Exlar Curtiss-Wright Tritex II Series Manual

Curtiss-Wright | TRITEX II AC 75 Rev. KPN61928 7/12/2022

1

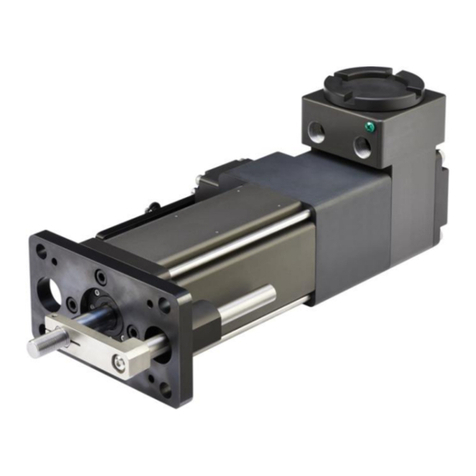

Tritex II®Series Actuators

240VAC Linear and Rotary Actuator

75 mm Frame Size

Installation and Service Manual

Information furnished by Exlar Corporation is believed to be accurate and reliable.

However, no responsibility is assumed by Exlar Corporation for its use. Exlar reserves the

right to change the design and operation of the equipment described herein and any

associated motion products that may appear in this document. Information in this document

pertaining to equipment not furnished by Exlar should be confirmed by that equipment

manufacturer. Exlar assumes no responsibility for changes to information by other

manufacturers or errors in that information or the description of that information. Information

in this document is subject to change without notice.

This document does not contain any export controlled technical data.

Curtiss-Wright | TRITEX II AC 75 Rev. KPN61928 7/12/2022

3

TABLE OF CONTENTS

Safety Considerations ............................................................................... 5

Warnings and Cautions......................................................................... 5

Underwriters Laboratories UL Recognized ........................................... 8

UL Certificate of Compliance ................................................................ 9

CE Declaration of Conformity.............................................................. 11

UK Declaration of Conformity.............................................................. 11

EU Declaration of Conformity.............................................................. 11

CSA Certified Product ......................................................................... 16

General Specifications ............................................................................19

Tritex II Overview ................................................................................ 19

Drive Specification for all Tritex 240 Volt Models................................20

Actuator Selections ............................................................................. 21

Linear Actuator Ordering Guide .......................................................... 22

Rotary Motor and Gearmotor Ordering Guide ....................................22

Mechanical Installation............................................................................24

Mounting and Operating Considerations ............................................24

Lubrication........................................................................................... 24

General Operation...............................................................................25

Mounting Configurations ..................................................................... 25

T2M Series Linear Actuator Anti-rotation Option ................................25

Outdoor and Wash Down Installations................................................ 26

Manual Drive Operating Instructions................................................... 27

Electrical Installation ............................................................................... 29

Introduction.......................................................................................... 29

Cable Entry.......................................................................................... 30

Grounding............................................................................................ 32

Shielding.............................................................................................. 33

AC Input Power ................................................................................... 34

Input Power Ratings ......................................................................34

AC Supplies NOT Requiring Transformers ...................................34

AC Supplies Requiring Transformers............................................37

Single Phase Isolation Transformer connections..........................38

Wire Size, Branch Circuit Protection and Overcurrent Protection....39

Power Terminal Wiring ..................................................................39

Power Connector Wiring ...............................................................41

Over Temperature Protection.............................................................. 41

Brake / Shunt Resistor Considerations ...............................................42

Curtiss-Wright | TRITEX II AC 75 Rev. KPN61928 7/12/2022

4

Logic and IO Power Supply................................................................. 44

Tritex Input and Output Wiring ......................................................46

Input/Output Connections.............................................................. 47

Digital Inputs.................................................................................. 49

Digital Outputs ............................................................................... 50

Actuator Brake Option ...................................................................51

Analog Input ..................................................................................53

Analog Output................................................................................ 54

Communications............................................................................54

