Exlar Tritex II DC Series Manual

Curtiss-Wright | Tritex II DC Rev. J PN49220 2/8/2016

1

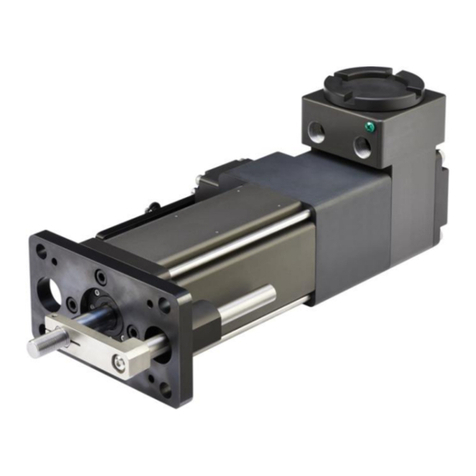

Tritex II™DC Series Actuators

Models TDM/TDX 060 & 075, RDM/RDG 060, 075 & 090

48 VDC Linear and Rotary Actuator

Installation and Service Manual

Information furnished by Exlar Corporation is believed to be accurate and reliable.

However, no responsibility is assumed by Exlar Corporation for its use. Exlar reserves the

right to change the design and operation of the equipment described herein and any

associated motion products that may appear in this document. Information in this document

pertaining to equipment not furnished by Exlar should be confirmed by that equipment

manufacturer. Exlar assumes no responsibility for changes to information by other

manufacturers or errors in that information or the description of that information. Information

in this document is subject to change without notice.

This document does not contain any export controlled technical data.

Curtiss-Wright | Tritex II DC Rev. J PN49220 2/8/2016

2

Warranty and Limitation of Liability

Products are warranted for two years from date of manufacture as determined by the

serial number on the product label. Labels are generated and applied to the product at the

time of shipment. The first and second digits are the year and the third and fourth digits

represent the manufacturing week. Product repairs are warranted for 90 days from the date

of the repair. The date of repair is recorded within Exlar’s database tracked by individual

product serial number.

Exlar Corporation warrants its product(s) to the original purchaser and in the case of

original equipment manufacturers, to their original customer to be free from defects in

material and workmanship and to be made only in accordance with Exlar's standard

published catalog specifications for the product(s) as published at the time of

purchase. Warranty or performance to any other specifications is not covered by this

warranty unless otherwise agreed to in writing by Exlar and documented as part of any and

all contracts, including but not limited to purchase orders, sales orders, order confirmations,

purchase contracts and purchase agreements. In no event shall Exlar be liable or have any

responsibility under such warranty if the product(s) has been improperly stored, installed,

used or maintained, or if Buyer has permitted any unauthorized modifications, adjustments

and/or repairs to such product(s). Seller's obligation hereunder is limited solely to repairing

or replacing (at its opinion), at the factory any product(s), or parts thereof, which prove to

Seller's satisfaction to be defective as a result of defective materials, or workmanship and

within the period of time, in accordance with the Seller's stated product warranty (see

Terms and Conditions above), provided, however, that written notice of claimed defects

shall have been given to Exlar within thirty (30) days from the date of any such defect is

first discovered. The product(s) claimed to be defective must be returned to Exlar,

transportation prepaid by Buyer, with written specification of the claimed defect. Evidence

acceptable to Exlar must be furnished that the claimed defects were not caused by misuse,

abuse, or neglect by anyone other than Exlar.

Components such as seals, wipers, bearings, brakes, bushings, gears, splines, and

roller screw parts are considered wear parts and must be inspected and serviced on a

regular basis. Any damage caused by failure to properly lubricate Exlar products and/or to

replace wear parts at appropriate times, is not covered by this warranty. Any damage due

to excessive loading is not covered by this warranty.

The use of products or components under load such that they reach the end of their

expected life is a normal characteristic of the application of mechanical products. Reaching

the end of a product’s expected life does not indicate any defect in material or workmanship

and is not covered by this warranty.

Costs for shipment of units returned to the factory for warranty repairs are the

responsibility of the owner of the product. Exlar will return ship all warranty repairs or

replacements via UPS Ground at no cost to the customer.

