www.seagullmodels.com

3

NOTE: To avoid scratching your new aero-

planewesuggestthatyoucoveryour

workbench with an old towel. Keep a

couple of jars or bowls handy to hold

the small parts after you open the

bags.

Pleasetrialfitallparts.Makesureyou

have the correct parts and that they

fit and are aligned properly before

gluing! This will ensure proper as-

sembly as the CHRISTEN EAGLE II

is made from natural materials and

minor adjustments may have to be

made.

The paint and plastic parts used in

this kit are fuel proof. However, they

arenottolerantofmanyharshchemi-

cals including the following: paint

thinner, cyano-acrylate glue accel-

erator,cyanoacrylategluede-bonder

andacetone.Donot let these chemi-

calscome incontact withthe colours

onthecoveringand the plastic parts.

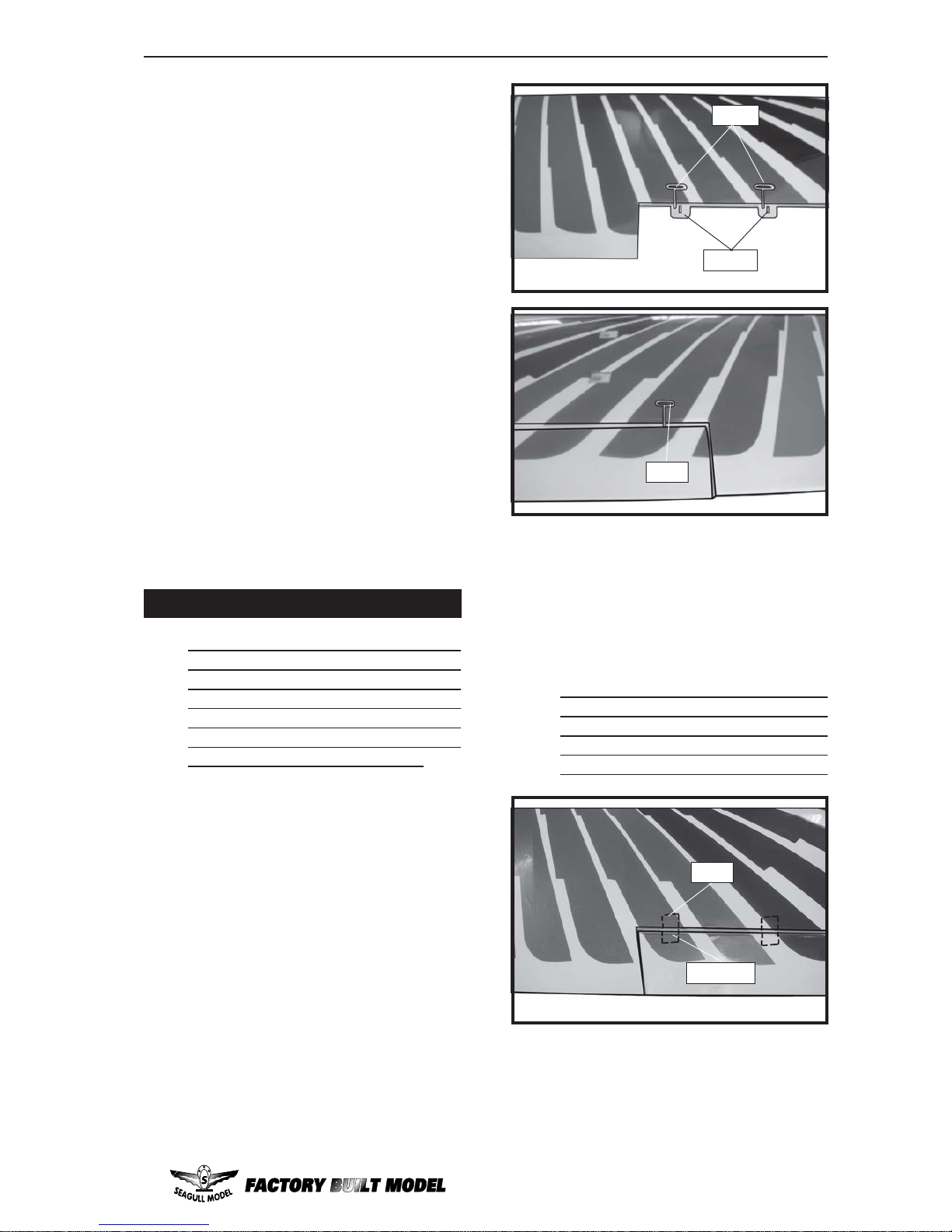

1) Carefully remove the aileron from one

of the wing panels. Note the position of the

hinges.