PC Communications......................................................................56

IA4 Option board connections .......................................................57

AF Option, Absolute Feedback .....................................................60

Ethernet Options, EIP,TCP or ProfiNet IO .................................... 61

CANopen ....................................................................................... 63

Maintenance Procedures for Re-Greasing .............................................65

Maintenance Procedure for Roller Screw Re-Greasing......................65

Disassembly ..................................................................................65

Lubrication Maintenance ............................................................... 66

Grease Renewal............................................................................67

Reassembly...................................................................................67

Maintenance Procedures for Complete Re-Greasing .........................68

Disassembly ..................................................................................68

Lubrication Maintenance ............................................................... 69

Grease Renewal............................................................................69

Reassembly...................................................................................70

Accessories............................................................................................. 72

Cables ................................................................................................. 72

TTIOC-xxx I/O Cable..................................................................... 72

TTICO-xxx Communications Cable...............................................74

Communication Converter .................................................................. 75

Braking Resistor T2BR1...................................................................... 76

Returning a Product for Repair ...............................................................77

Curtiss-Wright | TRITEX II AC 75 Rev. KPN61928 7/12/2022

5

SAFETY CONSIDERATIONS

Warnings and Cautions

As with any electro-mechanical device, safety must be considered

during the installation and operation of your Tritex Series actuator.

Throughout this manual you will see paragraphs marked with CAUTION

and WARNING signs as shown below:

“WARNING”indicates the information following is essential

to avoiding a safety hazard.

“CAUTION”indicates the information following is necessary

for avoiding a risk of damage to the product or other

equipment.

General

Failure to follow safe installation guidelines can cause death

or serious injury. The voltages used in the product can

cause severe electric shock and/or burns and could be lethal. Extreme

care is necessary at all times when working with or adjacent to the

product. The installation must comply with all relevant safety legislation

in the country of use. The forces created by actuator could be lethal or

cause severe injury if proper protection is not provided to keep personnel

away from moving components.

System Design and safety for personnel

The actuator is intended as a component for professional

incorporation into complete equipment or a system. If

installed incorrectly, the actuator may present a safety hazard. The

actuator uses high voltages and currents, carries a high level of stored

electrical energy, and is used to control equipment which can cause

injury. Close attention is required to the electrical installation and the

system design to avoid hazards either in normal operation or in the event

WARNING

CAUTION

WARNING

WARNING

Curtiss-Wright | TRITEX II AC 75 Rev. KPN61928 7/12/2022

6

of equipment malfunction. System design, installation, commissioning

and maintenance must be carried out by personnel who have the

necessary training and experience. They must read this safety

information and this manual carefully.

None of the functions or features of the Tritex actuator may be

used to ensure safety of personnel, i.e. they must not be used for

safety-related functions.

For example, the actuators enable / disable, brake, stop/start and

forward/reverse functions are not sufficient for use in safety-critical

applications without additional independent channels of protection.

Careful consideration must be given to the functions of the actuator

which might result in a hazard, either through their intended behavior or

through incorrect operation due to a fault. In any application where a

malfunction of the actuator or its control system could lead to or allow

damage, loss or injury, a risk analysis must be carried out, and where

necessary, further measures taken to reduce the risk.- for example a

failsafe brake in case of loss of actuator braking power.

Never attempt to connect or disconnect the actuator

with power applied.

Dangerous voltages are present. Damage to equipment

and injury to personnel can result. Refer to the following warnings on

supply isolation and stored energy discharge time for more information.

Supply isolation

The AC supply or high voltage DC supply must be removed

from the actuator using an approved isolation device or

disconnect before any maintenance is performed except adjustments to

the settings or parameters as specified in the manual.

Risk of Electric Shock

Allow 3 minutes for Discharge Time

The actuator contains capacitors that remain charged to a

potentially lethal voltage for up to 3 minutes after the

supply has been removed. Do not remove cable or cover or touch power

wiring terminals until this discharge time has expired.

