Expo Technologies Limited Page 2 of 8 ML384 Issue 05 –04.06.15

of the Minimum Pressure Sensor or to replace the SA with

one of another size. (** denotes the nominal thread size of

the SA body)

- For low flow rates, the Outlet Orifice may be

incorporated within the Relief Valve making use of the

existing Spark Arrestor. The Relief Valve will then have a

suffix /CF**, where ** is the orifice size in millimeters.

Section 1 Installation of the System

The installation of the MiniPurge system, the

protective gas supply, any alarm device should be in

accordance with the requirements of NFPA 496.

The electrical installation associated with the

MiniPurge system shall conform to the local codes

and the relevant clauses of NFPA 496.

All electrical parts of the MiniPurge system shall be

installed in accordance with the applicable

requirements of the NEC for USA and CEC for Canada.

1.1 Installation of the Expo LC and CFHP Systems

1.1.1 The Expo system should be installed either directly

on or as close as possible to the Pressurized Enclosure

(PE). It should be installed so that the system indicators

may be readily observed.

1.1.2 All parts of any system carry a common serial

number. If installing more than one system, ensure that

this commonality is maintained on each installation.

1.1.3 Any tubing, conduit and fittings used to connect to

the PE should be metallic, or, if non-metallic, conform to

the local codes for flammability ratings. No valve may be

fitted in any tube connecting the Expo system to the PE.

1.1.4 The user or manufacturer of the PE shall determine

the volume of the PE, the necessary purging volume, and

the time to be allowed for purging, using the chosen Expo

system purging flow rate. It is the user's responsibility to

verify or enter this data on the PE and/or Expo system

nameplate. Ask Expo if in doubt.