For international customers, Exlar will return ship warranty repairs or replacements via

UPS Expedited Service and cover the associated shipping costs. Any VAT or local country

taxes are the responsibility of the owner of the product.

The foregoing warranty is in lieu of all other warranties (except as Title), whether

expressed or implied, including without limitation, any warranty of merchantability, or of

fitness for any particular purpose, other than as expressly set forth and to the extent

specified herein, and is in lieu of all other obligations or liabilities on the part of Exlar.

Seller's maximum liability with respect to these terms and conditions and any resulting

sale, arising from any cause whatsoever, including without limitation, breach of contract or

negligence, shall not exceed the price specified herein of the product(s) giving rise to the

claim, and in no event shall Exlar be liable under this warranty otherwise for special,

incidental or consequential damages, whether similar or dissimilar, of any nature arising or

resulting from the purchase, installation, removal, repair, operation, use or breakdown of

the product(s) or any other cause whatsoever, including negligence.

The foregoing warranty shall also apply to products or parts which have been repaired

or replaced pursuant to such warranty, and within the period of time, in accordance with

Seller's stated warranty.

NO PERSON, INCLUDING ANY AGENT OR REPRESENTATIVE OF EXLAR, IS

AUTHORIZED TO MAKE ANY REPRESENTATION OR WARRANTY ON BEHALF OF

EXLAR CONCERNING ANY PRODUCTS MANUFACTURED BY EXLAR, EXCEPT TO

REFER PURCHASERS TO THIS WARRANTY.

Curtiss-Wright | Tritex II DC Rev. J PN49220 2/8/2016

3

TABLE OF CONTENTS

SAFETY CONSIDERATIONS.............................................................................. 4

CSA Certified Product....................................................................................... 7

EU Declaration of Conformity for CE Mark ....................................................... 9

TRITEX™ PRODUCT OVERVIEW.................................................................... 11

System overview, shown with SIO / Ethernet Option Board ........................... 12

Tritex Configurations....................................................................................... 12

60mm frame, top exiting connections, shown with 90 deg, M23 connectors .. 13

General Specifications.................................................................................... 14

INSTALLATION................................................................................................. 15

Mechanical Installation.................................................................................... 15

Lubrication ........................................................................................15

Mounting Configurations.....................................................................15

Mounting and Operating Considerations...............................................15

Outdoor and Wash Down Installations............................................................ 16

Manual Drive Operating Instructions............................................................... 17

Electrical Installation....................................................................................... 24

Introduction .......................................................................................24

Main Power Supply Selection..............................................................24

Unregulated AC/DC Power Supplies....................................................25

Regulated AC/DC Power Supplies.......................................................25

Power from Battery Systems...............................................................27

Handling Regen Energy –Internal Shunt Resistor and Regulator ...........27

Handling Regen Energy –External Shunt Resistor and Regulator ..........28

Logic Power Supply ...........................................................................28

Shielding...........................................................................................31

NPT Connections...............................................................................31

Grounding.........................................................................................32

Power Supply Connections.................................................................33

Tritex Input and Output Wiring.............................................................35

Input/Output Connections ...................................................................36

CANopen..........................................................................................37

I/O Power Supply...............................................................................38

Two Power Supply Configuration.........................................................38

Single Power Supply Configuration......................................................38

Digital Inputs .....................................................................................39

Digital Outputs...................................................................................40

Actuator Brake Option ........................................................................41

Analog Input......................................................................................42

Analog Output ...................................................................................43

Communications................................................................................43

PC Communications...........................................................................44

IA4 Option board connections .............................................................46

AF Option, Absolute Feedback............................................................49

Ethernet Options, EIP,TCP or ProfiNet.................................................50

EMC Considerations ..........................................................................52

Curtiss-Wright | Tritex II DC Rev. J PN49220 2/8/2016

4

TROUBLESHOOTING PROCEDURES............................................................. 54

MAINTENANCE................................................................................................. 55

Procedures for Roller Screw Re-Greasing...................................................... 55

Lubrication Maintenance.....................................................................56

Grease Renewal................................................................................56

Reassembly ......................................................................................57

Procedures for Complete Re-Greasing........................................................... 58

Disassembly......................................................................................58