WARNING

WARNING

WARNING

3-Minutes

Curtiss-Wright | TRITEX II AC 75 Rev. KPN61928 7/12/2022

7

If connected by plug and socket

A special hazard may exist where the actuator is

incorporated into a system connected to the AC supply by a

plug and socket. The pins of the plug are not generally isolated from the

charge stored in the bus capacitor, so must be considered electrically

“hot” until the discharge time has expired. It is the responsibility of the

user to avoid any possibility of electric shock from the pins when they are

accessible.

Grounding - High Leakage Current

The drive must be grounded by a conductor sufficient to

carry all possible fault current in the event of a fault. This

equipment has high earth leakage current. You must comply with local

safety regulations with respect to minimum size and special installation

requirements on the protective earth conductor for high leakage current

equipment. The instructions for ground connections shown in this manual

must be followed.

Compatibility with Residual Current-operated

Protection Device (RCD)

This product can cause a DC current in the protective

earthing conductor. Where a residual current –operated protective (RCD)

or monitoring (RCM) device is used for protection in case of direct or

indirect contact, only an RCD or RCM of Type B is allowed on the supply

side of this product.

Hot Surface – Risk of Burn

Exposed surfaces of the actuator may exceed 70°C under

normal operation and can take a long time to cool,

resulting in a risk of burns when touched.

WARNING

WARNING

CAUTION

WARNING

Curtiss-Wright | TRITEX II AC 75 Rev. KPN61928 7/12/2022

8

Underwriters Laboratories UL Recognized

Tritex II 75 mm Linear and Rotary Actuators are marked “UL

Recognized” after passing a rigorous set of design and testing criteria

developed by Underwriters Laboratories UL 508C, UL 1004-1,

UL 1004-3 and UL 1004 -7. This UL logo indicates that UL certifies this

product to be safe when installed according to the installation instructions

and used in accordance with the product specifications and the following

conditions of acceptability:

The conditions of acceptability required by UL are:

•Drive input maximum continuous operating ratings:

Input Voltage (all models): 240 VAC, 1 Ф, 50/60 Hz

Drive/Motor Model

Stator

Input Continuous

Current (Arms)

T2M/R2M/R2G 075

1 Stack Stator

4.3

T2M/R2M/R2G 075

2 Stack Stator

4.0

T2M/R2M/R2G 075

3 Stack Stator

3.6

•Above full load ratings are at a maximum surrounding air

temperature of 40°C.

•Suitable for use on a circuit capable of delivering not more than

10,000 rms symmetrical amperes, 240 Volts maximum when

protected by Class CC or Class RK1 fuses, or when protected by a

circuit breaker having an interrupting rating.

•Integral solid state short circuit protection does not provide branch

circuit protection. Branch circuit protection must be provided in

accordance with the National Electrical Code and any additional local

codes.

•Use 14 AWG wire with insulation rated for 105°C input power and PE

terminals.

•Multiple connection options covered in the model mask

nomenclature in the report.

UL Recognized

UL File E353255

Curtiss-Wright | TRITEX II AC 75 Rev. KPN61928 7/12/2022

9

UL Certificate of Compliance

Curtiss-Wright | TRITEX II AC 75 Rev. KPN61928 7/12/2022

10

Curtiss-Wright | TRITEX II AC 75 Rev. KPN61928 7/12/2022

11

CE Declaration of Conformity

The Tritex II 75 mm Linear and Rotary Actuators are marked with the

“Conformité Européenne Mark” (CE Mark) after passing a rigorous set of

design and testing criteria. This label indicates the product meets

applicable electrical safety, and electromagnetic immunity and emissions

(EMC) standards when installed according to the installation instructions.