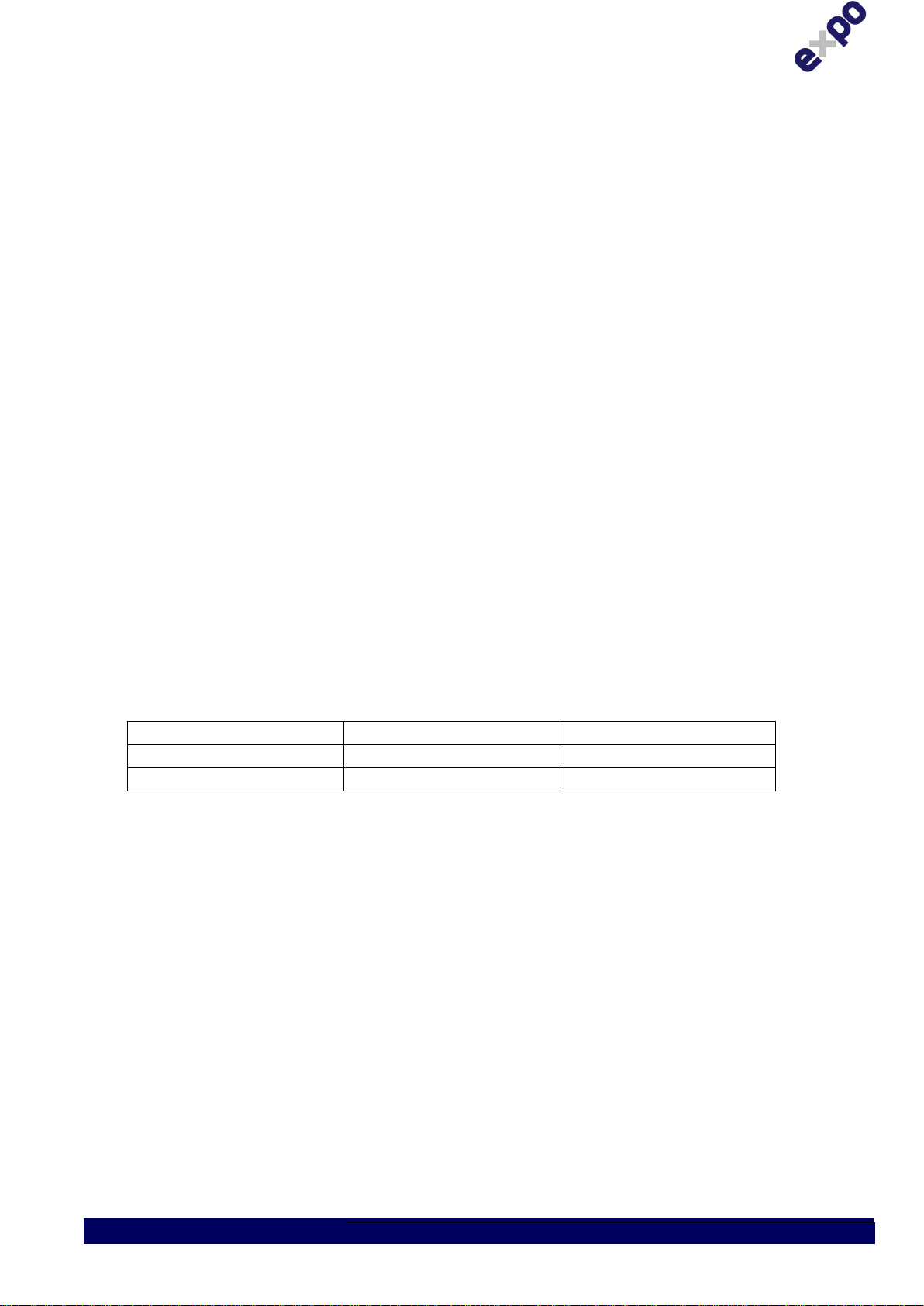

Example calculations:

a) If the PE external dimensions give a volume of 20 cubic

feet, and it is NOT a motor, multiply the volume by four to

get the Purging Volume i.e. 80 cubic feet. Divide the

Purging Volume by the purge rate e.g. 32 cubic feet per

minute, and round up to the next even minute above, i.e.

Purging time would be 4 minutes.

b) If the PE is a motor, multiply the internal free volume by

ten to get the Purging Volume. For the example above,

Purging time would be 8 minutes.

For Type “Y” or “Z” Pressurization, the protected

equipment may be permitted to be energized immediately

where 25 Pa (0.1”WC) exist in the enclosure and the

enclosure is known to be below the ignitable concentration

of combustible material.

1.1.5 If the PE contains an internal source of release of

flammable gas or vapor, the procedures for assessment of

the release as given in NFPA 496 shall be observed.

1.1.6 User must take precaution if abnormal release of

flammable gas or vapor within the enclosure can affect the

external area.

1.1.7 Where a release of flammable gas or vapor

within an enclosure can occur either in normal

condition or abnormal operation, protection shall be

provided by one of the step as specified in NFPA 496.

For more information on enclosure containing internal

source of release or enclosure containing an open

flame, contact Expo Technologies.

The user must verify that the specification of the Expo

system e.g. pressures, continuous flow (dilution) rate

and type of protective gas are correct for the specific

application. If an inert protective gas is required, the

Expo Control Unit can be specified to have

Compressed Air for the control logic and Inert Gas for

the protective gas to minimize Inert Gas consumption.

1.1.8 More than one PE can be protected by a single

system. If PEs are connected and purged in “series”

e.g. “Daisy Chained”, the Outlet Orifice must be fitted

on the last enclosure with the Purge Inlet to the first

enclosure. The bore and length of the tube or conduit

used to interconnect the enclosures is critical and will

determine the maximum pressure experienced by the

first enclosure in the series. Advice on sizing can be

obtained from Expo Technologies. The test pressure

for all the enclosures should be 3 times the pressure

inside the first enclosure when purging is taking place.

If PE’s are to be connected in parallel each enclosure

must have its own outlet Relief Valve, Purge Flow

Sensor and Pressure Sensor. System “Models” can be

mixed e.g. Model LC for one enclosure and Model CF

for another. An example would be a Gas

Chromatograph instrument. Expo systems with this

facility have option code “TW”.

1.2 Quality and Installation of the Pressurizing

Air or Inert Gas Supply

1.2.1 The source of the compressed air must be in a

non-classified area. Inert gas may be used as an

alternative to compressed air.

1.2.2 All pipe connection for the protective gas shall be

protected from mechanical damage; where the source

of the compressed air intake line passes through a

classified location, the construction shall be of non-

combustible material, and designed to prevent leakage

of flammable gases, vapours, or dust into the

protective gas. It must be protected against

mechanical damage and corrosion.

1.2.3 Unless a supply shut-off valve has been

specially fitted within the Expo system, a valve with the

same, or larger, thread size as the Control Unit inlet

fitting shall be fitted externally. In addition, for "Y" and

"Z" Pressurization systems, a suitable indicator shall

be provided: