1. Product information

1.1. Designations used in these instructions..............................................................................................6

1.1.1. Designations used in these instructions..........................................................................................6

1.2. Application.............................................................................................................................................. 6

1.3. Location requirements........................................................................................................................... 6

1.3.1. Space requirements........................................................................................................................7

1.3.2. Requirements for underlying surface.............................................................................................. 7

1.3.3. Condensation outlet........................................................................................................................ 8

1.3.4. Requirements for duct system........................................................................................................ 8

1.4. Description.............................................................................................................................................. 9

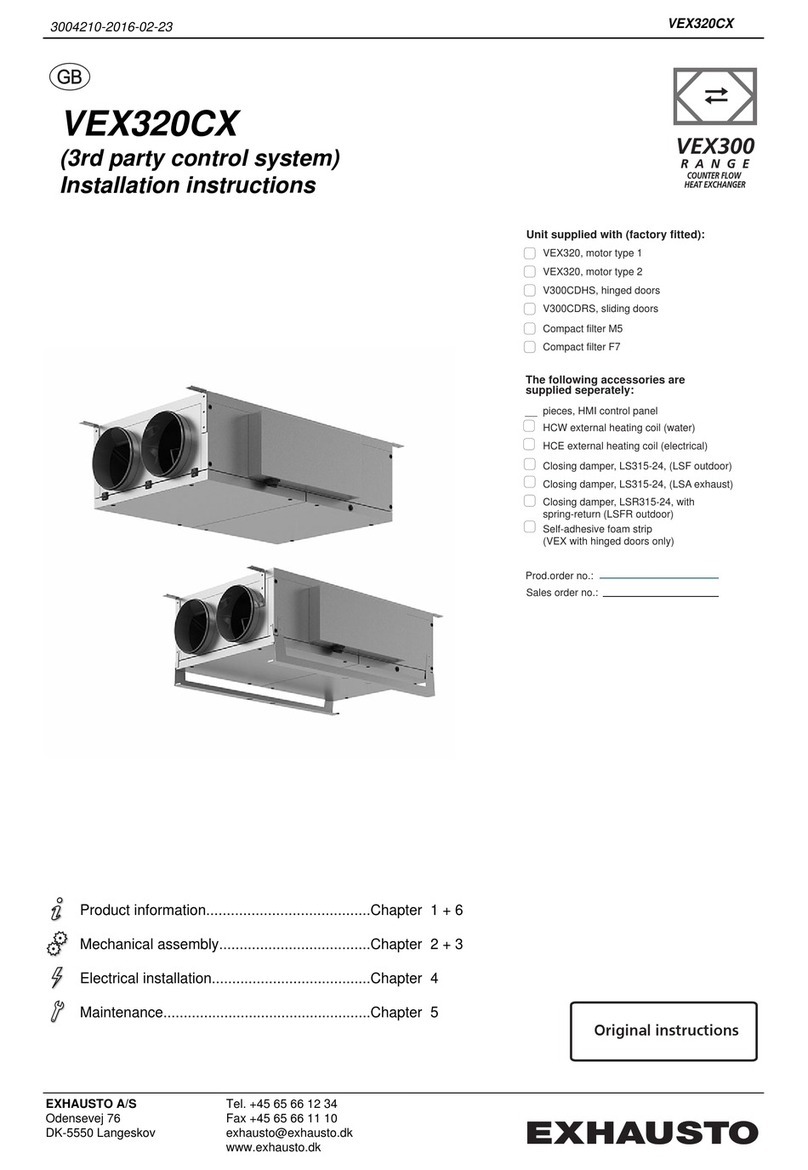

1.4.1. Horizontal VEX - design..................................................................................................................9