The conditions of acceptability required for CE are:

•Drive input maximum continuous operating ratings:

Input Voltage (all models): 240 VAC, 1 Ф, 50/60 Hz

Drive/Motor Model

Stator

Input Continuous

Current (Arms)

T2M/R2M/R2G 075

1 Stack Stator

4.3

T2M/R2M/R2G 075

2 Stack Stator

4.0

T2M/R2M/R2G 075

3 Stack Stator

3.6

•Above full load ratings are at a maximum surrounding air

temperature of 40°C.

•Field installation power connection wires: Use 2.5mm², 300 VAC

minimum rating, and 105º C minimum rating copper wires.

•Two externally connected ground wires must be used and connected

to protective earth ground (PE). Note: two PE connection terminals

are provided since touch is greater than 3.5mA. This wire is required

to be no less 2.5mm² since mechanical protection of is provided via

hard conduit or a cable assembly.

•This product is suitable for use on a circuit capable of delivering up

to 10,000 rms symmetrical amperes, 240 volts maximum, when

protected with by a Class RK1 or Class CC fuse or Inverse Time

Circuit Breaker, rated at 15 Arms.

•All cables must be shielded, with the outer shield bonded to

the case.

•When using cable glands use glands that connect the braided shield

of the cable directly to enclosure.

•When using connectors ensure that the outer shield of the cable is in

full contact with the connector housing. Connector housings must

conductive.

Curtiss-Wright | TRITEX II AC 75 Rev. KPN61928 7/12/2022

12

•Make ground connections as short as possible for low impedance.

•Keep cable runs as short as possible. Power and signal cables must

be separated and far as possible and only crossing them at right

angles as described in the Cable routing section of this manual.

•IP 66 rating:

•To maintain IP ratings, the RS485 cable or cap must be installed. All

other cable connections must be connected or sealed.

Curtiss-Wright | TRITEX II AC 75 Rev. KPN61928 7/12/2022

13

Curtiss-Wright | TRITEX II AC 75 Rev. KPN61928 7/12/2022

14

Curtiss-Wright | TRITEX II AC 75 Rev. KPN61928 7/12/2022

15

Per EU directives implemented on April 20th, 2016 the following requirement for

requirement must be followed by Importers and Distributors.

The requirements for importers include:

Importers shall indicate their name, registered trade name or registered trade mark and the

postal address at which they can be contacted on the apparatus (unless that is not

possible, in which case it should be included on the packaging or in an accompanying

document).

Importers shall ensure that the product is accompanied by instructions and safety

information in a language which can be easily understood by end-users, as determined by

the Member State concerned.

Importer is to translate the EU declaration of conformity into the languages required by the

member state(s), where the product is sold.” Importers shall keep a copy of the EU

declaration of conformity (for 10 years).

Importers shall provide a reasoned request from a competent national authority and provide

it with all the information and documentation in paper or electronic form necessary to

demonstrate the conformity of a product in a language which can be easily understood by

that authority.

Importers shall ensure that, while apparatus is under their responsibility, its storage or

transport conditions do not jeopardize its compliance with the safety objectives.

Importer shall corrective action necessary when they consider or have reason to believe

that the product is not in conformity with its directive(s).

The requirements for distributor include:

Distributors shall indicate their name, registered trade name or registered trade mark and

the postal address at which they can be contacted on the apparatus (unless that is not

possible, in which case it should be included on the packaging or in an accompanying

document).

Distributor shall ensure that apparatus is accompanied by instructions and safety

information in an appropriate language. Distributor shall translate the EU declaration of

conformity into the languages required by the member state(s), where the product is sold.”

Distributors shall keep a copy of the EU declaration of conformity (for 10 years).

Distributor shall ensure that, while apparatus is under their responsibility, its storage or

transport conditions do not jeopardize its compliance with the safety objectives.

Distributor shall corrective action necessary when they consider or have reason to believe

that the product is not in conformity with its directive(s).

