

*Function Parameter code

⇒Digital Filter I

⇒Digital Filter II

⇒Lock keypad function

⇒“F” function setting

⇒“F1” function setting

⇒Front panel indication “◄” setting (first)

⇒Front panel indication “◄” setting (second)

⇒Front panel indication “◄” setting (third)

⇒Front panel indication “◄” setting (fourth)

⇒Terms of back to zero

⇒Hold

⇒Rate for display rewrite

⇒Turn-on zero setting

⇒Stand-by mode setting

⇒Zero function record setting

11

040

1

1210

ZSME

4

00000

00

3

EXCELL PRECISION CO., LTD

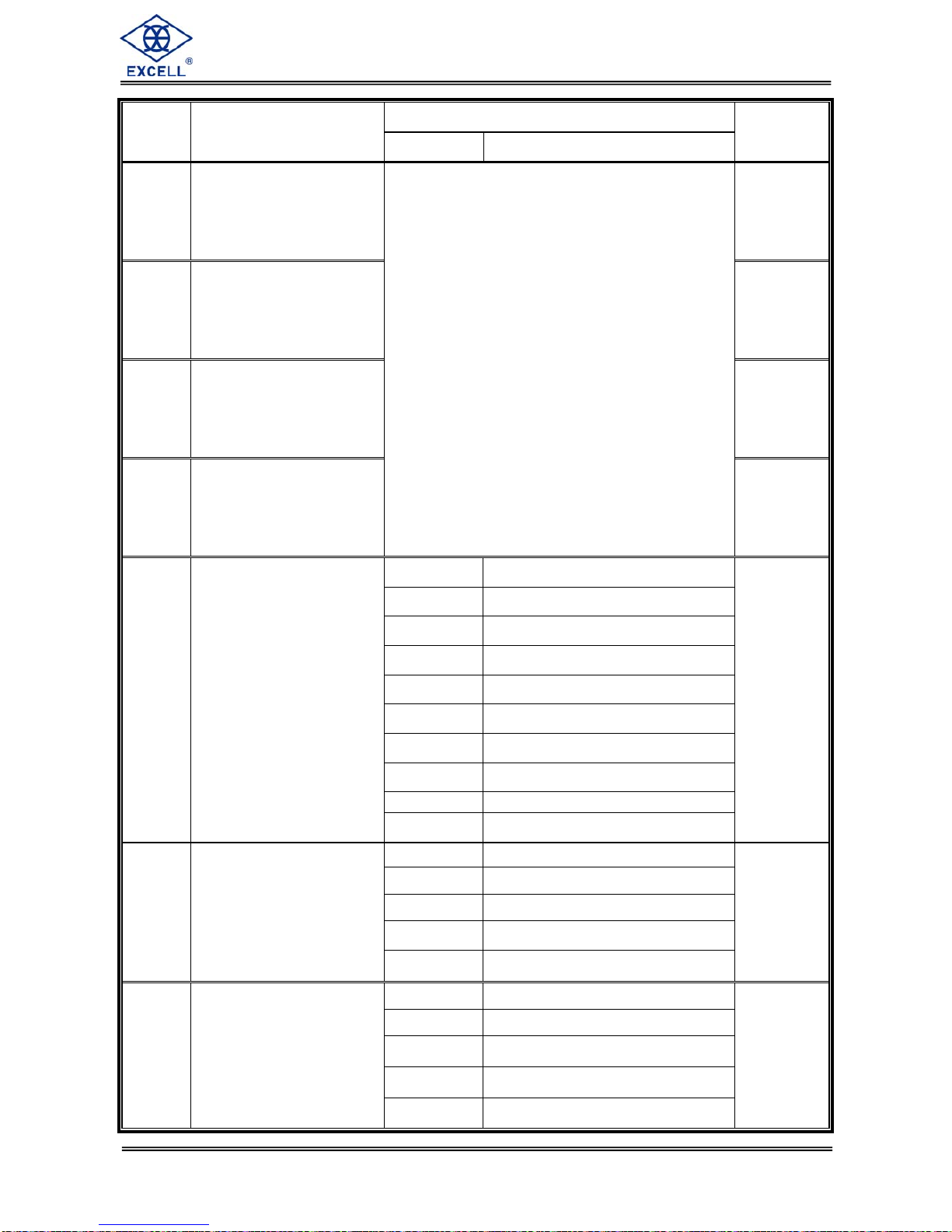

FNC Group function setting

Setting value

Item Function

Parameter Description Default

0 5 Hz

1 4.17 Hz

2 2.5 Hz

3 2.08 Hz

4 1.25 Hz

5 1.04 Hz

6 0.63 Hz

7 0.52 Hz

8 0.31 Hz

FNC-01 Digital Filter I

9 0.26 Hz

4

0 Disabled

1

2

3

4

FNC-02 Digital Filter II

5

Less filter

Greater

2

0Normal

(lock disable)

FNC-03 Key – Locked

000000

↓

111111 1Close

(lock enable)

The bits and front

panel key

positions are

related to each

other

000000

FNC-04 “F” function setting 1

FNC-05 “F1” function setting