Lubrication Maintenance.....................................................................59

Grease Renewal................................................................................59

Reassembly ......................................................................................60

ACCESSORIES ................................................................................................. 62

Cables............................................................................................................. 62

TTIOC-xxx I/O Cable..........................................................................62

TTIPC-xxx Power Cable .....................................................................63

TTICO-xxx Communications Cable......................................................63

Communication Converters....................................................................... 65

Power Supply.................................................................................................. 65

TTPS1048 Power Supply Introduction..................................................65

Shunt Regulator.............................................................................................. 67

TTSR1 Shunt Regulator Option...........................................................67

Power Distribution and Surge Filter ................................................................ 69

TDCESF1 Power Distribution and Surge Filter Accessory......................69

SAFETY CONSIDERATIONS

As with any electro-mechanical device, safety must be considered

during the installation and operation of your Tritex Series actuator.

Throughout this manual you will see paragraphs marked with CAUTION

and WARNING signs as shown below

“Warning” indicates the information following is essential

to avoiding a safety hazard.

“Caution” indicates the information following is necessary

for avoiding a risk of damage to the product or other

equipment.

General

Failure to follow safe installation guidelines can cause

death or serious injury. The voltages used in the product

_____________________________

WARNING

CAUTION

_____________________________

WARNING

Curtiss-Wright | Tritex II DC Rev. J PN49220 2/8/2016

5

can cause severe electric shock and/or burns and could be lethal.

Extreme care is necessary at all times when working with or adjacent to

the product. The installation must comply with all relevant safety

legislation in the country of use. The forces created by actuator could be

lethal or cause severe injury if proper protection is not provided to keep

personnel away from moving components.

System Design and safety for personnel

The actuator is intended as a component for professional

incorporation into complete equipment or a system.

If installed incorrectly, the actuator may present a

safety hazard.

The actuator uses high voltages and currents, carries a high level of

stored electrical energy, and is used to control equipment which can

cause injury. Close attention is required to the electrical installation and

the system design to avoid hazards either in normal operation or in the

event of equipment malfunction. System design, installation,

commissioning, and maintenance must be carried out by personnel who

have the necessary training and experience. They must read this safety

information and this manual carefully.

None of the functions or features of the Tritex actuator may be

used to ensure safety of personnel, i.e. they must not be used for

safety-related functions. For example the actuators enable / disable,

brake, stop/start and forward/reverse functions are not sufficient for use

in safety-critical applications without additional independent channels of

protection. Careful consideration must be given to the functions of the

actuator which might result in a hazard, either through their intended

behavior or through incorrect operation due to a fault. In any application

where a malfunction of the actuator or its control system could lead to or

allow damage, loss or injury, a risk analysis must be carried out, and

where necessary, further measures taken to reduce the risk.- for

example a failsafe brake in case of loss of actuator braking power.

Never attempt to connect or disconnect the actuator

with power applied.

Dangerous voltages may be present. Damage to

equipment and injury to personnel can result. Many

amplifiers have voltage present for a considerable time period after

incoming power is removed. Take care to insure that the amplifier has

discharged all power.

WARNING

WARNING

Curtiss-Wright | Tritex II DC Rev. J PN49220 2/8/2016

6

Supply isolation

The AC supply or high voltage DC supply must be

removed from the actuator using an approved isolation

device or disconnect before any servicing work is

performed, other than adjustments to the settings or parameters

specified in the manual. The actuator contains capacitors which remain

charged to a potentially lethal voltage after the supply has been

removed.

If connected by plug and socket

A special hazard may exist where the actuator is

incorporated into a system which is connected to the AC

supply by a plug and socket. When unplugged, the pins of

the plug may be connected to the drive input, which is only separated

from the charge stored in the bus capacitor. It is the responsibility of the

user to avoid any possibility of electric shock from the pins, if they are

accessible.

Grounding - High Leakage Current

In the event of a fault, this equipment has high earth

leakage current. You must comply with local safety

regulations with respect to minimum size and special

installation requirements on the protective earth conductor for high

leakage current equipment. The ground connections shown in this

manual must be followed.