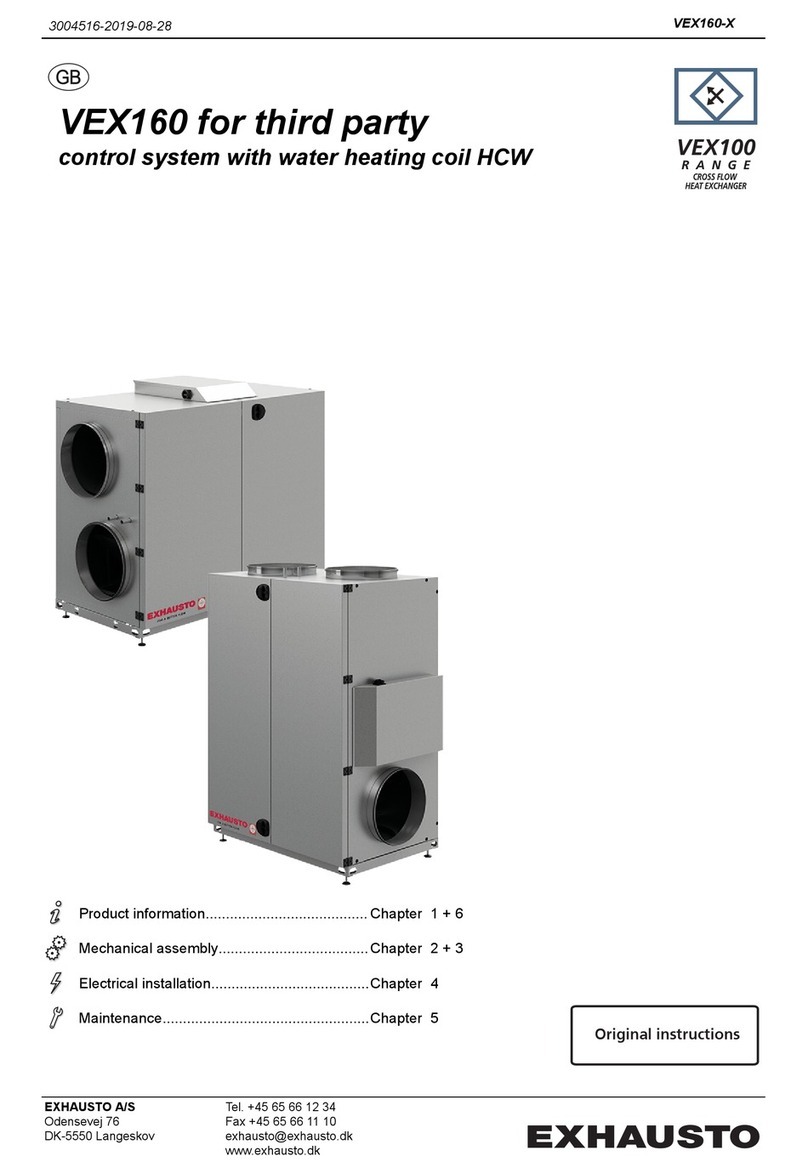

1.4.2. Vertical VEX - design.....................................................................................................................11

1.4.3. Parts of the VEX unit.....................................................................................................................12

1.5. Principal dimensions, Horizontal VEX................................................................................................12

1.6. Principal dimensions, Vertical VEX.....................................................................................................14

2. Handling

2.1. Unpacking............................................................................................................................................. 17

2.2. Transport............................................................................................................................................... 17

2.2.1. Transport of Horizontal air handling units..................................................................................... 17

2.2.2. Transport of Vertical air handling units..........................................................................................18

2.2.3. Passage through openings........................................................................................................... 19

2.2.4. Internal transport with reduced weight.......................................................................................... 20

3. Mechanical assembly

3.1. Installation of Horizontal and Vertical VEX........................................................................................ 24

3.1.1. Installation directly on floor........................................................................................................... 24

3.1.2. Installation on mounting base....................................................................................................... 24

3.2. Condensation outlet............................................................................................................................. 24

3.2.1. Establishment of condensation outlet........................................................................................... 24

3.3. Water heating coil.................................................................................................................................26

3.3.1. Principles for connecting the water heating coil............................................................................26

3.3.2. Bleeding of coils............................................................................................................................27

3.3.3. MVM valve.................................................................................................................................... 28