Curtiss-Wright | TRITEX II AC 75 Rev. KPN61928 7/12/2022

16

CSA Certified Product

The Tritex II 75 mm Linear and Rotary Actuators are marked as shown

after passing a rigorous set of design and testing criteria developed by

CSA International (C22.2 No. 139) and Underwriters Laboratories

(UL 429). This label indicates that CSA certifies this product to be safe

when installed according to the installation guidelines and used with the

scope of the product specifications.

The conditions of acceptability required by CSA are:

•Drive input maximum continuous operating ratings

Input Voltage (all models): 240 VAC, 1 Ф, 50/60 Hz

Drive/Motor Model

Stator

Input

Continuous

Current (Arms)

Torque Rating

max.

T2M/R2M/R2G 075

1 Stack

Stator

4.3

12.0 lbf-in

T2M/R2M/R2G 075

2 Stack

Stator

4.0

22.0 lbf-in

T2M/R2M/R2G 075

3 Stack

Stator

3.6

30.0 lbf-in

•Installation Requirements

- Hazardous Location (Class I Division 2 Group A, B, C, D)

installations – ½” rigid conduit with NPT connections and use

UL approved copper only wires, 14 AWG, 300 VAC minimum

rating, and 105º C minimum rating shall be used.

- For other non-hazardous locations:

• Use the above connection method, or

• Cable with connector assemblies, or

• Cables with cable glands are permitted.

For additional information on cable installations or part numbers

contact Exlar Corporation.

•Branch circuit protection must be provided. Reference the

manual’s electrical installation section for fuse and circuit breaker

options. Note: branch circuit protection must be located outside

of the hazardous location environment,

•The full load ratings are at 40°C ambient temperature and

ratings are derated linearly from 40°C to 65°C.

•These conditions of acceptability only apply to units with a CSA

mark on the product label.

Curtiss-Wright | TRITEX II AC 75 Rev. KPN61928 7/12/2022

17

Curtiss-Wright | TRITEX II AC 75 Rev. KPN61928 7/12/2022

18

Curtiss-Wright | TRITEX II AC 75 Rev. KPN61928 7/12/2022

19

General Specifications

Tritex II Overview

Tritex II is Exlar’s advanced family of integrated drives. This manual

applies to 75 mm frame size only with 240VAC input power. All of the

required power components and motion processor are contained in the

actuator housing.