Fuses and Branch circuit protection

“The Integral solid state short circuit protection does not

provide branch circuit protection. Branch circuit protection

must be provided in accordance with the National

Electrical Code and any additional local codes”, or equivalent. Fuses or

over-current protection must be provided at the input in accordance with

the instructions in the manual.

CAUTION –Hot Surface –Risk of Burn.

WARNING

WARNING

WARNING

WARNING

CAUTION

Curtiss-Wright | Tritex II DC Rev. J PN49220 2/8/2016

7

CSA Certified Product

The Tritex II DC Linear and Rotary Actuators are marked

as shown after passing a rigorous set of design and testing

criteria developed by CSA International (C22.2 No. 139).

This label indicates that CSA certifies this product to be

safe when installed according to the installation guidelines and used with

the scope of the product specifications.

The conditions of acceptability required by CSA are:

The drive voltage rating range and maximum current operating rating:

Voltage

Current (Adc)

12-24 Vdc

18.0A max.

Installation Requirements

- Hazardous Location (Class I Division 2 Group A, B, C, D)

installations –½” rigid conduit with NPT connections must be used.

- For NPT connections the power wires must be UL approved copper

only wires, 12 AWG, 300 VAC minimum rating, and 105º C

minimum rating..

- For other non-hazardous installations:

•Use the above connection method, or

•Cable with connector assemblies, or

•Cables with cable glands are permitted.

- When an AC to DC power supply is used to supply main power then

the power supply must be agency approved and provided with its

own enclosure.

- If a customer requires an additional +24 VDC power supply to

provide power to the Digital I/O, 4-20 mA I/O, or the Analog Input

then it must be a recognized or listed Class 2 Power Supply.

- The full ratings are at 40C ambient temperature. Derate the input

current linearly above the 40°C ambient temperature to 14.0Adc at

maximum ambient temperature of 65°C.

- These conditions of acceptability only apply to units with a CSA

mark on the product label.

For additional information on cable installations or part numbers contact

Exlar.

Curtiss-Wright | Tritex II DC Rev. J PN49220 2/8/2016

8

Curtiss-Wright | Tritex II DC Rev. J PN49220 2/8/2016

9

Curtiss-Wright | Tritex II DC Rev. J PN49220 2/8/2016

10

EU Declaration of Conformity for CE Mark

Curtiss-Wright | Tritex II DC Rev. J PN49220 2/8/2016

11

TRITEX™ PRODUCT OVERVIEW

The Exlar Tritex Series of electric actuators combines an integrated

brushless servo motor, amplifier and motion controller. Optionally the

system can be configured for remote mounting of the amplifier and

motion control

Integrated actuator, servo motor, amplifier and motion control

*Note: 48V (Nominal) for full speed (except CSA certified installations).

24V and 12V (Nominal) will result in reduced speeds.

The Tritex actuators are available in linear and rotary versions with

integrated amplifier and motion control.

Frame

Size

Linear

Rotary

Motor

Rotary

Gearmotor

Std.

Capacity

High

Capacity

60 mm

TDM060

TDX060

RDM060

RDG060

75 mm

TDM075

TDX075

RDM075

RDG075

90 mm

NA

NA

RDM090

RDG090

All of the required power components and motion processor are

contained in the actuator housing.

12–48V* DC

Power Supply

I/O

Digital and Analog I/O

Connections

RS485

Communication

Port

Ethernet

Communication

Port

(Optional)

Curtiss-Wright | Tritex II DC Rev. J PN49220 2/8/2016

12

System Overview, Shown with SIO / Ethernet Option Board

Tritex Configurations

The models TDM, TDX, RDM & RDG include the drive and motion

controller integrated into the rear of the actuator. Various power and I/O

connections are available. 60 mm frame sizes have top exiting 90 degree

M23 connectors (shown below), or embedded leads connection options.

75mm and 90mm frame sizes have rear exiting connectors and a top

access cover for field wiring. Connector option include straight M23

connectors (shown below), NPT or M20 threaded holes or embedded

leads. Customized connection options are also available. See ordering

section for model mask information.