2)Removeeachhinge from the wingpanel

and aileron and place a T-pin in the center of

each hinge. Slide each hinge into the aileron

untiltheT-pin is snug against the aileron. This

will help ensure an equal amount of hinge is

oneithersideofthehingelinewhentheaileron

is mounted to the wing panel.

HINGING THE AILERONS.

The control surfaces, including the

ailerons, elevators, and rudder, are

prehinged with hinges installed, but the

hinges are not glued in place. It is

imperativethat you properly adhere the

hingesin place per the stepsthat follow

using a high-quality thin C/A glue.

Note:

T-pin.

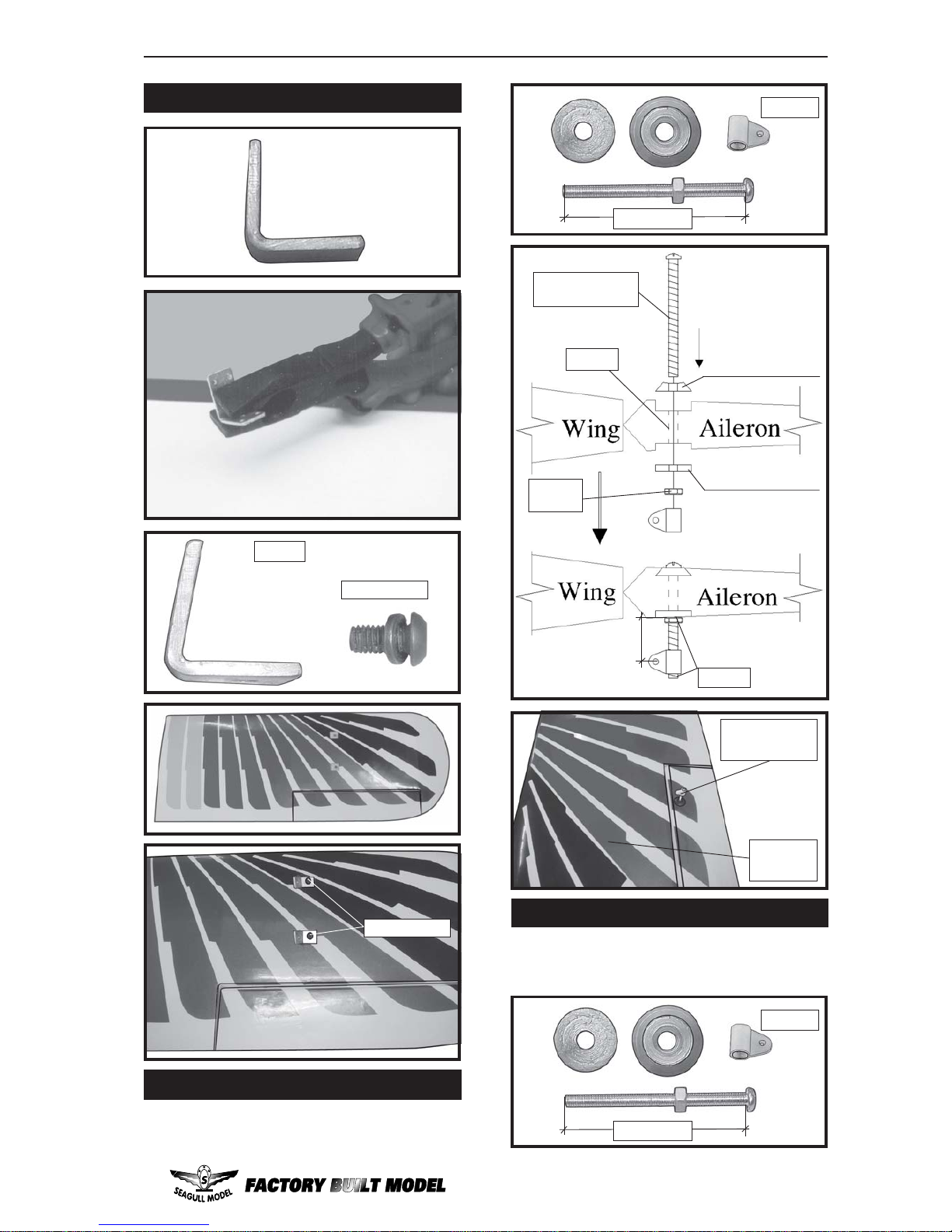

3) Slide the aileron on the wing panel until

there is only a slight gap. The hinge is now

centered on the wing panel and aileron.