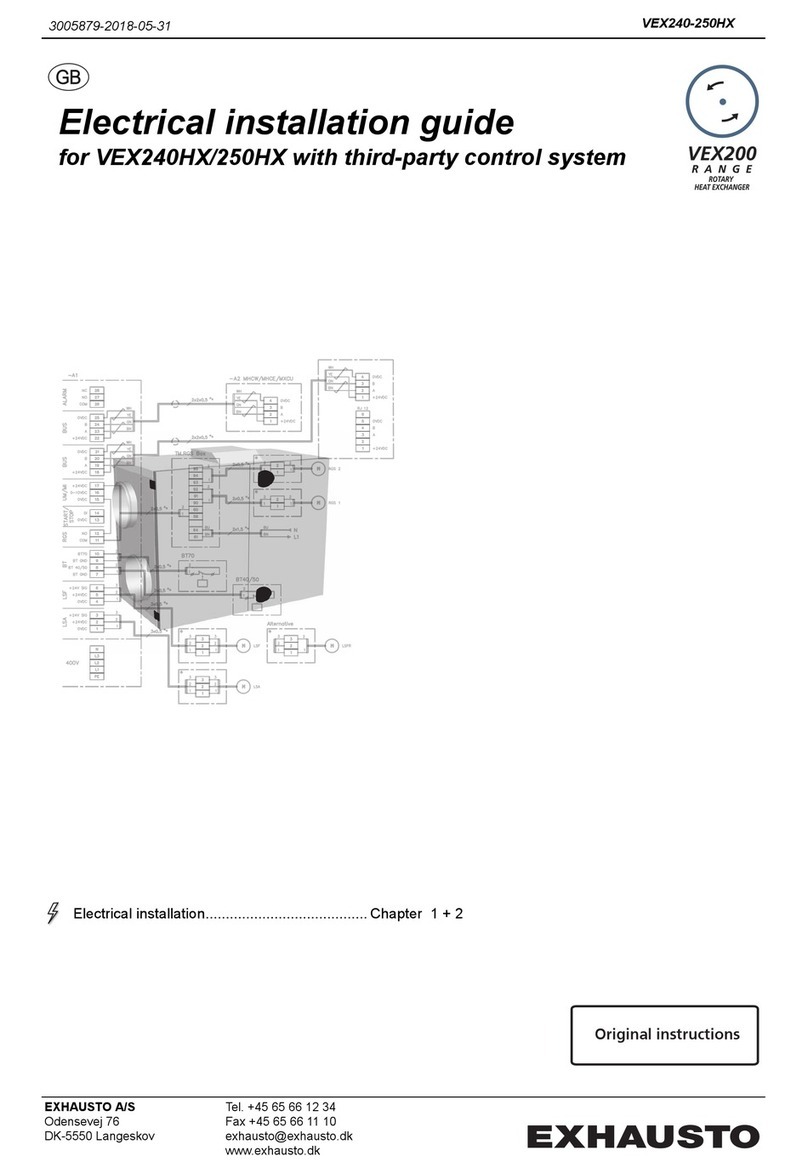

4. Electrical installation

4.1. Electrical installation............................................................................................................................29

5. Maintenance, hygiene and servicing

5.1. Maintenance.......................................................................................................................................... 30

5.1.1. Overview of maintenance intervals............................................................................................... 30

5.2. Hygiene (VEX100VDI only)...................................................................................................................30

5.3. Servicing and cleaning.........................................................................................................................31

5.3.1. Filter replacement......................................................................................................................... 31

5.3.2. Cleaning the fans.......................................................................................................................... 31

5.3.3. Cleaning the heating coils.............................................................................................................31

5.3.4. Removing and cleaning the counterflow heat exchangers........................................................... 31

5.3.5. Cleaning the counterflow heat exchanger.....................................................................................32

5.4. Airflow measurement........................................................................................................................... 33

5.4.1. Determining airflow and pressure................................................................................................. 33

6. Technical data

6.1. Weight, corrosion class, temperature ranges, etc.............................................................................36

6.2. Panel filters........................................................................................................................................... 37

6.3. Water heating system...........................................................................................................................38

6.4. Capacity diagram..................................................................................................................................38

6.5. EC Declaration of Conformity..............................................................................................................38

6.6. Ordering spare parts............................................................................................................................ 38

3005724-2023-03-30

2/40