Digitel MPC Manual Page 2 of 72

I. Contents

I. Introduction......................................................................................................................................... 6

Description.............................................................................................................................................. 6

MPC Configurations........................................................................................................................... 6

RS-232/422/485 Serial Interface......................................................................................................... 6

Set Points ............................................................................................................................................ 6

High Voltage Modules........................................................................................................................ 7

Analog Outputs................................................................................................................................... 7

SAFE-CONN™ High-Voltage interlock............................................................................................ 7

AUTORUN™..................................................................................................................................... 7

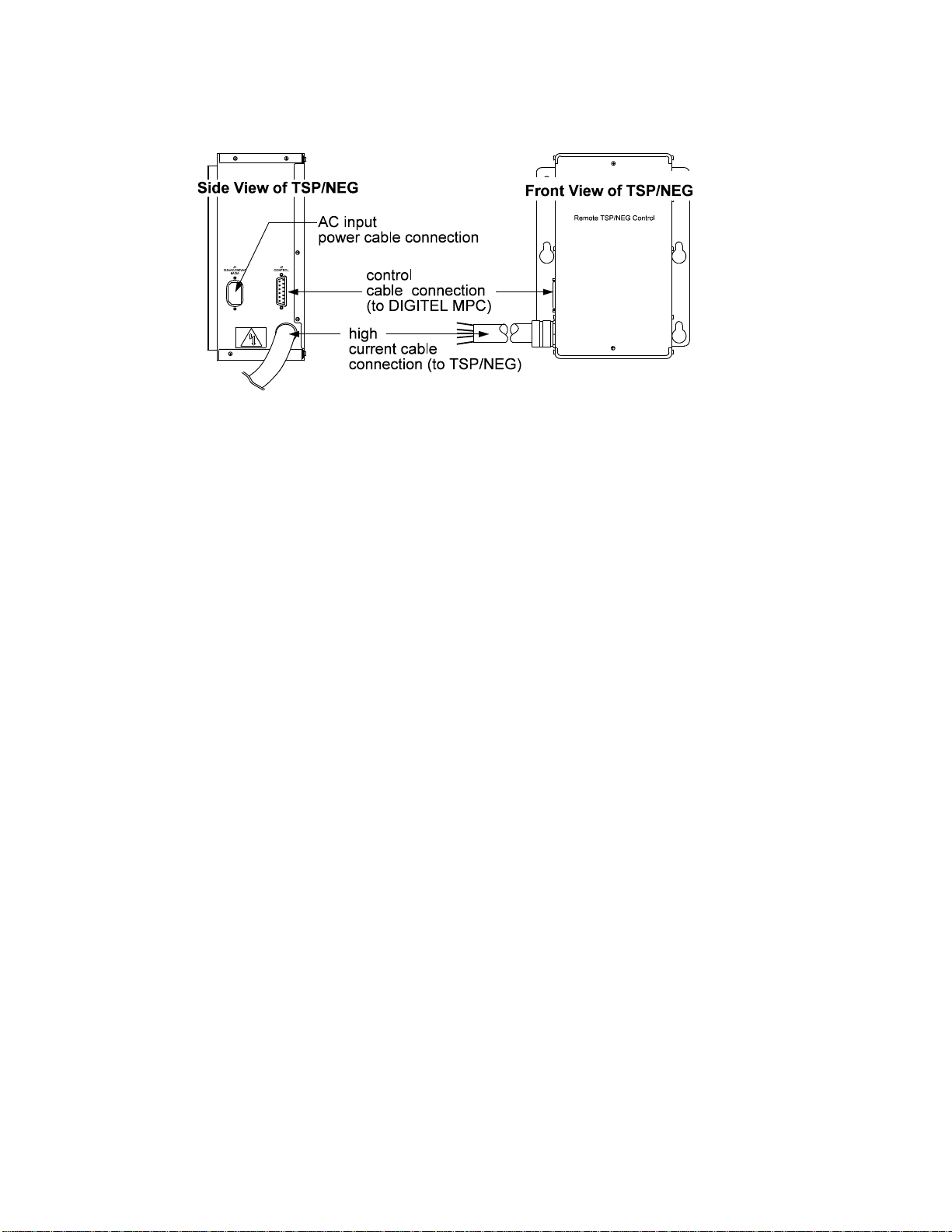

Remote TSP/NEG Control Option...................................................................................................... 7

High-Voltage/TSP Filament Interlock Option.................................................................................... 8

Specifications.......................................................................................................................................... 9

II. Installation......................................................................................................................................... 10

Inspection for Damage.......................................................................................................................... 10

Installing the DIGITEL MPC ............................................................................................................... 10

Required items.................................................................................................................................. 10

Procedure .......................................................................................................................................... 11

Installing the Remote TSP/NEG Control Option.................................................................................. 11

Required Items.................................................................................................................................. 12

Procedure .......................................................................................................................................... 12

SAFE-CONN™ Installation on an Ion Pump....................................................................................... 13

Required Items.................................................................................................................................. 13

Procedure .......................................................................................................................................... 13

III. Operation....................................................................................................................................... 15

Front Panel Description ........................................................................................................................ 15

Rear Panel Description ......................................................................................................................... 17

Operating the Ion Pump........................................................................................................................ 18

To Evacuate the Pump...................................................................................................................... 18

To Start the Pump ............................................................................................................................. 18

Using the Controls ................................................................................................................................ 19

Display Selection.............................................................................................................................. 19

Disable and Enable ........................................................................................................................... 19

Keypad.............................................................................................................................................. 19

Program Mode Keys......................................................................................................................... 21

Menu Key.......................................................................................................................................... 29

Display Messages.................................................................................................................................. 41

Event Log.............................................................................................................................................. 41

General Description.......................................................................................................................... 41

Front Panel Display of Events .......................................................................................................... 42

Serial Port Output of Events............................................................................................................. 42

Analog Outputs..................................................................................................................................... 43

Voltage measuring............................................................................................................................ 43

Current measuring............................................................................................................................. 43

High Voltage/TSP Filament Interlock Option...................................................................................... 44

Serial Interface...................................................................................................................................... 44

Standard ............................................................................................................................................ 44

Specifics............................................................................................................................................ 45

IV. Service........................................................................................................................................... 52