Page

1

T: +44 (0) 20 8398 8011

Expo Technologies US

T: +1 (440) 247 5314

Expo Technologies China

T: +86 532

8906 9858

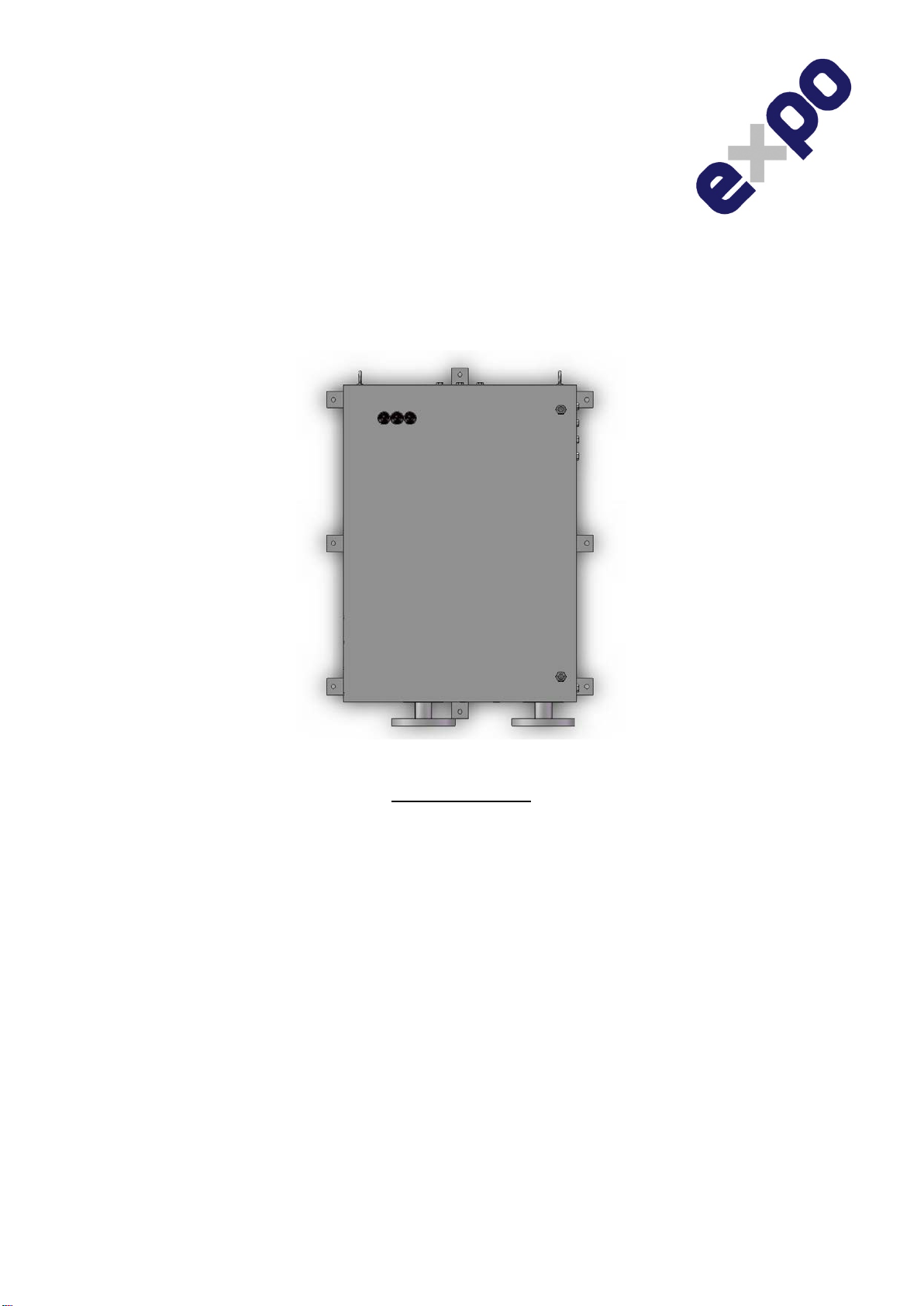

1. D801 MiniPurge

- General System Specification

Pressurized Motor Housing

Pressurized Motor Enclosure : A range of Electrical Motor housings

Classification : Zone 1 Group IIC

Volume (Litres) : Various, system settings determined by motor manufacturer.

Total Purge Flow Rate : To be supplied by customer and must include flow to compensate for leakage.

Estimated Purge Time : To be determined by 10 x volume.

Contents of Enclosure : Electrical motor.

Access covers : Special Tool required or Key Operated, door Interlock System not required.

Enclosure Pressure : Normal: 10 mbarg. (Alternative set-points are available) This is also the set

point of the Automatic Leakage Compensation Pressure Sensor (CLAPS

Sensor)

Enclosure Test Pressure : Motor Test Pressure = Relief Valve opening pressure x 1.5

MiniPurge

Control Unit Data

Model Number : 7XLC/ss/ET/OV/PA/PC Special Design Number: D801SYS

Option codes : ET = Electronic Purge Timer

: OV = Outlet Valve is pneumatically operated

: PA = Integral Ex e Power & Alarm terminal box

: PC = Pressurized Enclosure (Motor) Pressure Control Automatic

Leakage Compensation Valve (CLAPS system)

Action on Pressure Failure : Alarm and Trip (Isolate power / motor) User adjustable “Alarm Only”

System Type : ThinMani MiniPurgeSystem

Type of Operation : Automatic Leakage Compensation using the "Closed Loop Automatic

Pressurization System" (CLAPS)

Purge Flow Capacity : Up to 0.25m3/s (14,000 Nl/min) @ 420kPag (4.2 barg) inlet pressure. See

individual system specification sheet

Leakage Compensation

Capacity : Up to 0.085m3/s (5100 Nl/min) @ 420kPag (4.2 barg) inlet pressure

Enclosure Type : Stainless Steel 316

Mounting method : Wall mounting lugs & spacers. Fixing holes as per drawing D801-GA.

Temperature Limits : -20ºC to +55ºC ambient temperature.

Supply Pressure : Clean Dry Oil Free Air or Inert Gas. Pressure 420 – 800kPag (4.2 - 8 barg).

50 micron automatic drain supply Inlet filter & 1.6MPag (16 barg) regulator fitted.

Logic Regulator & Gauge : Fitted. Set to 230kPag (2.3 barg).

CLAPS Regulator & Gauge : Set to system requirements

Process Connections : Purge Supply: ANSI 150 B16.5 flange (size as per customer specification).

Outlet to Motor: ANSI 150 B16.5 flange (size as per customer specification).

Minimum Supply Line 50mm (2”) I.D Pipe

Reference points & signals: 1/8” NPT female

Visual Indicators : Alarm/Pressurized (Red / Green)

: Intermediate Low Pressure (Red / Green)

: System Purging (Black / 4 x Yellow LEDs to indicate elapsed time)

Motor Interlock Switch : DPNO electrical switch, contact ratings AC-15 250 Vac 4 Amps,

Ex d IIC T6

Low Pressure Switch : SPNO electrical switch, contact ratings AC-15 250Vac 4 Amps,

Ex d IIC T6

Intermediate Switch : SPNO electrical switch, contact ratings AC-15 250 Vac 4 Amps,

Ex d IIC T6

Signal Junction box : Stainless Steel, Ex e IIC T5 Gb (Tamb -20ºC to 55ºC) IP66 / Ex e IIC T4 Gb

(Tamb -20ºC to 60ºC) IP66. Mounted inside D801 system c/w terminals, front

access cover & access for glands on bottom of D801 system.