Curtiss-Wright | Tritex II DC Rev. J PN49220 2/8/2016

13

60 mm Frame, Top Exiting Connections, Shown with 90 Degree,

M23 Connectors

75 & 90 mm Frame, Rear Exiting Connectors, Shown with M23 Connectors

M23 I/O connector

Communications

Connector

Ethernet

(Optional)

M23 Power

connector

M23 Power

connector

Communications

Connector

Ethernet

(Optional)

M23 I/O

connector

Field wiring access

Curtiss-Wright | Tritex II DC Rev. J PN49220 2/8/2016

14

General Specifications

Drive Specification for all Tritex II DC Models with embedded drives

Embedded Drive Specifications

Input Voltage,

Bus and Logic

12-24VDC nominal for CSA certified installation

12-48VDC nominal for general use

Internal logic remains active with Bus or Logic power at 9V min

I/O Power

Supply

12-24V nominal, 30V max, 9V min

Models with brakes require 24V +/- 10% for brake operation

SIO & Ethernet

Options

IA4 Option

Details

Digital Inputs,

8

4

Opto-isolated,

0-5V or 0-2mA OFF,

8-30V or >3mA ON,

programmable functions

Digital Outputs,

4

3

Opto-isolated,

1V max ON state voltage drop,

100mA max continuous load,

short circuit & overload protect,

programmable functions

Analog Input,

+/-10V,

differential

input 13 bit

resolution

Isolated 4-20 mA,

with >14 bit

resolution,

ext power, 12V

max drop @

22mA

Programmable as position,

velocity or torque command

Analog Output,

0-10V, 11 bit

resolution

Isolated 4-20 mA

12 bit resolution,

ext power, 8V lift-

off @ 21mA

Programmable functions

Serial Interface

RS485, Modbus RTU protocol, max baud rate 38.4k, Isolated

Commutation

Sinusoidal, 10kHz PWM

Resolution

(Std. Feedback)

0.001 revolution

Accuracy

(Std. Feedback)

+ / - 0.002 revolution

Output Current

Continuous and peak output current is dependent on actuator

Environmental

Ambient Temperature for rated output: 40°C

Maximum Operating Temperature Range:

0°-65°C with power de-rating

Humidity: 10-95% non-condensing

Altitude: 3000 m above sea level maximum

Curtiss-Wright | Tritex II DC Rev. J PN49220 2/8/2016

15

INSTALLATION

Mechanical Installation

Lubrication

The TDM / TDX Series actuators are shipped from the factory fully

greased and ready for installation. Exlar recommends using Mobilith

SHC 220, a high performance, extreme-pressure grease. The unique

physical properties of the synthetic base oil provide outstanding

protection against wear, rust, corrosion and high or low-temperature

degradation. Mobilith SHC allows for very low starting and running torque

values. Its operating range is -40° C to 177° C (-40° F to 350° F).

However, in installation below 0° C is stiffer using some of the motors

available torque, for cold temperature operation contact Exlar Application

Engineer for lubrication options. See Maintenance section for detail on

disassembly for greasing.

Mounting Configurations

The standard configurations available are Rear Clevis, Side Mount,

Side Trunnion and Front Flange (See Model Mask and ordering guide

in Overview section). General drawings are shown in the product

section guide.

Mounting and Operating Considerations

Every effort should be made to minimize misalignment. Any

misalignment will decrease the life of the components within the actuator

and also may create problems within the application associated with

misalignment.

Excessive side load on the output rod of the actuator will

dramatically reduce the life of the actuator and should be

avoided completely. Side load can be caused from misalignment or

loading that is not in line with the actuator output rod.

Care should be taken not to exceed the physical travel

limits of TDM Series Actuators. Doing so will cause the

actuator to end-crash internally. End crashes can physically

damage the roller screw and the internal components of the

actuator.

Curtiss-Wright | Tritex II DC Rev. J PN49220 2/8/2016

16

Outdoor and Wash Down Installations.

Tritex ratings: The TDM/X, RDM/G actuators have been tested to IP

66. Tritex actuators are not intended for applications where the actuator

could possibly be submerged.

1. Avoid rod/shaft up installations if possible; if not possible, make

external provisions to keep rod/shaft exposure to water to a

minimum. When new, the seals are effective to IP 66 or better.

However over time, depending on the amount of side load, they

can wear and eventually allow moisture to ingress. Contact Exlar

application engineering for special options.