Parameter ⇒Description

0 ⇒Display Net / Gross weight

1 ⇒Setpoint parameter setting

2⇒Tare reset

3⇒Manual serial, parallel print output

4⇒Start load

5⇒Stop load

6⇒Start comparison

7⇒Unload command

8⇒Totalise weight and counts

command

9⇒Clear totalised weight and counts

10 ⇒Hold mode

11 ⇒Escape Hold mode(I / O DSP)

12 ⇒Convert to Gross / Net / totalised

weight / totalised Count

0

12

040

1

1210

ZSME

4

00000

00

3

EXCELL PRECISION CO., LTD

Setting value

Item Function

Parameter Description

Default

FNC-06 Front panel indication “◄”

setting (top) 0

FNC-07 Front panel indication “◄”

setting (next to top) 1

FNC-08 Front panel indication “◄”

setting (next to bottom) 2

FNC-09 Front panel indication “◄”

setting (bottom)

Parameter ⇒Description

0⇒Zero

1⇒MD

2⇒Gross

3⇒Net

4⇒Totalised weight (Accu. V)

5⇒Totalised transactions (Accu. C)

6⇒SP1

7⇒SP2

8⇒SP3

9⇒Hi

10 ⇒OK

11 ⇒Lo

12 ⇒Under

13 ⇒Over

14 ⇒Discharge

15 ⇒Running

16 ⇒Hold

3

0 5 d

1 10 d

2 20 d

3 40 d

4 60 d

5 80 d

6 100 d

7 150 d

8 200 d

FNC-10 Return to zero band

(d: refer to CSP-03)

