5

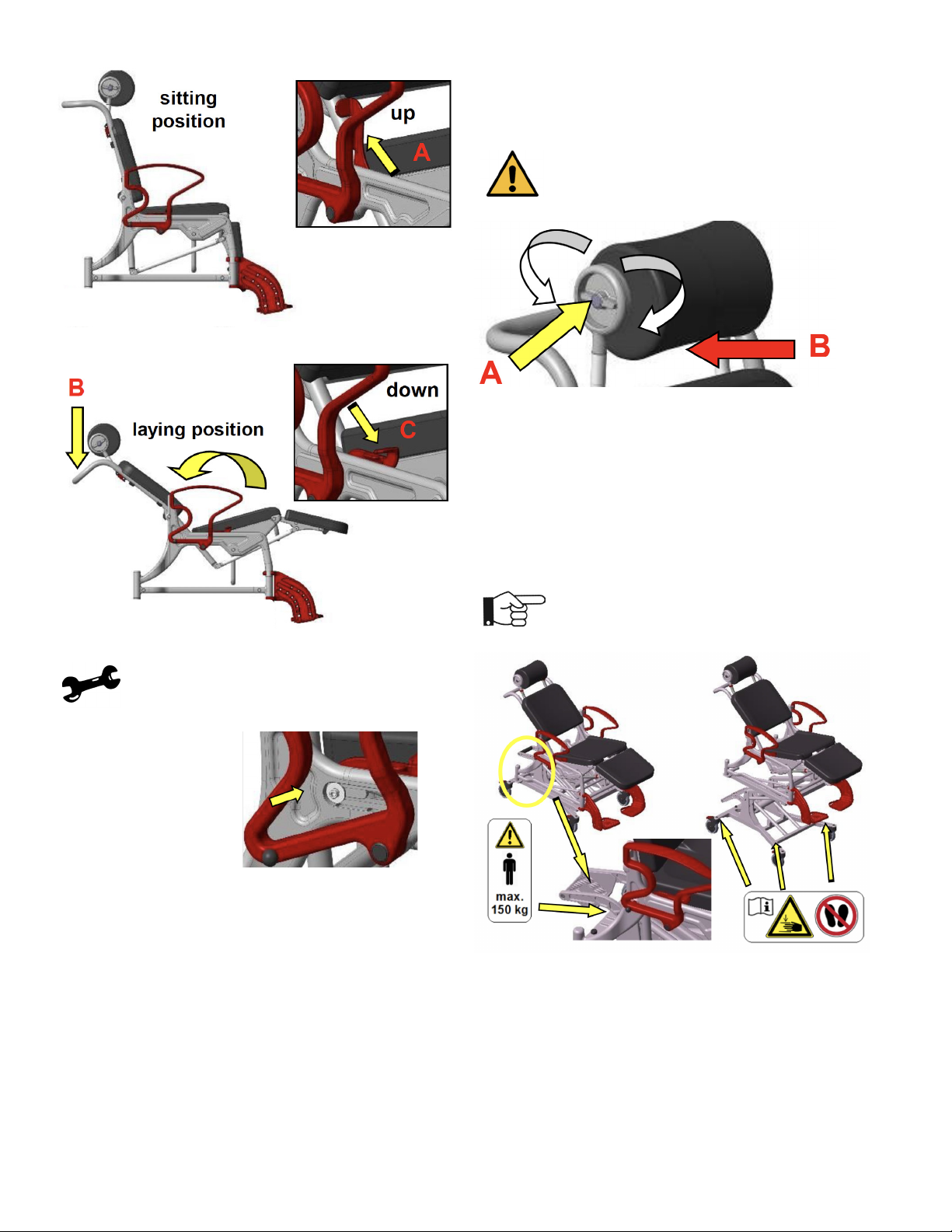

Danger of pinching!

• To prevent body parts, etc. from being pinched,

never reach into the hinge area when folding the

armrests up or down. See section 10.8, page 10

for more information.

• To prevent body parts or objects from getting

pinched, do not reach between the seat and the

frame when pressing the pad into the seat frame or

adjusting the inclination.