2. With the NPT connection option use thread sealant or Teflon tape

on the connector/conduit threads.

3. If straight metric conduit connection is used verify the connector/

fitting IP rating and verify the connector O-ring is in place.

4. If cord-grip type cable glands are used, the type with soft rubber

glands are preferred (IP 68). The firmer rubber can cause the

cable to compress over time, compromising the seal between the

gland and the cable. Cable strain reliefs should also be considered

to assure tension, bending radius or flexing of the cable over time

does not compromise the seal. Careful consideration and testing is

required when these glands are used in outdoor applications.

5. If the I connector option is used verify the connector plugs are

properly sealed and have the desired

IP rating. During installation be sure to

screw the plug all the way on to the

receptacle for proper sealing.

6. Position conduit fittings or loop cable /

flexible conduit so water does not drain

towards the conduit fitting.

7. When the wire termination cover is re-

installed verify the gasket is in place

and the surfaces of the gasket as well as the cover are free from

debris so a good seal can be achieved. If the gasket is missing,

replace it with PN 51530.

8. When re-installing the termination cover, tighten all 4 screws

evenly to be sure the cover seats flat. Tighten the screws to assure

the cover is securely held against the gasket. Caution, over

tightening can strip the threads in the enclosure. If a screw is

missing replace it with Exlar PN 01185. (4-40 x ¼ Button Head

Cap Screw, Stainless Steel)

Curtiss-Wright | Tritex II DC Rev. J PN49220 2/8/2016

17

Manual Drive Operating Instructions

Isolate all sources of energy to prevent safety hazard due

to unexpected motion. System design and operating

procedures must ensure that the drive will have no

unintended motion that can create a hazard to personnel when operating

the drive manually. This includes electrical energy turning the motor as

well as energy stored in a vertical load or spring.

There are two manual drive options available on the Tritex, Hand

Wheel (HW) and Side Drive (SD)

The hand wheel option includes an internal switch that is closed when

the hand-wheel drive is fully disengaged and opens when an attempt is

made to engage the hand wheel drive. This switch is in series with the

actuator overtemperature sensor to form a combined run permissive

signal. When manual drive is engaged, an Actuator Overtemperature

fault occurs. The fault action for this fault will disable the drive.

This function is not safety rated, so is not usually sufficient to ensure

safety. Power to the drive must be isolated before manually operation.

The Side Drive does not include and interlock switch so power must

be removed before use.

Important information to avoid damage to the manual drive

If manually driving with a brake engaged or high force is

necessary, please consult Exlar Application Engineering.

If a power tool is used to operate the manual side drive the

speed should be limited to 600 RPM

An impact driver should never be used to operate the manual

side drive.

Determine end of stroke of actuator or system and do not apply

force past it.

Refer to Table 1 for maximum torque specifications.

WARNING

CAUTION

Curtiss-Wright | Tritex II DC Rev. J PN49220 2/8/2016

18

Push in to engage

Side Drive Instructions

1) Isolate all sources of energy from the drive

2) Press down on the hex until you feel you have bottomed out the

manual drive. Constant downward force is required to

maintain engagement during operation.

3) Give the hex a slight turn while observing if you are moving the

rod or not. It is possible that during engagement the gear teeth

have not completely engaged; this will prevent the gears from

meshing. If the rod is not moving continue to press down while

turning the manual drive slowly until it pushes farther down. When

this happens you have proper gear engagement.

4) After gear engagement is achieved, the manual drive can be

operated. The maximum torque input for the manual drive should

not exceed the values shown in Table 1.

5) When the manual drive movement is completed, cease the

downward force and the manual drive will disengage.

Table 1 - Maximum operating conditions

Model

Maximum Torque

in-lbs / (Nm)

T2M/X 090

30 / (3.4)

T2M/X 115

40 / (5.6)

Push in to

engage

Release to disengage

Curtiss-Wright | Tritex II DC Rev. J PN49220 2/8/2016

19

Dimensions

Curtiss-Wright | Tritex II DC Rev. J PN49220 2/8/2016

20

This manual suits for next models

10

Table of contents

Other Exlar Controllers manuals