9 250 d

0

0 Hold

1 Peak hold (positive 1)

2 Peak hold (negative)

3 Peak hold (absolute value)

FNC-11 Hold

4 Peak hold (positive 2)

0

0 No limitation

1 20 times/s

2 10 times/s

3 5 times/s

FNC-12 Rate for display rewrite

4 1 time/s

0

13

040

1

1210

ZSME

4

00000

00

3

EXCELL PRECISION CO., LTD

Setting value

Item Function

Parameter Description

Default

0 Disable

FNC-13 Turn-on zero setting

1 Enable

0

0 Disable all the functions under

stand-by mode

FNC-14 Stand-by mode setting

1

Only turn off display but not

disable other functions under

stand-by mode

0

0 Zero point record not saved into

EEPROM

FNC-15 Zero function record

setting 1 Zero point record saved into

EEPROM

0

Chapter 3 Calibration

3-1 Load Cell Connection

14

040

1

1210

ZSME

4

00000

00

3

EXCELL PRECISION CO., LTD

Specification

Calibration Linearity

Calibration Digital

Calibration

MODBUS

Calibration

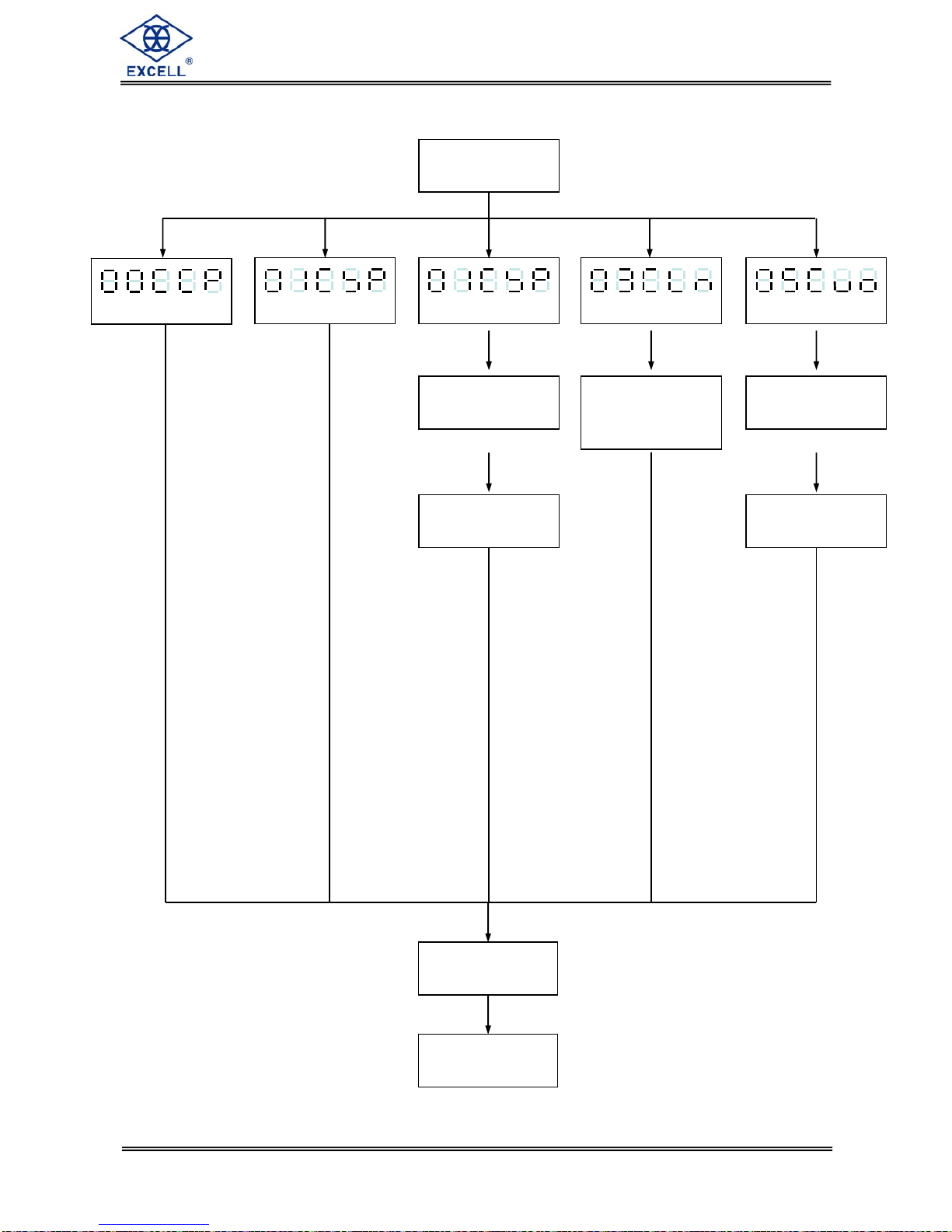

3-2 Parameter Setting and Calibration Flow Chart

Calibration

Switch ON

Zero Point Voltage

Calibration

Span Voltage

Calibration

Select 1 Point for

Weight Calibration

(1P~5P)

Calibration Switch

OFF

Calibration

Completed

Zero point

Calibration

Weight Calibration

General

Calibration

15

040

1

1210

ZSME

4

00000

00

3

EXCELL PRECISION CO., LTD

Calibration process

Before the Linearity Calibration, the General Calibration should be completed.