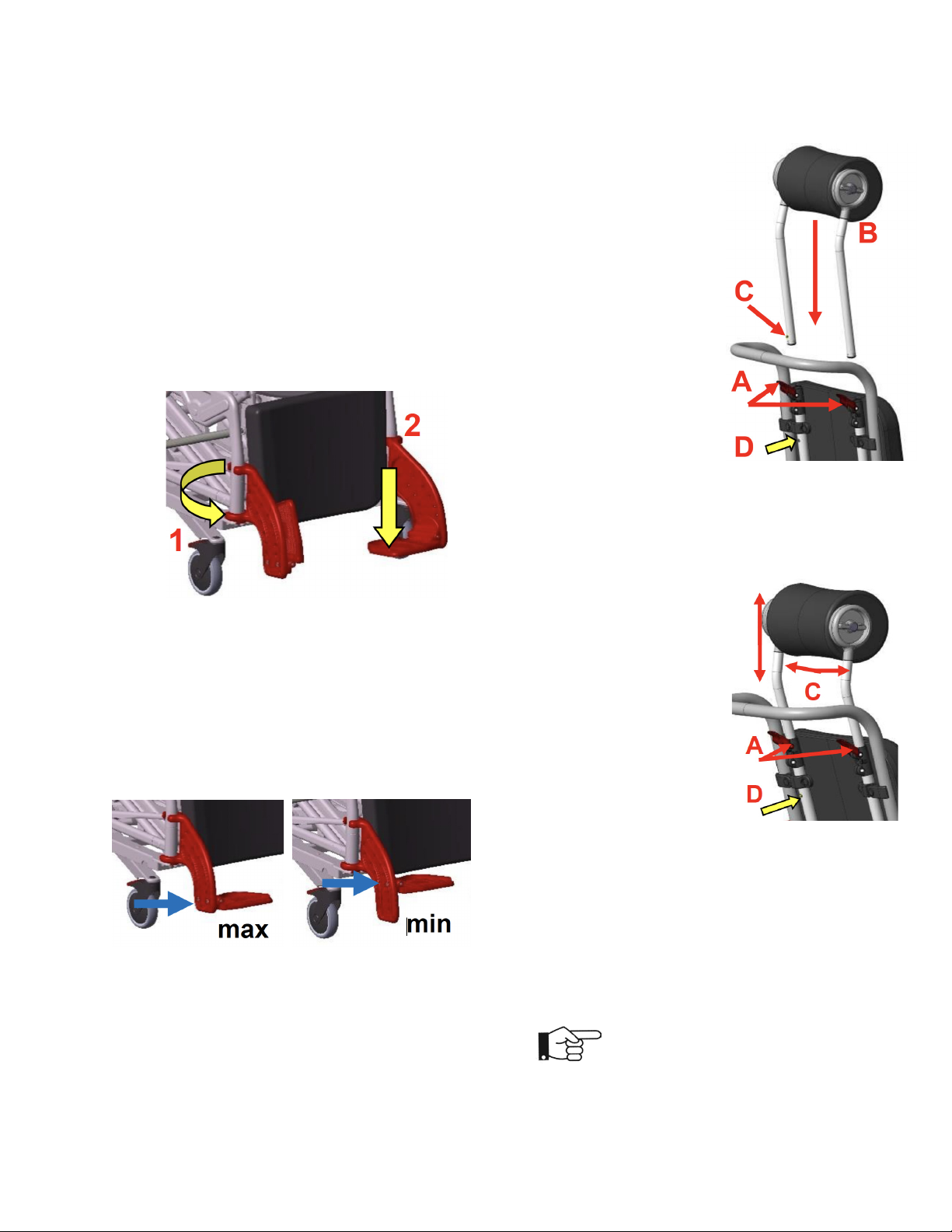

• Be sure other parts do not get jammed when folding

and unfolding the footrests.

• When adjusting the headrest, be sure that no body

parts or objects get pinched.

• There’s a risk of pinching soft flesh when pulling out

and pushing in the commode pan. To avoid injury,

the commode pan may be pulled out or pushed in

only when no one is sitting on the chair.