Remove the T-pins and snug the aileron

against the wing panel.A gap of 1/64” or less

shouldbe maintained betweenthe wing panel

andaileron.

Hinge.

T-pin.

C/Aglue.

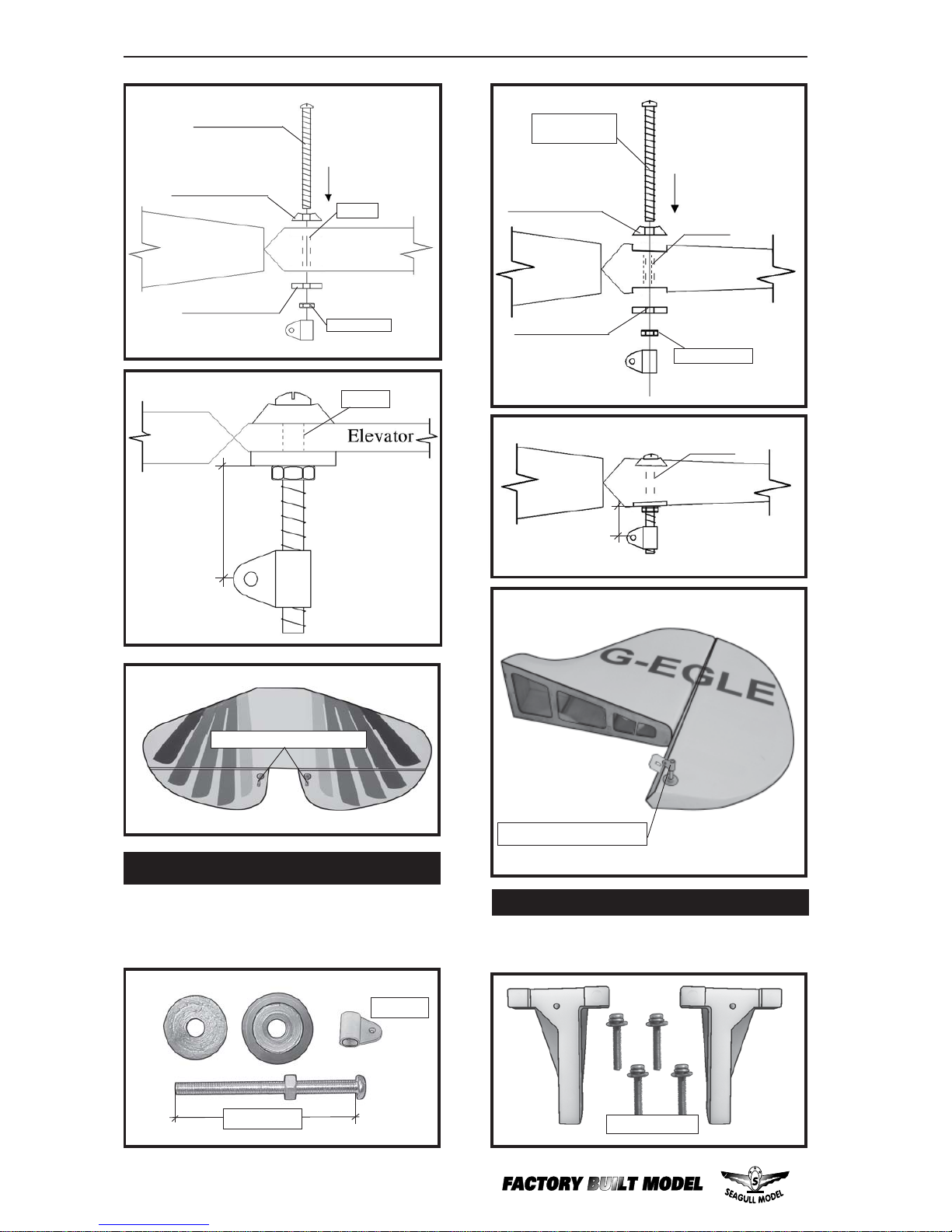

4)Deflect the aileron and completely

saturate each hinge with thin C/A glue. The

aileronsfrontsurfaceshouldlightly contact the

wing during this procedure. Ideally, when the

hinges are glued in place, a 1/64” gap or less

will be maintained throughout the lengh of the

aileron to the wing panel hinge line.

Note: The hinge is constructed of a special

material that allows the C/A to wick or

penetrateanddistributethroughout the

hinge, securely bonding it to the wood

structureof the wingpanel and aileron.

5)Turnthe wingpanelover and deflectthe

aileron in the opposite direction from the

opposite side. Apply thin C/A glue to each

hinge,makingsure that theC/Apenetratesinto

both the aileron and wing panel.

T-pin.