Calibration Switch set to ON

Entering the specification

calibration, see 3.4 for

details

Entering the General

calibration, see 3.3 for

details

Entering the General

calibration, see 3.5 for

details

Entering the linearity

calibration, see 3.6 for

details

Entering the Digital

calibration, see 3.7 for

details

Spec. Calibration

General Calibration

Linearity Calibration

Digital calibration

MODBUS Calibration

16

040

1

1210

ZSME

4

00000

00

3

EXCELL PRECISION CO., LTD

3-3 MODBUS Calibration

2RS1-02 set as “4” (MODBUS RTU mode)

RS1-07 set as “01” (address)

Eg:

Zero calibration

Input 01050423FF007CC0 ←zero calibration

Reading calibration status

Input 0101004100565AC1D ←Refer to “Appendix 3: MODBUS data

address table”

The zero calibration is finished, and there should be no Err message

appeared.

Span calibration

Input weight calibration value 3000

Input 0110044C0001020BB8EADE ←Input weight calibration value 3000

Put 3kg on the platter

Span calibration

Input 01050424FF00CD01 ←Span calibration

Reading calibration status

Input 0101004100565AC1D ←Refer to “Appendix 3: MODBUS data

address table”

The span calibration is finished, and there should be no Err message

appeared.

Press key

Keep flashing

17

040

1

1210

ZSME

4

00000

00

3

EXCELL PRECISION CO., LTD

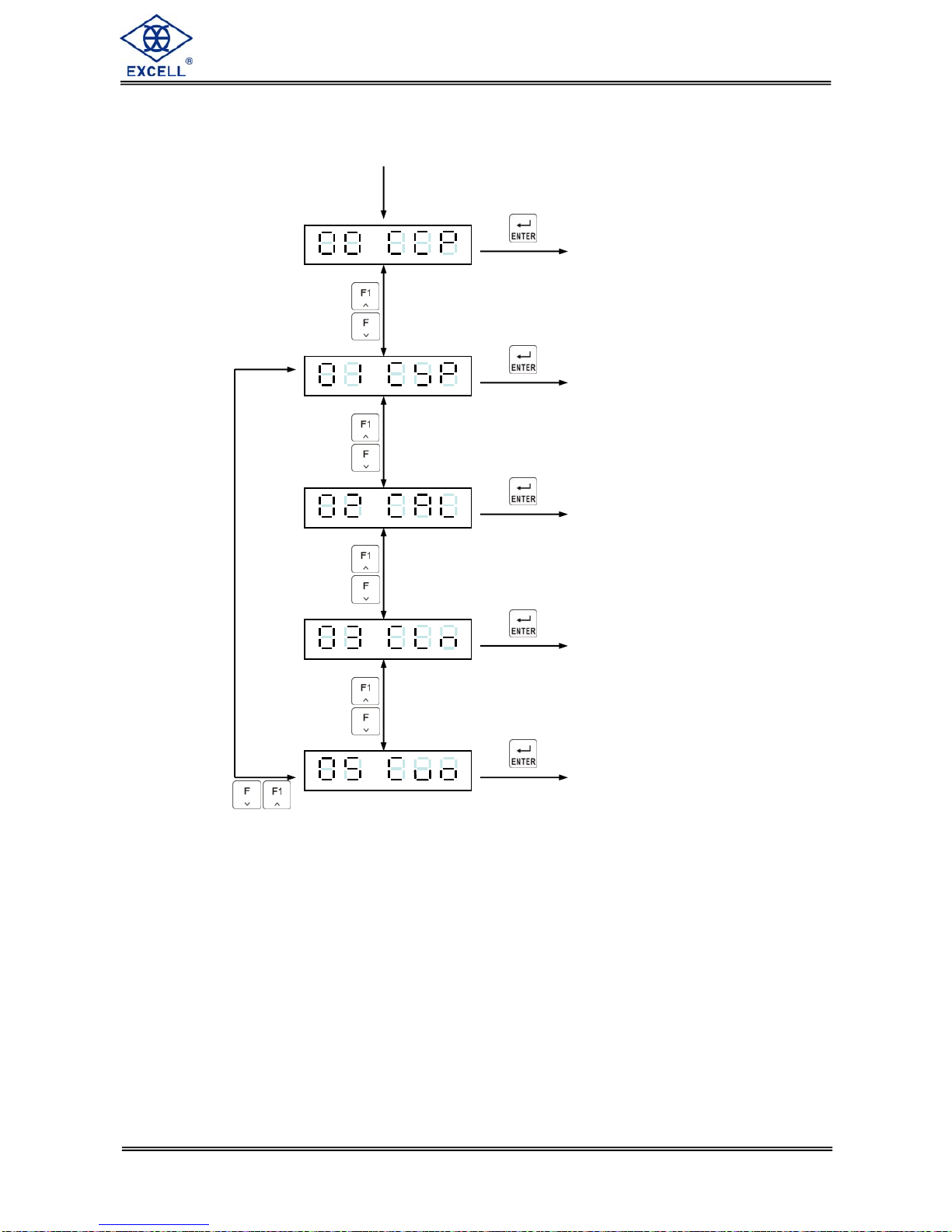

3-4 Specification calibration

Press key

Key in calibration

code

Press key

Display shows the

previous parameter

code. Input the new

code as required

Press key

To continue the next function setting

or press key to escape

⇒Increment flashing digit

⇒Decrement flashing digit

⇒Move flashing point left

⇒Move flashing point right

⇒Store data in memory

⇒Exit / Escape

*Calibration parameter code