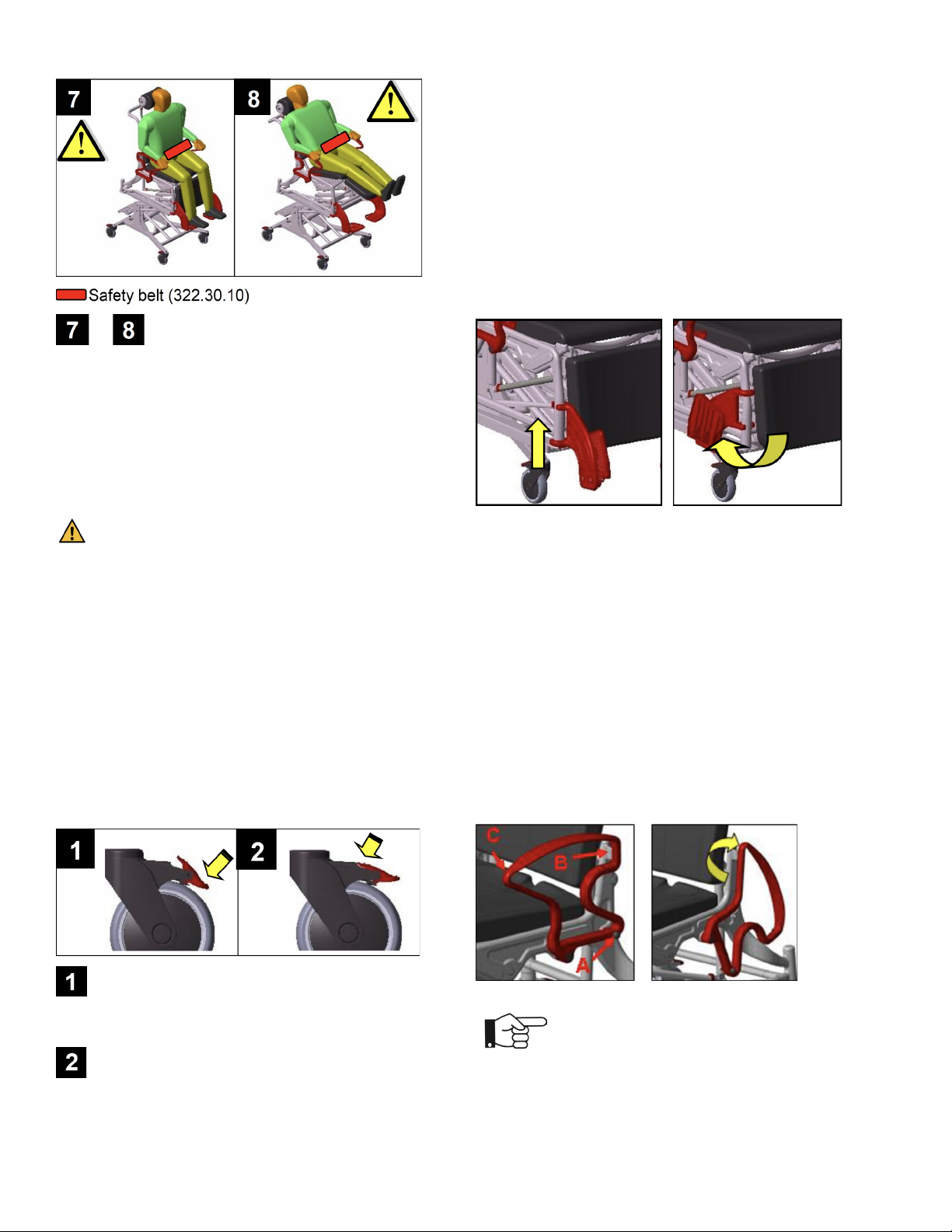

Danger of tipping!

• When standing up, sitting and moving with

the chair, do so only when both armrests are

latched in position.

• Sitting, standing up, moving, or laying in the chair

(when chair is in the inclined position) by the

patient, and lifting (height adjustment with lifting

unit) of the patient, are to be done only with the

help of a trained attendant. This depends on the

health condition of the patient.

• Before and during the placement of the patient on

the chair, the patient should firmly hold on to the

armrests.

• Use by patients who tend to have uncontrolled

movement and handling ability must not be done

without supervision.

• Travelling on an inclined surface or ramp may be

done only with the help of an attendant. In general

an upward grade may be travelled on while moving

forwards, and a downward grade while moving the

chair backwards.

Danger of breakage!

• The chair is suited only for the intended purpose.

Abide by the maximum allowable body weight

(specified on the nameplate)!

Danger of injury through temperature!

• There is a risk of injury at a surface temperature

over 104°F. Therefore never keep the chair near a

strong heat source including direct sunlight. Do not

store the chair near a heat source such as a heater,

or clean it with hot water). Allow the surface of

the chair to first cool off before use.

When the chair is to be used by patients

with insensitive skin (persons who cannot

feel temperature rises and / or have skin

damage), an attendant must rst check the

chair for heat (feel with the palm of the

hand). Observe Section 1.4

Safety advisory – lifting unit

Danger of pinching/crushing!

• When raising or lowering the chair height, observe

the warning advisories (stickers in the area of the

lifting unit). The lifting unit in part comprises

parts that move with respect to each other and thus

present a danger of pinching or crushing when not

properly operated or used. Therefore keep hands and

feet away from these parts, and do not reach into the

lifting unit during raising and lowering the chair.

• The hydraulic unit has a spring-loaded pedal

that returns on its own. Do not leave the chair

unattended while the pedal moves back because

there is a risk of injury.

Warning! Danger of injury!

• Be sure that no third party or object is in the area of

hazard when the lifting unit is raising or lowering.

• Before using the chair and the lifting unit, the chair

must be on a solid and stable surface.

• Use the lifting unit only with protected feet (proper

footwear) in order to avoid injury.

• Do not place any object on the foot pedal.

• Observe the maximum allowable patient body

weight, as the chair is designed only for this max.

load.

• There is a risk of slipping in the event of leaked

hydraulic oil. Before each use of the chair, check it

for leaks.

• If there is leakage from the hydraulic cylinder

(hydraulic oil leakage) and there is contact between

the fluid and an open flame or a hot surface, then it

could ignite. Be sure there is no risk of ignition!

• Do not stomp on the pedal and do not apply your

entire body weight to activate the pedal. One foot

must always remain firmly on the floor.

7. Product specifications

7.1 Delivery scope

The product was checked for freedom of defects

and for completeness at the factory. After receiving

the product, check it for any damage that may have

occurred during transport and for completeness.

• 1 wheelchair

• 1 headrest unit