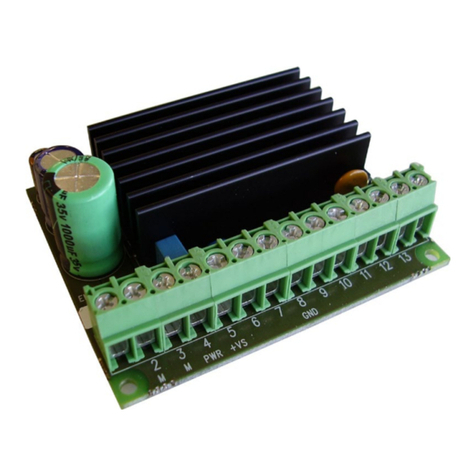

Basic Block Diagram with SIO Option

Table of contents

Other Exlar Controllers manuals

Popular Controllers manuals by other brands

Johnson Controls

Johnson Controls Penn P216 Series installation instructions

BENDIX

BENDIX ULTIMATE TOW Installation & operating instructions

MOTECK

MOTECK CIS3 user guide

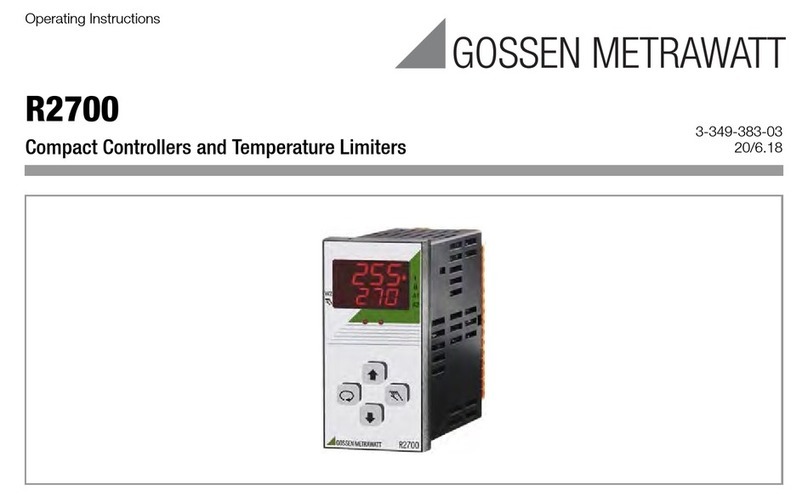

Gossen MetraWatt

Gossen MetraWatt R2700 operating instructions

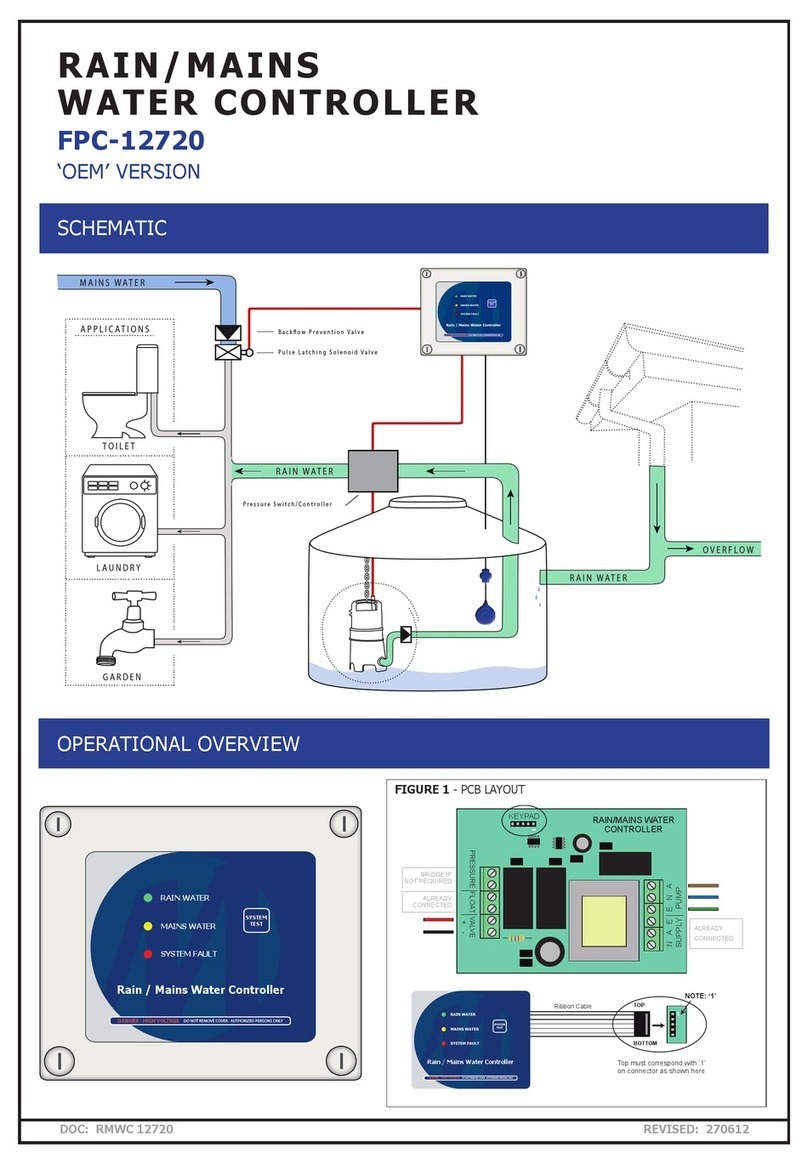

Matelec

Matelec FPC-12720 quick start guide

Hunter

Hunter Pro-C Product information