⇒Unit

⇒Decimal Point

⇒Min. Division

⇒Max. Capacity

⇒Zero Range

⇒Time of Zero tracking

⇒Range of Zero tracking

⇒Investigate period of unstable

⇒Investigate range of unstable

⇒Function Zero and Tare when the

weight is unstable

⇒Tare function availability when

gross weight is negative

18

040

1

1210

ZSME

4

00000

00

3

EXCELL PRECISION CO., LTD

Setting value

Item Function

Parameter Description

Default

0 None

1 g

2 Kg

3 t

CSP-01 Unit

4 lb

2

0 None

1 1 Decimal Point

2 2 Decimal Point

CSP-02 Decimal

Point

3 3 Decimal Point

0

1

2

5

10

20

CSP-03 Division

50

Division size 1

CSP-04 Max.

Capacity

999999

↓

000000

Max. capacity 999999

CSP-05 Zero range 0 =full range

(±1%~30%)

Zero range = calibration zero point ±(Max.

capacity×setting value %) 0

CSP-06

Time of

zero

tracking

0.0 ~ 5.0

(sec)

Time and range of zero tracking should be

use at the same time. If the time is set to 0.0,

the zero tracking function is disabled

1.0

CSP-07

Range of

zero

tracking

0 ~ 9

Range of zero tracking = (setting value×½)D ,

D=min. division

Range and time of zero tracking should be

use at the same time. If the range is set to 0,

the zero tracking function is disabled

2

CSP-08 Investigate

time in stable

0.0 ~ 5.0

(sec)

Investigate time and range should be use at

the same time. If the time is set to 0.0, the

investigate time is disabled

1.0

CSP-09 Investigate

range in stable 0 ~ 9

Investigate time and range should be use at

the same time. If the range is set to 0, the

investigate range is disabled

2

0 Action

CSP-10

Weight

unstable,

function ZERO

and TARE 1 None

0

0 Action

CSP-11

Gross Weight

is negative,

function TARE 1 None

0

Table of contents

Other Excell Accessories manuals